Method for preparing polyurea coating materials for ships and cured film with polyurea coating materials

A coating material and technology for ships, which is applied in the field of preparation of polyurea coating materials for ships, can solve the problems of reducing coating uniformity and stability, agglomeration, and large specific surface area of inorganic nanomaterials, achieving uniformity and Good stability, improved heat resistance and mechanical properties, easy and uniform dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

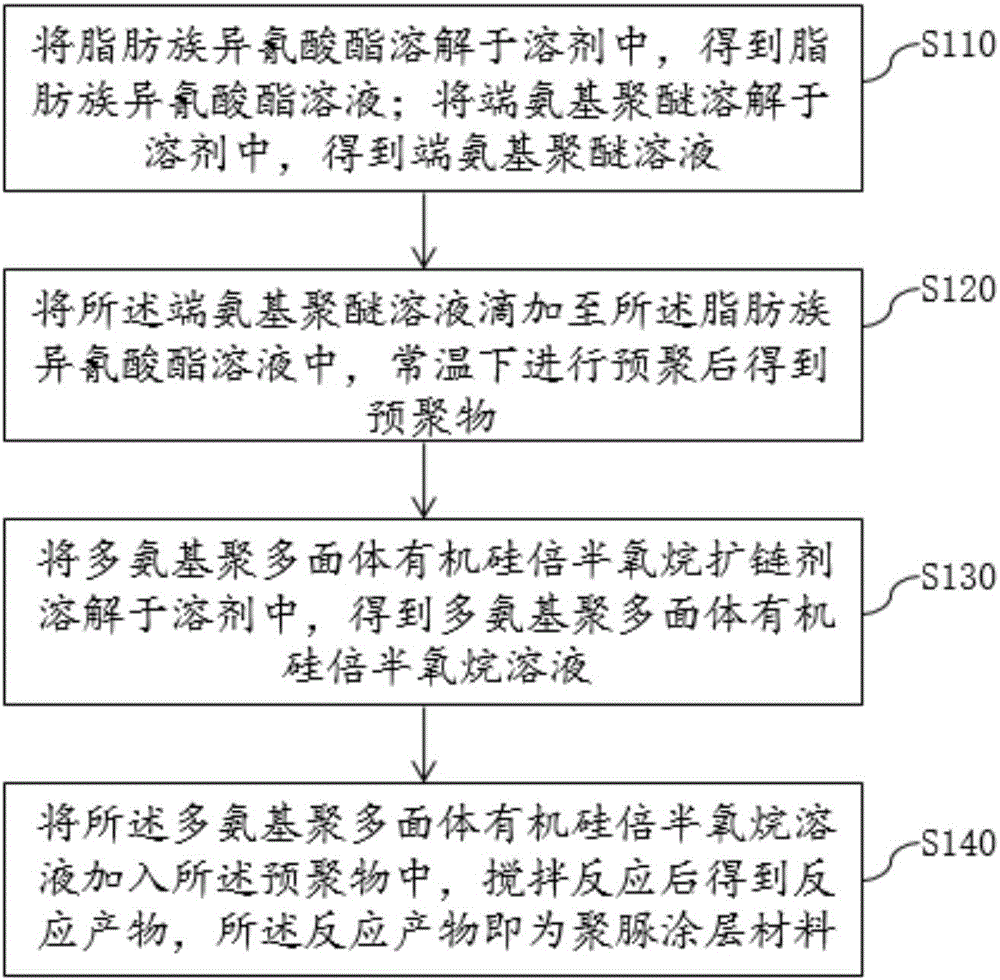

[0028] The invention provides a method for preparing a polyurea coating material for ships, comprising:

[0029] dissolving the aliphatic isocyanate in a solvent to obtain an aliphatic isocyanate solution;

[0030] dissolving the amino-terminated polyether in a solvent to obtain an amino-terminated polyether solution;

[0031] Adding the amino-terminated polyether solution dropwise into the aliphatic isocyanate solution, and performing prepolymerization at room temperature to obtain a prepolymer;

[0032] Dissolving the amino polyhedral organosilsesquioxane chain extender in a solvent to obtain an amino polyhedral organosilsesquioxane solution;

[0033] Adding the amino polyhedral organosilsesquioxane solution into the prepolymer, stirring and reacting to obtain a reaction product, which is the polyurea coating material.

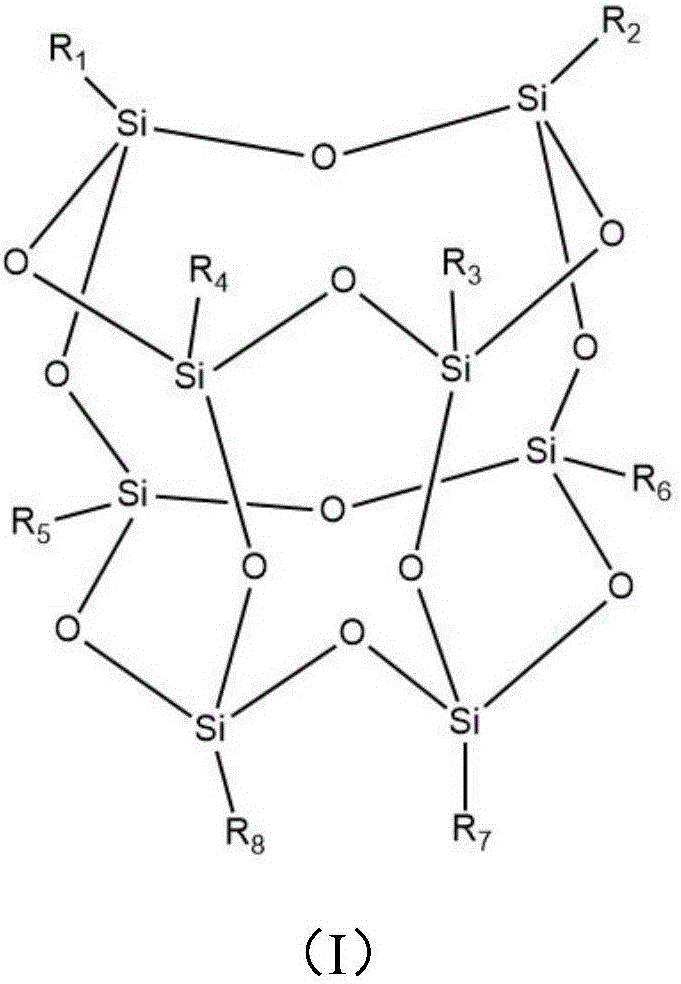

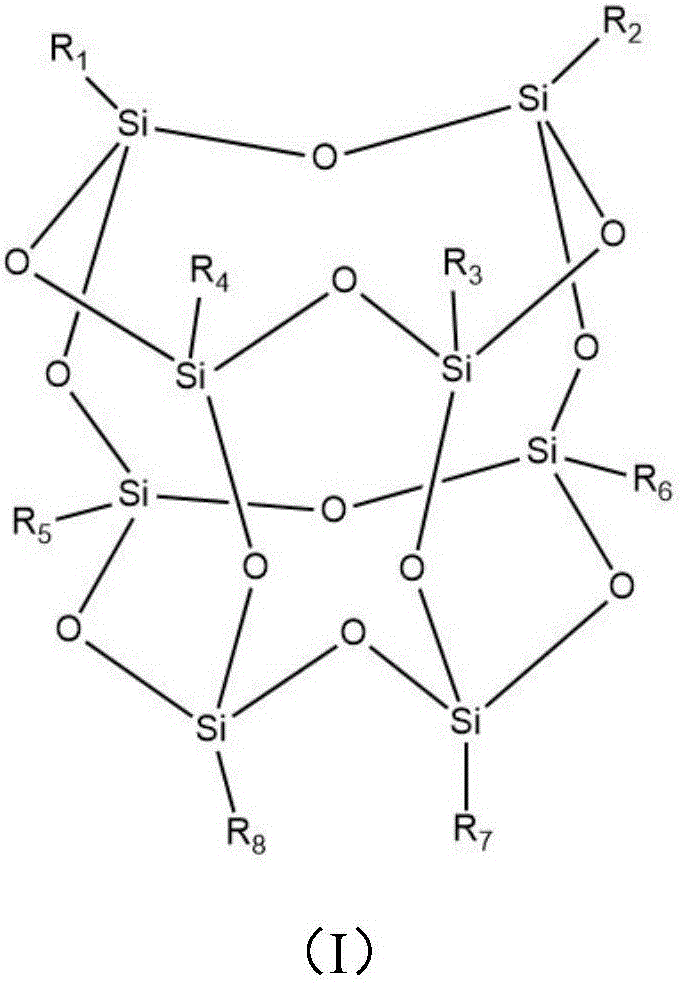

[0034] It can be seen from the above that since polypolyhedral organosilsesquioxane (POSS) is an organic-inorganic core-shell material with a hollow nanos...

Embodiment 1

[0063] Add 50g of hexamethylene diisocyanate (HDI) into 5g of N,N-dimethylacetamide (DMAc), and stir well; add 100g of amino-terminated polyether D2000 into 10g of DMAc and stir well; then The DMAc solution of polyether D2000 was added dropwise to the HDI solution at a rate of 5 ml / min, and prepolymerized for 0.5 hour to obtain a prepolymer. Then the DMAc solution (concentration is 0.5g / ml) that is dissolved with the amino POSS chain extender shown in 15g formula (I) is imported in the described prepolymer, and continues to stir 5 minutes, obtains the thick polyurea coating Material. Finally, the polyurea coating material was poured into a petri dish, placed in a fume hood to dry at room temperature for 48 hours, and then placed in an oven at 60° C. for 5 hours to obtain a cured film of the polyurea coating material.

Embodiment 2

[0065] Add 75g of hexamethylene diisocyanate (HDI) into 18g of toluene and stir evenly; add 100g of amino-terminated polyether D2000 into 25g of toluene and stir evenly; then add the toluene solution of aminopolyether D2000 at 20ml / min Add it dropwise to the HDI solution at a high speed, and prepolymerize for 1 hour to obtain a prepolymer. Then, a toluene solution (concentration of 1 g / ml) dissolved with 20 g of the amino POSS chain extender represented by formula (I) was introduced into the prepolymer, and the stirring was continued for 10 minutes to obtain a viscous polyurea coating material. Finally, the polyurea coating material was poured into a petri dish, placed in a fume hood to dry at room temperature for 48 hours, and then placed in an oven at 60° C. for 5 hours to obtain a cured film of the polyurea coating material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com