Method for manufacturing high-strength aluminum alloy material for vehicle heat exchanger

A technology of aluminum alloy materials and heat exchangers, which is applied in the field of high-strength aluminum alloy materials, can solve problems such as roughening, uneven wave height of heat sink materials, and uneven deformation, so as to inhibit erosion, improve strength and corrosion resistance , the effect of inhibiting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0024] A first embodiment of the method of manufacturing an aluminum alloy material of the present invention will be described below.

[0025] In the production method of the present embodiment, a molten aluminum alloy is used, which contains Si: 0.3% to 1.2%, Fe: 0.7% to 2.0%, Mn: 0.2% to 0.8%, Zn: 0.1% to 1.0% by mass. %, and the remainder containing Al and unavoidable impurities.

[0026] The composition of aluminum alloy materials

[0027] Next, the numerical limits of the composition of the aluminum alloy material determined in the present embodiment will be described in detail.

[0028] Si: 0.3% to 1.2% (more preferably 0.8% to 1.0%)

[0029] Silicon (Si), which coexists with Mn in the form of an Al-Mn-Si compound, is dispersed in the matrix or forms a solid solution, and has the effect of increasing the strength of the aluminum alloy material.

[0030] The content of Si is preferably 0.3% to 1.2% by mass, more preferably 0.8% to 1.0%.

[0031] When the content of ...

no. 2 approach

[0132] A second embodiment of the method of manufacturing an aluminum alloy material of the present invention will be described below.

[0133] In the production method of the present embodiment, a molten aluminum alloy is used, which contains Si: 0.3% to 1.2%, Fe: 0.05% to less than 0.7%, Mn: more than 0.8% to 2.0%, Zn: 0.5% by mass. %~4.0%, and the rest containing Al and unavoidable impurities.

[0134] The composition of aluminum alloy materials

[0135] Next, the numerical limits of the composition of the aluminum alloy material determined in the present embodiment will be described in detail.

[0136] Si: 0.3% to 1.2% (more preferably 0.4% to 1.2%)

[0137] Silicon (Si), which coexists with Mn in the form of an Al-Mn-Si compound, is dispersed in the matrix or forms a solid solution, and has the effect of increasing the strength of the aluminum alloy material.

[0138] The content of Si is preferably 0.3% to 1.2% by mass, more preferably 0.4% to 1.2%.

[0139] When...

Embodiment A

[0213] The manufacturing method and evaluation test items of the aluminum alloy material of Example A will be described.

[0214] Manufacturing method

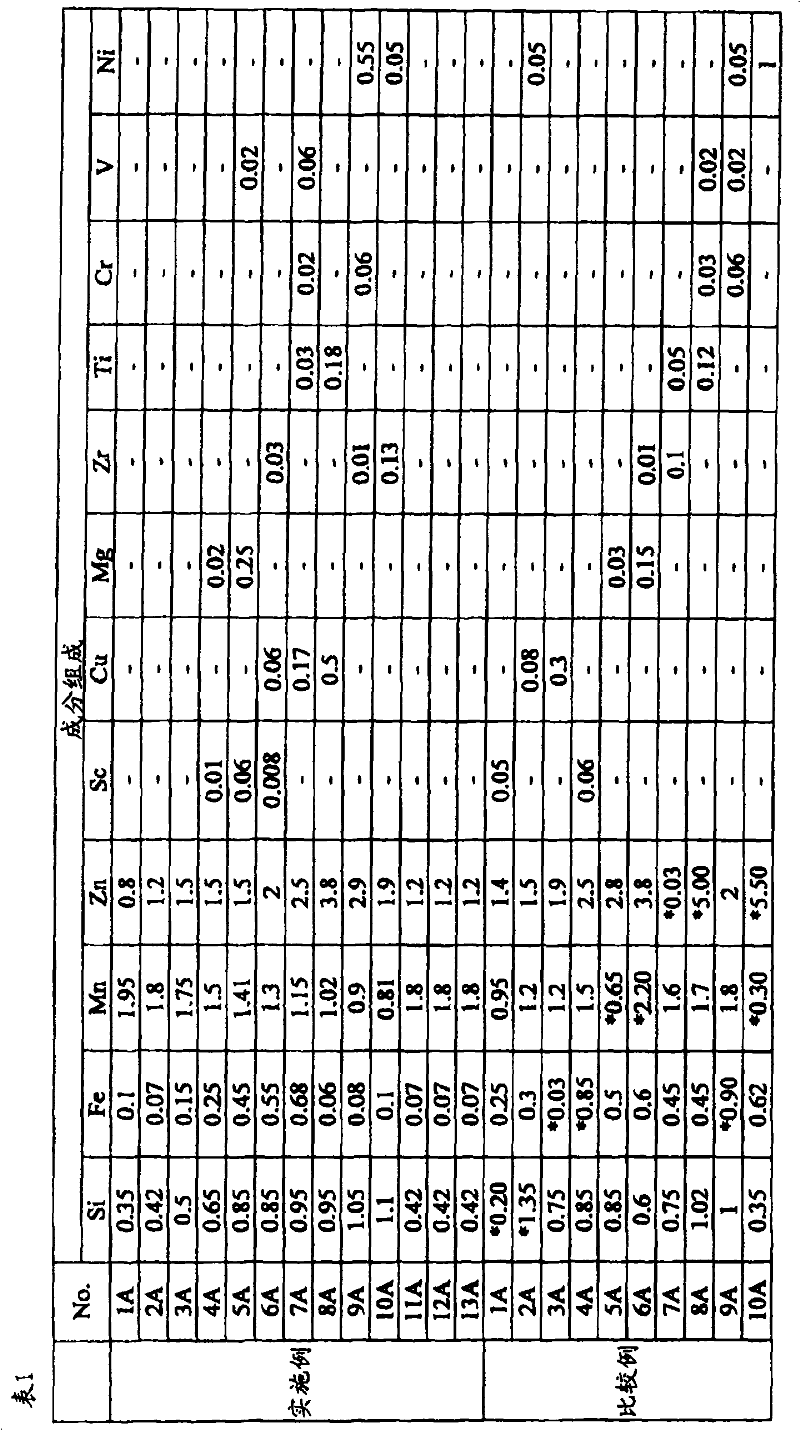

[0215] In Example A, an aluminum alloy material was produced using an aluminum alloy having the composition shown in Table 1 under the production conditions shown in Table 2.

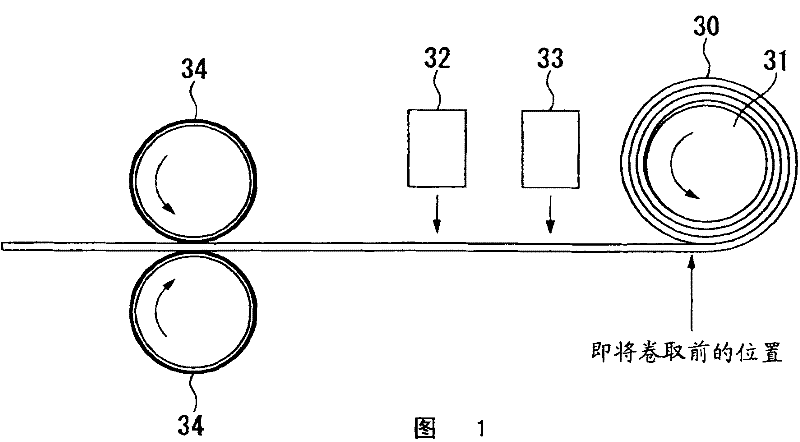

[0216] First, molten aluminum alloys obtained by melting aluminum alloys having respective compositional compositions are subjected to treatments such as processes for removing impurities by degassing and using a filter. Subsequently, the molten aluminum alloy was cast into a plate having a width of 1000 mm using a twin-roll continuous casting and rolling mill with a roll body diameter of 600 mm. During the casting process, the figure 1 The flow rate of water in the water-cooled roll 34 shown in controls the rate of solidification.

[0217] Such as figure 1 As shown in the schematic diagram of , an air-cooling fan (air-cooling fan) 32 and a mist s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com