Sample preparation method for testing tensile property of asphalt-based carbon fiber multifilament

A technology of pitch-based carbon fiber and tensile properties, which is applied in the preparation, sampling, and measuring devices of test samples, can solve the problems of large dispersion and low tensile strength test values, and achieves improved accuracy and improved manufacturing. Sample efficiency and ensure full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

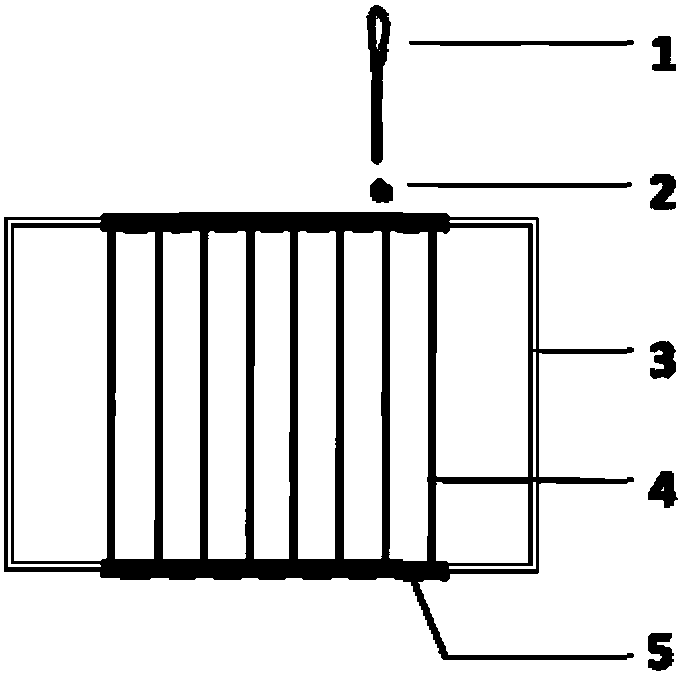

Image

Examples

Embodiment 1

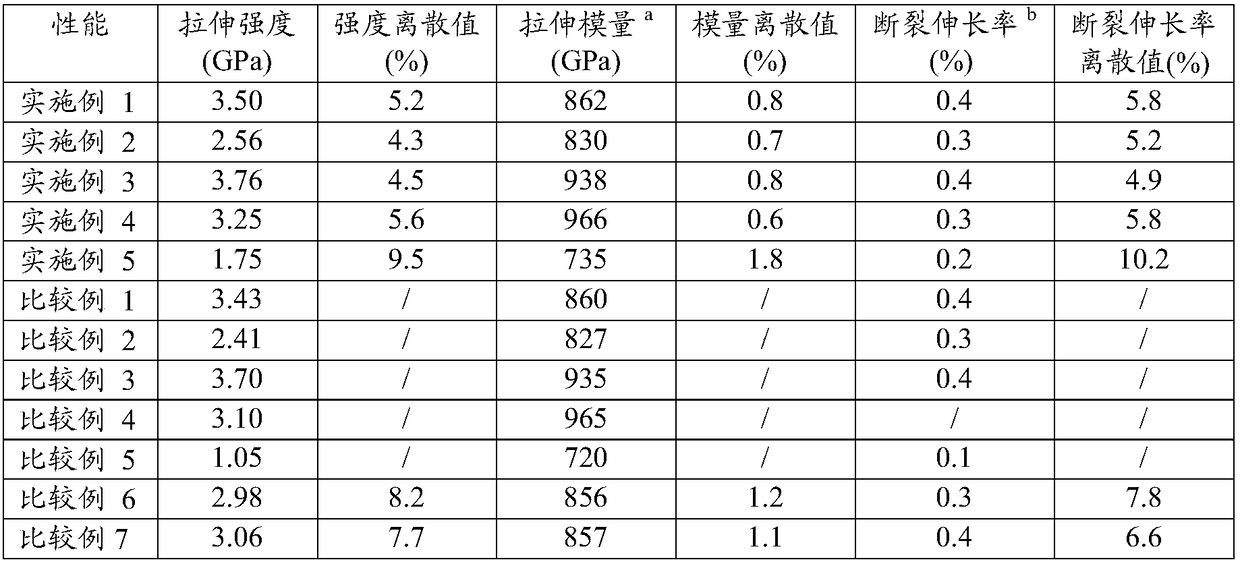

[0038] Use 5N tension to wind the XN-90 pitch-based carbon fiber multifilament of 6K specifications on the iron frame, and fix the bending part of the multifilament on the frame with adhesive tape; add 100 parts by mass of 1, Diglycidyl 2-epoxycyclohexane 4,5-dicarboxylate, 60 parts by mass of hexahydrophthalic anhydride and 0.5 parts by mass of N,N dimethylaniline, then add 120 parts of acetone and stir for 5 minutes to obtain the resin Glue solution: Use a dropper to inhale epoxy resin glue solution and drop glue solution from the upper end of the frame along the fiber multifilament bundle. Dry and solidify in a blast oven. The curing process conditions are (80°C / 1h)+(140°C / 2h)+(200°C / 3h). After cooling, the multifilaments are cut, and paper reinforcement sheets are pasted to obtain tensile samples. The tensile properties of pitch-based carbon fiber multifilament are shown in Table 1.

Embodiment 2

[0040] Use 1N tension to wind the P-120 pitch-based carbon fiber multifilament of 2K specifications on the iron frame, and fix the bending part of the multifilament on the frame with adhesive tape; add 100 parts by mass of 4, 4'-Diaminodiphenylmethane, 100 parts by mass of methylhexahydrophthalic anhydride and 1.5 parts by mass of diethylaminopropylamine, then add 100 parts by mass of toluene and stir for 5 minutes to obtain a resin glue; use a dropper to inhale the epoxy resin The glue solution is slowly dripped from the upper end of the frame along the fiber multifilament bundle, the dropping rate is 4mL / min, and the dropping time is 1 minute / segment; the dipped multifilament frame is dried and cured in a blast oven, and the curing process conditions (140°C / 1h)+(200°C / 1h), cut the multifilament after cooling, paste the paper reinforcing sheet to obtain the tensile sample. The tensile properties of pitch-based carbon fiber multifilament are shown in Table 1.

Embodiment 3

[0042] Wrap 2K specifications of K13D pitch-based carbon fiber multifilament on an iron frame with 1N tension, and fix the bending part of the multifilament on the frame with adhesive tape; add 100 parts by mass of 4,4' to a 500mL measuring cup in sequence -diaminodiphenylmethane, 80 parts by mass of methyltetrahydrophthalic anhydride and 3 parts by mass of 2-ethyl-4-methylimidazole, then add 60 parts of xylene and fully stir for 5 minutes to obtain the resin glue; The pipe sucks the epoxy resin glue solution from the upper end of the frame and slowly drops the glue solution along the fiber multifilament bundle. The glue dropping rate is 3mL / min, and the glue dropping time is 2 minutes / segment; Dry and solidify in an oven. The curing process conditions are (80°C / 1h)+(140°C / 1h)+(200°C / 2h). After cooling, the multifilaments are cut and pasted with a paper reinforcement sheet to obtain a tensile sample. The tensile properties of pitch-based carbon fiber multifilament are shown in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com