Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Save precious resources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

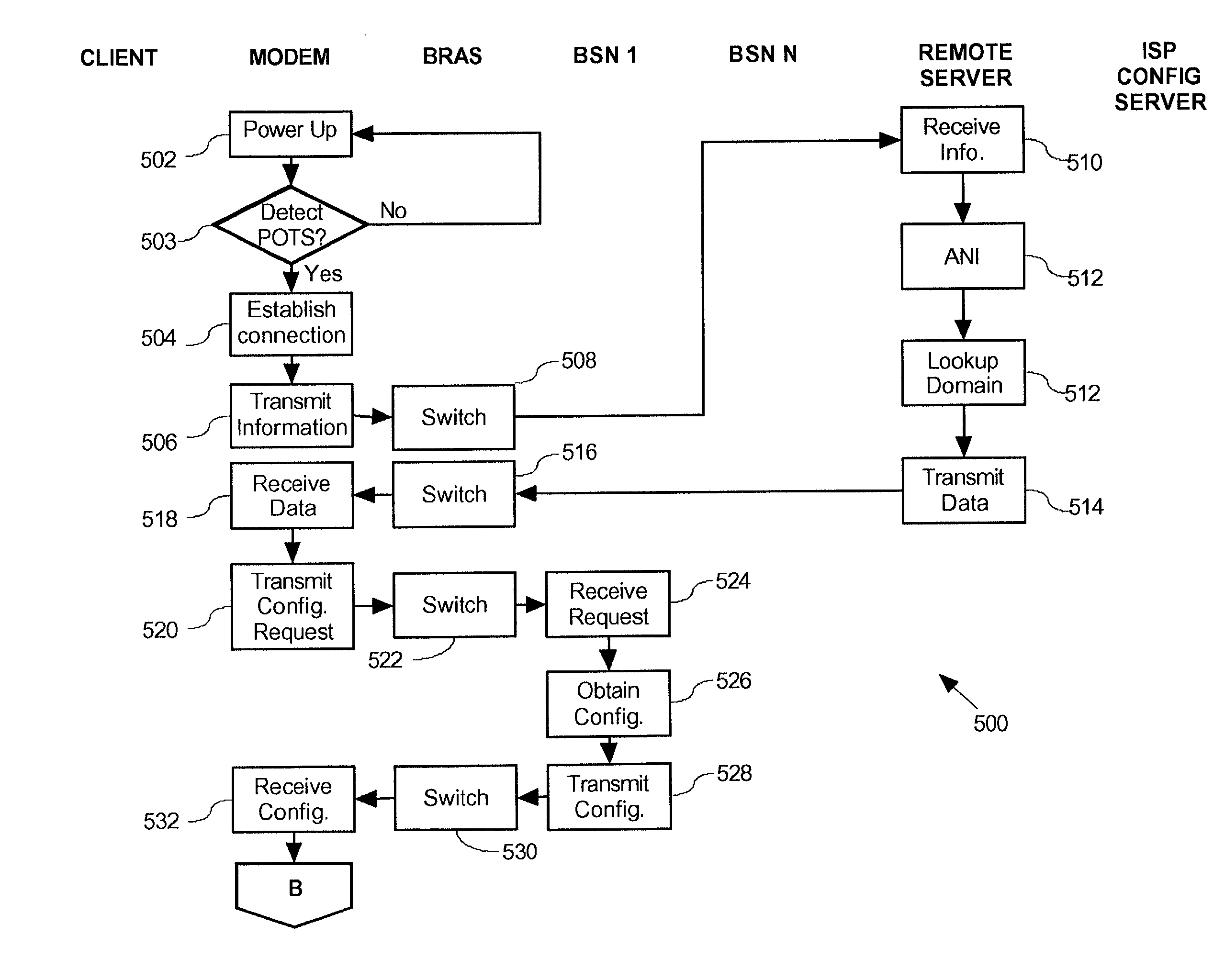

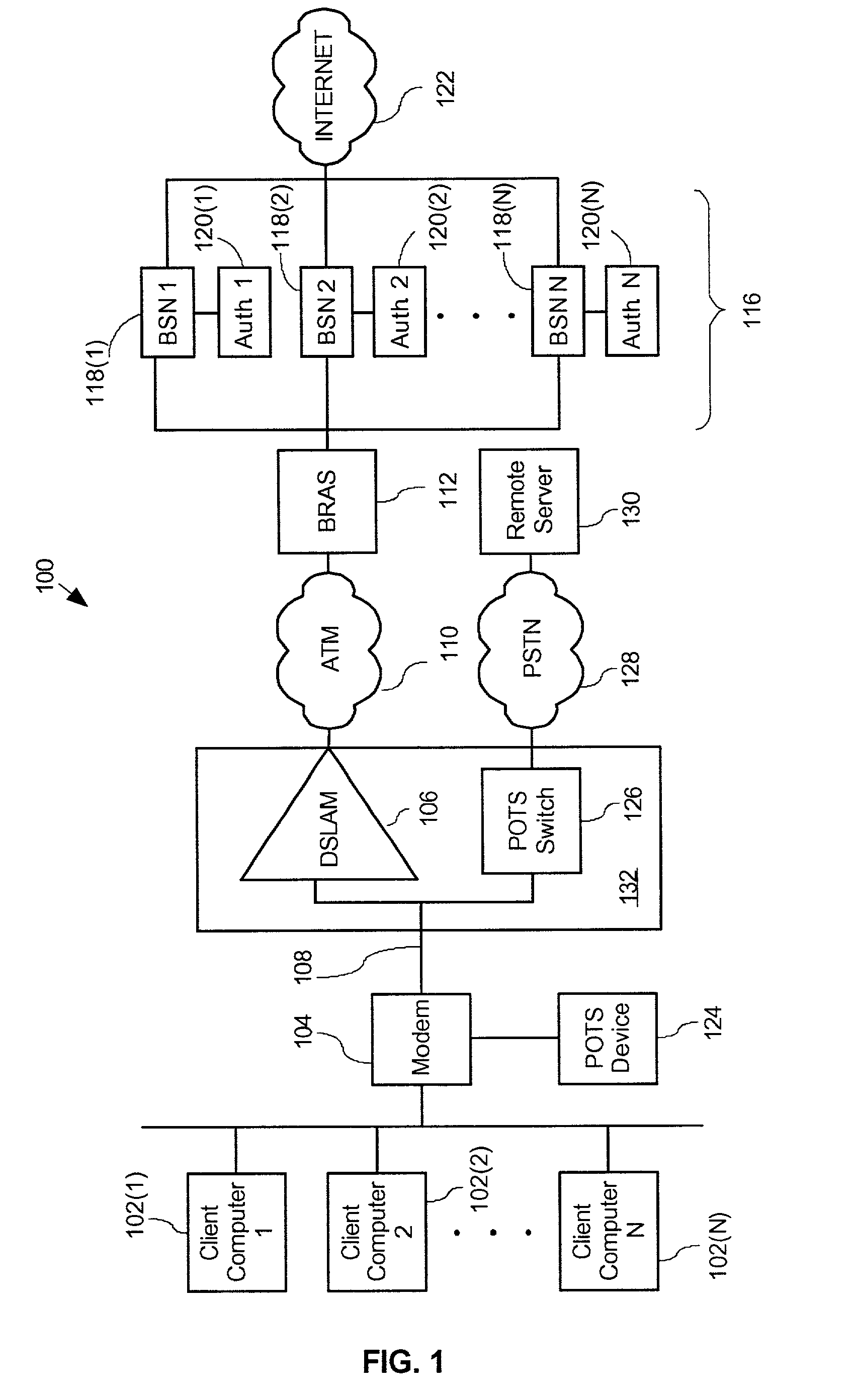

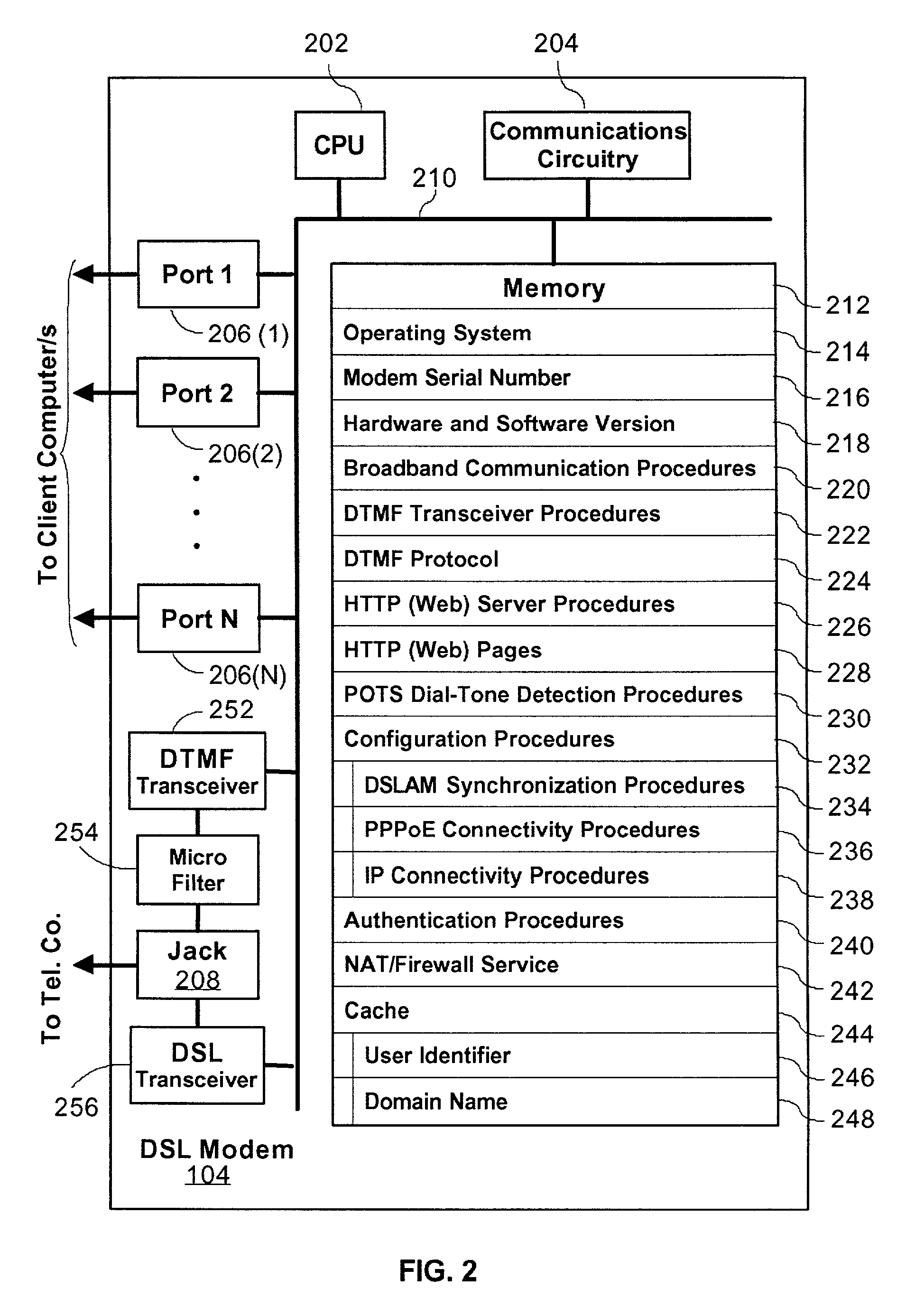

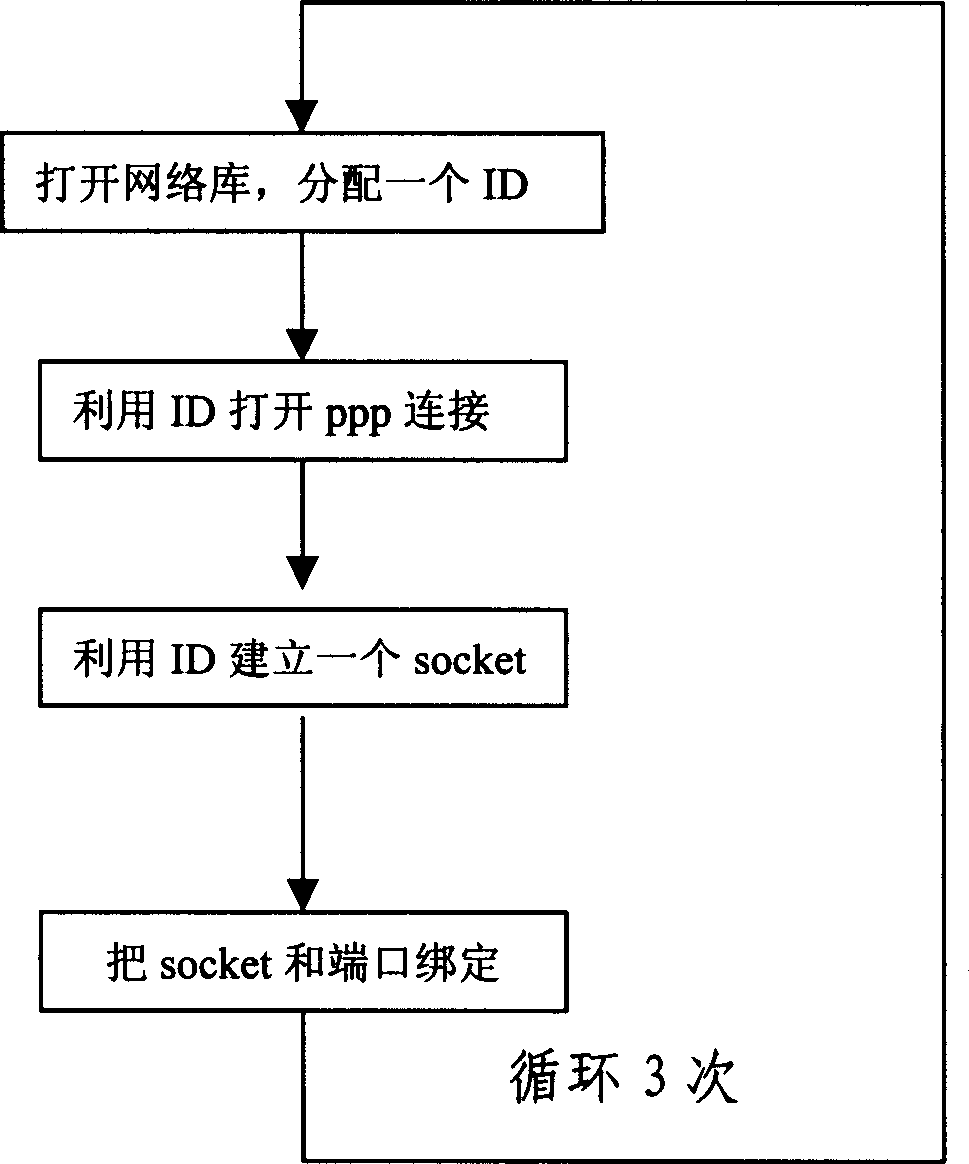

System and method for provisioning broadband service in a PPPoE network using DTMF communication

InactiveUS7079527B2Simple configurationSave precious resourcesAutomatic call-answering/message-recording/conversation-recordingData switching by path configurationDomain nameModem device

A Plain Old Telephone System (POTS) connection is established between a Broadband modem and a remote server. A configuration request is then transmitted from the Broadband modem to the remote server using DTMF tones. Subsequently a domain name associated with a Broadband Service Node (BSN) and a user identifier, such as a telephone number, is received from the remote server via the POTS connection using Dual-Tone Multi-Frequency (DTMF) tones. A PPPoE session is then established using the domain name, by firstly authenticating the Broadband modem for the PPPoE session and then configuring the DSL modem. This configuration is accomplished by transmitting a request for configuration details from the Broadband modem to the BSN having the domain name and then receiving configuration details from the configuration server. The Broadband modem then automatically configures itself using the configuration details.

Owner:HUGHES ELECTRONICS

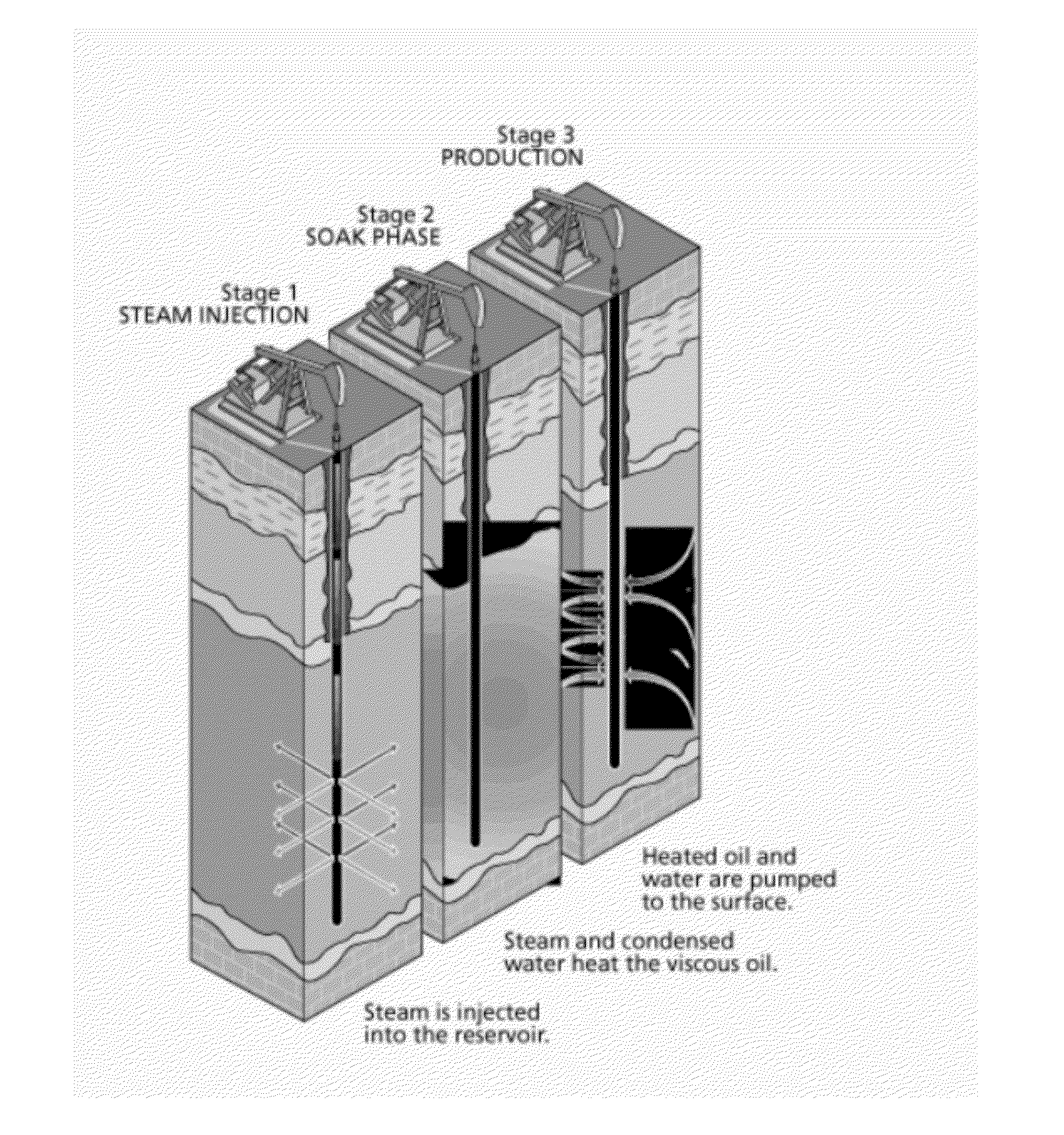

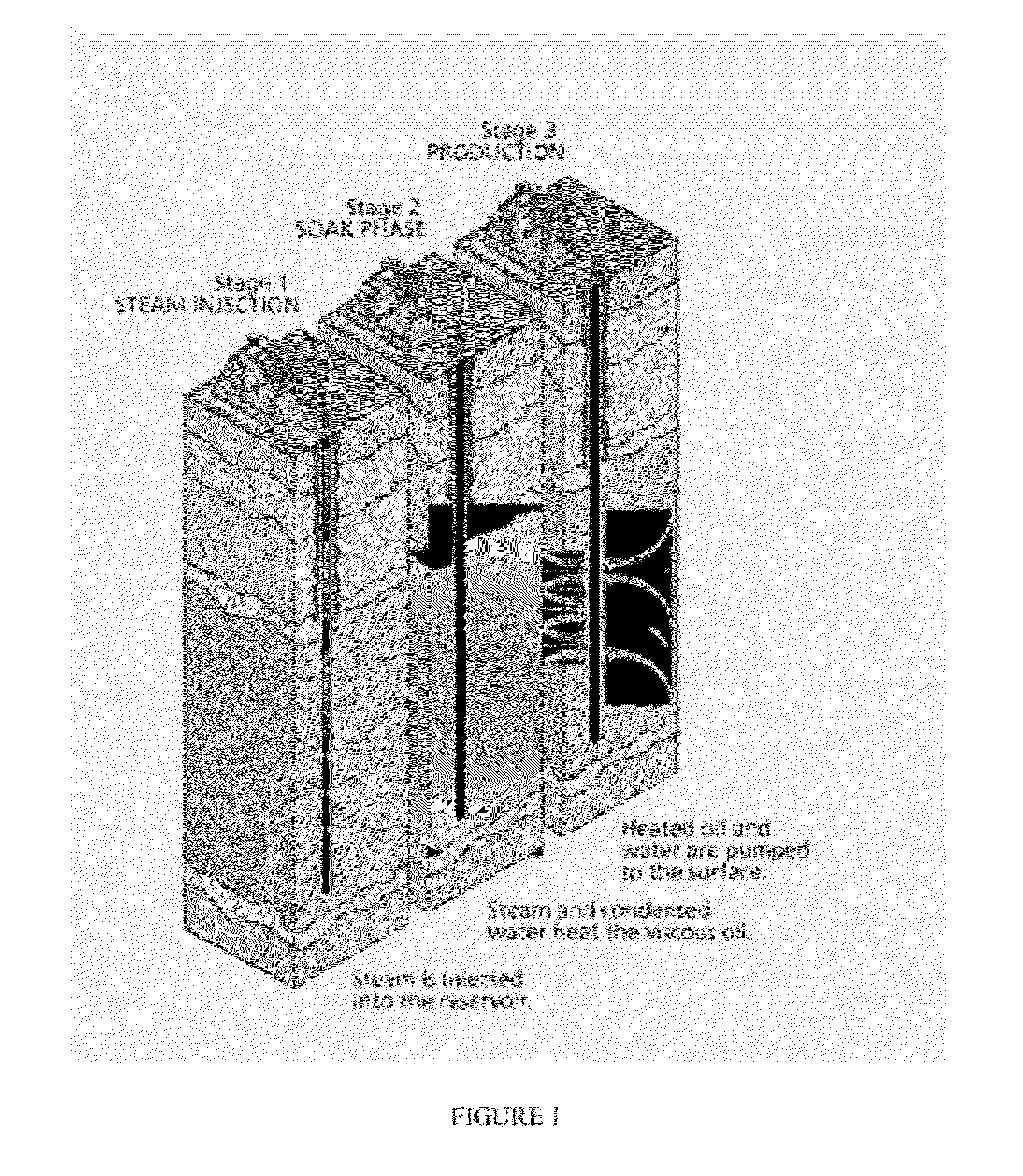

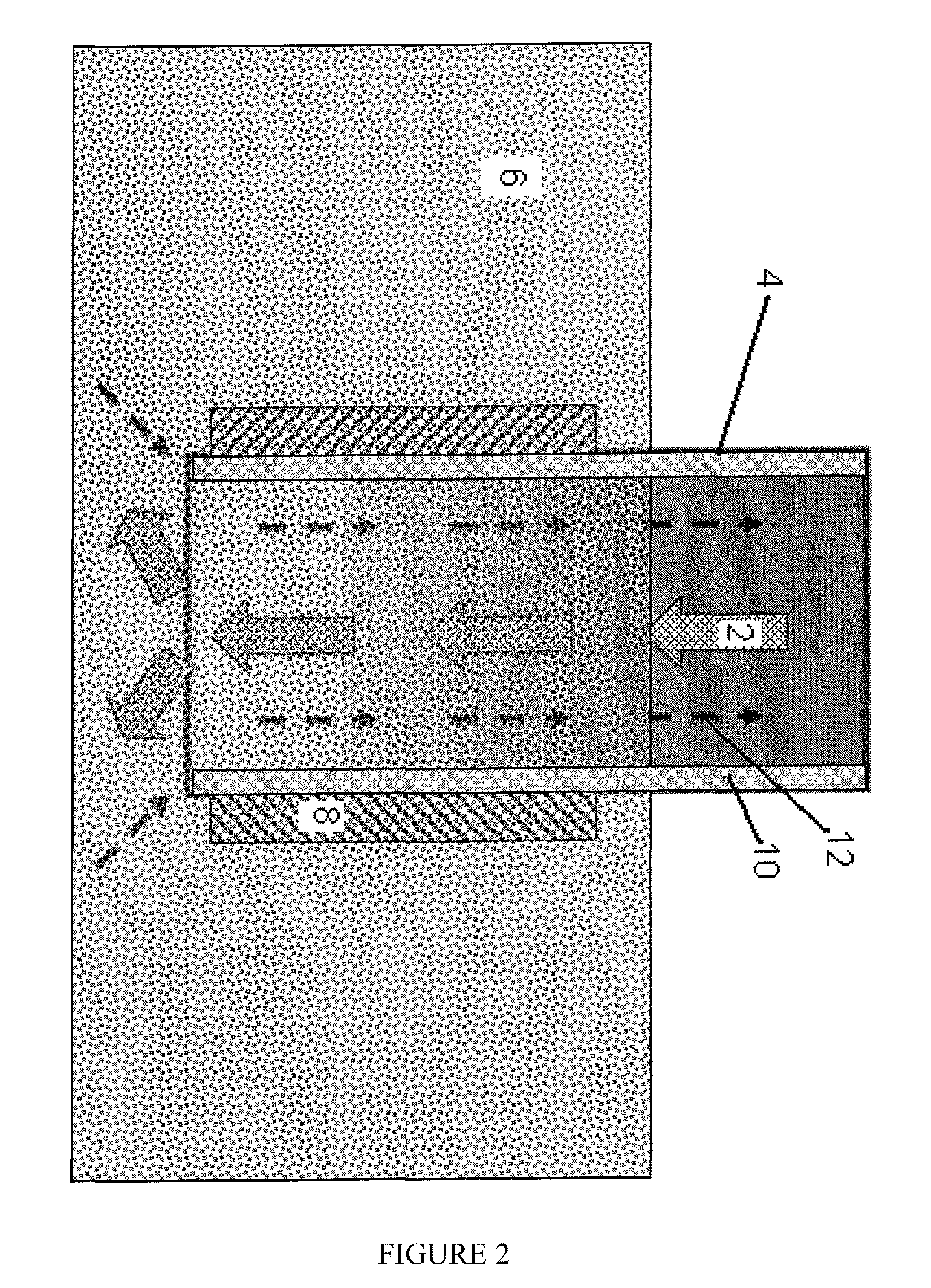

Cyclic steam stimulation using RF

ActiveUS20120085533A1Improve efficiencyReduce water consumptionInsulationFluid removalEngineeringSuperheated steam

A method of producing hydrocarbons from a well. The method begins by injecting steam into a well. The bitumen in the formation is then heated with the injected steam, followed by ceasing the injection of steam into the well and then by soaking the bitumen with the injected steam and collecting the heated oil. Steam that has condensed is revaporized by directing RF / MW radiation to the steam allowing for more bitumen to be produced without injecting more steam. In addition, some of the steam could become superheated, wherein the temperature of the superheated steam is greater than the temperature of the steam. The bitumen is heated by the revaporized steam and the superheated steam, followed by soaking the bitumen with the revaporized steam and the superheated steam. Hydrocarbons are then produced from the well.

Owner:HARRIS CORP +1

Nickel-containing sponge iron, and its preparing method and method for producing nickel alloy billet

InactiveCN1641051AReduce manufacturing costEliminate pollutionRetort furnacesElectric arc furnaceFerrosilicon

The present invention relates to one kind of nickel-containing sponge iron and its production process as well as process of producing nickel alloy steel billet. The waste from stainless steel smelting, including fume, slime and iron scale as the main material is mixed with coke powder; the mixture is extruded to form, filled into reducing tank and reduced through roasting in kiln at 1000-1500 deg.c to obtain nickel-containing sponge iron. Further, the nickel-containing sponge iron, ferrosilicon powder, limestone powder and carbon powder are smelted in arc furnace into nickel alloy steel billet, which is used for smelting stainless steel. The present invention utilizes the waste and can lower the production cost of stainless steel.

Owner:李增元

Non-autoclaved waste residue sand lime brick and preparation method thereof

InactiveCN102173701AReduce equipment investment and production costsReduce pollutionSolid waste managementScrapIndustrial waste

The invention discloses a non-autoclaved waste residue sand lime brick and a preparation method thereof. Waste materials discharged in an industry are selected, and a simple and convenient non-autoclaved process is used, so that the production cost and equipment investment of the conventional sand lime brick are greatly reduced and the intensity of a product reaches the standard of a building brick. The non-autoclaved waste residue sand lime brick comprises the raw materials in part by weight or volume: 30 to 300 parts of one or more of tailing sand, wind sand, and waste rock powder, 50 to 500 parts of one or more of active waste residue, 0 to 300 parts of coarse aggregate, 3 to 30 parts of cement, and a proper amount of water. The non-autoclaved waste residue sand lime brick also comprises one or more of the following materials in part by weight or volume: 0 to 300 parts of coagulant material, 0 to 200 parts of carbide slag, and 0 to 200 parts of chemical gypsum. The non-autoclaved waste residue sand lime brick is formed by stirring, shaking and pressing the raw materials. By the method, harmful industrial waste materials can be changed into favorable industrial waste materials, the secondary energy consumption of a steaming and pressing process is saved, the manufacturing method is easy to grasp, materials can be selected flexibly, materials can be selected according to the local conditions, and novel building materials with various specifications can be produced by replacing different moulds.

Owner:刘丽华

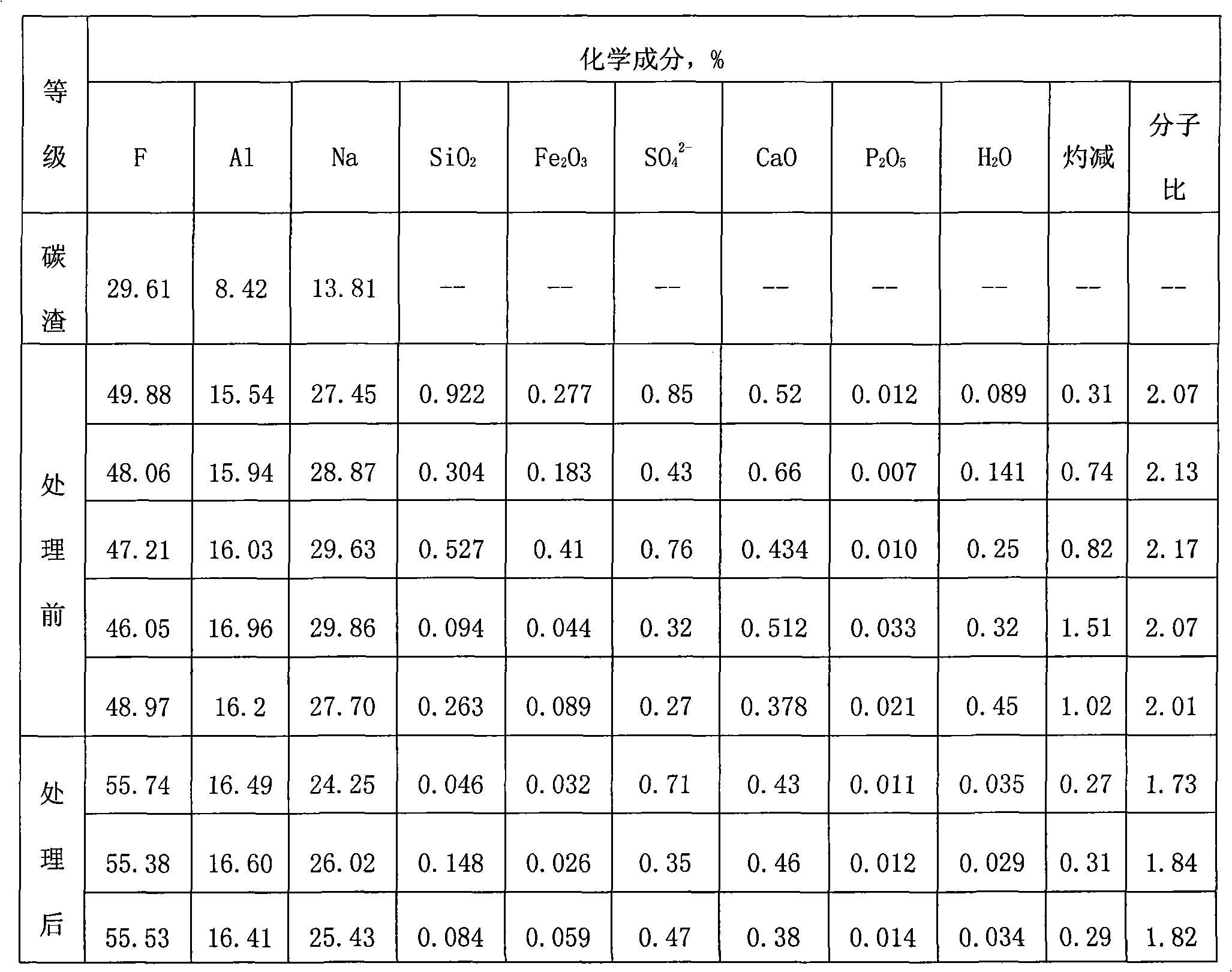

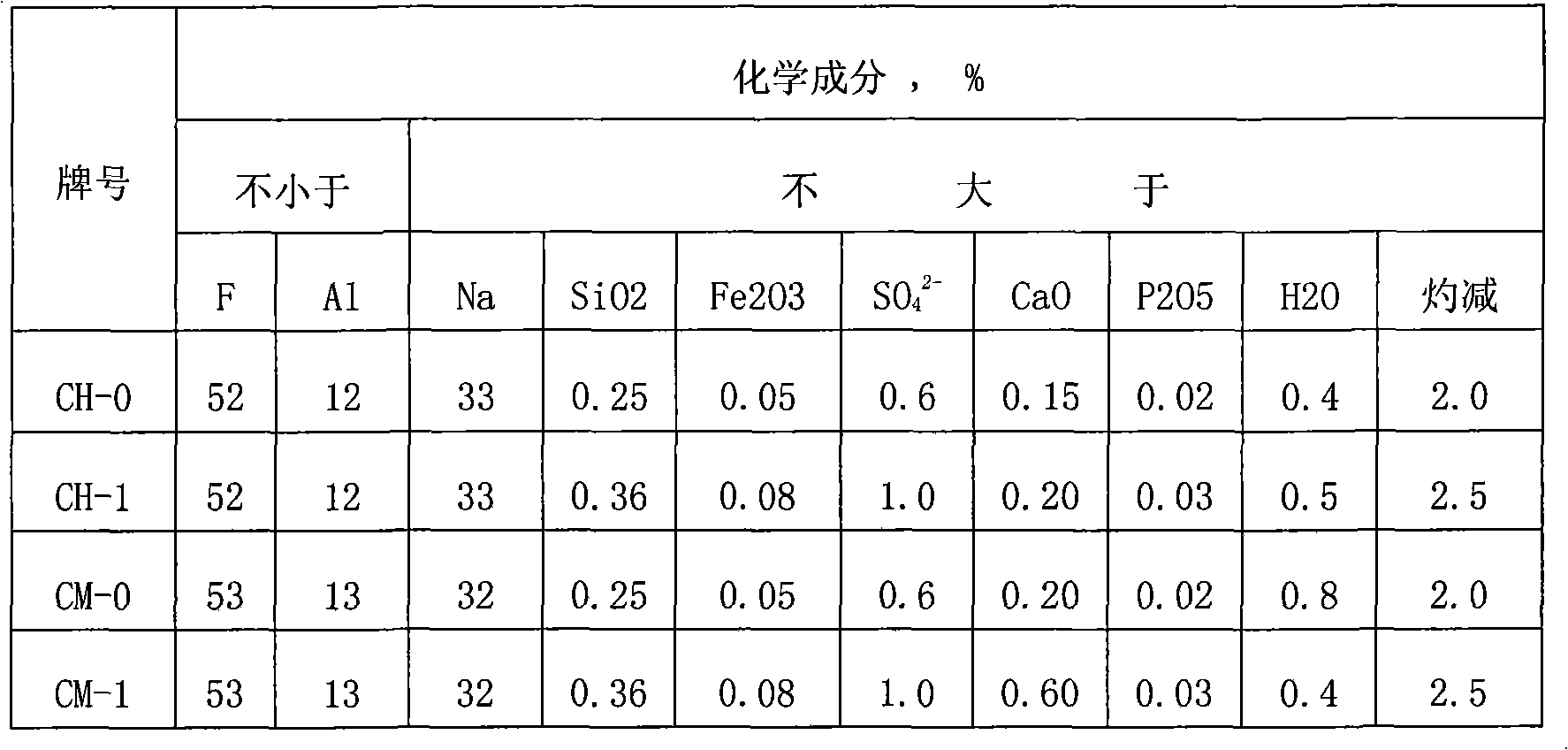

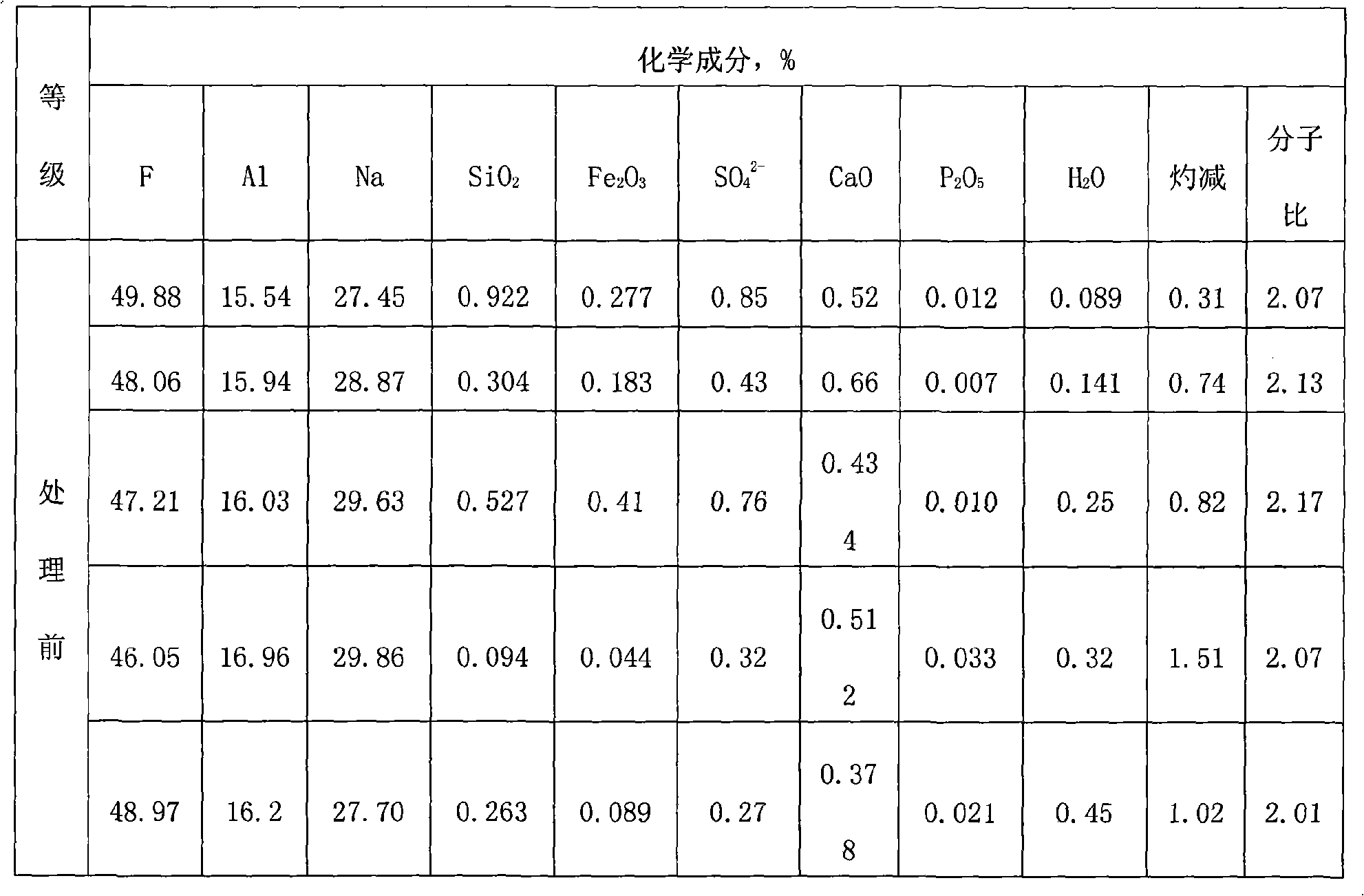

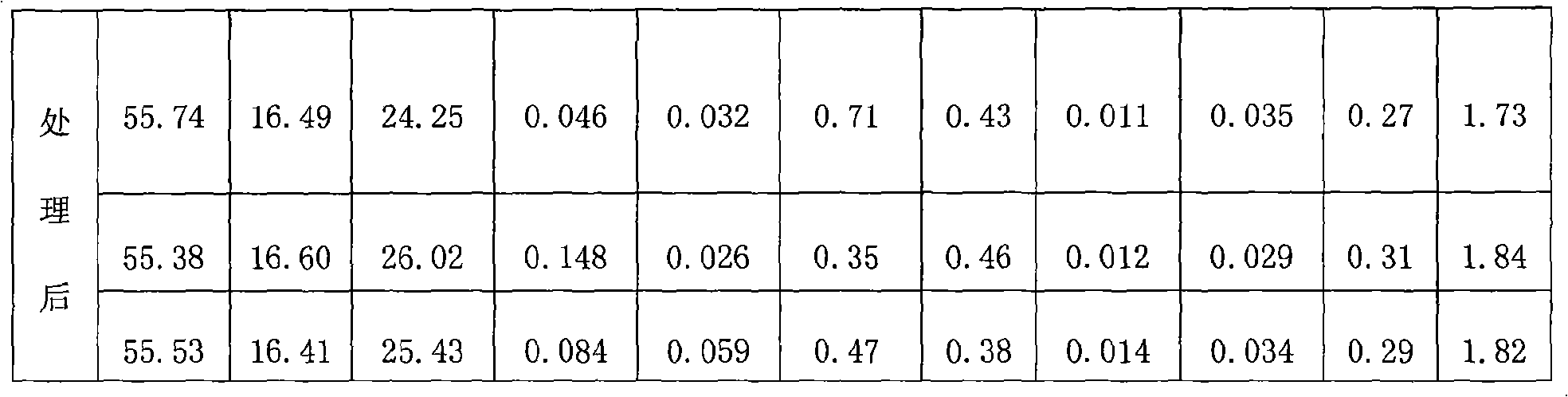

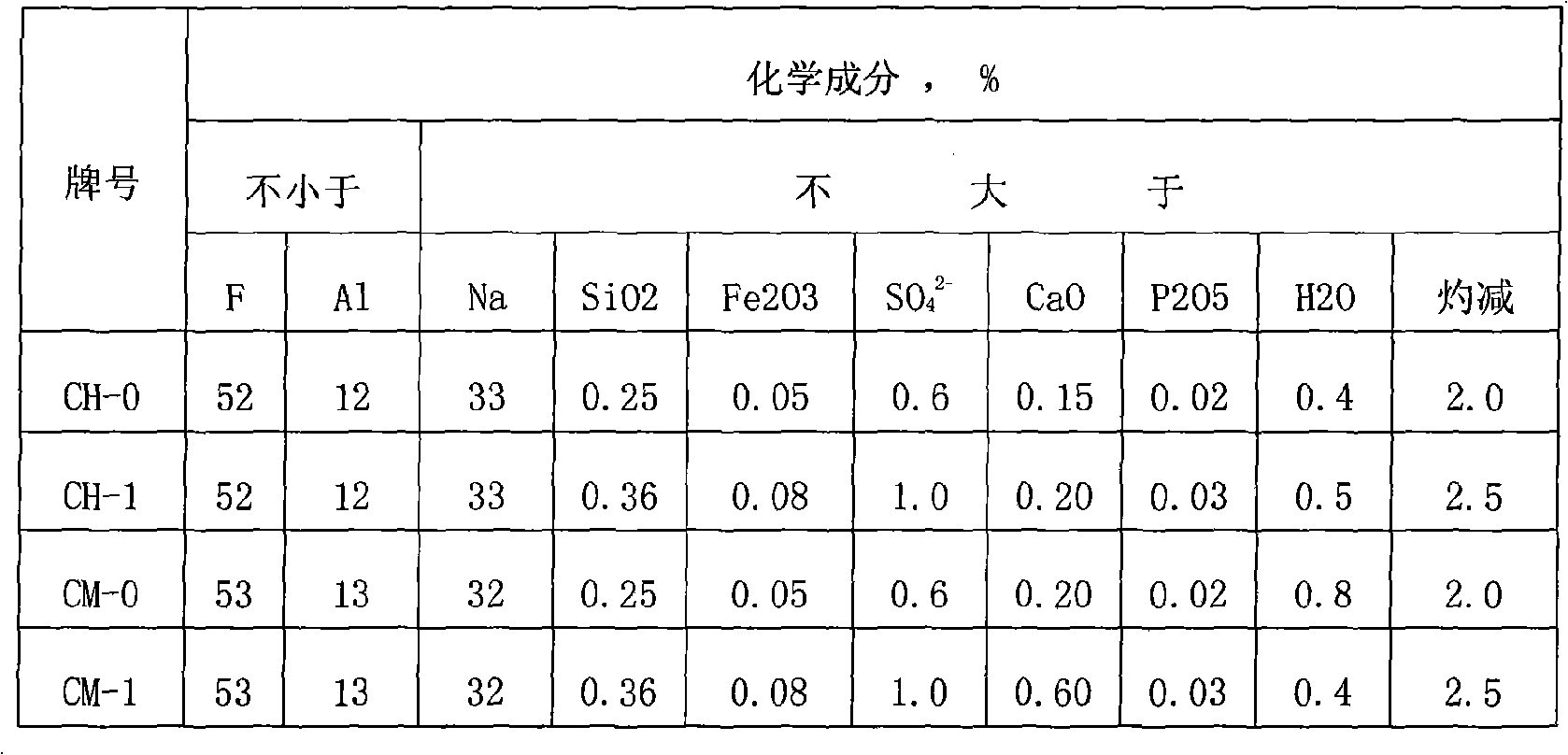

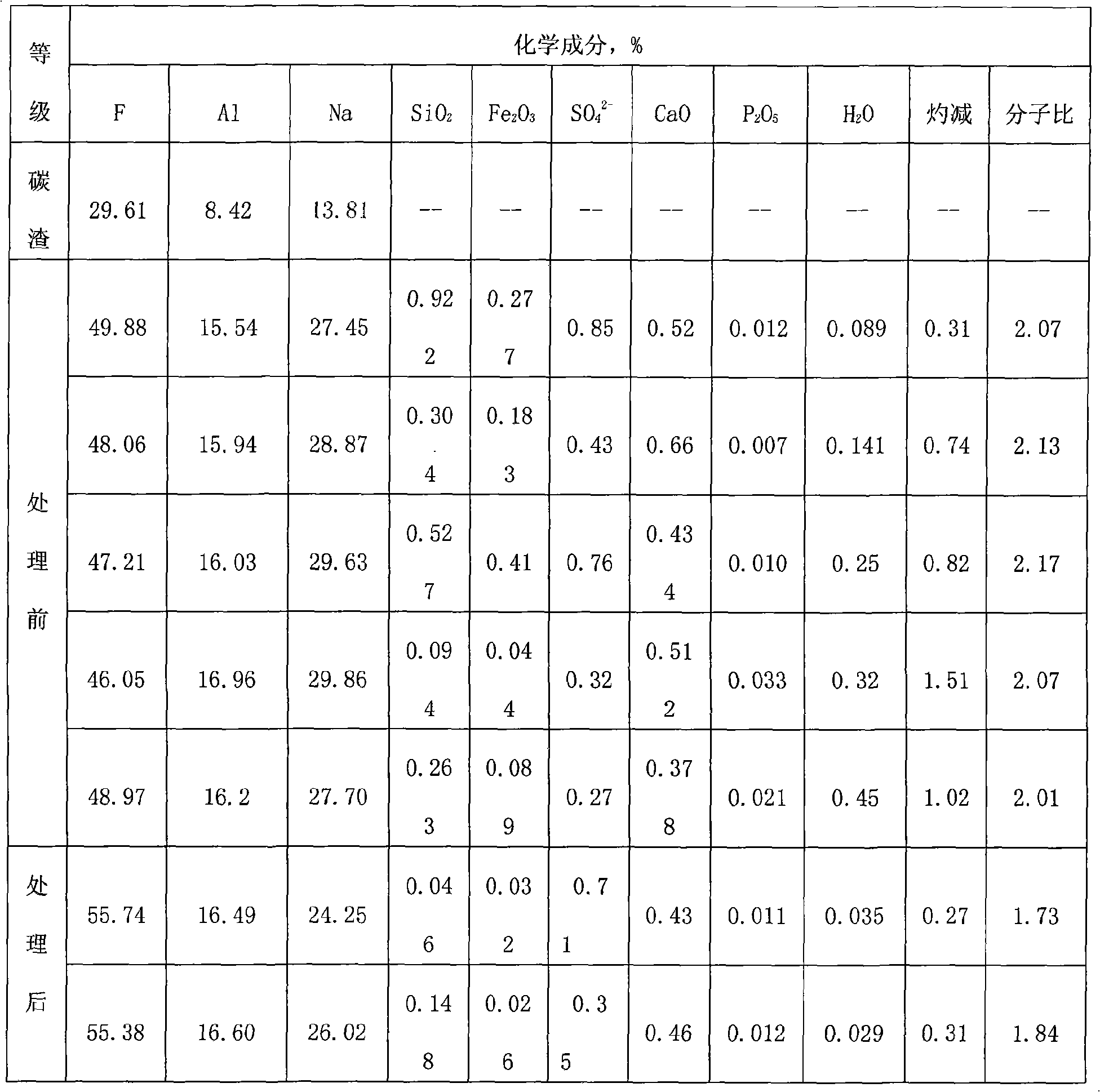

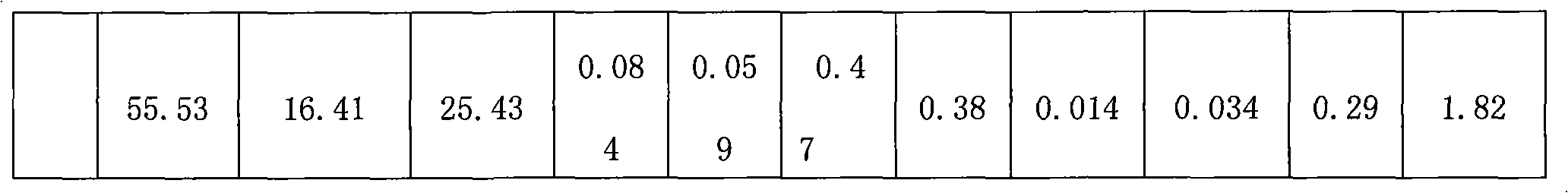

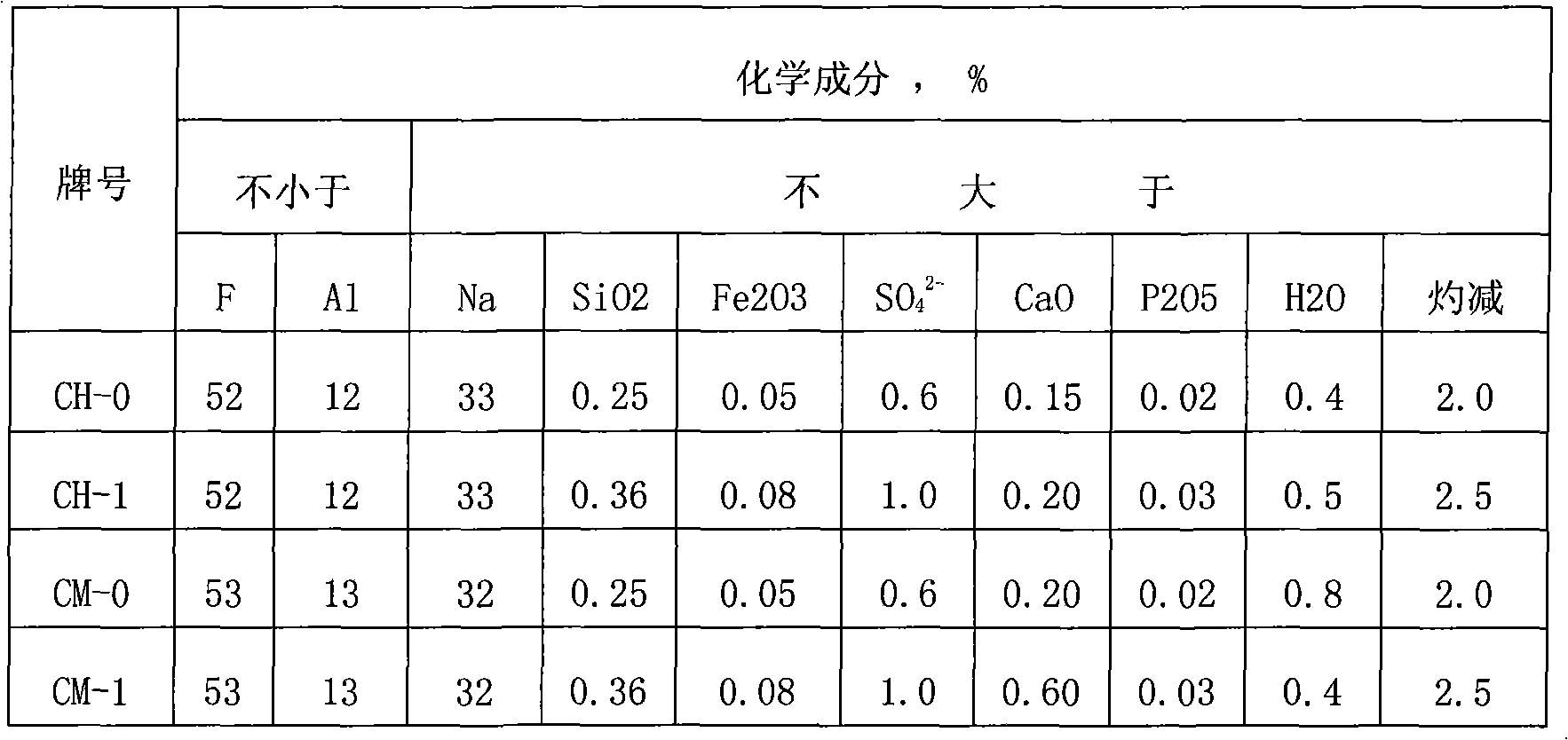

Method for preparing kryocide

The invention relates to a method for preparing cryolite, which takes carbon residue of aluminum factories and ammonium fluoroaluminate as raw materials which are then reacted with each other in a solid phase. The method adopts a great deal of waste residue of the electrolytic aluminum factories - the carbon residue and waste residue of the aluminum section industry - the ammonium fluoroaluminate as the raw materials, thereby the method creates a source of raw materials for producing villiaumite, relieves the dependency on fluorite, saves a large number of valuable resources, has low cost, greatly reduces the production cost, and relieves the ambient environmental pollution problem. Carbon powder containing about 10 percent of electrolyte obtained after flotation of the carbon residue can be dried and then used as auxiliary materials for adequate addition when bottom paste is manufactured, and used for building a novel groove. The compositions of electrolyte in a great deal of waste residue produced by the electrolytic aluminum factories - the carbon residue are the cryolite and alumina; the method converts the alumina in the electrolyte into aluminum fluoride; and the cryolite is double salt of sodium fluoride and the aluminum fluoride. Moreover, products during the reaction process of the method can be recycled, thereby the method greatly reduces the production cost to a certain degree, has good social benefit and economic benefit, and is easy to promote and apply.

Owner:DO FLUORIDE CHEM CO LTD

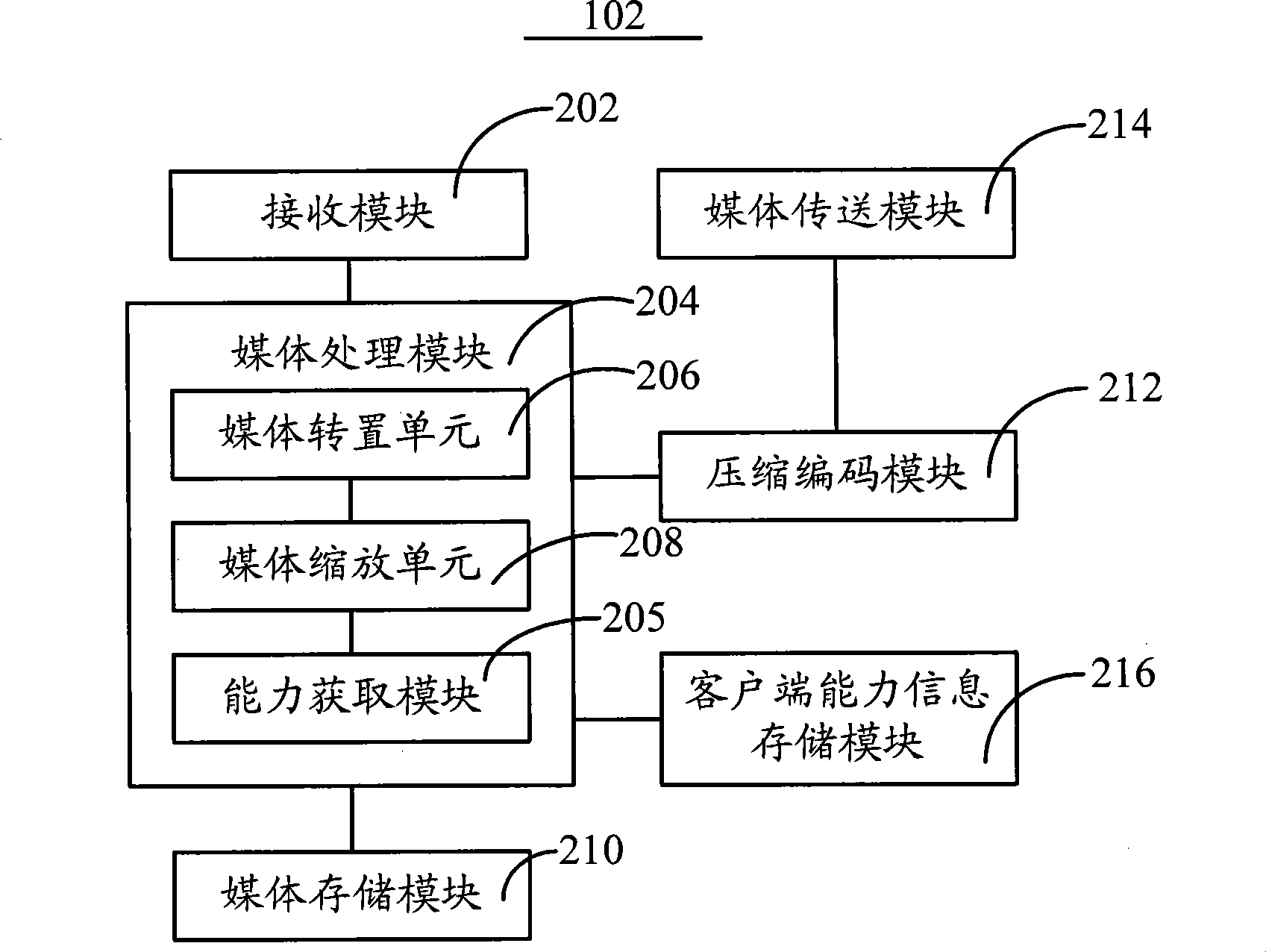

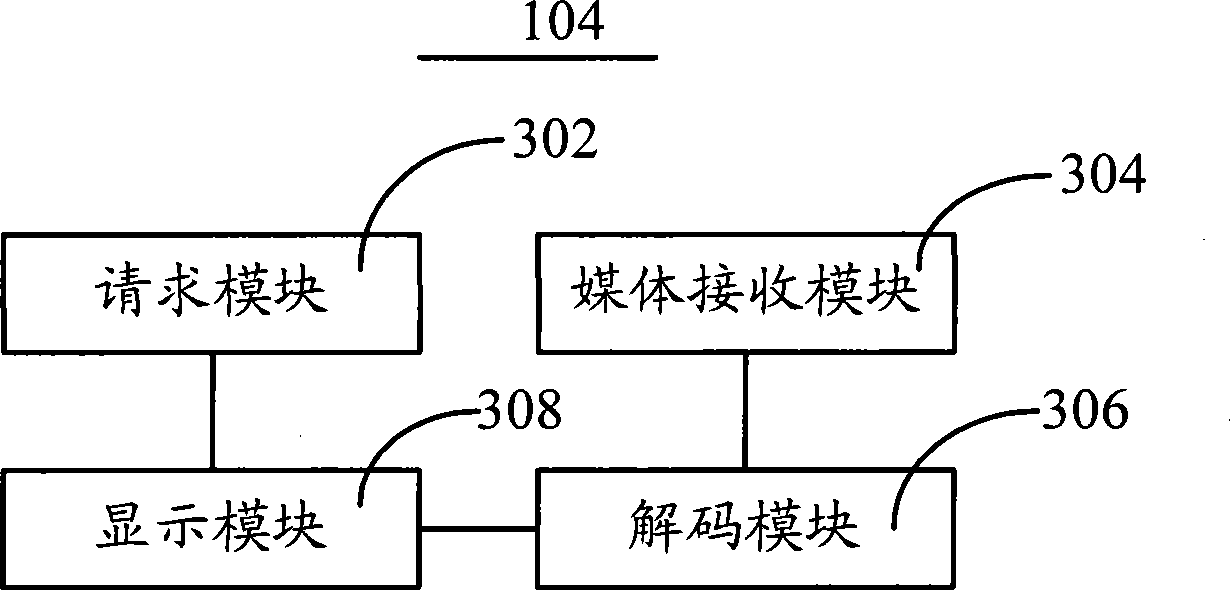

Method and system for media providing, downloading

InactiveCN101420604ASave resourcesSave precious resourcesPulse modulation television signal transmissionTwo-way working systemsComputer science

A media providing method is characterized in that the method comprises the following steps: display capacity information of a client is obtained; a match display mode which is applicable to a media which is requested by the client is determined according to the display capacity information of the client; the original media is processed to the media with the matched mode which is corresponding to the match display mode, or the stored media with the matched mode which is corresponding to the match display mode is selected; and the media with the matched mode is transmitted to the client. The invention also provides a media providing system and a device. The embodiment of the invention can effectively save valuable resources of the client, lead the media provided by a coding system to be adapted to the clients with the different display capacities so as to be contributive to the business generalization.

Owner:HUAWEI TECH CO LTD

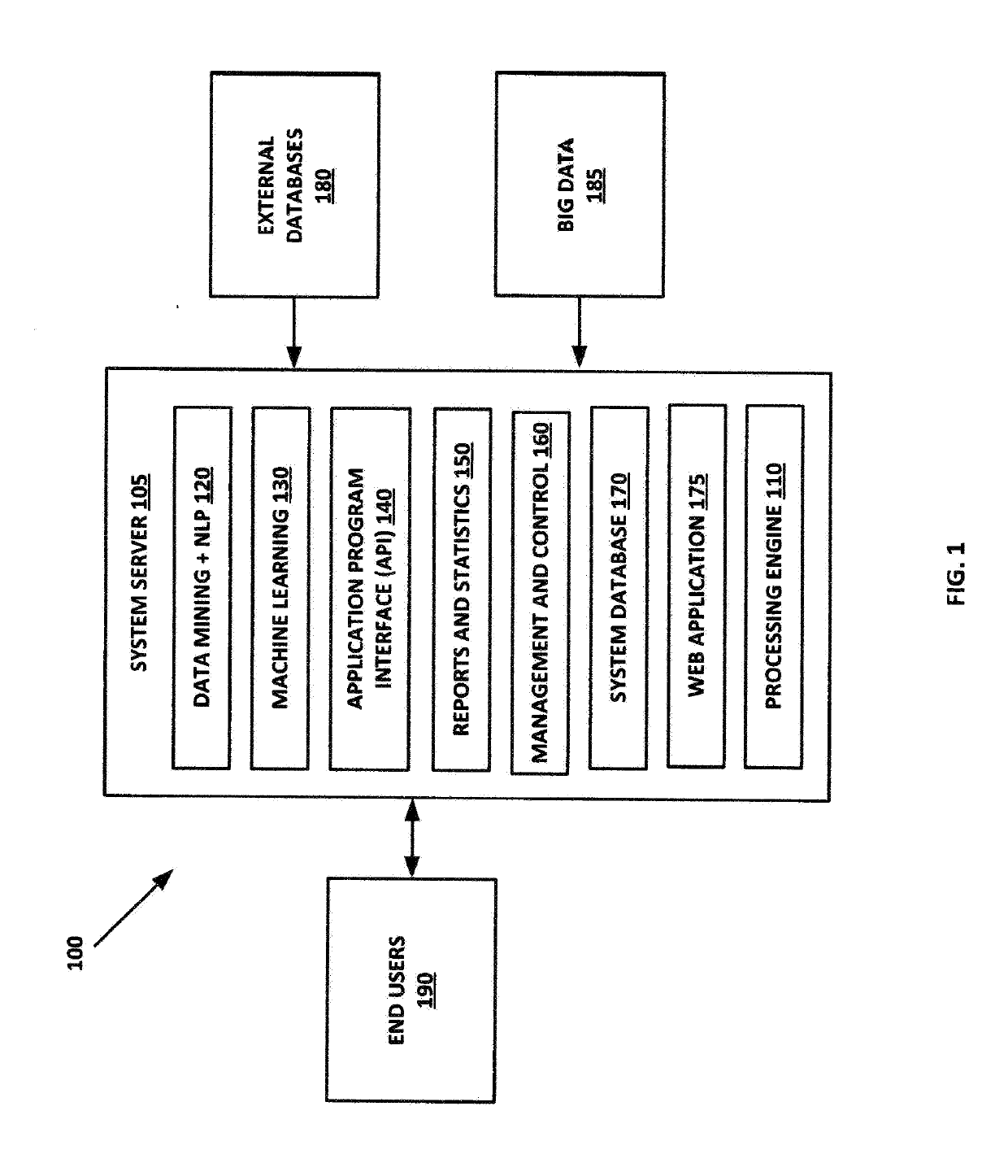

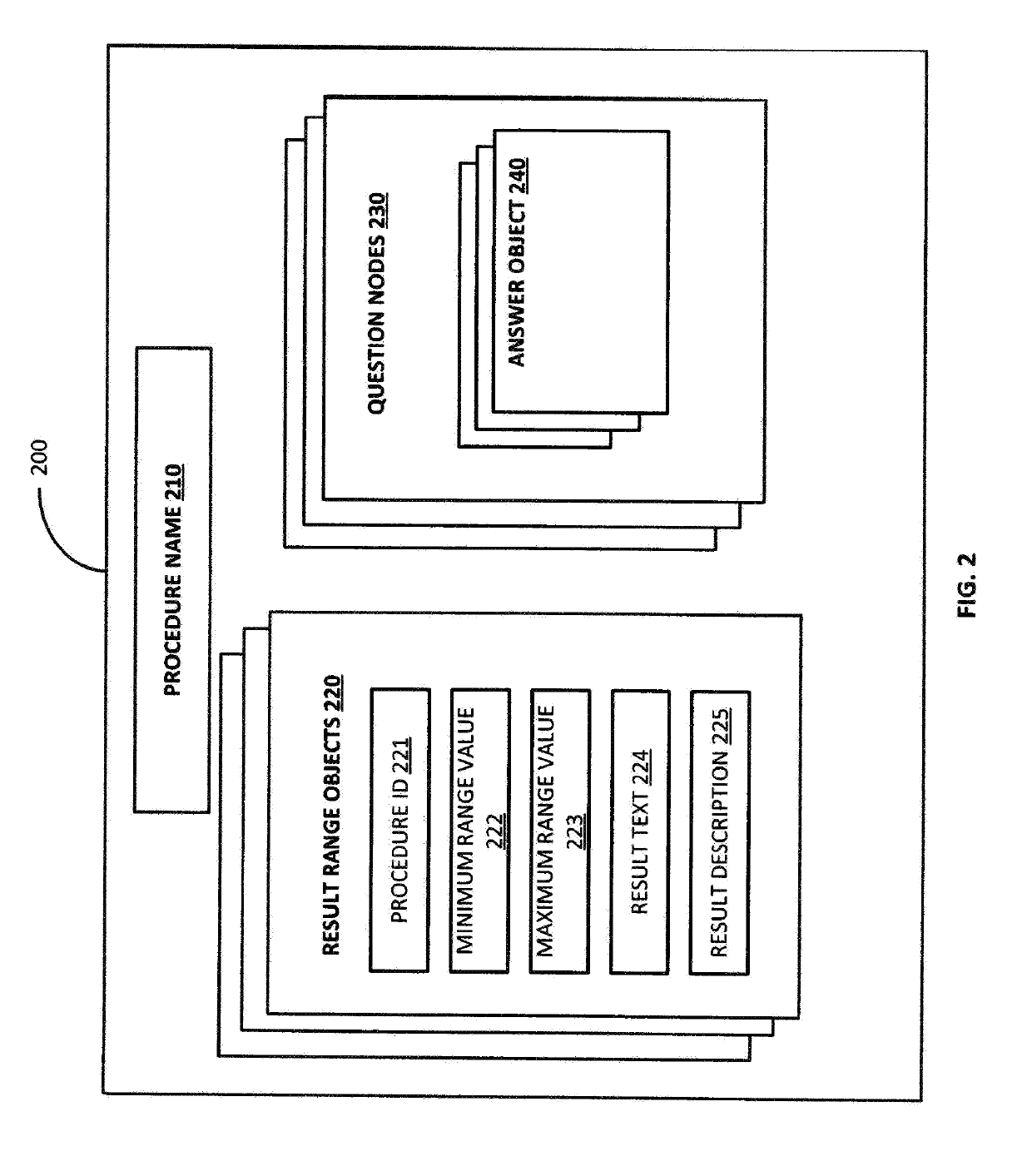

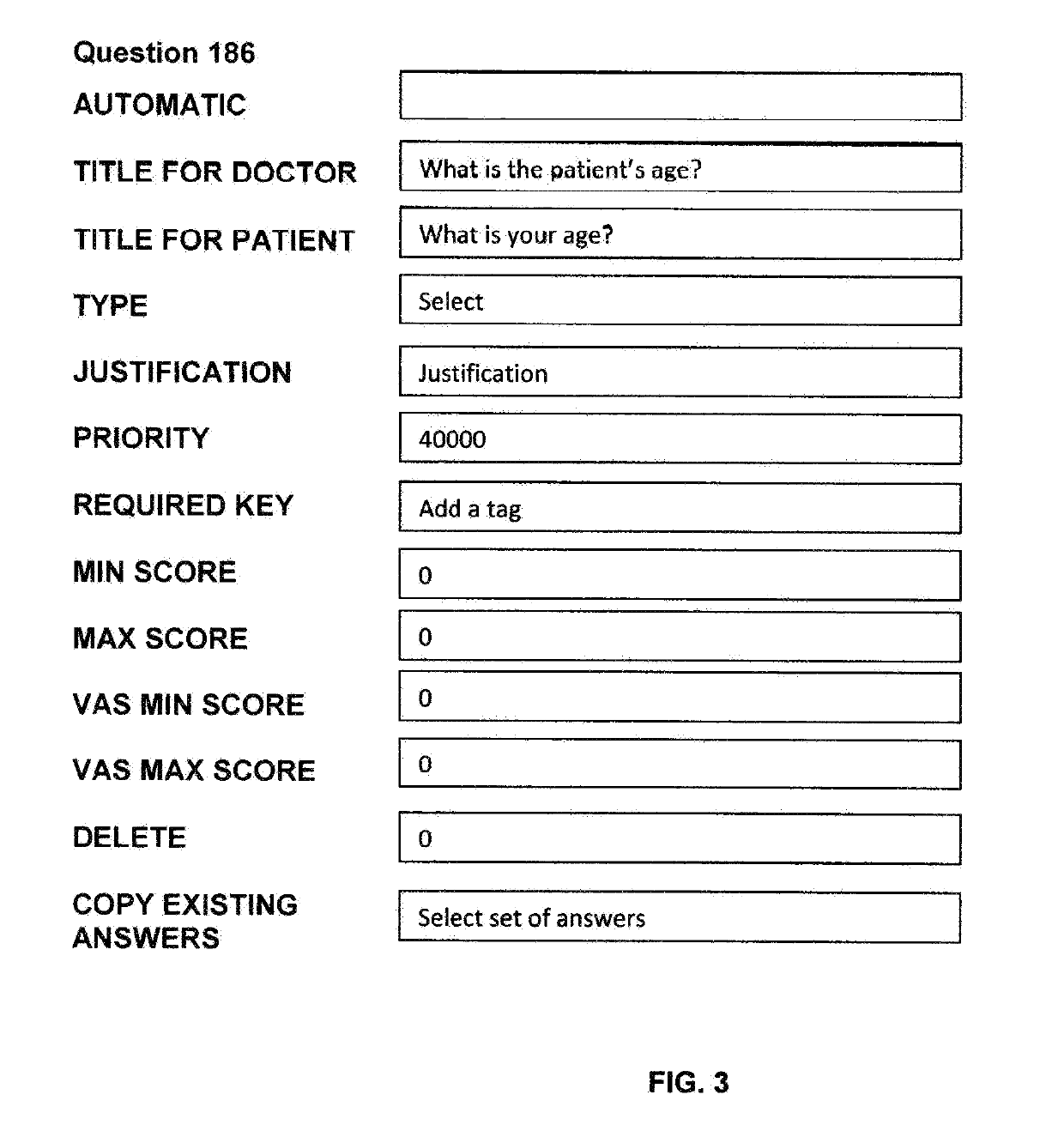

Automated method and system for screening and prevention of unnecessary medical procedures

ActiveUS20190333638A1Negative impactProcedures—preventing patients from facing unnecessary proceduresMechanical/radiation/invasive therapiesHealth-index calculationKnowledge managementAutomated method

An automated method for screening and preventing unnecessary medical / surgical procedures, comprising: retrieving medical / surgical procedures data from external and internal sources; computerizing a dynamic questioner with complex relations between questions and answers and a different impact for each answer in the context of the specific scenario and procedure by using experts input, latest research, statistics and machine learning modules; receiving from a user a request to provide a recommendation for a given medical / surgical procedure; providing a customized dynamic questionnaire to said user; computing a relative indication according to said answer's relative importance and impact on the decision to conduct said medical / surgical procedure; and generating a specific output for said user based on said medical / surgical procedure and the relative impact, including a relative indication for said medical / surgical procedure.

Owner:MEDECIDE LTD

Sponge iron ocntained nickle and its preparation process, process for producing nickle alloy steel blank

InactiveCN1624160AReduce manufacturing costEliminate pollutionRetort furnacesElectric arc furnaceFerrosilicon

A process for preparing the Ni-contained sponge iron includes such steps as proportionally mixing the rejected substances generated by smelting stainless steel, such as flue ash, dust deposit and iron scale, die pressing, loading in reductor, adding reducing agent, and calcining at 1000-1500 deg.C. A process for preparing Ni-alloy steel billet from said sponge iron includes such steps as adding said Ni-contained sponge iron, ferrosilicon powder, lime stone powder, and carbon powder into electric arc furnace, and conventional smelting to obtain Ni-alloy steel billet sued to smelt stainless steel.

Owner:李增元

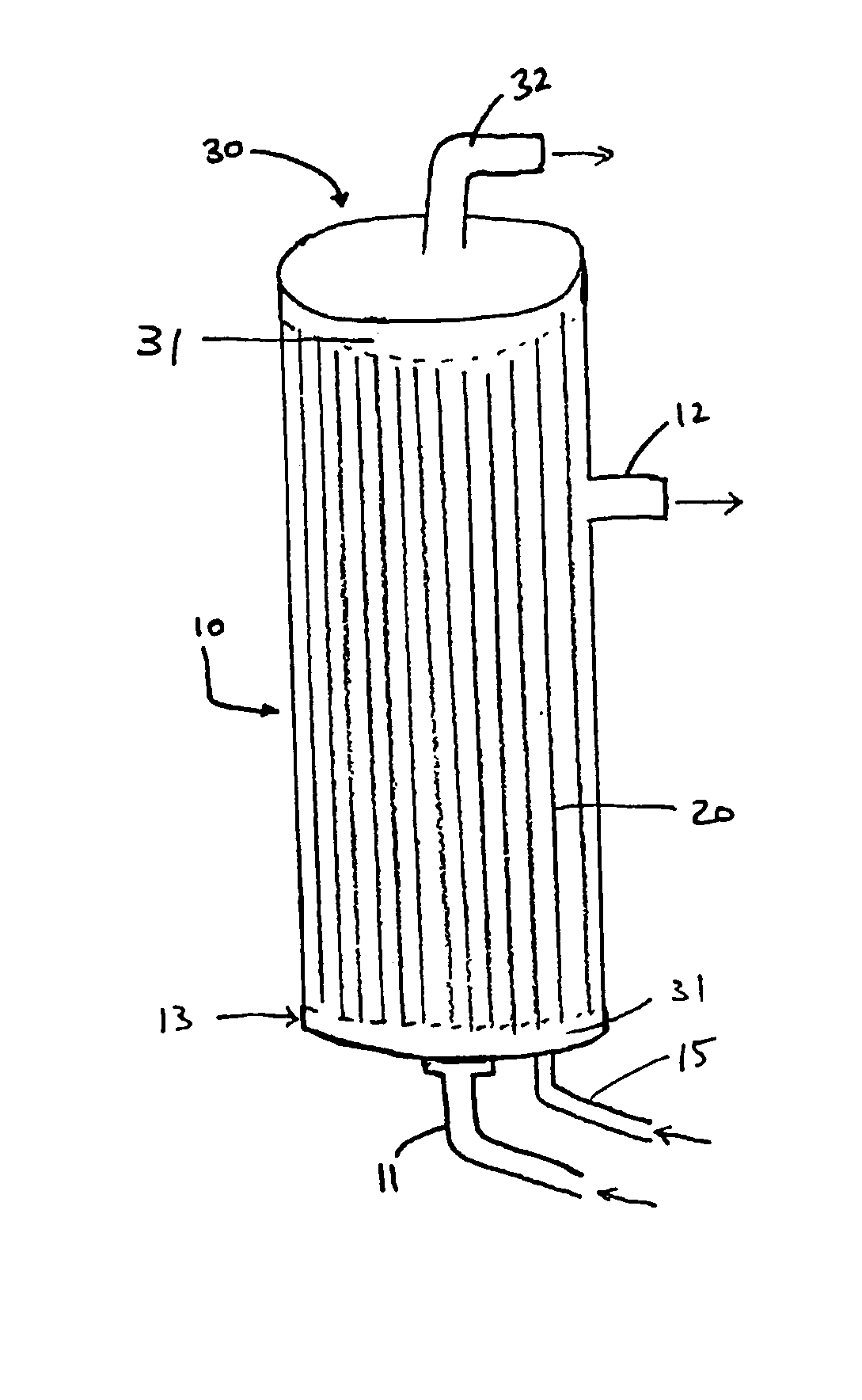

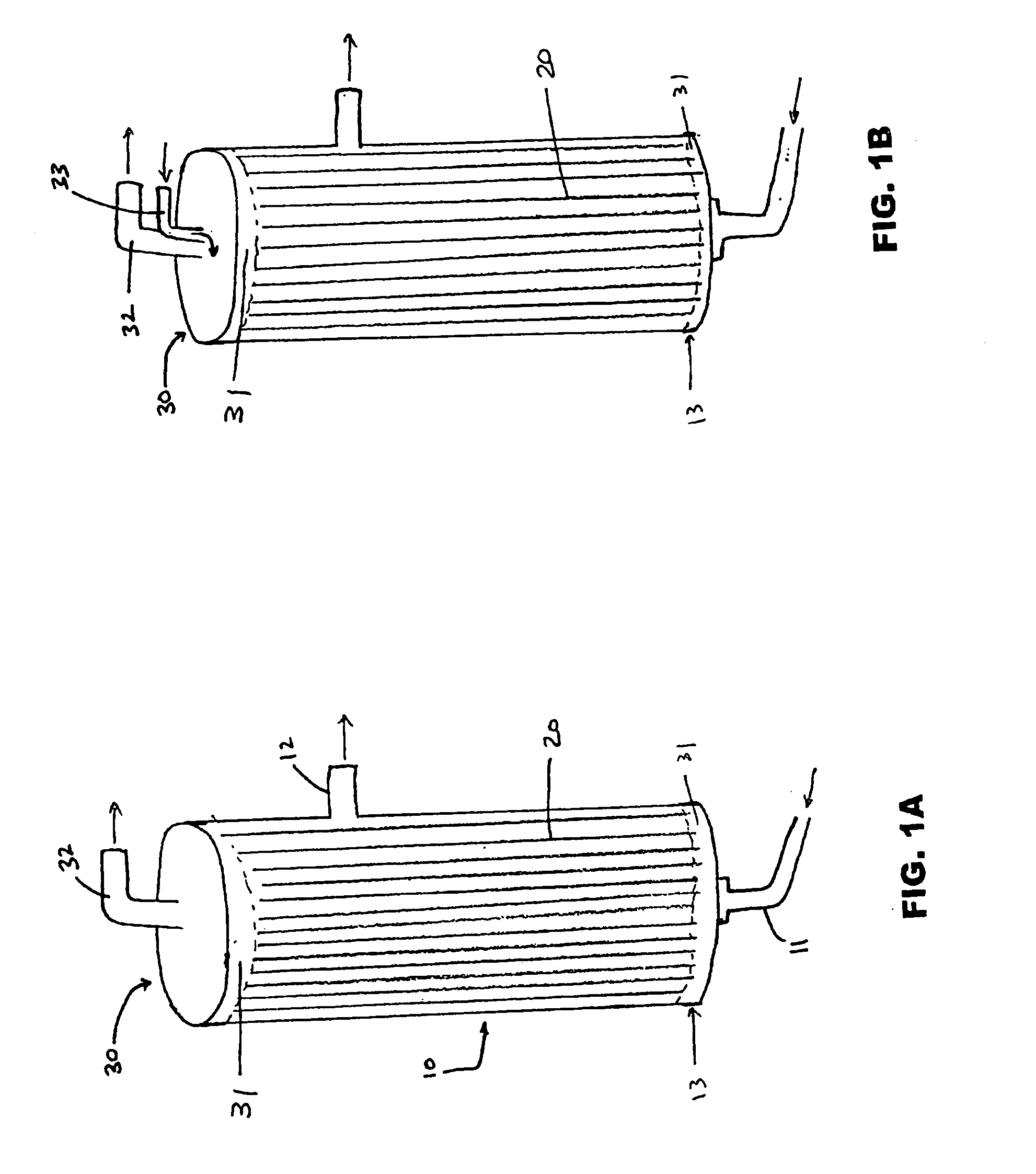

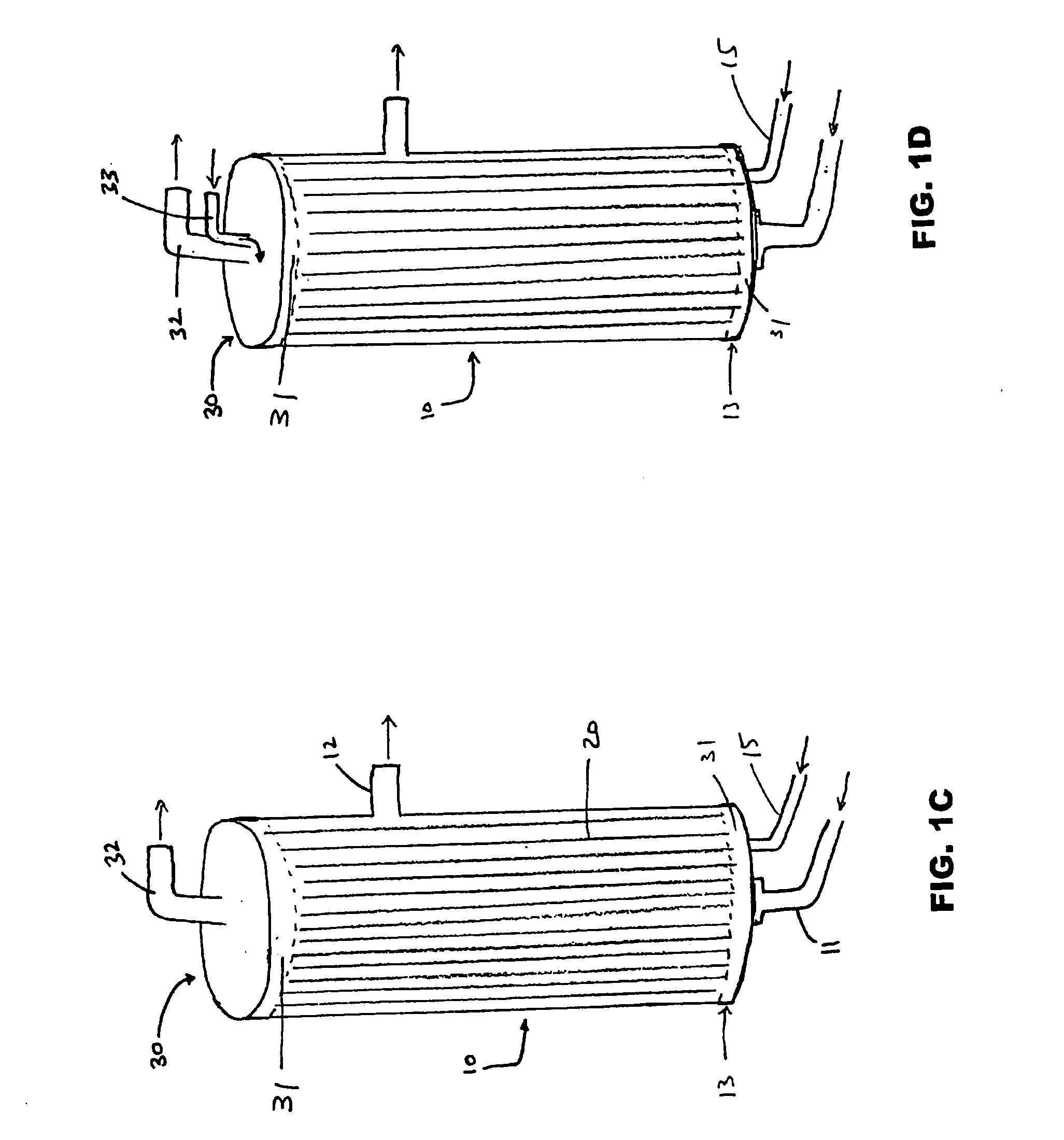

Hemodilution cap and methods of use in blood-processing procedures

InactiveUS20050000882A1Facilitates fluid mixingPreventing hemoconcentrationMembranesOther blood circulation devicesPeritoneal dialysisHaemodialysis machine

Devices and methods that prevent clotting of blood during blood-processing procedures such as hemofiltration, hemodialysis, hemodiafiltration, and peritoneal dialysis are described. The device comprises a cap and a housing that is shaped to receive a blood filter. The housing has an inlet for blood and may have an outlet for waste and ultrafiltrate. The cap is attached to the housing. The cap has an outlet for blood and a port adjacent the outlet for receiving dilution fluid. Methods of use during blood-processing procedures to provide immediate hemodilution to blood exiting a filter are also described.

Owner:BRUGGER JAMES M +2

Method for utilizing fingerprint as traffic ticket

InactiveCN101527054ARealize cost-free productionStop ScalpingOther printing matterIndividual entry/exit registersData informationHandling system

The invention relates to a method for utilizing a fingerprint as a traffic ticket. The method comprises the following steps that: a ticket purchaser fills in a ticket purchasing sheet; ticket-selling staff collects a fingerprint of the ticket purchaser, and stores the ticket purchasing sheet and the fingerprint of the ticket purchaser in a ticket database; a ticket processing system compares the stored information with the prior data information and judges whether the ticket purchaser is a repetitive ticket purchaser or a person with low credit standing or not; the ticket is sent to a non-repetitive ticket purchaser with high credit standing; the train number, the seat number, the departure location, the departure time and the arrival location are bond with the fingerprint of the ticket purchaser; when passengers enter a station, the passengers press the fingerprints, and according to the fingerprints, whether the passenger can enter the station or not is checked; when the passengers leave the station, the passengers press the fingerprints, and according to the fingerprints, whether the passenger can leave the station or not is checked; when one passenger traffic work is finished, the ticket processing system automatically carries out the check of passenger departure and arrival; if no passenger departure information is in the ticket database, the passenger is considered as ticket evasion; and corresponding credit standing value of the fingerprint of passenger in the ticket database is reduced.

Owner:董明磊 +2

Environment-friendly energy-saving automobile brake lining and production method thereof

The invention discloses an environmental friendly energy-saving vehicle brake block and relative producing method, which is characterized in that: it is prepared by following components and weight percentages: iron: lead: graphite: silicon dioxide: phosphor: sulfur flour: zinc stearate: lubricant= 77-85:2-3:9-15:1-3í†0.7 -1í†0.3-0.8í†0.6-0.8í†0.01-0.03. The producing method comprises: breaking the casting slag into 60-100 deals into container to be fed into electric furnace to be heated, and reduced into 97-98.5% iron content; adding lead powder, graphite powder, phosphor powder, sulfur flour powder, zinc stearate and lubricant, to be uniformly mixed and fed into vehicle brake block mould to be compressed and molded in 4-5T / cm2; getting out and putting it into the container to be sintered in high-temperature electric furnace for 2 hours; cooling and drilling the screw hole. The invention can save material, reduce the cost, improve the abrasion resistance property and reduce the abrasion of couple element.

Owner:王友德

Modified gas-forming additive and lightweight concrete doped with a large amount of tailings wet slag

The invention discloses a modified gas-forming additive and lightweight concrete doped with a large amount of tailings wet slag. The modified gas-forming additive is prepared by mixing the following compositions in parts by weight: 1.8+ / -0.036 part of light calcium carbonate (CaCO3), 1.5+ / -0.03 part of calcium lignin sulphonate(C20H24CaO10S2), 1.2+ / -0.02 parts of calcium carbide (CaC2), 0.8+ / -0.016 part of corn starch (C6H10O5)n, 1.8+ / -0.036 parts of sodium aluminate (Ai2Na2O4), 0.1+ / -0.002 part of lithium carbonate (Li2CO3), 0.4+ / -0.008 part of sodium bicarbonate (NaHCO3), and 0.2+ / -0.004 part of aluminium sulfate ([Ai2(SO4)]3). The lightweight concrete is prepared by mixing the following compositions in percent by weight: 10%-49% of a base material ordinary portland cement, 0.5%-1% of the modified gas-forming additive, 27%-50% of water, and 50%-90% of waste tailings wet slag. The additive is simple to prepare, low in cost and easy to store. The lightweight concrete is good in thermal-insulation property, light in weight, low in elasticity and damping property, and excellent in compaction resistance, freeze thaw resistance, sound resistance and water proofness, and the raw material and product comprehensive cost is reduced.

Owner:唐山冀东发展集成房屋有限公司

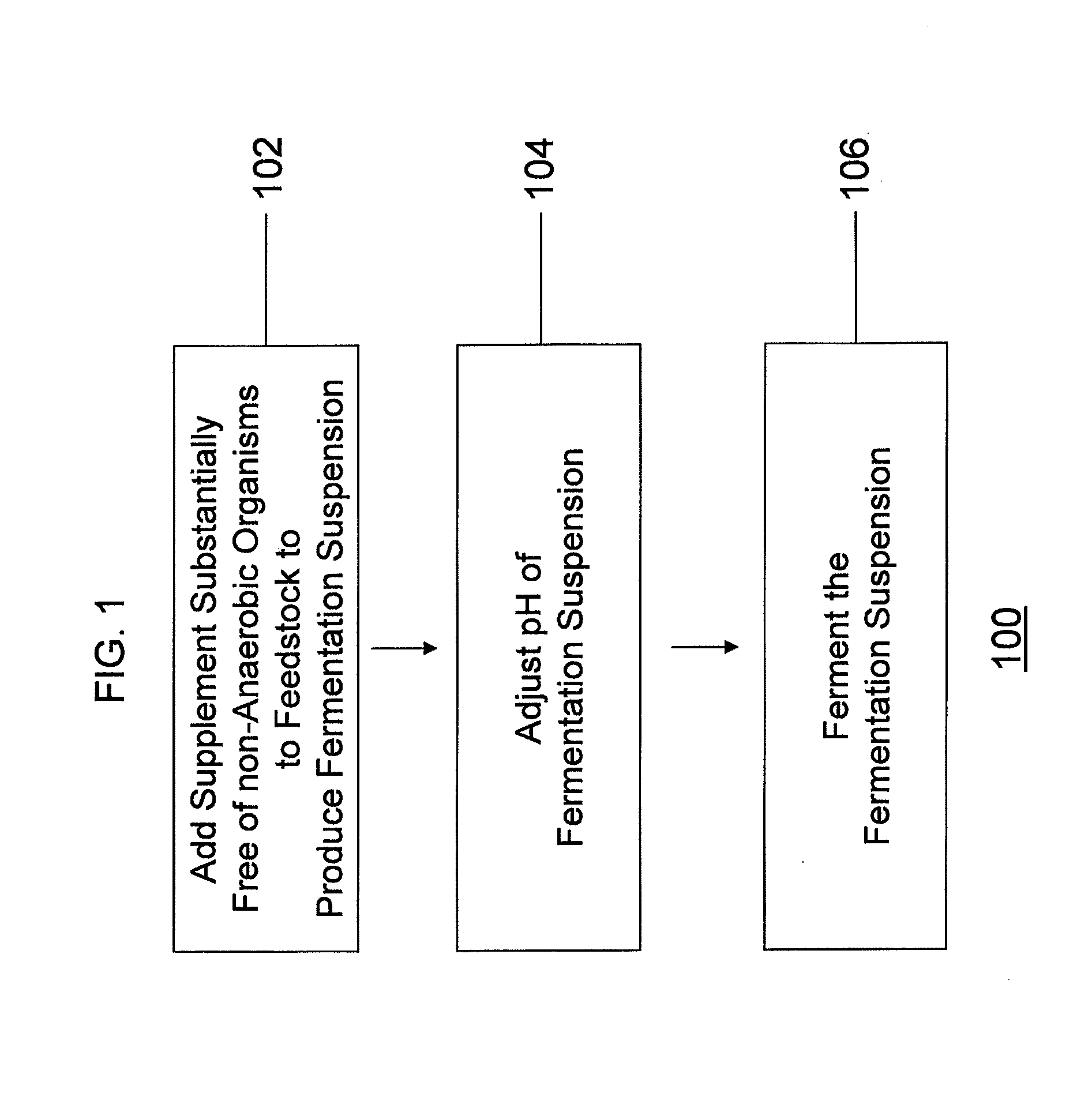

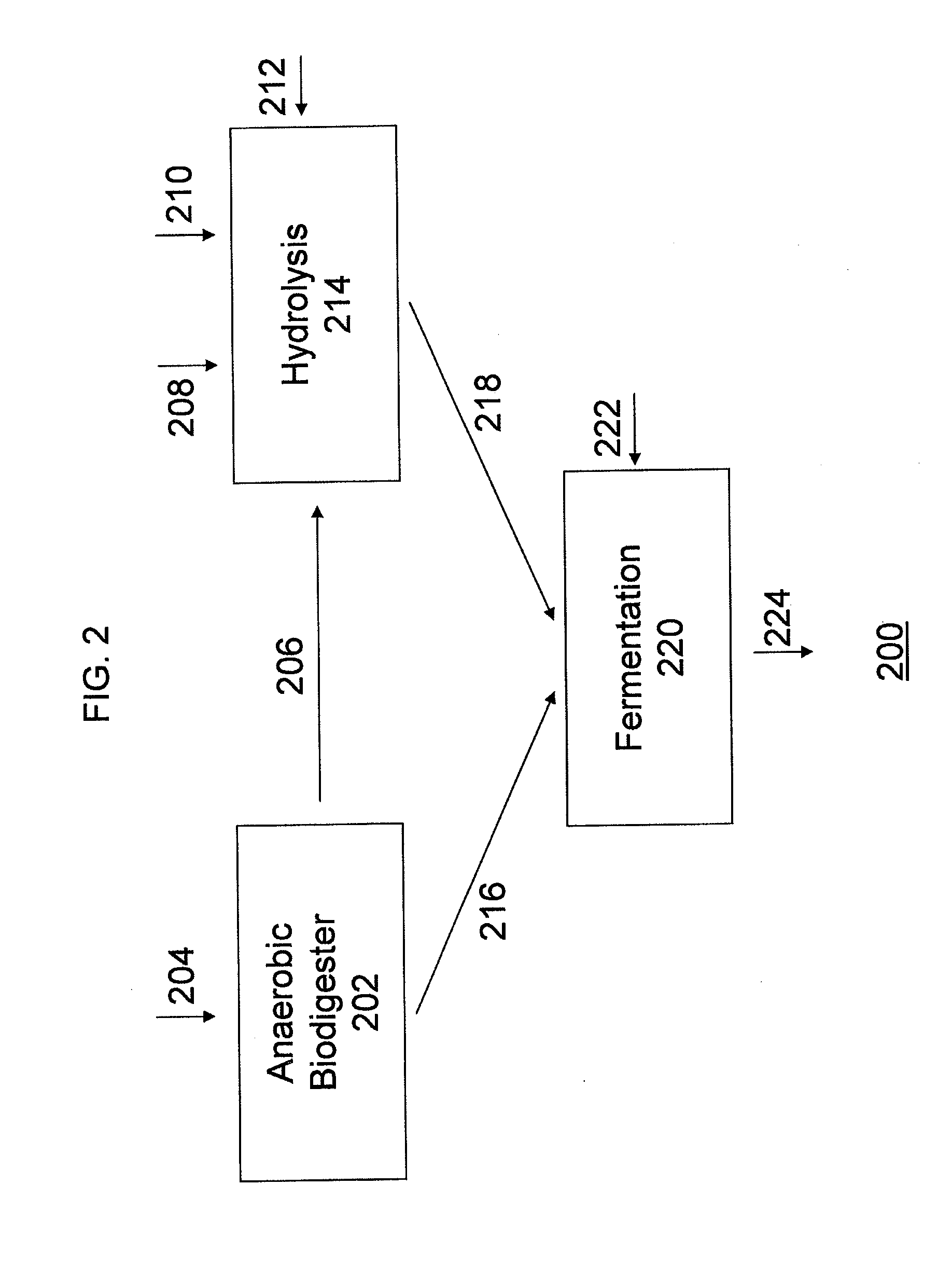

Enhanced ethanol fermentation using biodigestate

InactiveUS20100136629A1Increased ethanol productionSave precious resourcesBio-organic fraction processingProductsAnaerobic microorganismsSugar

Methods and systems for enhancing ethanol production using a suspending fluid are described. The suspending fluid includes organic material that has at least partially been anaerobically digested and anaerobic microorganisms, and is substantially free of non-anaerobic microorganisms. Also described are methods and systems for hydrolyzing a feedstock for fermentation that include hydrolyzing a feedstock suspension. The feedstock suspension can include feedstock that includes complex sugars, and a suspending fluid, wherein the suspending fluid includes organic material that has at least partially been anaerobically digested and anaerobic microorganisms, and is substantially free of non-anaerobic microorganisms.

Owner:HIGHMARK RENEWABLES RES PARTNERSHIP

Process for preparing kryocide

The invention relates to a method for producing cryolite, which takes electrolyte blocks of aluminum factories and sodium bifluoride as raw materials which are then reacted with each other in a solid phase. The method adopts a great deal of waste residue of the electrolytic aluminum factories - the electrolyte blocks as the raw materials, thereby the method increases a source of raw materials for producing villiaumite, relieves the dependency on fluorite, saves a large number of valuable resources, has low cost, greatly reduces the production cost, and relieves the ambient environmental pollution problem. Moreover, products generated during the reaction process of the method can be recycled, thereby the method greatly reduces the production cost to a certain degree, has good social benefit and economic benefit, and is easy to promote and apply.

Owner:DO FLUORIDE CHEM CO LTD

Process for preparing kryocide

InactiveCN101318678AReduce manufacturing costSave resourcesAluminium fluoridesSocial benefitsElectrolysis

The invention relates to a method for producing cryolite, which takes carbon residue of aluminum factories and sodium bifluoride as raw materials which are then reacted with each other in a solid phase. The raw materials of the method adopt a great deal of waste residue - the carbon residue of the electrolytic aluminum factories, and the cryolite product is prepared after flotation treatment and particularly refining treatment of products. The method increases a source of raw materials for producing villiaumite, relieves the dependency on fluorite, saves a large number of valuable resources, has low cost, greatly reduces the production cost, and relieves the ambient environmental pollution problem. Moreover, carbon powder containing about 10 percent of electrolyte obtained after flotationof the carbon residue can be dried and then used as auxiliary materials to be added when bottom paste is manufactured, and used for building a novel groove. Products generated during the reaction process of the method can be recycled, thereby the method greatly reduces the production cost to a certain degree, has good social benefit and economic benefit, and is easy to promote and apply.

Owner:DO FLUORIDE CHEM CO LTD

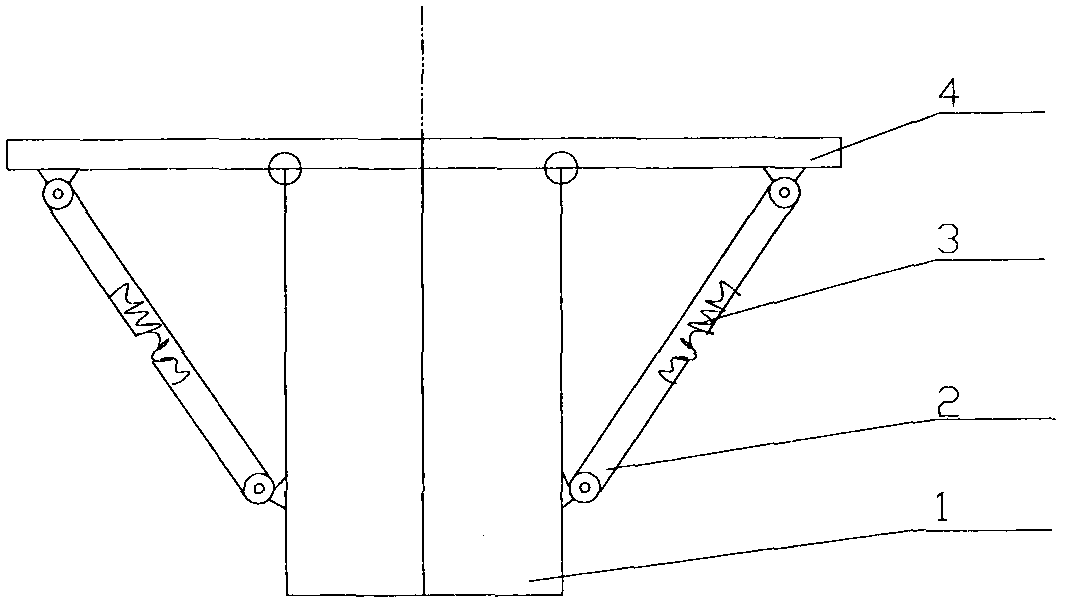

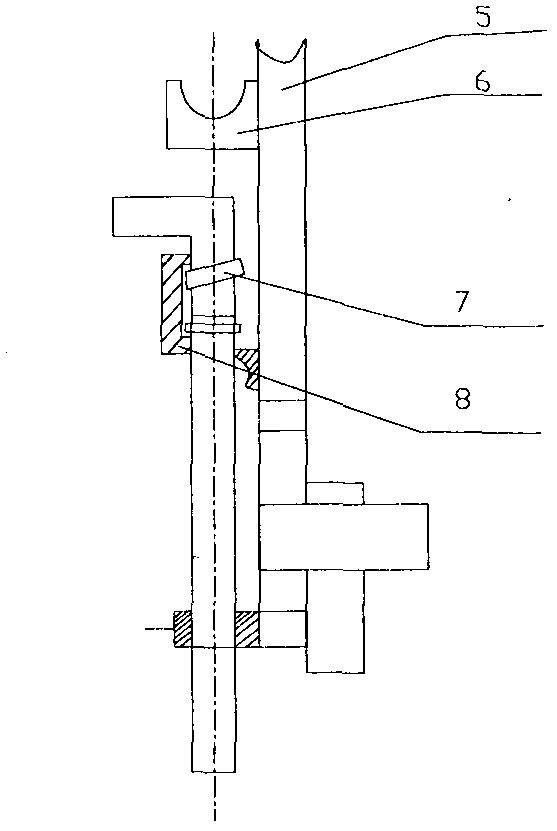

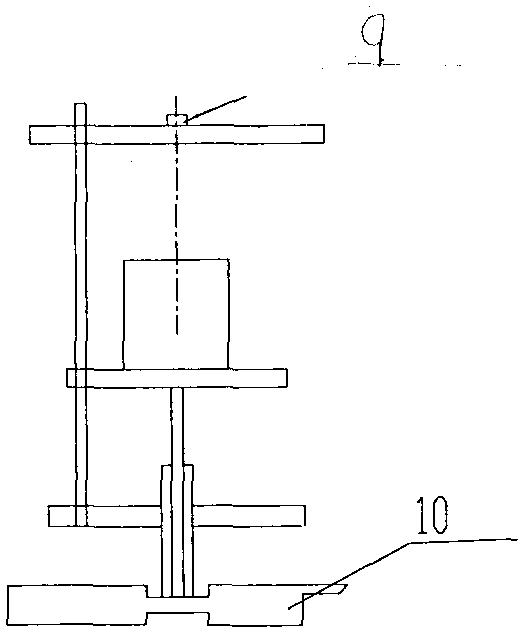

Steel ladle slag layer thickness measuring device and preparation method and measurement method thereof

ActiveCN102865842ASimple structureSave precious resourcesMeasurement devicesCasting parameters measurement/indication devicesSlagAluminum can

The invention discloses a steel ladle slag layer thickness measuring device and belongs to the technical field of steel metallurgy. The steel ladle slag layer thickness measuring device comprises a rod with a fixed clamping head, the rod clamps a steel bar through the fixed clamping head, and a slag wrapping layer is arranged outside the steel bar. The steel ladle slag layer thickness measuring device is simple in structure and is prepared from waste generated during production so as to achieve waste use and save valuable resources, and a preparation method is low in cost. The steel ladle slag layer thickness measuring device is used for measuring the thickness of slag layers in steel ladles and is simple and feasible in method, accurate in measurement result and low in energy consumption, and aluminum cannot be doped in molten steel. Besides, the steel ladle slag layer thickness measuring device can be reused after measurement procedures are completed, so that production cost is reduced.

Owner:LAIWU IRON & STEEL GRP

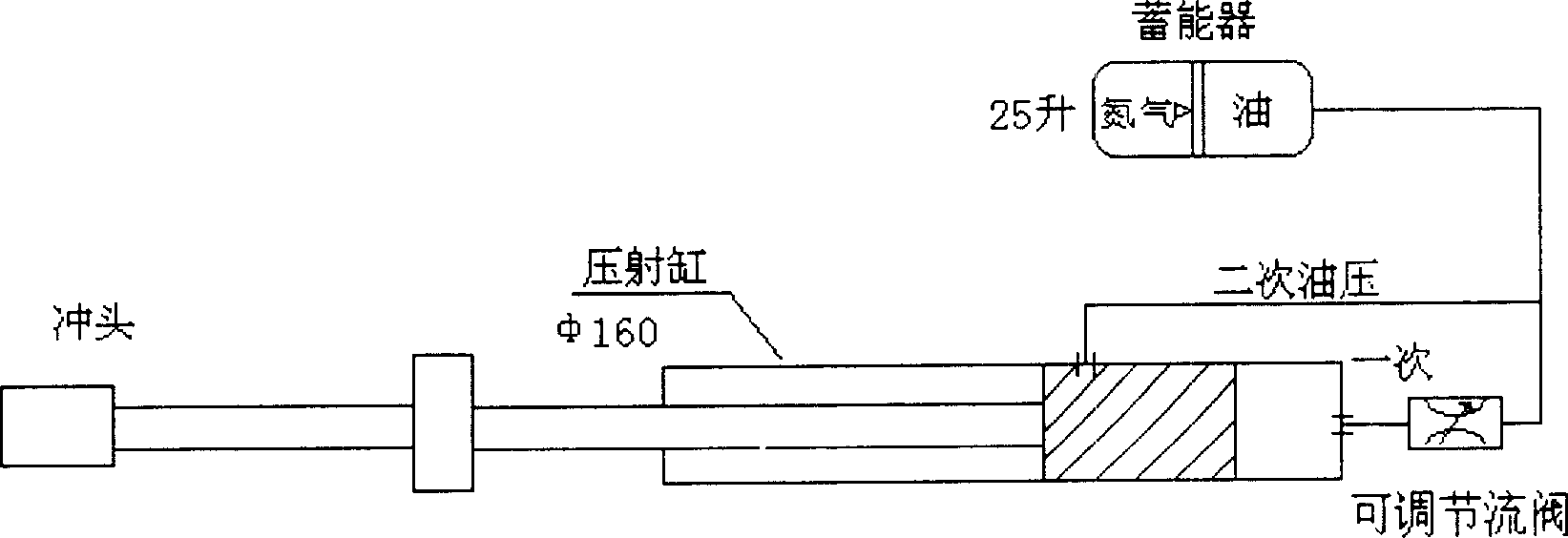

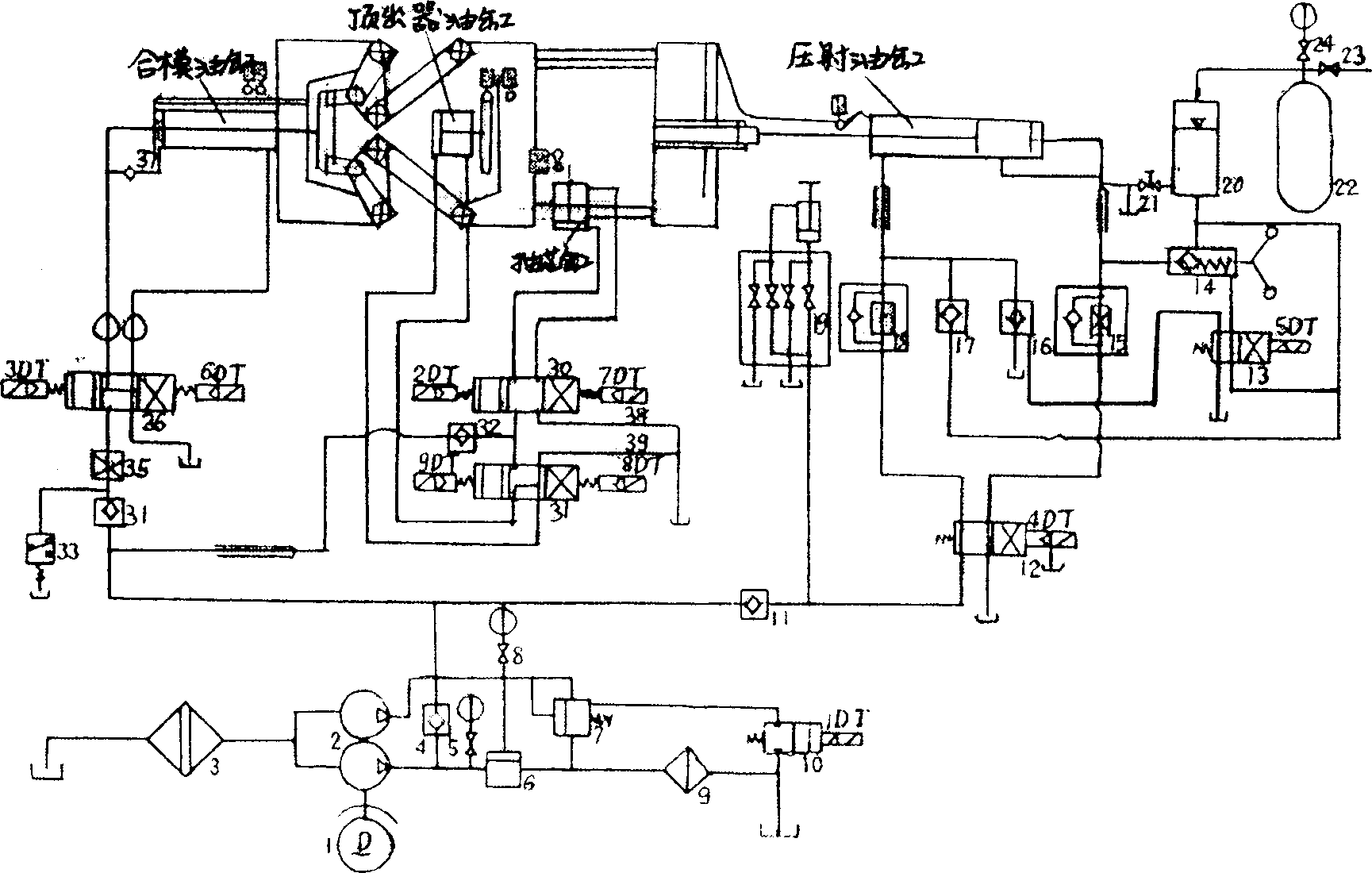

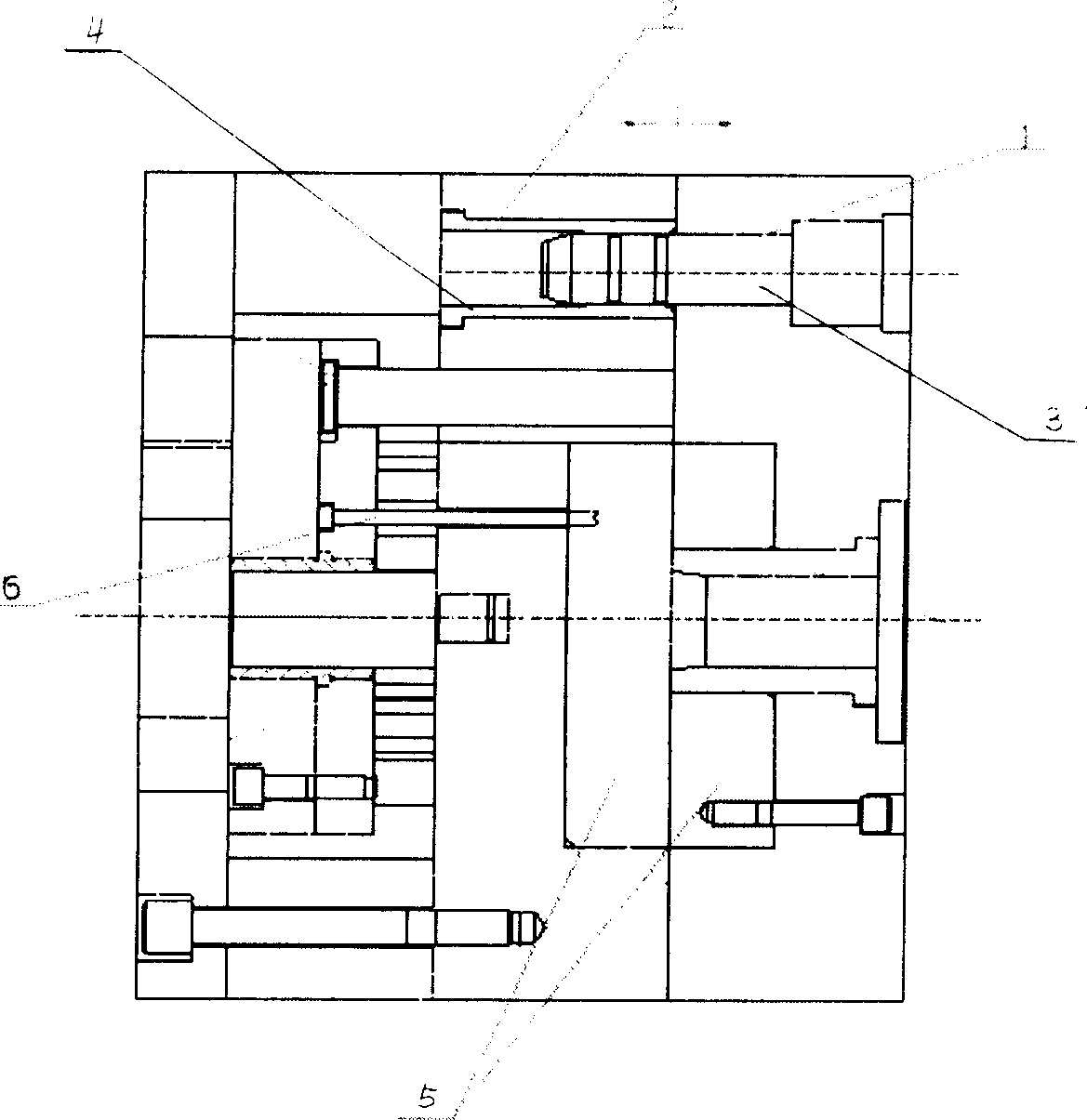

Production of copper-alloy bearing retainer by die casting method

A technology for manufacturing the bearing holder with copper alloy by die casting method includes such steps as correctly matching and locating 4 pairs of guide post and guide sleeve for moving die and static die, pouring the molten copper alloy in a cup, slowly moving the cup into casting system by press head, quickly pouring the molten alloy in moulding cavity when the stop block of piston rod is in contact with a limit switch, hardening for 8-15 S, and demoulding. Its advantage is no need of finish allowance.

Owner:FAW GROUP +1

Moble terminal data communication method

InactiveCN1561077ASave precious resourcesIncrease data communication applicationsTransmissionTelephonyTelephone call

Owner:HISENSE +1

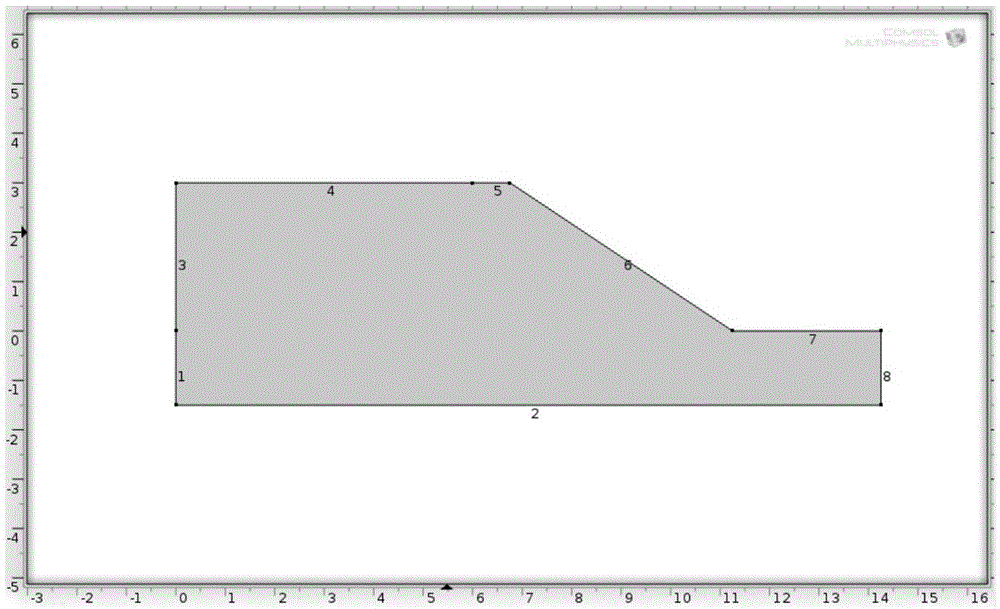

Partition disposal method for salts on saline soil subgrade

InactiveCN106599444AMeet disposal requirementsLow costGeometric CADDesign optimisation/simulationDiseasePhysical field

The invention discloses a partition disposal method for salts on a saline soil subgrade. The salt accumulation laws of the unsaturated soil subgrade under a non-partition condition and a local partition condition are obtained by coupling two physical fields of moisture movement in the unsaturated soil subgrade under the influence of capillarity and solute transport of salts serving as solutes and moving along with the moisture movement together, and a reasonable partition length is determined. Based on the above method, the reasonable partition length is calculated and then applied to practical engineering, so that the partition length is effectively determined, the effects of partition are ensured, and diseases of the saline soil subgrade are avoided; the local partition technology can substitute an all partition technology, thereby meeting the disposal requirement of the saline soil subgrade, saving a large amount of precious resources, effectively accelerating the construction progress, furthest reducing the influence on surrounding environment and having a broad application prospect.

Owner:SHANDONG UNIV +1

Cyclic steam stimulation using RF

ActiveUS9027638B2Improve efficiencyReduce water consumptionFluid removalEngineeringSuperheated steam

A method of producing hydrocarbons from a well. The method begins by injecting steam into a well. The bitumen in the formation is then heated with the injected steam, followed by ceasing the injection of steam into the well and then by soaking the bitumen with the injected steam and collecting the heated oil. Steam that has condensed is revaporized by directing RF / MW radiation to the steam allowing for more bitumen to be produced without injecting more steam. In addition, some of the steam could become superheated, wherein the temperature of the superheated steam is greater than the temperature of the steam. The bitumen is heated by the revaporized steam and the superheated steam, followed by soaking the bitumen with the revaporized steam and the superheated steam. Hydrocarbons are then produced from the well.

Owner:HARRIS CORP +1

Fuel pump inner and outer rotor assembly and production method thereof

InactiveCN103194666AAvoid smashingGive full play to the chemical functionRotary piston pumpsRotary piston liquid enginesBench testHardness

The invention discloses a fuel pump inner and outer rotor assembly and a production method thereof. The fuel pump inner and outer rotor assembly comprises an inner and outer rotor, a shaft and a fixed stud, and is characterized in that the inner and outer rotor body is prepared by comprising the following components according to the weight ratio: Fe: C: P: sulphur: zinc stearate: lubricant is equal to (94.3-98): (1-1.5): (0.5-1.1): (0.4-1.1): (0.6-0.8): (0.01-0.03). Through tests, after being subjected to bench test and installing for use, the technological indexes of the fuel pump inner and outer rotor assembly can achieve the standards of imported components, the density is greater than 6.5MP2, the apparent hardness is HB80-130, and the warp-wise conquassation strength is greater than 410MP2. Copper with higher cost is omitted, the precious resource can be saved, and the production cost can be lowered by 20.4%; and the wear resistance property of products can be improved, the strength and hardness of the products are proper, the thermal absorption and radiation properties are good, the sufficient oil supply can be ensured, and the service life of the product can be prolonged.

Owner:SICHUAN PROVINCE NANBU JIALING POWDER METALLURGY

Intensification smelting technology in blast furnace at superhigh utilization coefficient

InactiveCN1664115AEfficient use ofReduce pollutionFuel feedersBlast furnace detailsFurnace temperatureAlkalinity

The invention relates to a technical project for blast furnace smelting, particularly on the precondition of not increasing smelting device for increasing the foundry iron yield, comprising: (1) large air quantity, reforming D900 draught fan to make the air quantity in air outlet being 750m3, the pressure 310KPa; (2) high air temperature, employing combustion air preheating, automatic boiler, reinforced air heater stove to improve coal gas quality and make sure the dust content in coal gas is below 5mg / m3 ; (3)smelting with less silicon, decreasing the powder content in the furnace-entering ore, increasing the air permeability in the material column, stabilizing the sintered ore proportioning, increasing the quality, alkalinity and intensity of sintered ore gradually, improving the sintered ore reduction, employing sintered ore with low-silicon and low-ferrous iron to control the coke ash content effectively and improve the coke intensity of heat and cold, increasing the press on the top if the furnace, blowing fuel and controlling the theoretical burning temperature in air outlet, and decreasing the furnace temperature gradually on the premise of the condition of furnace is stably proceeded. The invention is characterized by the high ferrous iron yield, low investment and simple process.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Sponge iron processing technology

InactiveCN103276134AReduce manufacturing costSave precious resourcesRetort furnacesProcess efficiency improvementManganeseMaterials science

Owner:江苏三志电器有限公司

Smelting process for nickel-containing sponge iron

InactiveCN105779678ASave precious resourcesReduce manufacturing costProcess efficiency improvementYttriumTungsten

The invention provides a smelting process for nickel-containing sponge iron. The smelting process includes the following steps that (1) raw materials mainly include 2.1wt.%-3.2wt.% of nickel, 2.4wt.%-3wt.% of chrome, 1.1wt.%-1.2wt.% of molybdenum, 0.85wt.%-1.1wt.% of tungsten, 0.01wt.%-1.1wt.% of yttrium, 0.35wt.%-0.4wt.% of silicon, 1wt.%-1.2wt.% of manganese, 0.025wt.%-0.035wt.% of sodium, 0.025wt.%-0.035wt.% of phosphorus, 1.1wt.%-2.2wt.% of silicon, 1.1wt.%-3wt.% of chrome, 1.1wt.%-1.2wt.% of molybdenum, 0.85wt.%-1.1wt.% of potassium, 0.01wt.%-1.1wt.% of calcium, 0.35wt.%-0.4wt.% of copper, 1wt.%-1.2wt.% of zinc, 0.025wt.%-0.035wt.% of chlorine, and the balance waste iron; (2) formed rough blanks are placed into reduction pots; and (3) the reduction pots filled with the rough blanks are brought into a smelting kiln together. According to the melting process for the nickel-containing sponge iron, a large block of meshed primary carbide is made to be subjected to necking and balling by adding rare earth; and through changes of the dimensions, forms and quantities of the primary carbide and secondary carbide, the service life of the nickel-containing sponge iron is prolonged.

Owner:HARBIN RUNDE WEIYE TECH DEV

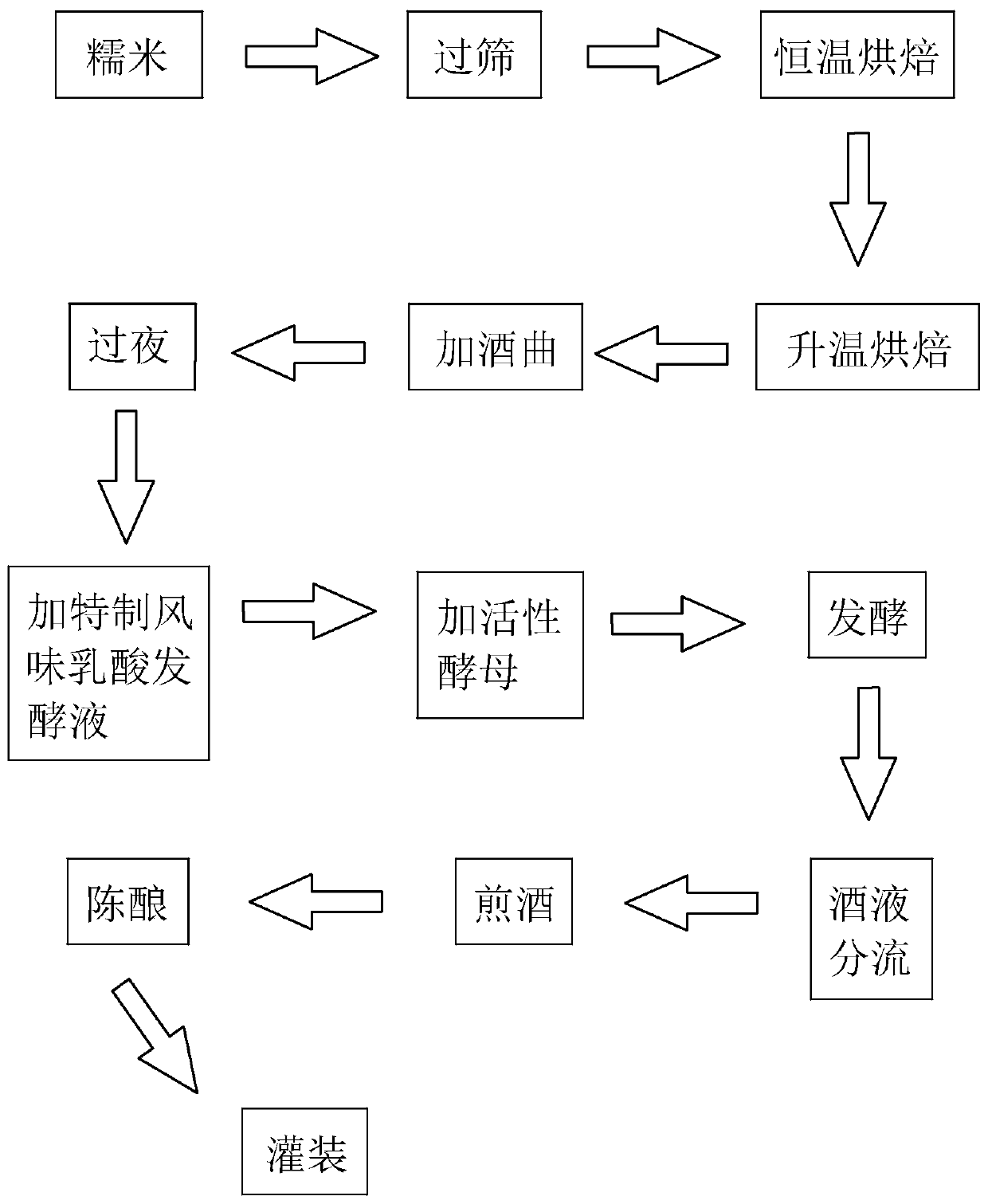

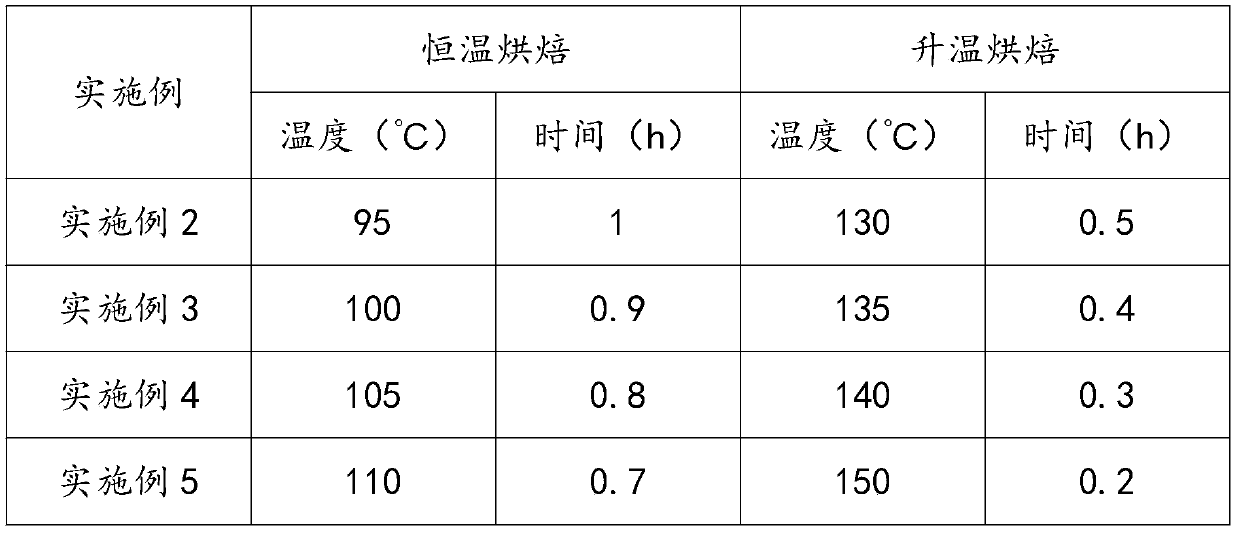

Energy-saving and water-saving yellow rice wine brewing method

The invention, which relates to the technical field of yellow rice wine processing, discloses an energy-saving and water-saving yellow rice wine brewing method. The method comprises the following steps: S1, making early-stage preparation; to be specific, step a, sieving glutinous rice; step b, carrying out baking at constant temperature; and step c, carrying out heating and baking; S2, adding thedistiller's yeast; S3, performing fermentation; and S4, distributing the wine liquid to obtain yellow rice wine. The preparation method disclosed by the invention has advantage of saving energy consumption and water for yellow rice wine brewing.

Owner:绍兴润博生物科技有限公司

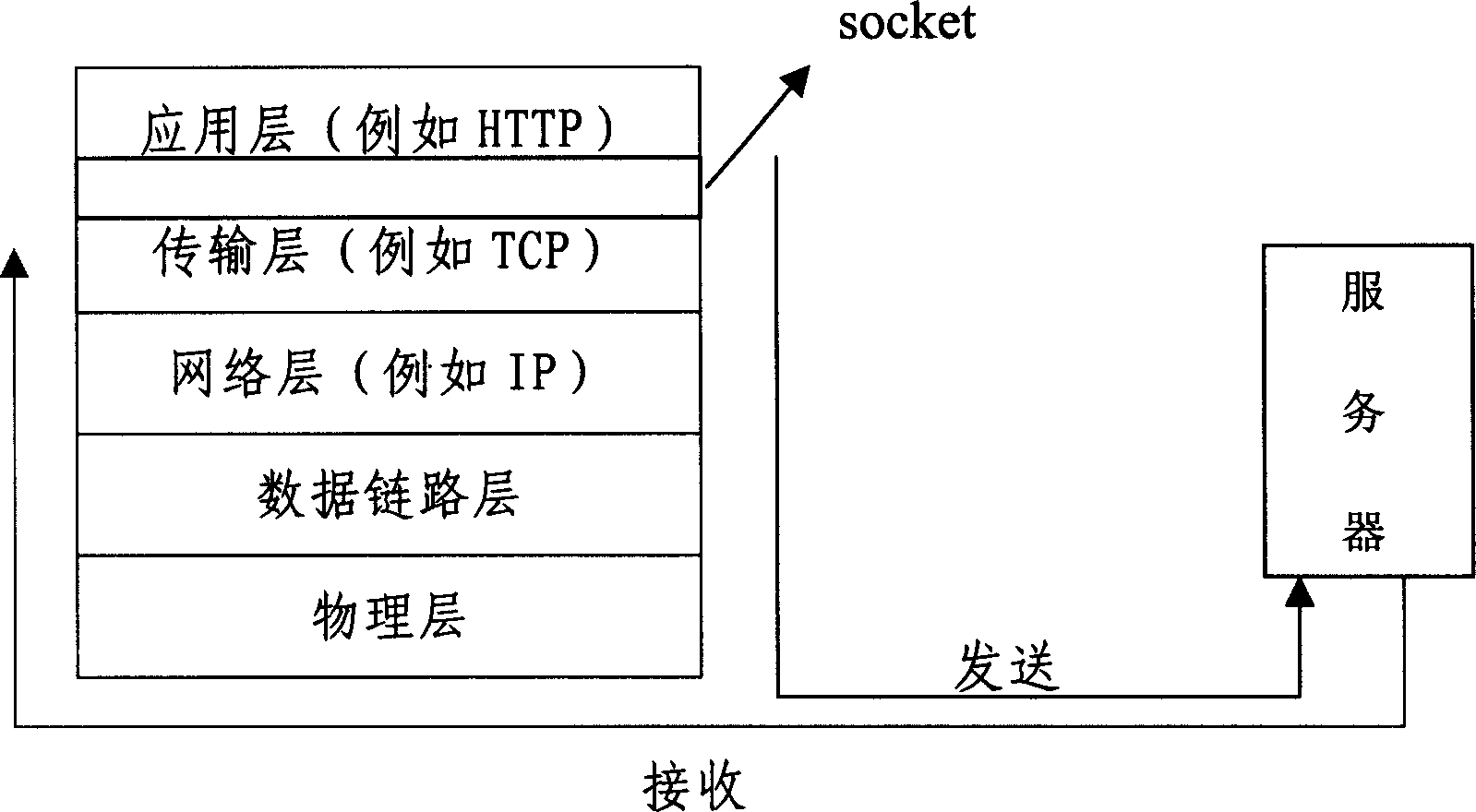

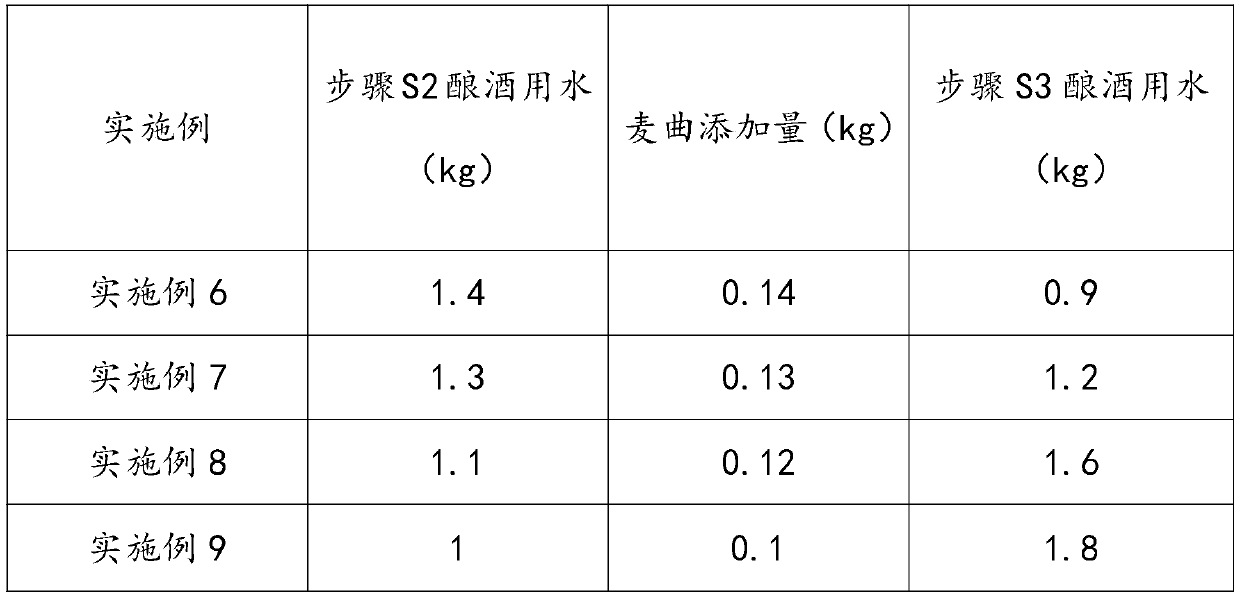

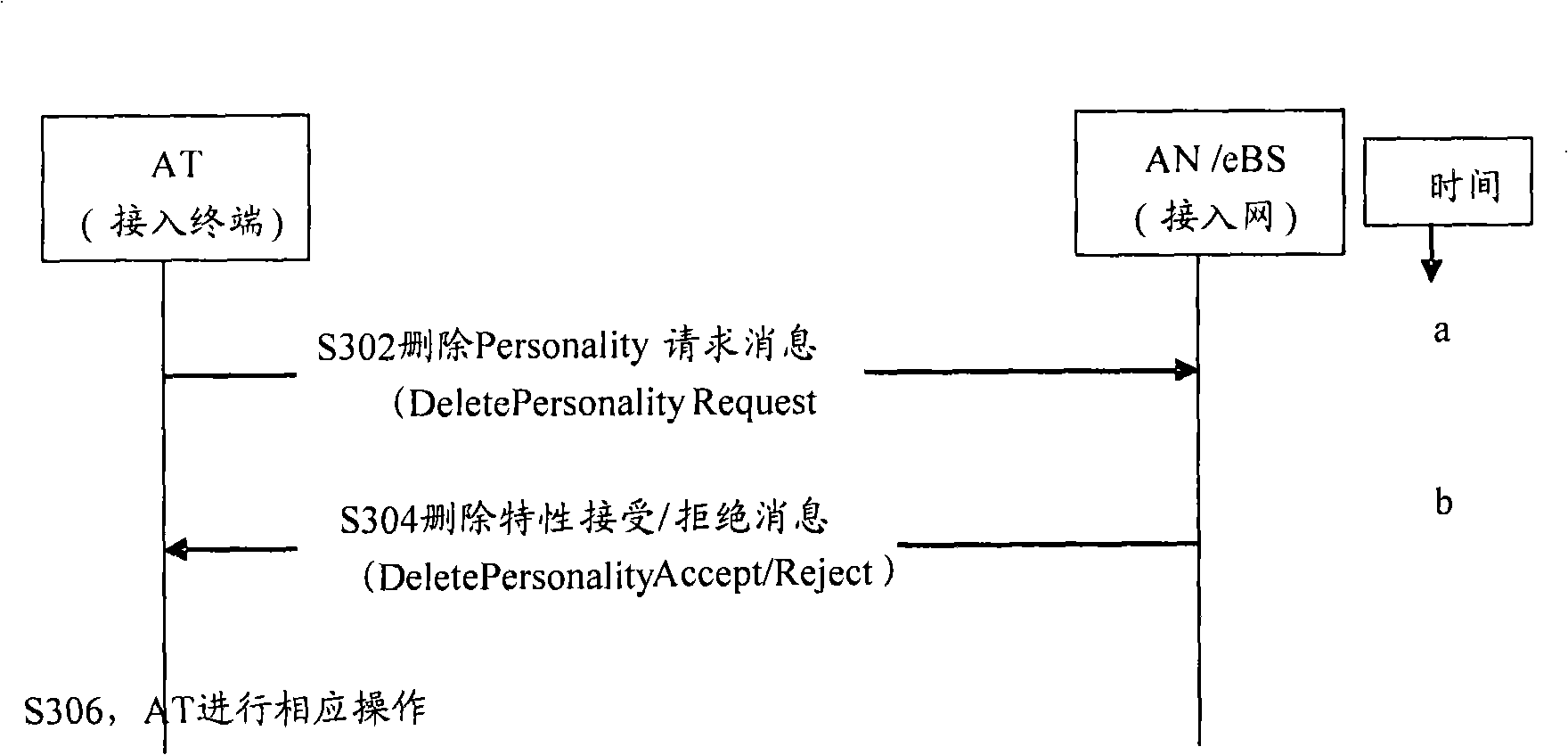

Characteristic management method and system used for ultra-mobile wide band network

InactiveCN101296438AEnhanced management mechanismAdd delete mechanismData switching by path configurationRadio/inductive link selection arrangementsAccess networkAir interface

The invention discloses a method for managing the characteristics of a super mobile wideband network and a system thereof. The method includes the following steps: step S302, an access terminal decides to delete one or a plurality of characteristics and sends a request message for deleting the characteristics to an access network; step S304, the access network determines whether to delete the characteristics requesting to be deleted of the request message of the delete characteristics and sends the message of acceptance or rejection of deleting the characteristics to the access terminal; and step S306, the access terminal carries out corresponding operation according to the message of acceptance or rejection of deleting the characteristics. The method enhances the management mechanism of the characteristics, and increases the mechanism of characteristics deleting sent by the access terminal. In addition, the request of deleting a plurality of characteristics sent by the network in the prior art can effectively save the spending of air interface signaling and further save the valued resources of the air interface.

Owner:ZTE CORP

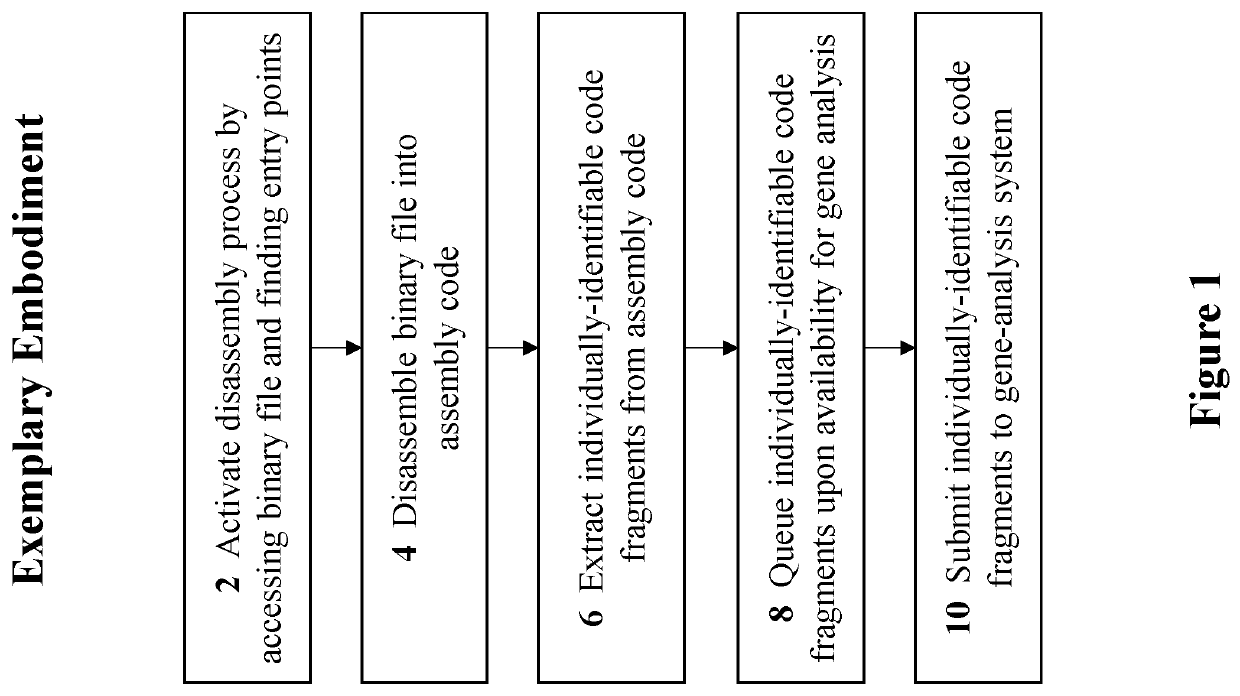

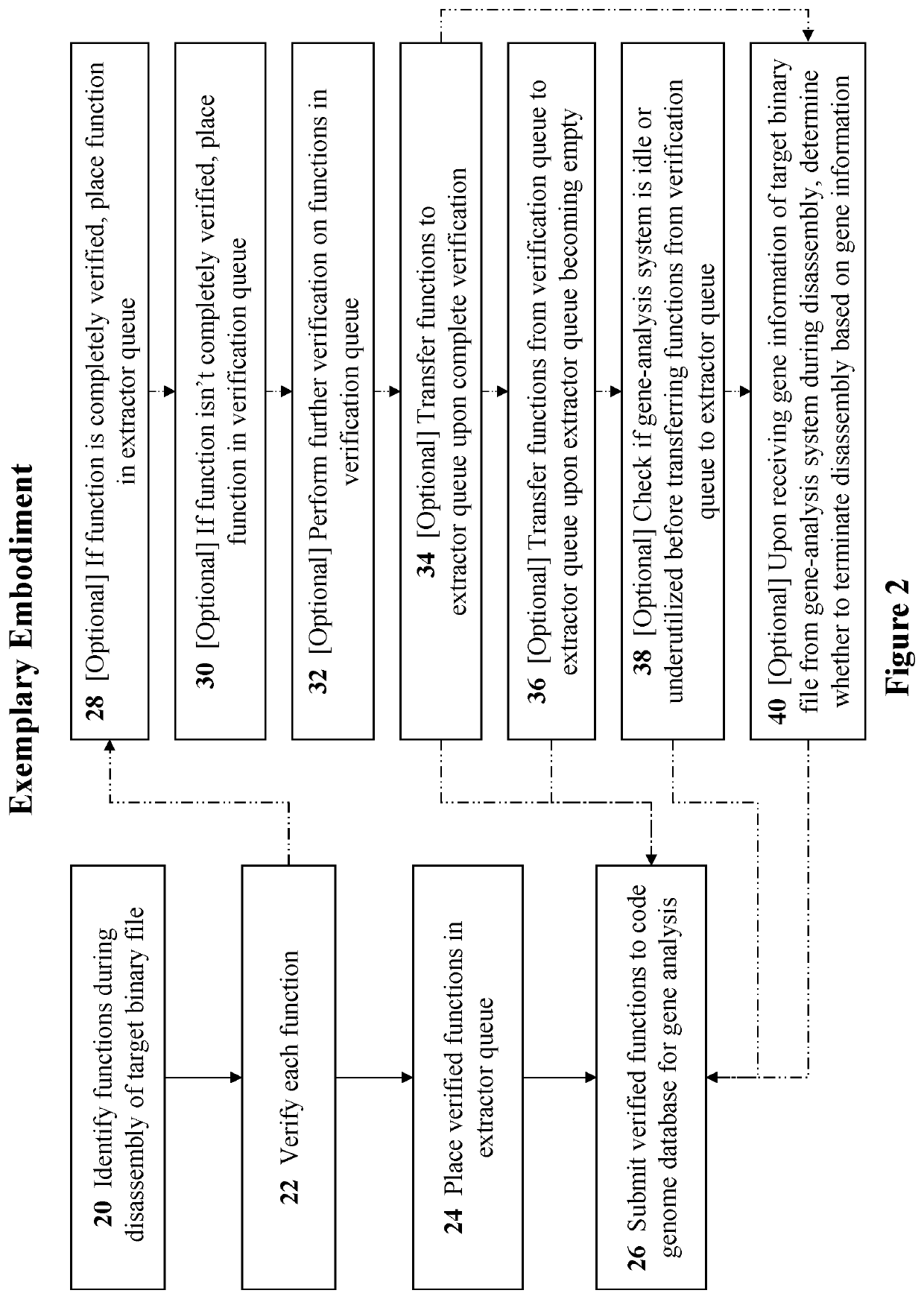

Methods and systems for an integrated disassembler with a function-queue manager and a disassembly interrupter for rapid, efficient, and scalable code gene extraction and analysis

ActiveUS20210202031A1Rapid and efficient and scalable code gene extraction and analysisSave a lot of timeDecompilation/disassemblyProteomicsData libraryGenome database

The present invention discloses methods and systems for an integrated disassembler with a function-queue manager and a disassembly interrupter for rapid, efficient, and scalable code gene extraction and analysis. Methods include the steps of: upon receiving a target binary file, disassembling the target binary file into assembly code; extracting code fragments from the assembly code; as each code fragment is extracted, verifying each code fragment; upon availability, placing each verified code fragment in an extractor queue; and upon availability, submitting each code fragment in the extractor queue to a gene-analysis system having a code genome database. Alternatively, upon determining the extractor queue is empty or determining resources of the gene-analysis system are underutilized, transferring partially-verified code fragments to the extractor queue. Alternatively, upon receiving gene information regarding the target binary file from the gene-analysis system during disassembly, determining whether to terminate the step of disassembling based on the gene information.

Owner:INTEZER LABS LTD

Technological method for comprehensively recovering rhenium, sulfur and arsenic through self-heating volatilization of acid mud containing rhenium, sulfur and arsenic in vortex furnace

ActiveCN112811399AImprove thermal efficiencyImprove direct yieldArsenic oxides/hydroxides/oxyacidsChemical industryRheniumFerrosilicon

The invention provides a technological method for comprehensively recovering rhenium, sulfur and arsenic through self-heating volatilization of rhenium, sulfur and arsenic-containing acid mud in a vortex furnace. The method comprises the following steps: drying a rhenium, sulfur and arsenic-containing acid mud raw material until a material discharged from a kiln is loose, adding a slag material, finely crushing, feeding into a vortex furnace, and carrying out volatilization and smelting, carrying out oxidation and exothermic reaction on the furnace material, wherein under the condition that the temperature is increased to 1400 DEG C or above and in an oxidizing combustion atmosphere, all rhenate in the furnace charge can be decomposed and volatilized, arsenic is oxidized into As2O3 steam, sulfur is oxidized into SO2 steam, and the As2O3 steam and the SO2 steam enter flue gas together; and carrying out rhenium and arsenic enrichment on the high-temperature flue gas in a flue gas washing tower, and feeding SO2 into a subsequent desulfurization tower for sulfur recovery. According to the method, the heat efficiency is high, more than 50% of energy is saved, high-value rare elements are saved, the direct recovery rate is about 10-30% higher, precious resources are effectively saved, the waste slag amount is reduced by about 75-90%, the waste slag is ferro-silicon calcium slag which is free of toxic substances and can be utilized, and the problem of secondary environmental pollution in a traditional method is thoroughly solved.

Owner:LEIYANG YANXIN NON FERROUS METALS

Process for processing tussah moth powders

InactiveCN101744231ARich in nutrientsSave precious resourcesAnthropod material medical ingredientsFood preparationBiotechnologyWater content

The invention discloses a process for processing tussah moth powders, which comprises the following steps: manually dividing tussah moths which are the raw materials for industrial production of oophagous trichogrammae into male tussah moths and female tussah moths; respectively removing the wings; after using a meat grinder to break the bellys of the female tussah moths, adding water the mass-to-volume ratio of which is 1:2 to immerse the processed female tussah moths, stirring the mixture, then passing the obtained product through a sieve, wherein the aperture of the sieve pore of the sieve is 3*3mm so that the egg granules can pass through the sieve pores and other parts of the tussah moths have larger volume so as to be left in the sieve; collecting the residues of the female tussah moths the eggs of which are removed; drying the collected female tussah moth residues and the male tussah moths at a temperature of between 40 and 60 DEG C; and grinding the dried collected female tussah moth residues and male tussah moths into 200 to 400 mesh of powders the water content of which is lower than 8 percent. The method furthest utilizes the tussah moth residues for the industrial production of the oophagous trichogrammae to process into the tussah moth powders under the condition of not breaking the eggs of the tussah moths. The tussah moth powders can be used as the by product for producing the oophagous trichogrammae. The process has simple process and low cost, and makes waste profitable.

Owner:JILIN AGRICULTURAL UNIV

Solar energy based remote control novel mower

InactiveCN109526357AEfficient managementReduce workloadBatteries circuit arrangementsTransmission systemsElectric machineRemote control

The invention discloses a solar energy based remote control novel mower mainly used for large-scale fruit-bearing forests, and belongs to the technical field of solar photovoltaic power generation andwireless remote control technologies. The mower includes a mower case body; a motor is arranged in the case body; a solar cell panel is attached to the upper surface of the case body, and two solar cell panels are arranged on the two sides of the case body, and can be unfolded during charging and folded on the two sides when the solar cell panels are not needed; redundant electric energy can be stored in a storage battery, and the storage battery can be charged and discharged according to needs; the case body is provided with a height adjusting bolt used for adjusting heights; and a remote control end can emit a signal to control the mower to move forward and backward and toward left and right.

Owner:郭孟月

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com