High-nitrogen organic-inorganic compound fertilizer and steam-free compound fertilizer pelleting equipment

A technology of compound fertilizer and granulation equipment, applied in fertilizer mixture, fertilizer form, fertilization device and other directions, can solve the problems of increasing production cost, insecurity, increasing energy consumption, etc., to increase output, reduce energy consumption, and improve cost The effect of ball pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

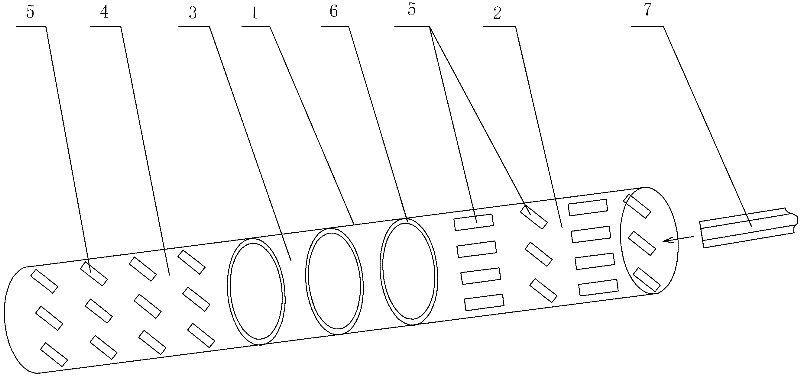

Image

Examples

example 1

[0028] Produce nitrogen-phosphorus-potassium (15-8-7) ≥ 30%, organic matter ≥ 20% organic-inorganic compound fertilizer.

[0029] Humic acid organic material 380 kg;

[0030] Urea: 225 kg;

[0031] Ammonium chloride: 100 kg;

[0032] Monoammonium phosphate: 185 kg;

[0033] Potassium chloride: 110 kg;

[0034] The measured value of the product: nitrogen-phosphorus-potassium (15.1-8.15-7.2) 30.45%, organic matter 23%, moisture 5.5%, smooth and uniform particles.

[0035] Meet the requirements of GB18877-2002 standard.

example 2

[0037] Produce nitrogen-phosphorus-potassium (18-12-10) ≥ 40%, chlorine-based medium-chlorine compound fertilizer.

[0038] Urea: 200 kg;

[0039] Ammonium chloride: 235 kg;

[0040] Monoammonium phosphate: 275 kg;

[0041] Potassium chloride: 170 kg;

[0042] Bentonite: 120 kg;

[0043] The measured value of the product: nitrogen-phosphorus-potassium (18.2-12.1-10.3) 40.5%, water content 1.3%, smooth and uniform particles.

[0044] Meet the requirements of GB15063-2009 standard.

example 3

[0046] Production: Potassium sulfate type compound fertilizer with nitrogen-phosphorus-potassium (20-15-10)≥45%.

[0047] Urea: 300 kg;

[0048] Ammonium sulfate: 150 kg;

[0049]Monoammonium phosphate: 350 kg;

[0050] Potassium sulfate: 200 kg;

[0051] The measured value of the product: nitrogen-phosphorus-potassium (20.55-15.3-10.1) 45.95%, moisture 1.6%, smooth and uniform particles.

[0052] Meet the requirements of GB15063-2009 standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com