Axial stacking type friction-stir welding material adding forming process for large thin-wall ring part

A friction stir and additive forming technology, which is applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problems of slow solidification speed, high efficiency, energy saving, material saving, coarse grain, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

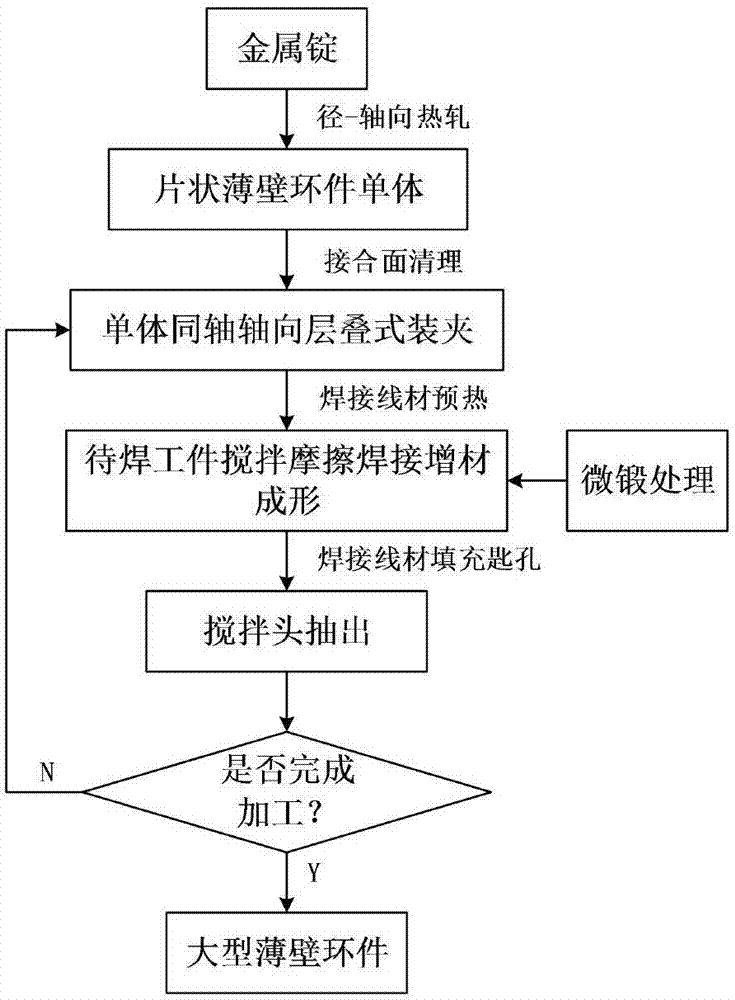

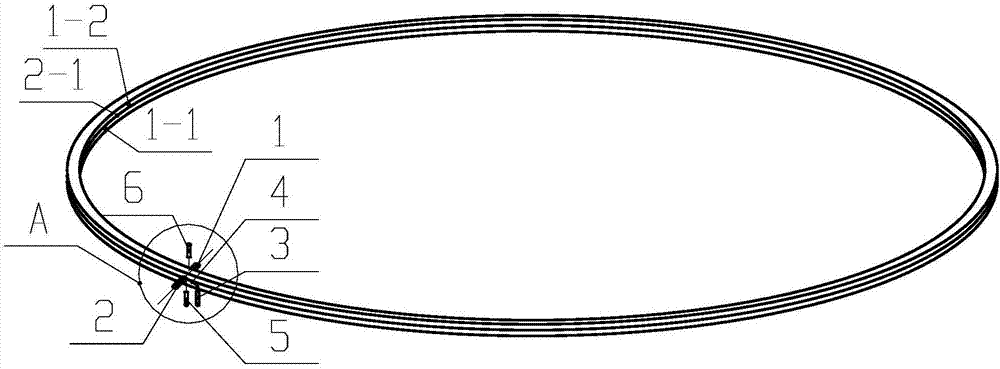

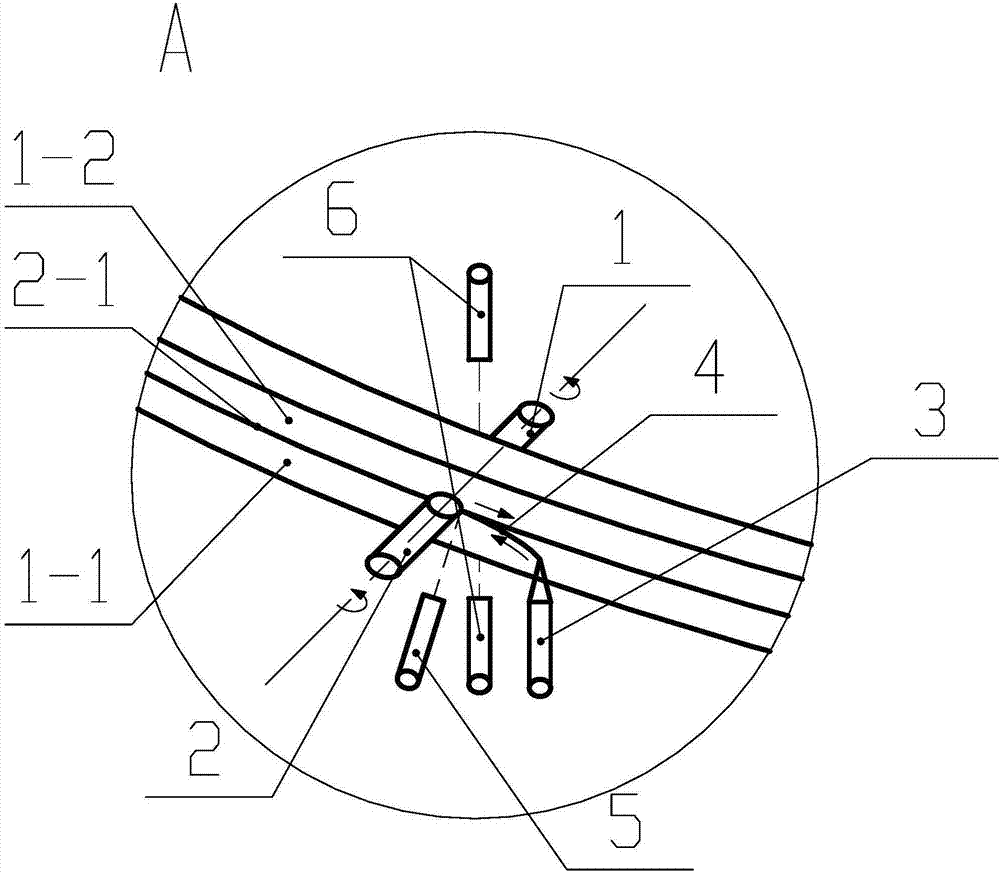

[0023] refer to figure 1 , figure 2 and image 3 , Axial layered friction stir welding additive forming process for large thin-walled rings, including the following steps:

[0024] 1) Sheet-shaped thin-walled rings are individually rolled and formed: the sheet-shaped thin-walled rings are billeted by radial-axial hot rolling technology, and the prepared metal ingots are prepared by blanking, blanking, ring rolling, heat treatment and machining processes Produce flake thin-walled rings;

[0025] 2) Axial stacking type friction stir welding additive forming of sheet-shaped thin-walled ring parts: first, the first sheet-shaped thin-walled ring body 1-1 and the second sheet-shaped thin-walled ring body 1-2 are coaxially stacked and docked The form is clamped on the welding workbench as the workpiece to be welded; then, the welding wire 4 is preheated by the laser he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com