Fuel pump inner and outer rotor assembly and production method thereof

A production method and oil pump technology, applied to pumps, mechanical equipment, machines/engines, etc., can solve problems such as poor suction and heat dissipation performance, unfavorable resource conservation, and increased production costs, so as to protect normal work and save Precious resources, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

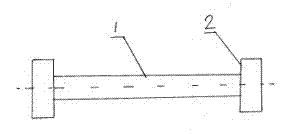

[0017] Example 1, such as figure 1 As shown, the present invention is composed of inner and outer rotors, shafts and fixed shafts, and is characterized in that the inner and outer rotor bodies are prepared from the following components; the iron content is more than 98%, the particle size is 80-100 mesh iron powder, and the content is 98-99 %, graphite powder with particle size of 320 mesh, phosphorus content of 17-21%, iron phosphorus powder with particle size of 80-100 mesh, content of 98-99.5%, sulfur powder with particle size of 80-100 mesh, content of 98-99% hard Zinc fatty acid, lubricating oil.

[0018] The two ends of the fixed shaft of the present invention are provided with a safety step device 2 which is fitted and connected with the shaft 1 in a row.

[0019] The production method is as follows:

[0020] 1. Crush ferrophosphorus into 80-100 mesh powder for later use;

[0021] 2. Detect the iron content, phosphorus content, and sulfur content of the iron powder, ...

Embodiment 2

[0022] Embodiment 2, prepare materials according to the following components and weight ratio, iron powder with a particle size of 80-100 mesh, content of 98-99%, graphite powder with a particle size of 320 mesh, phosphorus content of 17-21%, and a particle size of 80-100 mesh phosphorus Iron powder, content 98-99.5%, sulfur powder, content 98-99%, zinc stearate, lubricating oil.

[0023] The specific production method is as follows:

[0024] 1. Ferrophosphorus is crushed into 80-100 mesh granules for later use:

[0025] 2. Detect the iron content, phosphorus content, and sulfur content of the iron powder, and determine the exact dosage of other components according to the test data, and accurately weigh them. In this embodiment, iron powder is used to detect that the iron content is 98%, the phosphorus content is 0.3%, the sulfur content is 0.01%, and the particle size is 80-100 mesh. 95 kg of iron powder, the content is 98%, and the particle size is 320 mesh. 1.2 kg of gra...

Embodiment 3

[0026] Embodiment 3, prepare materials according to the following components and weight ratio: Iron powder with an iron content of more than 98%, a particle size of 80-100 mesh, a content of 98-99%, a particle size of 320 mesh graphite powder, and a phosphorus content of 17-21% , Iron phosphorus powder with particle size of 80-100 mesh, content of 98-99.5%, sulfur powder with particle size of 80-100 mesh, content of 98-99% zinc stearate, lubricating oil.

[0027] The specific production method is as follows:

[0028] l. Ferrophosphorus is crushed into 80-100 mesh powder for later use;

[0029] 2. Detect the iron content, phosphorus content and sulfur content of the iron powder, and determine the exact dosage of other components according to the test data, and weigh them accurately. The present embodiment selects 97.5 kilograms of iron powders with an iron content of 98%, a phosphorus content of 0.4%, a sulfur content of 0.01%, a particle size of 80-100 mesh, and 1.5 kilograms...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com