Process for preparing kryocide

A production method and cryolite technology, applied in aluminum fluoride, aluminum halide and other directions, can solve the problems of high production cost, environmental pollution, and different degrees, and achieve the effects of low cost, alleviating environmental pollution problems, and reducing dependence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

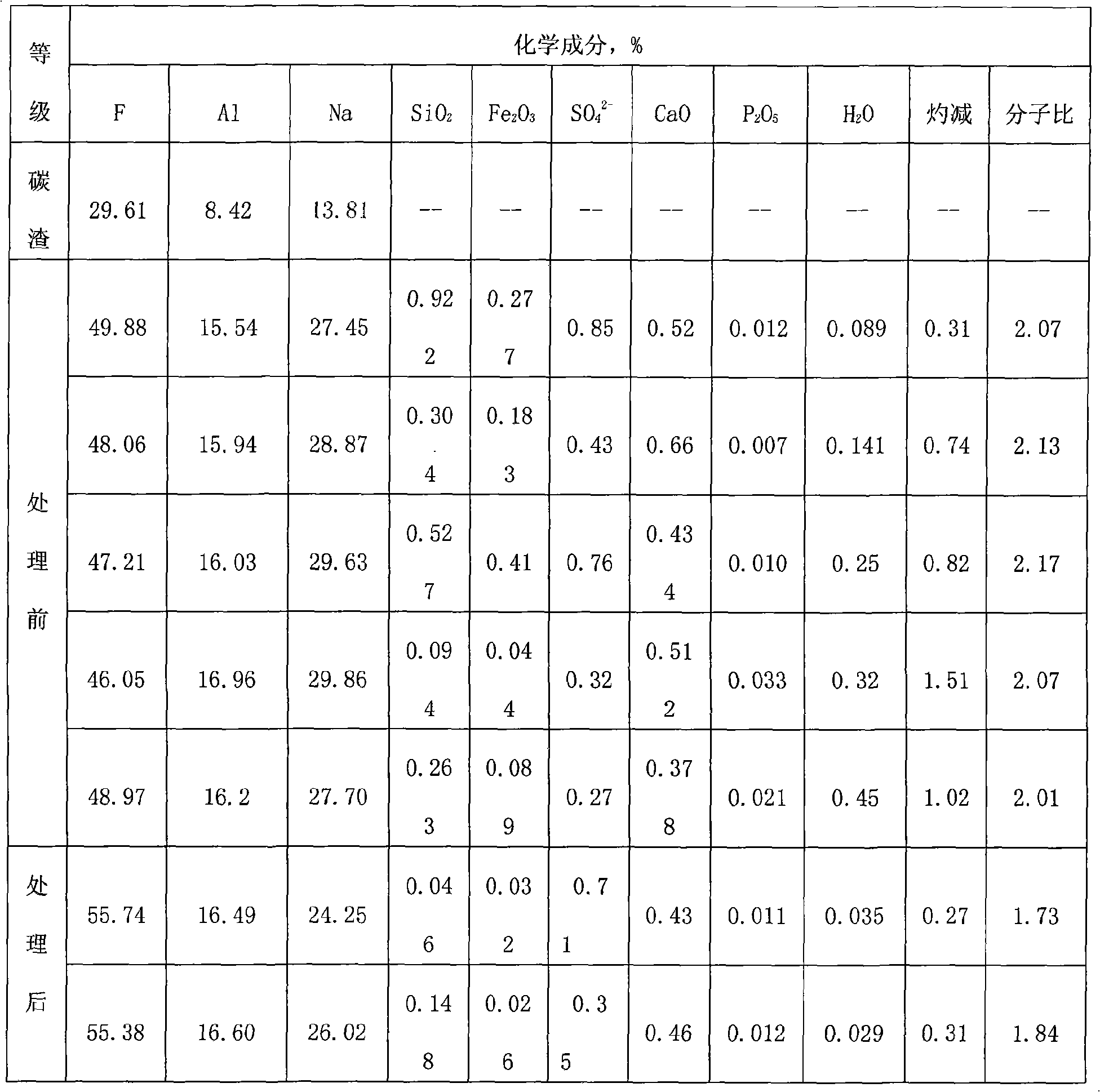

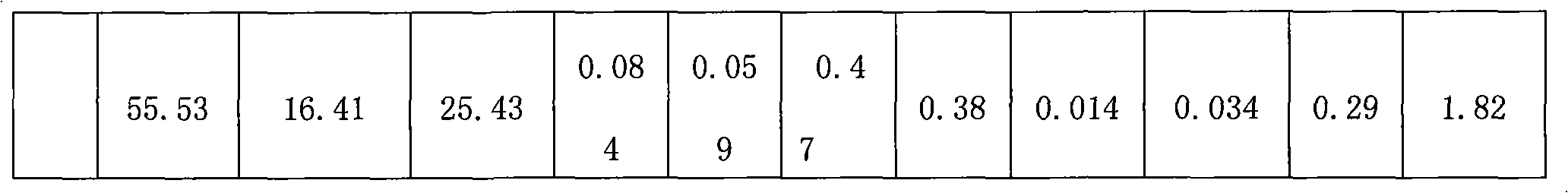

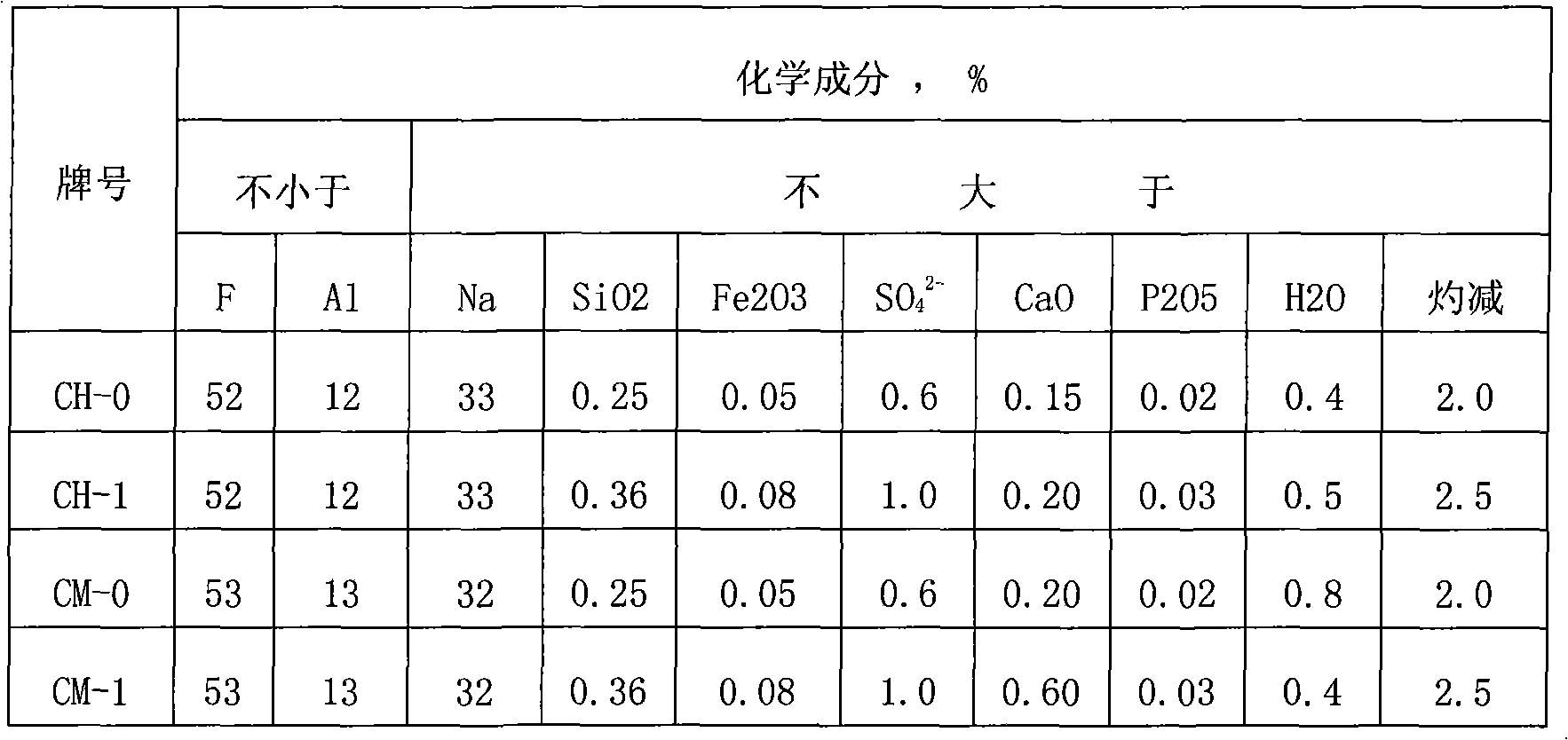

[0025] Production method of the present invention is:

[0026] (1) Pull out the carbon slag from the electrolytic cell, break it after cooling, then crush it to 3mm with a pair of rollers, and then grind it to the most suitable particle size for flotation with a ball mill, i.e. 0.45-0.76mm;

[0027] (2) Add a mixing drum, which contains flotation reagents, and the ground carbon residue and the reagents are fully stirred in the mixing drum;

[0028] (3) After stirring, it enters the flotation machine. There are two kinds of carbon slag flotation products, namely electrolyte containing a small amount of carbon and carbon powder containing a small amount of electrolyte. The electrolyte containing a small amount of carbon is further finely processed to prepare cryolite, which contains a small amount of carbon. The carbon powder of the electrolyte is used to prepare carbon, etc.;

[0029] (4) Fine product processing

[0030] ①Electrolyte containing about 5% carbon: Before it is u...

Embodiment 2

[0034] Production method of the present invention is:

[0035] (1) Pull out the carbon slag from the electrolytic cell, break it after cooling, then crush it to 3mm with a pair of rollers, and then grind it to the most suitable particle size for flotation with a ball mill, i.e. 0.45-0.76mm;

[0036] (2) Add a mixing drum, which contains flotation reagents, and the ground carbon residue and the reagents are fully stirred in the mixing drum;

[0037] (3) After stirring, it enters the flotation machine. There are two kinds of carbon slag flotation products, namely electrolyte containing a small amount of carbon and carbon powder containing a small amount of electrolyte. The electrolyte containing a small amount of carbon is further finely processed to prepare cryolite, which contains a small amount of carbon. The carbon powder of the electrolyte is used to prepare carbon, etc.;

[0038] (4) Fine product processing

[0039] ①Electrolyte containing about 5% carbon: Before it is u...

Embodiment 3

[0043] Production method of the present invention is:

[0044] (1) Pull out the carbon slag from the electrolytic cell, break it after cooling, then crush it to 3mm with a pair of rollers, and then grind it to the most suitable particle size for flotation with a ball mill, i.e. 0.45-0.76mm;

[0045] (2) Add a mixing drum, which contains flotation reagents, and the ground carbon residue and the reagents are fully stirred in the mixing drum;

[0046] (3) After stirring, it enters the flotation machine. There are two kinds of carbon slag flotation products, namely electrolyte containing a small amount of carbon and carbon powder containing a small amount of electrolyte. The electrolyte containing a small amount of carbon is further finely processed to prepare cryolite, which contains a small amount of carbon. The carbon powder of the electrolyte is used to prepare carbon, etc.;

[0047] (4) Fine product processing

[0048] ①Electrolyte containing about 5% carbon: Before it is u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com