Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

123results about How to "Save on energy bills" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

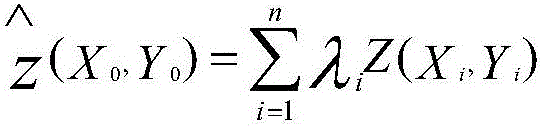

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

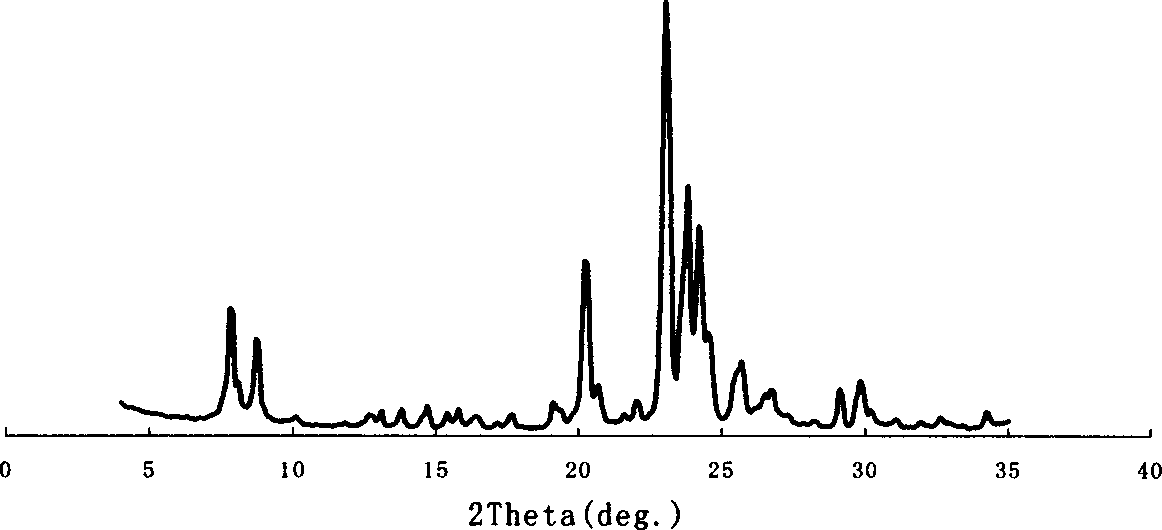

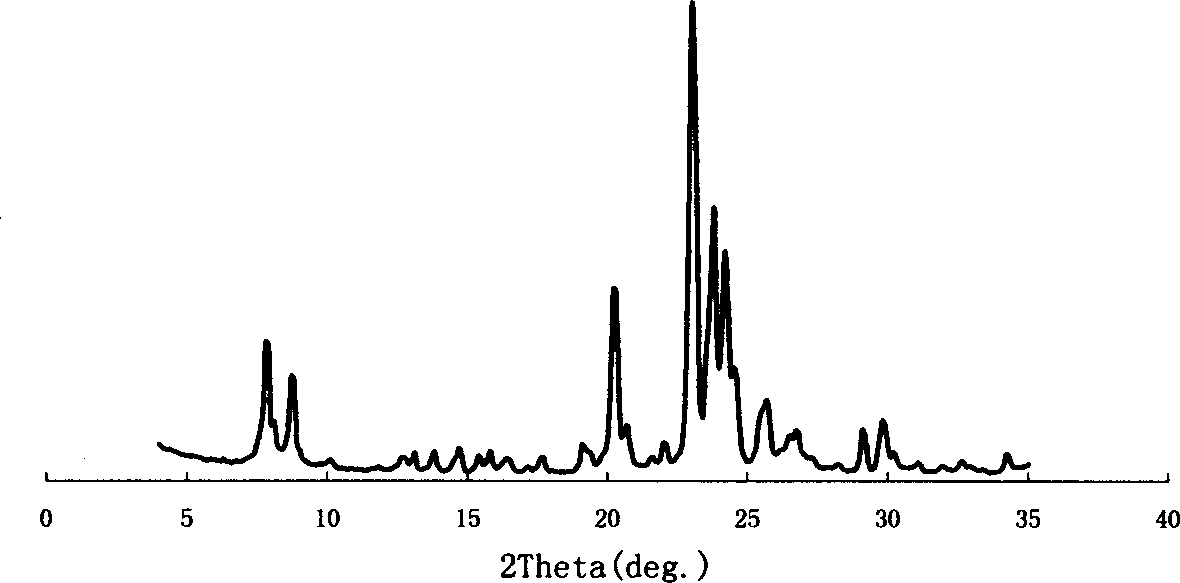

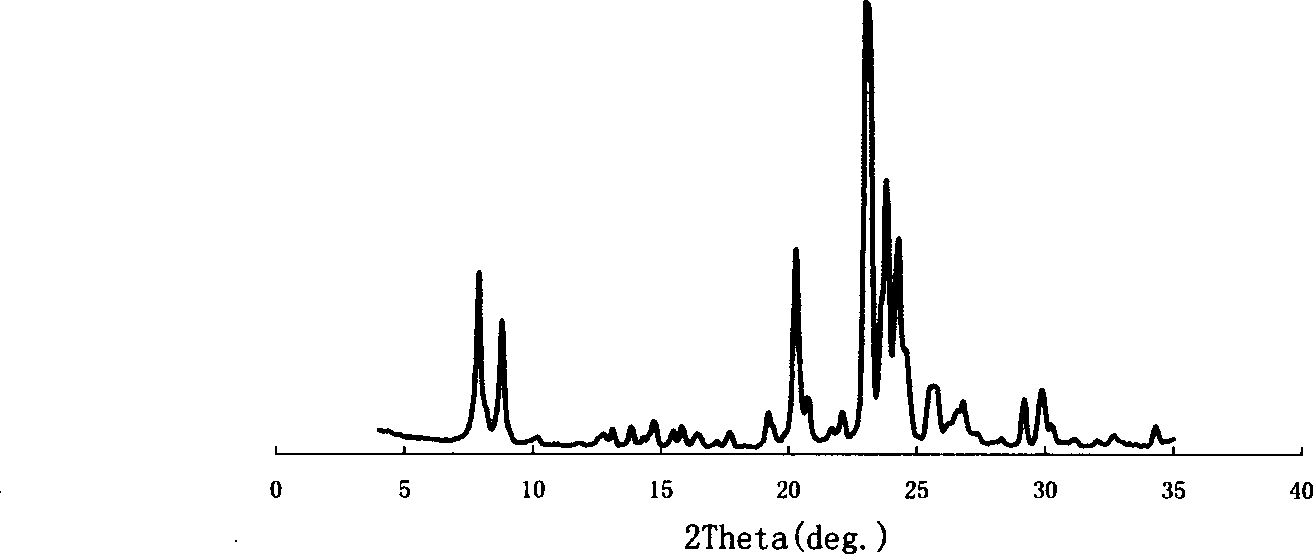

Mole cular sieve with composite structure and preparing method thereof

InactiveCN1552625AHigh activityHigh selectivityCrystalline aluminosilicate zeolitesMolecular sieveCrystallization

A composite molecular sieve with TON and MFI structures is prepared in static crystallizing condition. In the procedure of preparing gel, less crystal seeds and salt are added. The Si / Al ratio on its crystal lattice is greater than 50.

Owner:CHINA PETROLEUM & CHEM CORP +1

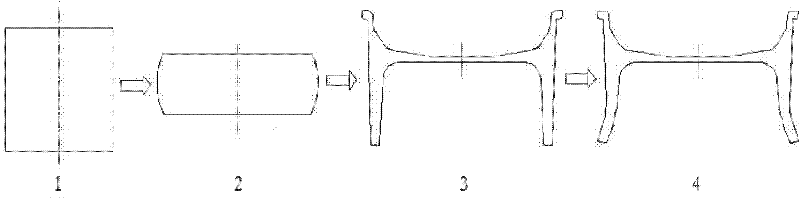

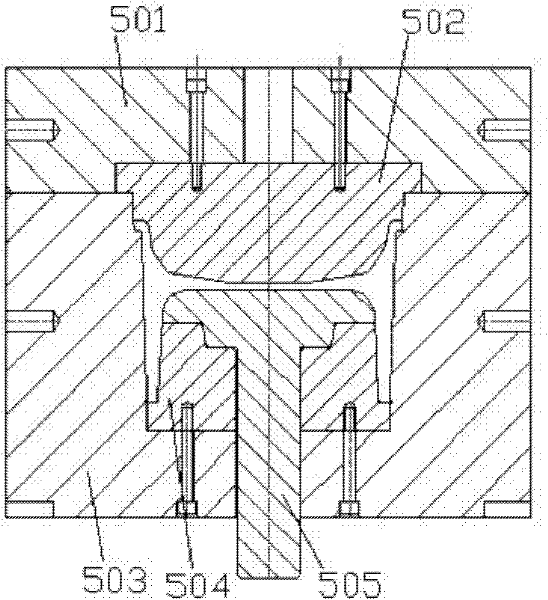

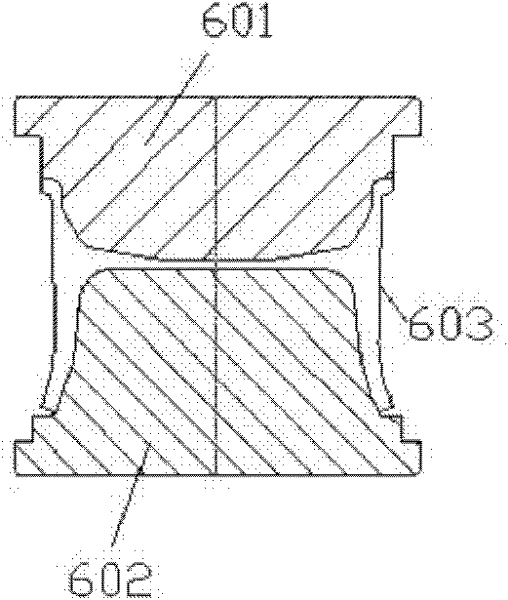

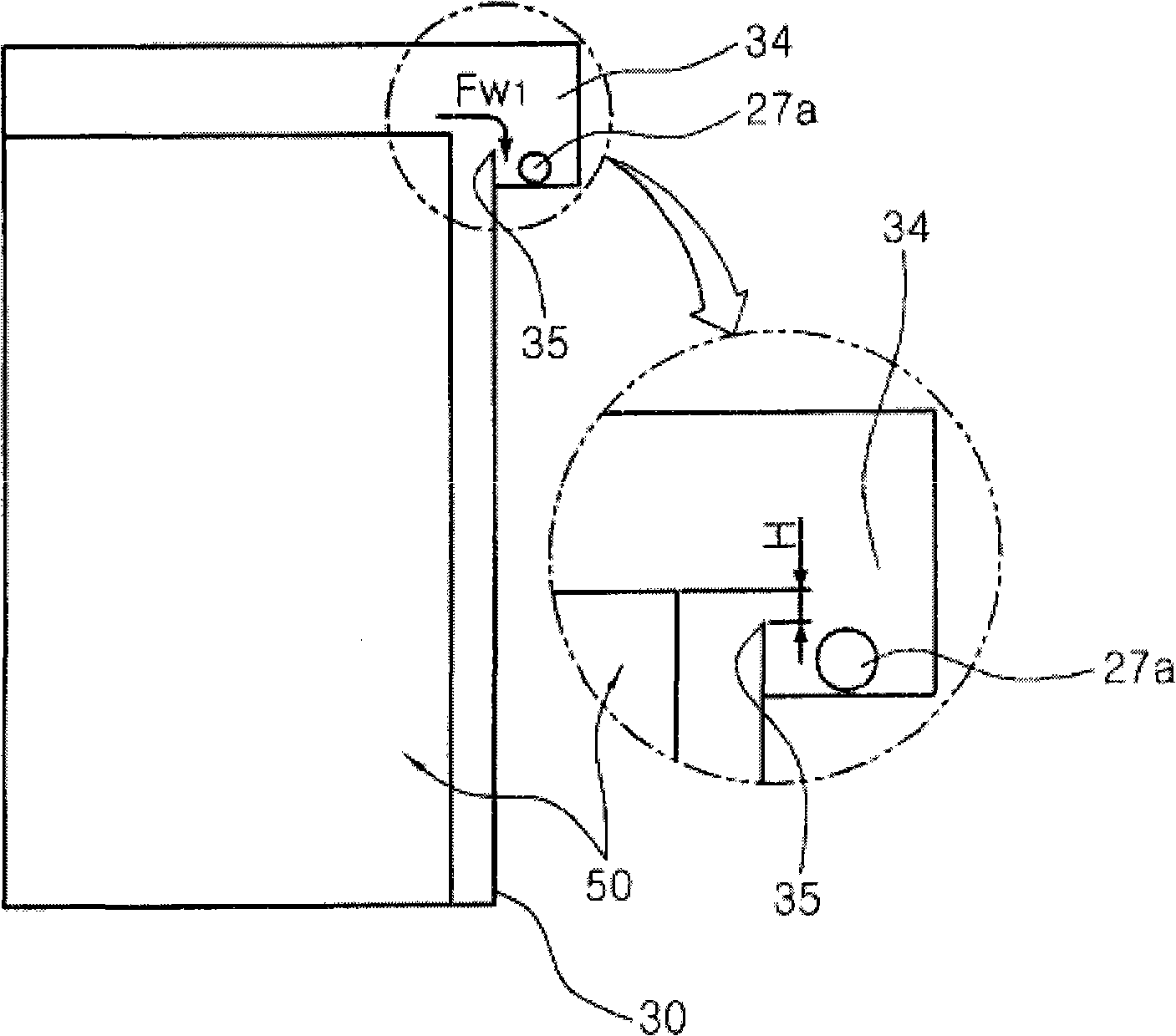

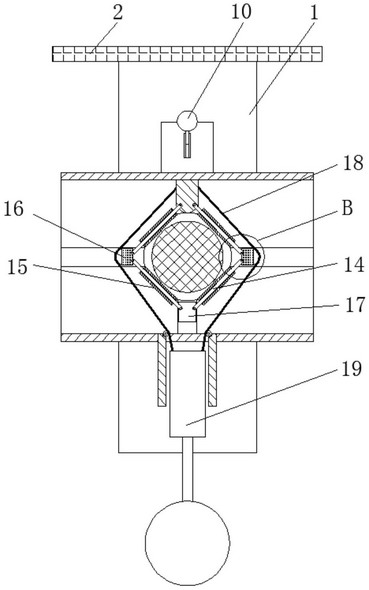

Chambering-forging forming method for aluminum alloy hub with complex structure and die thereof

InactiveCN102228951AReduce maintenance costsIncrease profitForging/hammering/pressing machinesWheelsAlloy wheelMaterials science

The invention provides a chambering -forging forming method for an aluminum alloy hub with a complex structure and a die thereof. The forming method comprises the steps of: preparing for materials; heating blanks; upsetting; mould-pressing and chambering a rim. The die for realizing the chambering-forging forming method for the aluminum alloy hub with the complex structure comprises a forging die and a rim-chambering die, wherein an upper die of the forging die consists of an upper die body and an upper die core which are sequentially nested and mounted, a lower die consists of a lower die body, a lower die core and an ejector rod which are sequentially nested and mounted; and the bottom and the side wall of the assembling part of the lower die core and the lower die body are uniformly provided with 4-8 R3 penetrating exhaust grooves, the rim-chambering die consists of an upper chambering die and a lower chambering die, and the size of a cavity of the upper chambering die is same as the size of the cavity of the upper die core of the forging die. The invention realizes once-heating forming; a non-burr forging and rim-chambering forming process is adopted, thus two trimming procedures are eliminated, material utilization rate is improved, and number of equipment is reduced; and the rim-chambering die has a simple structure and is convenient for operation.

Owner:HARBIN HAFEI IND

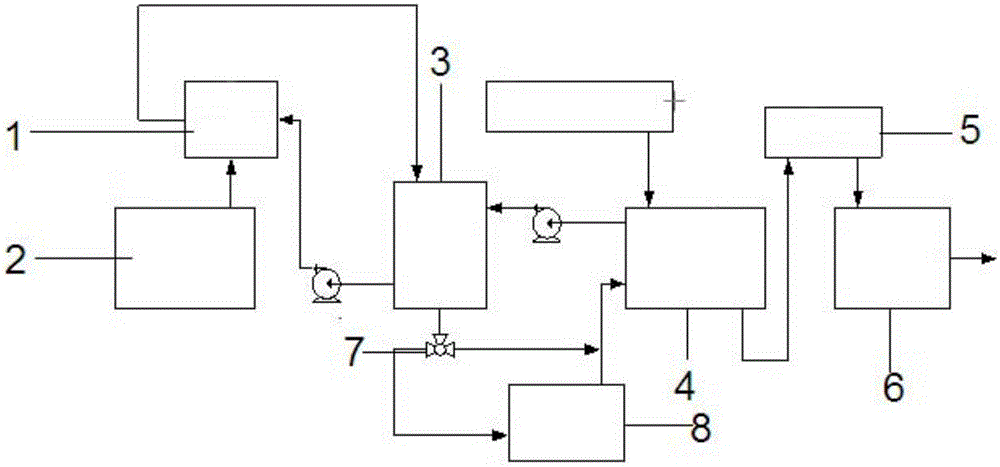

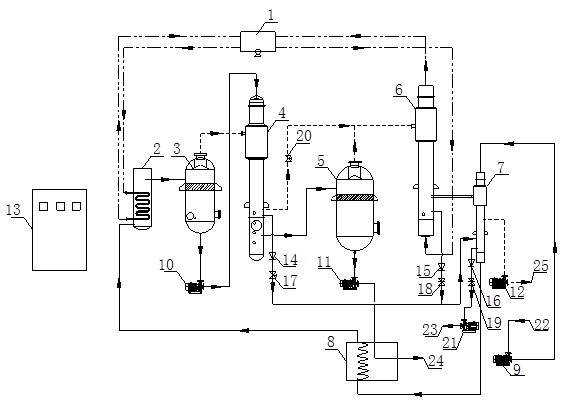

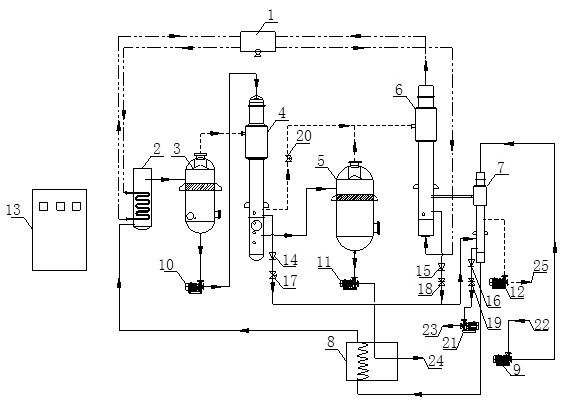

Energy-saving resourceful treatment technology for drilling mud

InactiveCN106517718ASave on energy billsReduce processing costsSludge treatment by de-watering/drying/thickeningEvaporationSewage

The invention relates to the technical field of drilling pollution treatment, especially to an energy-saving resourceful treatment technology for drilling mud. The treatment technology includes: high temperature tail gas waste heat recovery, mud drying treatment and high temperature ceramic solidification treatment of mud. The waste heat recovery operation is carried out in a waste heat recovery system, the mud drying treatment is carried out in a mud drying system, and the high temperature ceramic solidification treatment of mud adopts a dry mud high temperature ceramic solidification system. The waste heat recovery system, the mud drying system and the dry mud high temperature ceramic solidification system are three independent systems. The technology is simple, the traditional solid-liquid separation process is no longer used, treatment of complex sewage is no longer needed, an evaporation process is employed directly, and the core equipment is simple. The technology has the characteristics of zero emission and thorough harmlessness, and completely achieves zero emission of pollutants and harmless steam. Dry mud is sintered at high temperature into ceramic, and heavy metals are completely solidified and not dissolved. The technology realizes recycling, the ceramic obtained by high temperature sintering of dry mud is an available industrial raw material or a directly usable product.

Owner:JIANGSU QINGQUAN ENVIRONMENTAL PROTECTION EQUIP

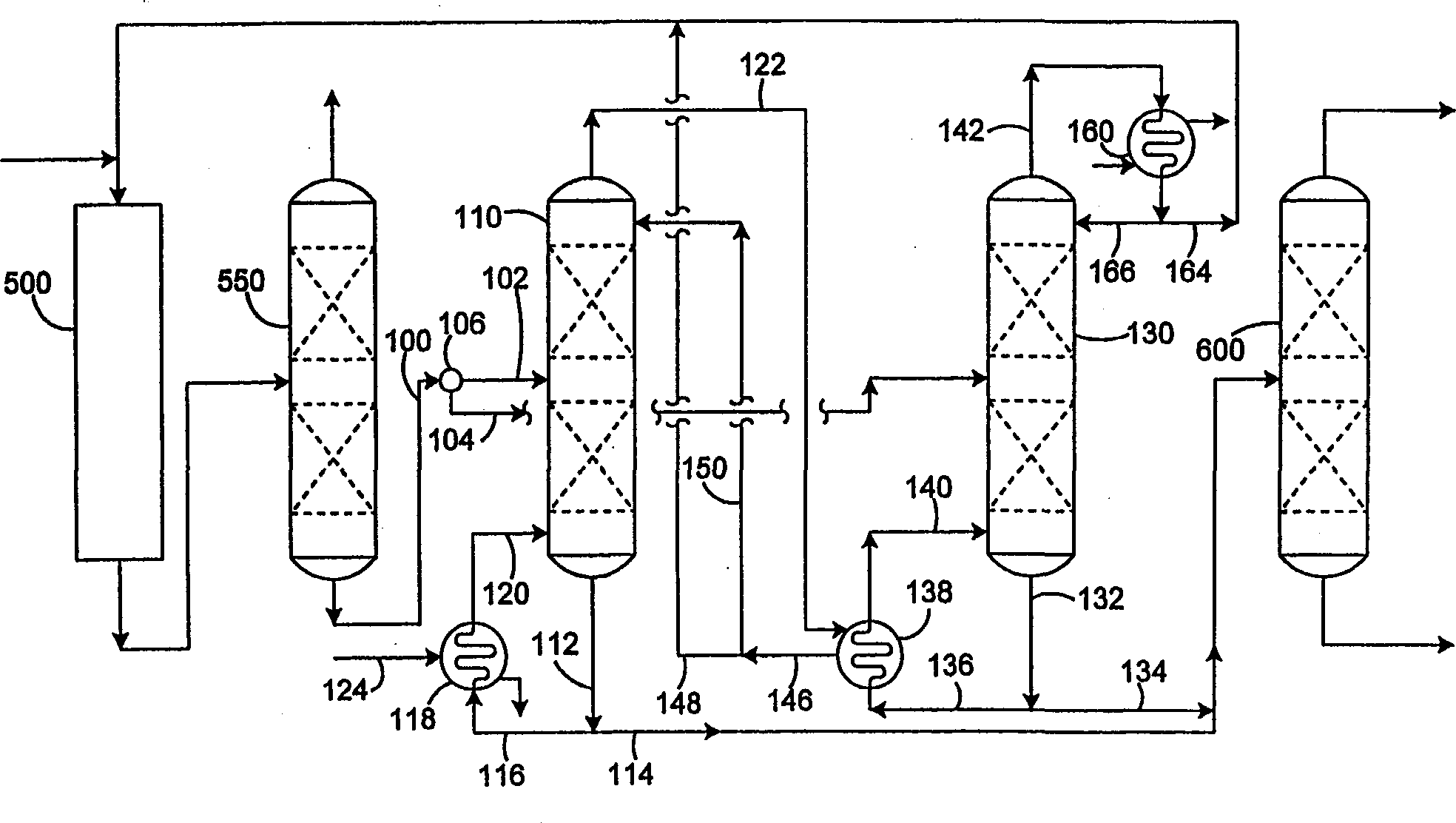

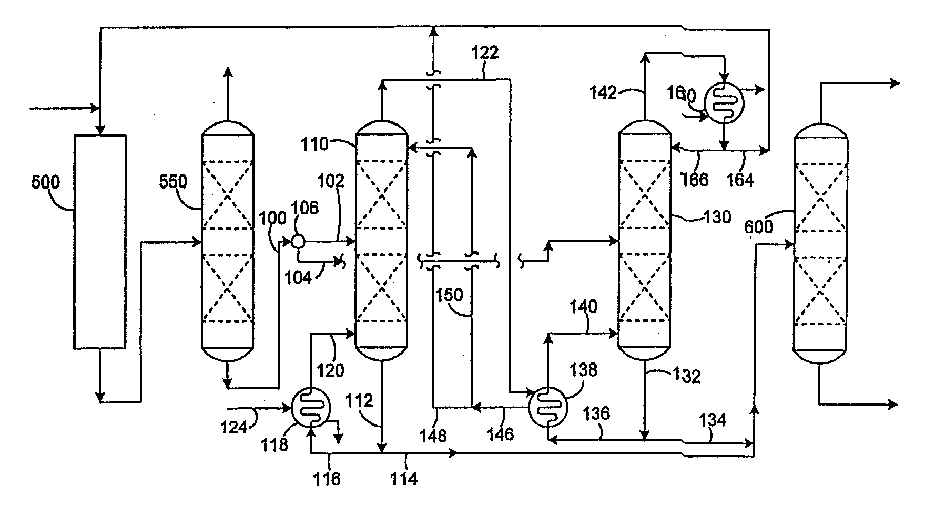

Cascade reboiling of ethylbenzene/styrene columns

InactiveCN1309578AIncrease lossIncrease the rate of polymerizationDistillation regulation/controlDistillation purification/separationThermal energyFractionating column

Apparatus and process are disclosed for the distillation separation of styrene monomer from ethylbenzene utilizing a split feed to two distillation columns in conjunction with cascade reboiling utilizing thermal energy from the overhead of one column to supply heat to the second.

Owner:STONE & WEBSTER PROCESS TECH

Metal surface cleaning solution

The invention relates to a metal surface cleaning solution which is prepared by following raw materials of, by weight percentage, sulfuric acid, hydrochloric acid, a high polymer composite enhanced active agent, sodium dodecyl benzene sulfonate, urotropin, sodium silicate, citric acid, urea, industrial salt, triethanolamine and water. The cleaning solution can completely clean up various greasy dirt, rust and scale cinder attached on a metal surface effectively, and protective film can forms on the metal surface after being cleaned so as to prevent metal from rusting and oxidizing in a certain period. Waste water of a used cleaning solution can be reused after being recovered, precipitated and filtered.

Owner:杨恒春

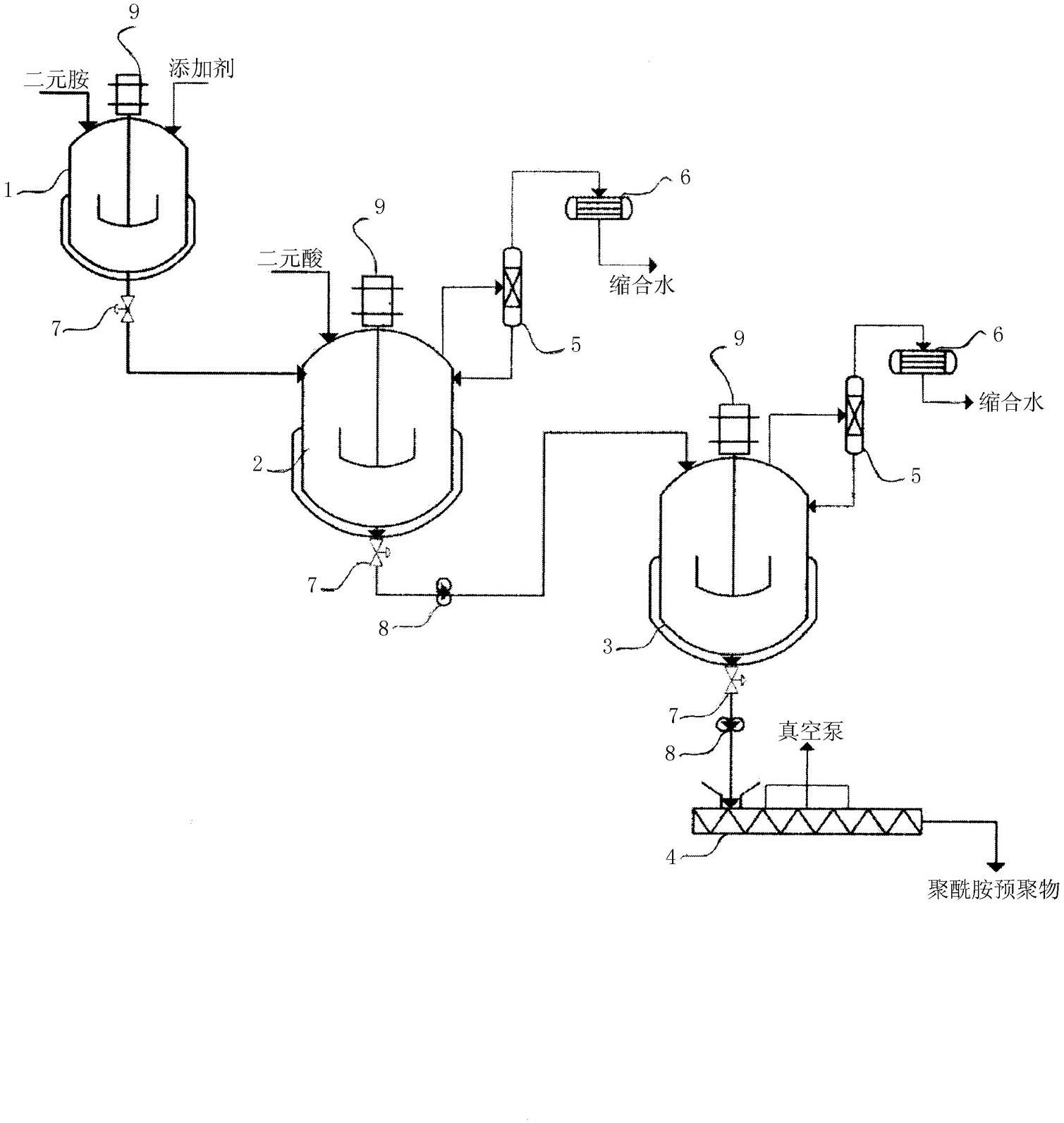

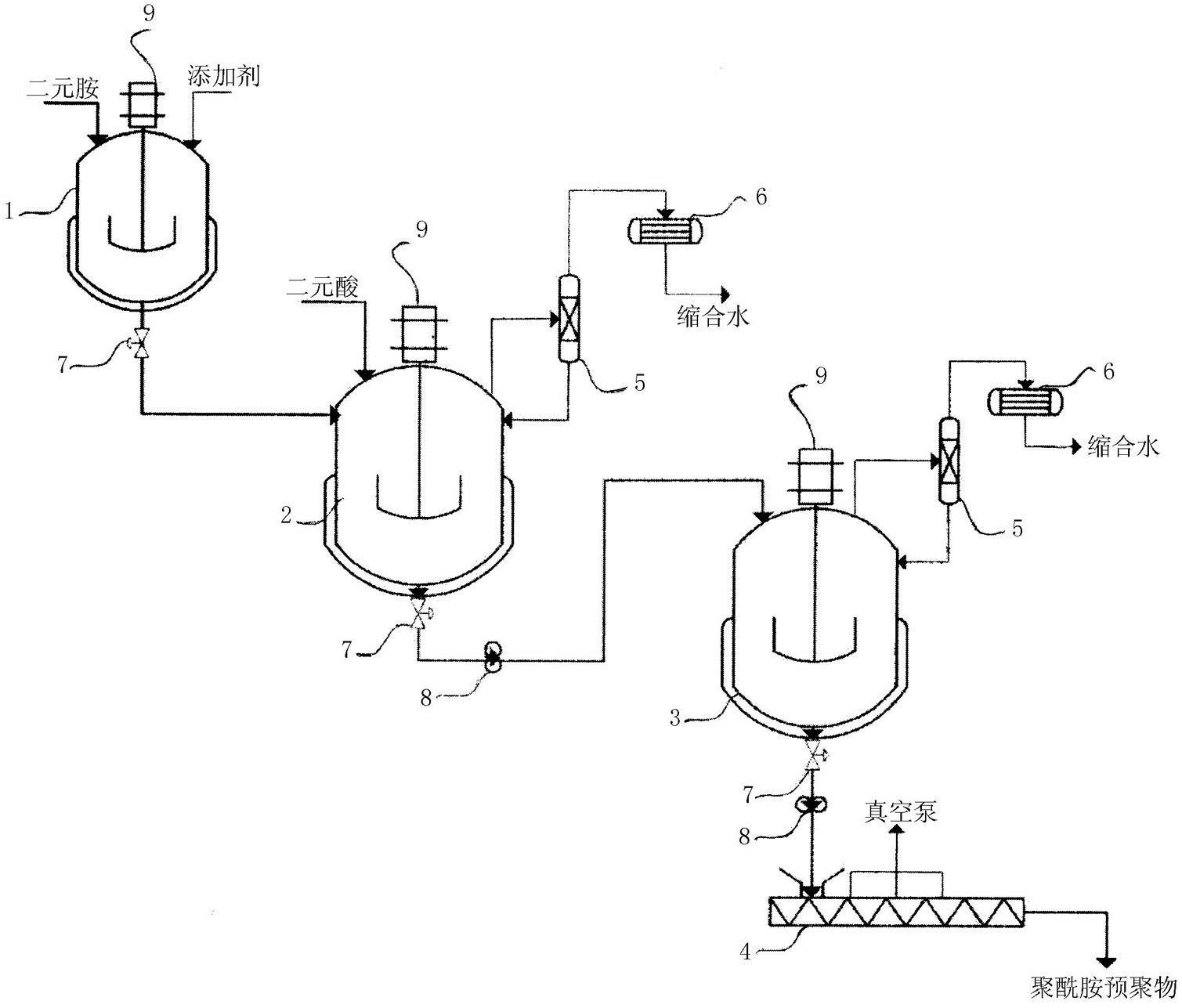

Method for producing polyamide

The invention discloses a method for producing polyamide. The method comprises the following steps: 1, adding a molten diamine to a solid dicarboxylic acid without a solvent, forming a mixed solution of the dicarboxylic acid and the diamine or a suspension with good fluidity in a first polymerization reactor, and forming a prepolymer of polyamide with the inherent viscosity of 0.3-0.7dl / g in a second polymerization reactor; and 2, granulating the prepolymer with a double screw extruder with at least two vent holes, adding prepolymer particles to a solid phase polymerization reactor of a fixedbed, heating the prepolymer particles with hot nitrogen with a certain flow and a certain temperature, reacting for 1-15h to obtain products of polyamide with the inherent viscosity of 1.0-2.5dl / g. Compared with previous polyamide polymerization methods, extra energy costs needed by solvent removal are reduced and the operation cost is reduced because polycondensation is carried out without the solvent; energy consumption in the melting process is reduced and possible problems of raw material oxidation and the like caused by a high melting temperature are avoided because cases that the diamine and the diacid for polyamide production have different melting points and the melting point of the diamine is low, and the molten diamine is added to the solid diacid are skillfully used in the method of the present invention.

Owner:卢建国

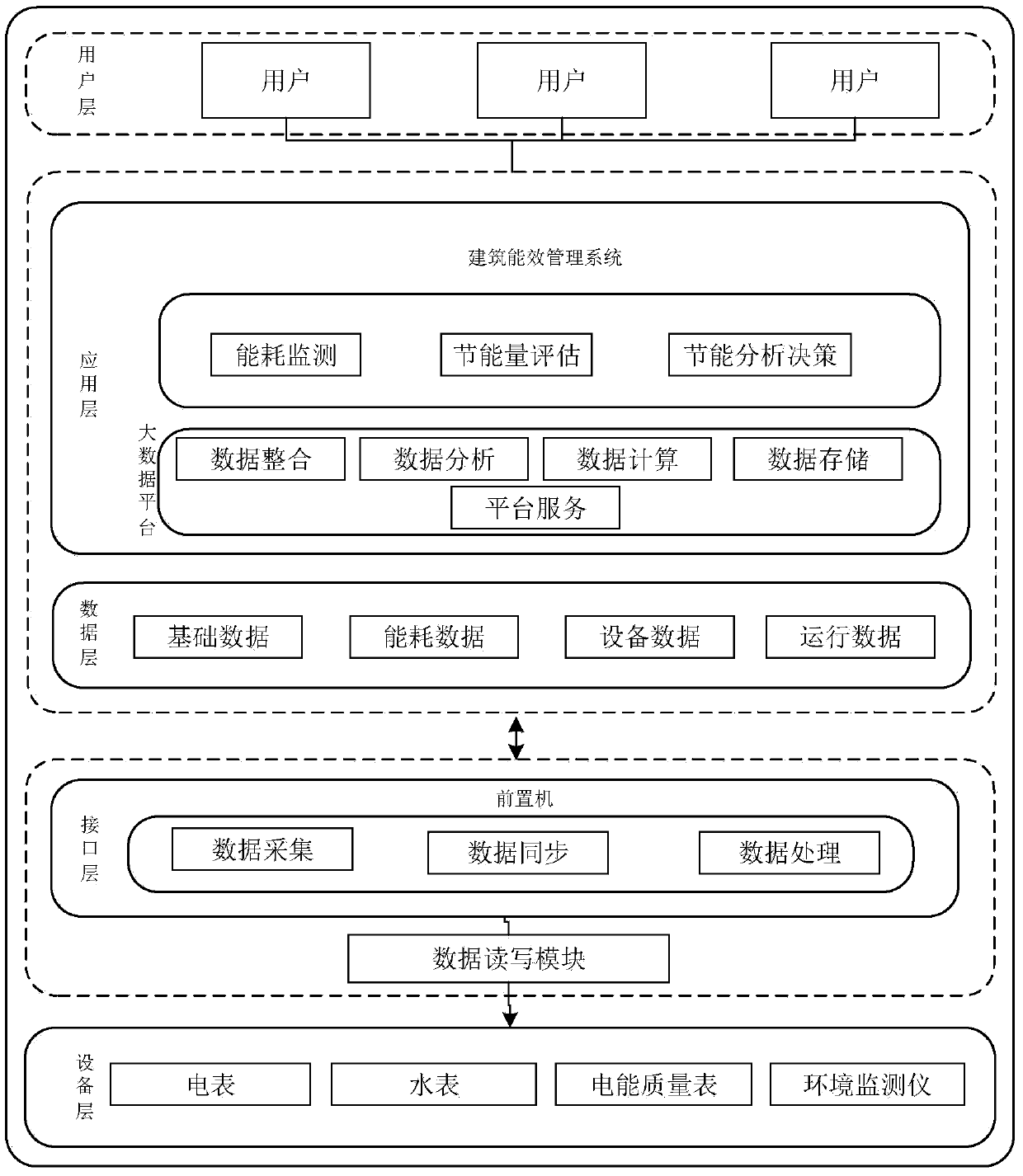

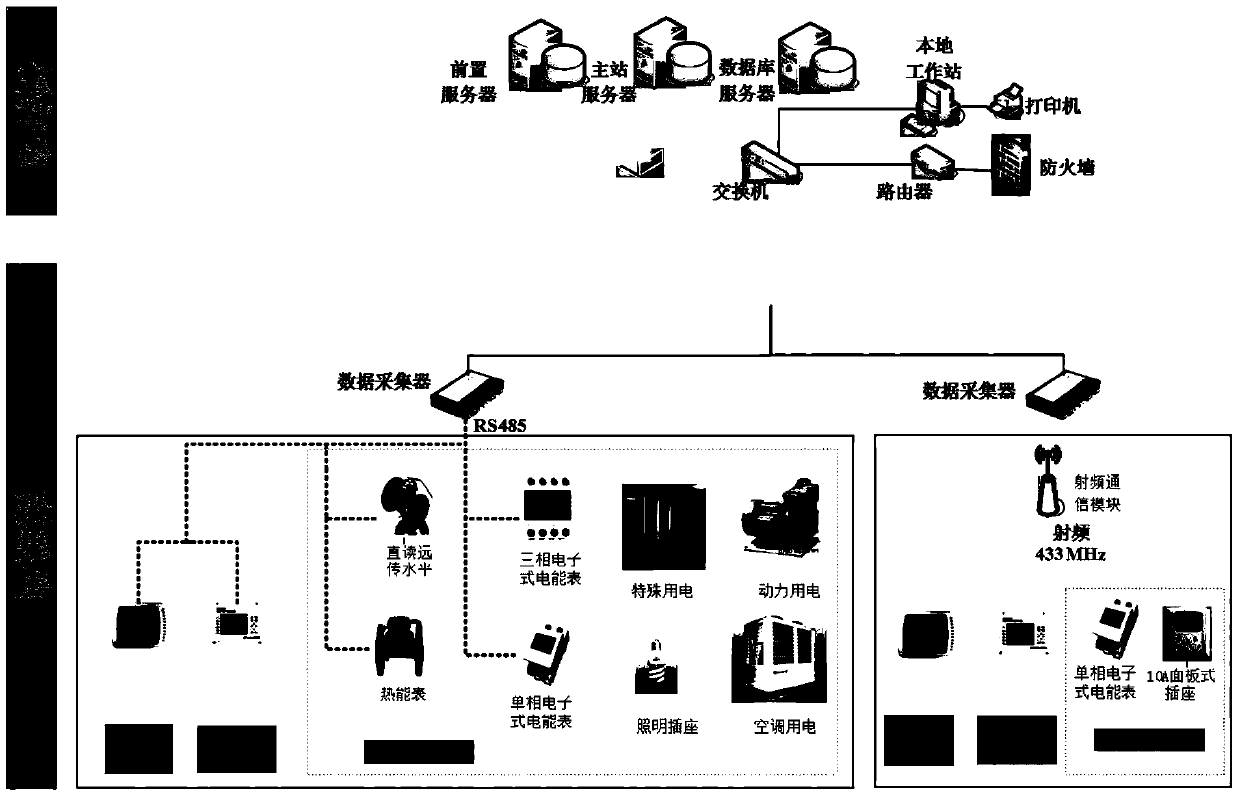

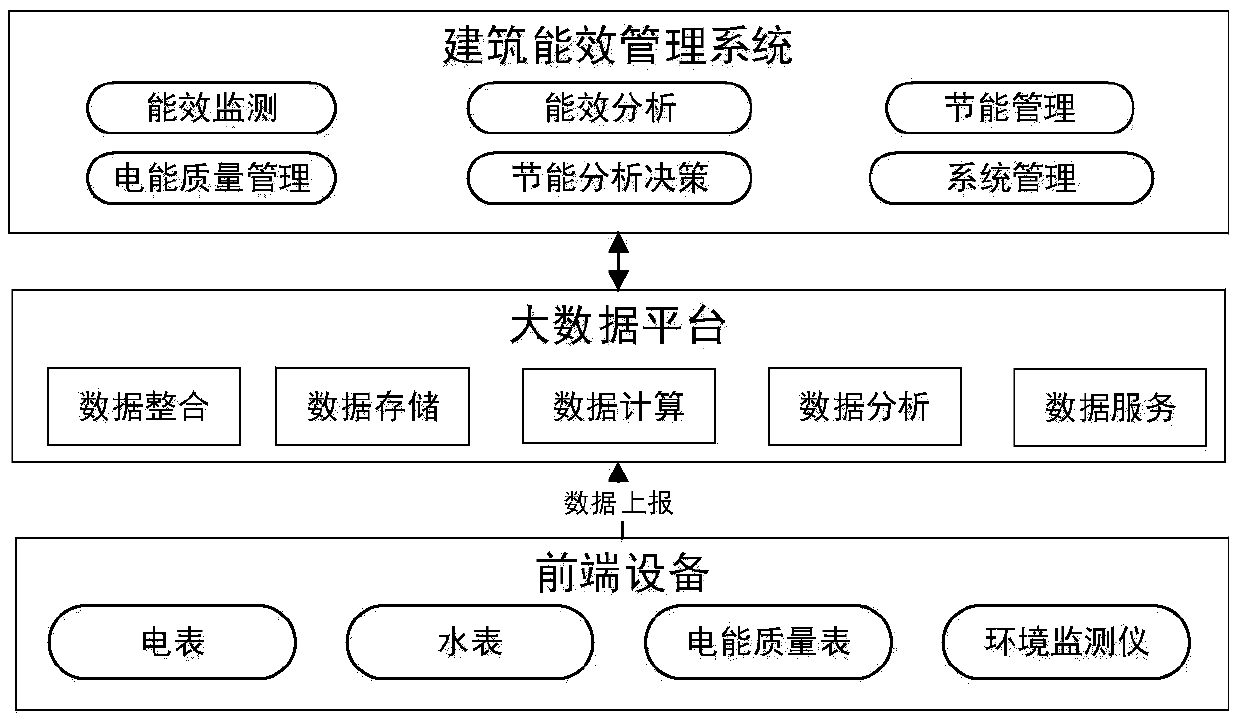

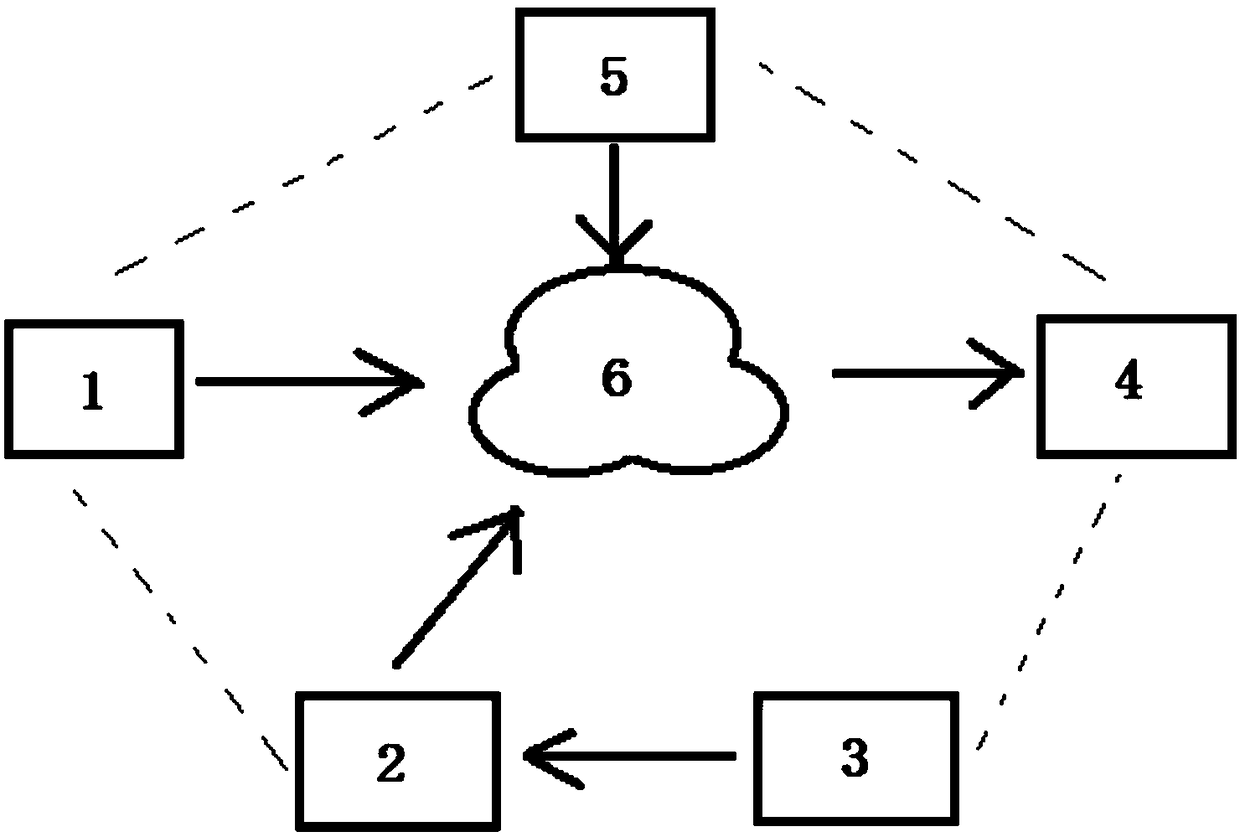

Method of building energy efficiency management on the basis of big data

InactiveCN105373971AImprove operational qualitySave on energy billsData processing applicationsSingle pointButt joint

The present invention discloses a method of building energy efficiency management on the basis of big data. The method of building energy efficiency management on the basis of big data comprises a building energy efficiency management system architecture on the basis of big data consisting of a user layer, a master station layer, an interface layer and a mechanical layer. The user layer is configured to allow a user to log in a main station system through a system portal in a single sign-on or direct entry mode; and the master station layer is composed of an application layer and a data layer. The application layer is mainly composed of a building energy efficiency management system and a big data platform, the big data platform and the master station of the building energy efficiency management system are subjected to butt joint so as to upload various data to the building energy efficiency management system, and the building energy efficiency management system performs final real time display and historical analysis and comparison of the various data to form a report and a diagnosis opinion of energy conservation and provide related analysis ideas for energy conservation reconstruction. The big data platform is able to issue data inputted into the big data platform and also perform further data analysis and processing so as to provide data basis for more advanced function applications.

Owner:STATE GRID CORP OF CHINA +4

Method for controlling artificial intelligence home environment system based on big data

InactiveCN108829074AImprove comfortGuarantee air qualityComputer controlSimultaneous control of multiple variablesCommunications systemRemote control

The invention discloses a method for controlling an artificial intelligence home environment system based on big data, wherein the system comprises an identity recognition system, an intelligent integrated communication system, a sensor system, a home environment terminal system, an artificial intelligence operation management system and a cloud server. The method includes steps from one to eight.The method for controlling the artificial intelligence home environment system based on big data adopts a combination of big data and artificial intelligence to manage environment equipment of home space, and can realize precision control of environment equipment while ensuring user comfort and safety, thereby improving the control efficiency. At the same time, compared with the traditional independent control and remote control, the scheme can greatly save energy cost in the use of home environment equipment.

Owner:上海晶友智家节能电子设备有限公司

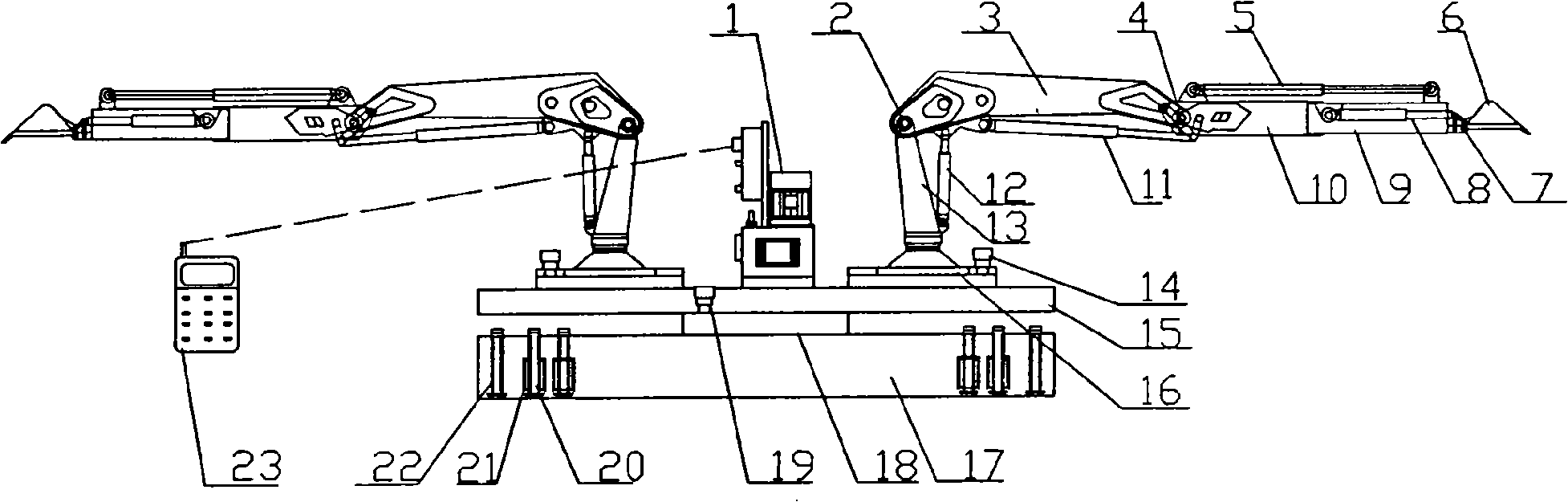

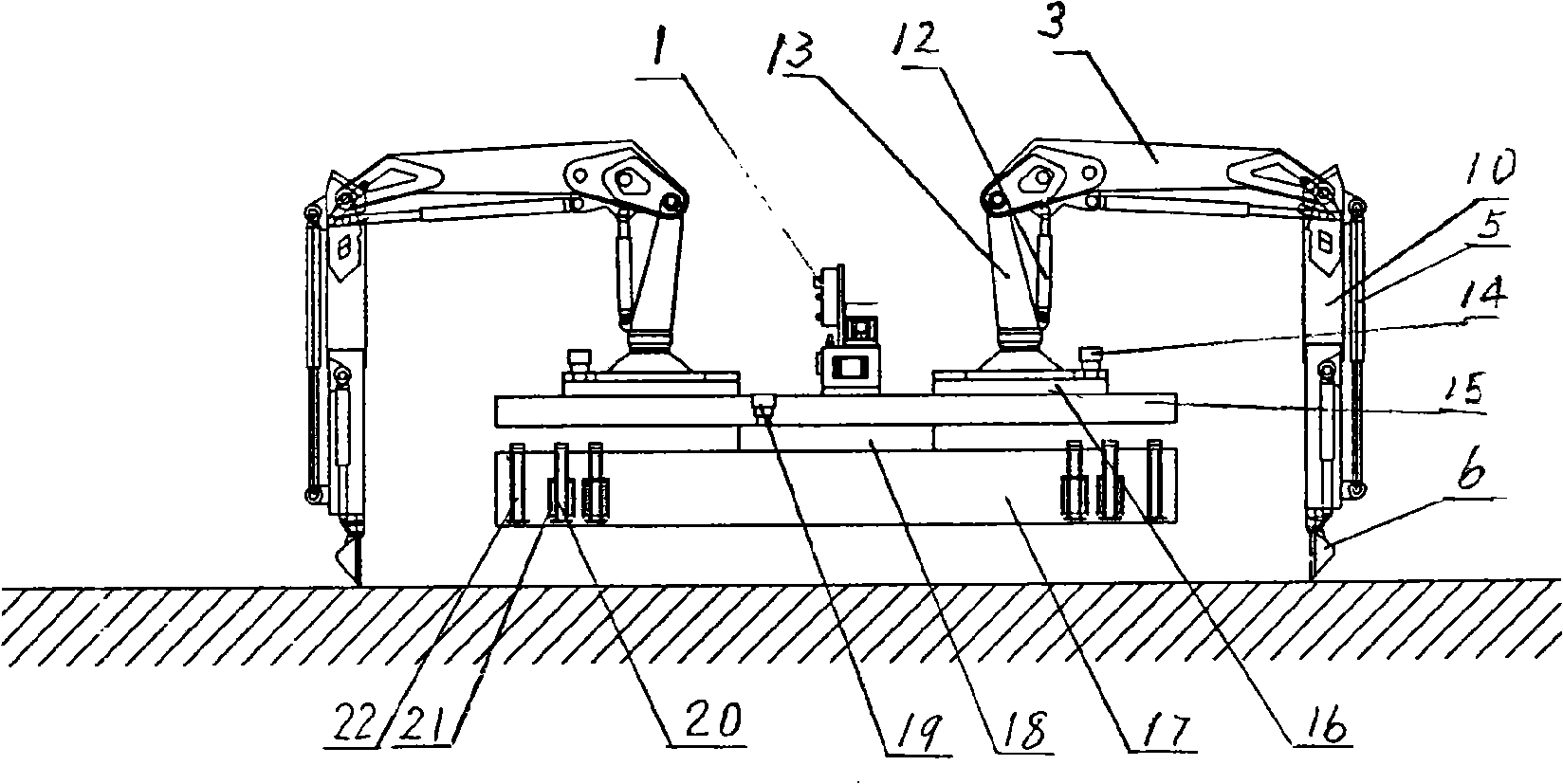

Walking telescopic arm type remote control digging machine

InactiveCN101280569AMove freelyAvoid Personal Safety AccidentsMechanical machines/dredgersRemote controlControl engineering

Disclosed is a walking type and telescopic arm type remote control excavating machine applied to construction machinery of underground engineering, which comprises folding telescopic excavators, a chassis, a telescopic excavating mechanism, a walking mechanism and a remote control unit. Two folding telescopic excavators are positioned on the upper platform of the chassis in a manner of 180 degrees symmetry, and the middle of the upper platform is provided with a set of electric hydraulic pump to provide power to the excavators. The lower platform of the chassis is provided with the special walking mechanism; after the two excavators support the whole machine away from the ground, the lower platform is rotated so as to have the whole machine walk at any directions. Under the control of the remote control unit, the two excavators can carry out excavating works independently. The upper platform and the lower platform rotate relatively when the whole machine needs walking and are fixedly connected together under normal excavation. The two excavators are 12m long after lateral extension and the radius of one-arm excavation is 5m. The whole machine is driven by electric power and controlled by the remote control unit, and has large excavation radius and high borrow efficiency.

Owner:TONGJI UNIV

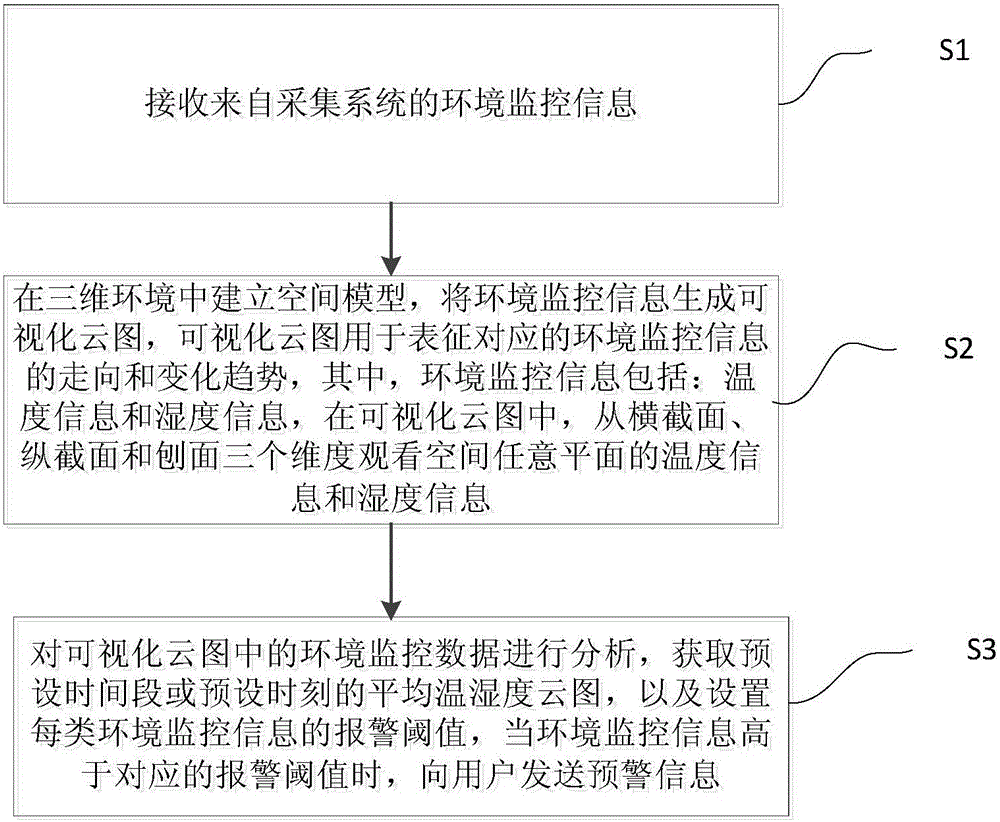

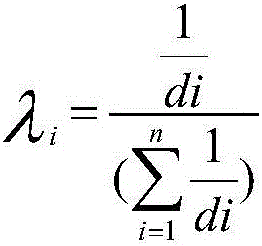

Cloud map display method for environment monitoring information

InactiveCN105955357AIntuitive display of temperature distributionNot easy to ignoreSimultaneous control of multiple variablesCollection systemTemperature monitoring

The invention puts forward a cloud map display method for environment monitoring information, comprising the following steps: receiving environment monitoring information from a collection system; building a space model in a three-dimensional environment, and generating a visual cloud map based on the environment monitoring information, wherein the visual cloud map is used to represent the trend and change of the corresponding environment monitoring information, and the temperature and humidity information of any plane of a space can be viewed in the visual cloud map from three dimensions, namely, the transverse cross section, the longitudinal cross section and the profile; analyzing the environment monitoring data in the visual cloud map, and getting the average temperature and humidity cloud map in a preset period of time or at a preset time; and setting an alarm threshold for each type of environment monitoring information, and sending warning information to users when the environment monitoring information is higher than the corresponding alarm threshold. According to the invention, discretely distributed temperature monitoring points are changed into a continuously-distributed temperature field through an interpolation algorithm, the temperature and humidity trend and the heat island effect are reflected intuitively by means of three-dimensional display, and operation and maintenance staff can be helped to carry out positioning.

Owner:北京航天联智科技有限公司

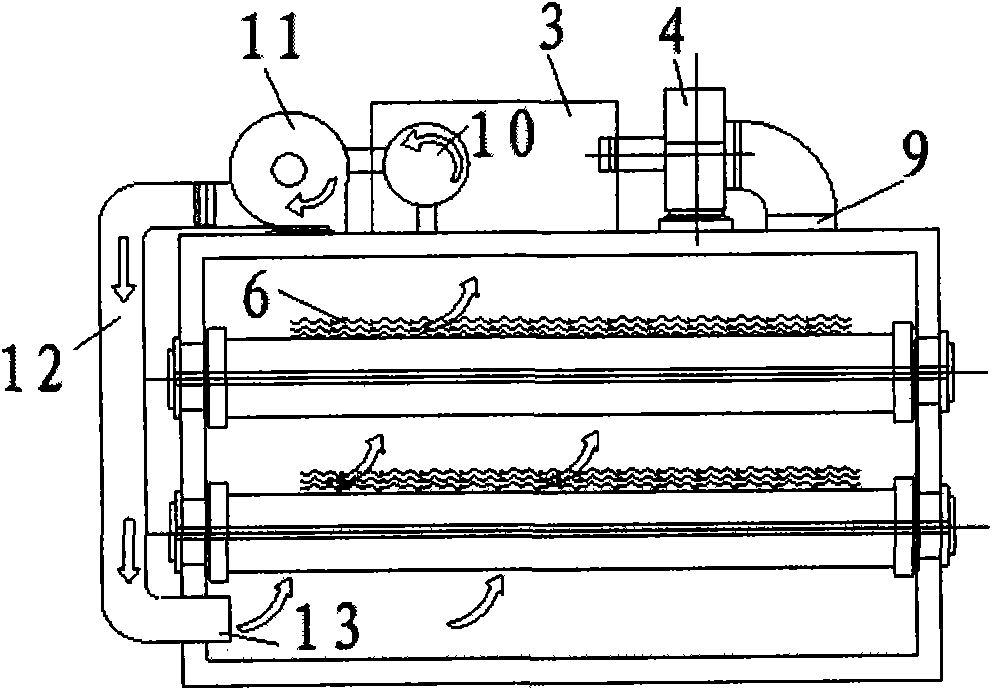

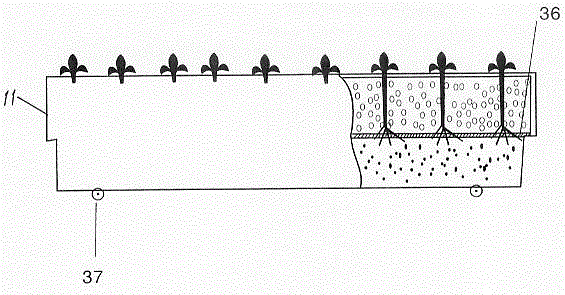

Sludge band type drier and drying processing method

InactiveCN101993185ASafe storageShort tripSludge treatment by de-watering/drying/thickeningSludgeHeat losses

The invention relates to a sludge band type drier and a drying processing method, belonging to the field of solid wastes. The drier comprises a sludge noodle preparing device, a box body, an air blower, an air flue, an air blower for exhausting the air, an air mixing cavity, an air heating device, a sludge water-cooling spiral conveyer arranged in the box body, and an air draft device, wherein the sludge noodle preparing device is arranged in the position of a sludge feeding port on the top of the box body; a feeding port and a discharge port are respectively arranged on the upper part and the lower part of the box body; a drying band and a driving device thereof form a vertical module device, and at most two layers of drying bands are arranged; one air draft device, one air heating device and one air blower form a horizontal module device; and the box body is provided with a plurality of air outlets and air inlets so that the sludge is blown by the lateral dry hot air from the side to reach a drying state. The system of the invention has the advantages of safe and environment-protection operation, short route of the sludge, high drying efficiency, less heat loss, simplicity in operation, low maintenance cost, safety, energy-saving performance, environmental-friendliness and recycling.

Owner:BMEI +1

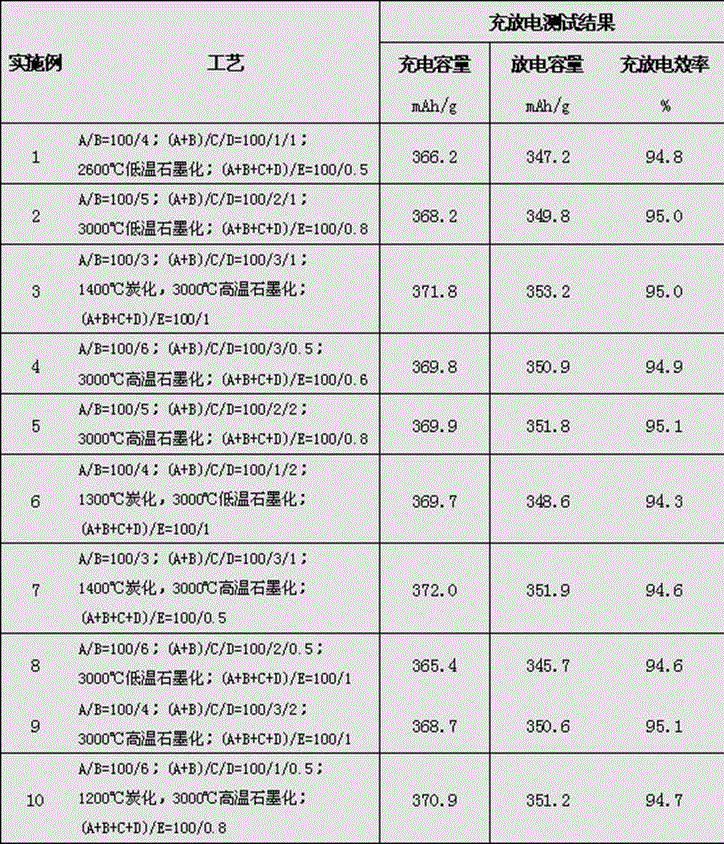

Production method for modified artificial graphite negative electrode material

ActiveCN105428615ALow costChange structureCell electrodesSecondary cellsCarbon nanotubeCarbonization

The invention provides a production method for a modified artificial graphite negative electrode material. The method comprises: taking powder obtained by grinding petroleum coke as a main raw material and performing shaping treatment; adding a certain proportion of petroleum asphalt into the shaped petroleum coke material, and performing secondary granulation treatment in an extrusion fusion way; adding the granulated material into a mixture of petroleum asphalt and coal asphalt or coal tar, and performing coating modification treatment; putting the material into a graphitization furnace in bulk to perform high-temperature graphitization treatment, or performing carbonization and graphitization treatment in sequence; performing dispersion and grading treatment after the material is cooled to the room temperature; and finally adding few carbon nanotubes to perform mixing and screening. The method has the advantages that the main raw material is ground petroleum coke powder, and the powder is recycled, so that the cost can be reduced; secondary granulation of small granules can increase the capacity of the material and improve the cycle performance of the material; and due to the adoption of a graphite plate loading mode, the graphitization degree of the material can be increased, namely, the capacity can be increased, and the energy consumption cost can be reduced.

Owner:大连宏光锂业有限责任公司

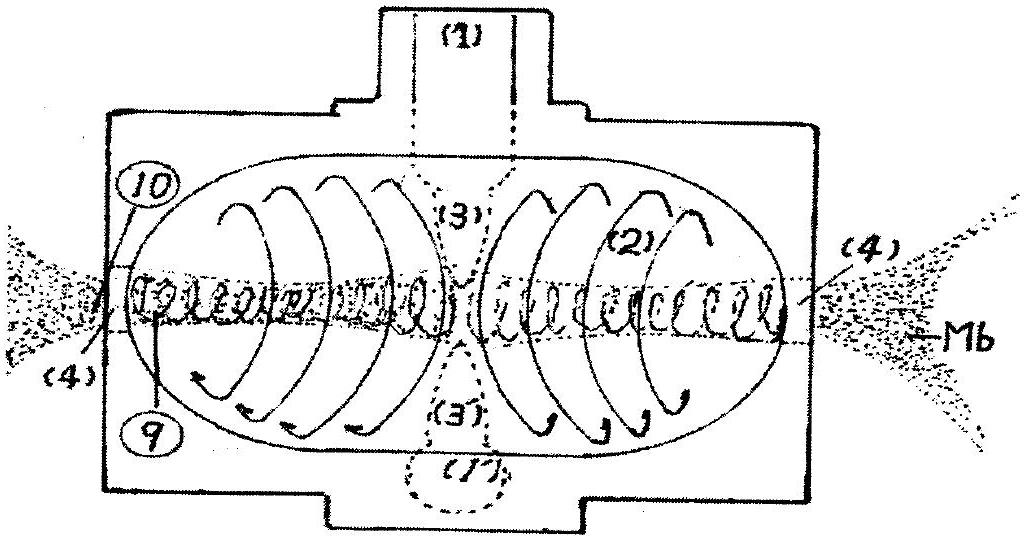

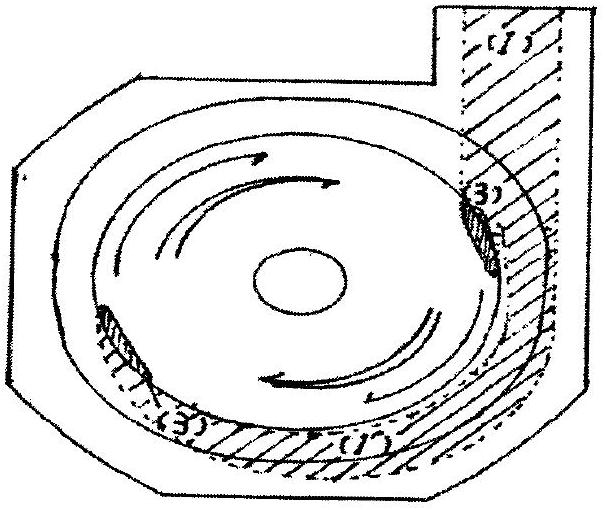

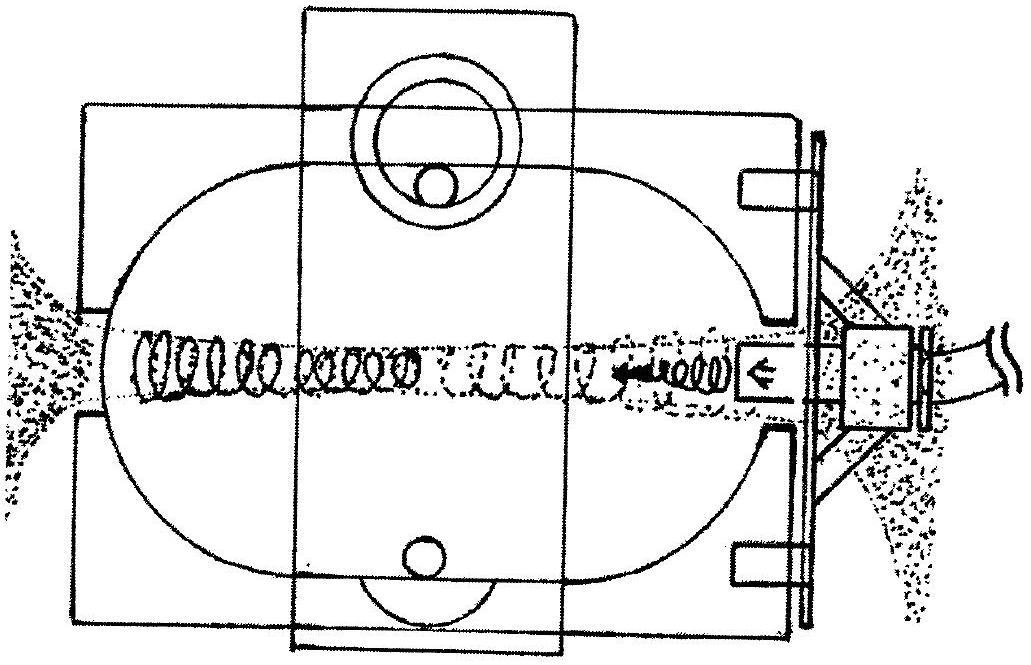

High-speed cyclic gas-liquid mixed micro-nano foam generating device

InactiveCN102688709ALarge amount of bubblesUniform amount of air bubblesFlow mixersMixing methodsMicro nanoHybrid type

The invention discloses a high-speed cyclic gas-liquid mixed micro-nano foam generating device, which consists of two hemispherical containers and a cylindrical container which is connected with a water inlet pipe, hollow C-shaped pipes (3) and (3') are arranged on the cylindrical inner surface, and a circular hole (4) for spraying liquid to achieve the effects of micro-nano foam and an air conduit is formed at each of two hemispherical ends. Due to the hollow C-shaped pipes, the rotating speed of liquid is improved (so that super-micro thinning of foam is promoted), and the superfine foam generating rate is improved by 25 percent compared with the conventional superfine foam generating rate.

Owner:金强

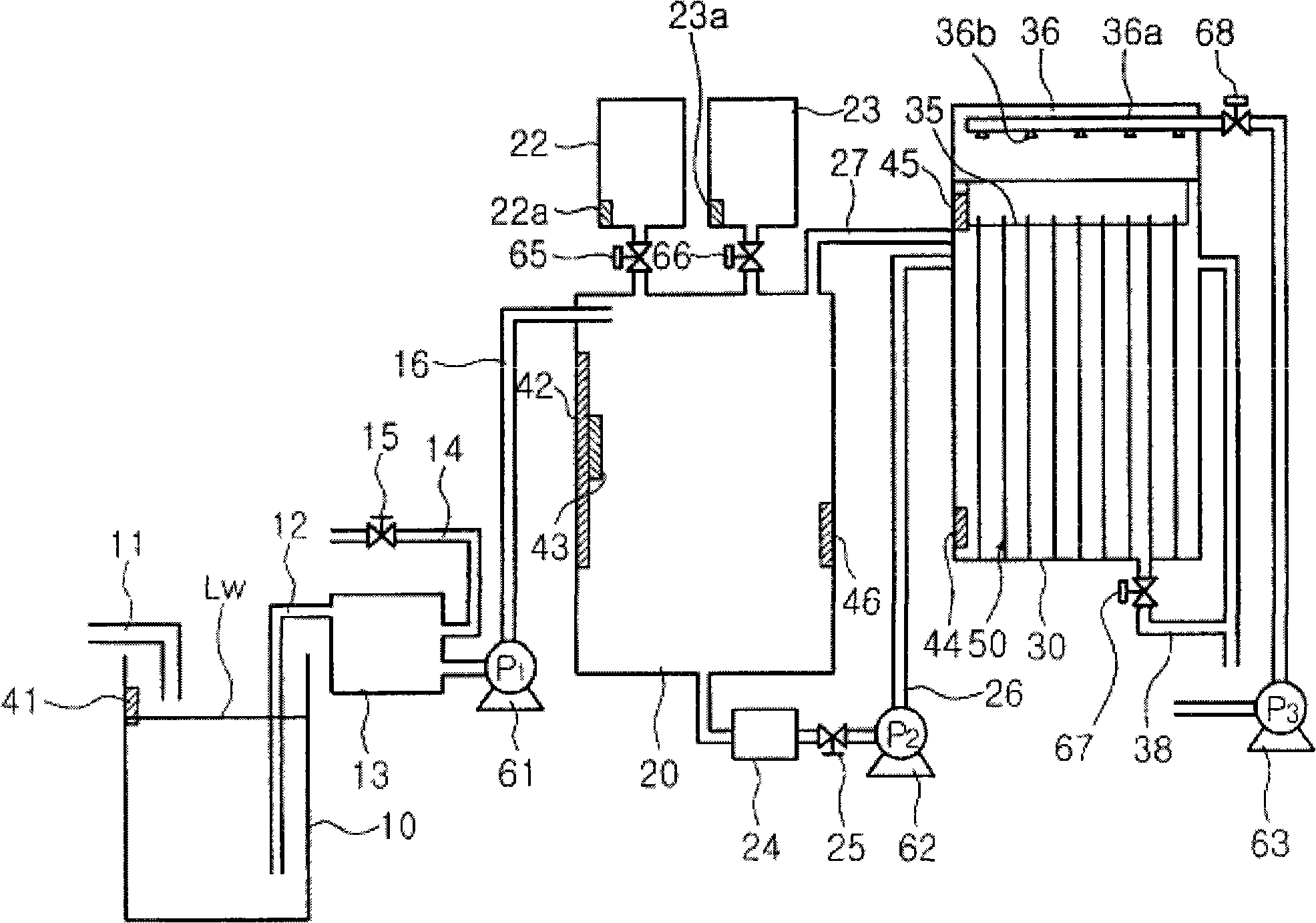

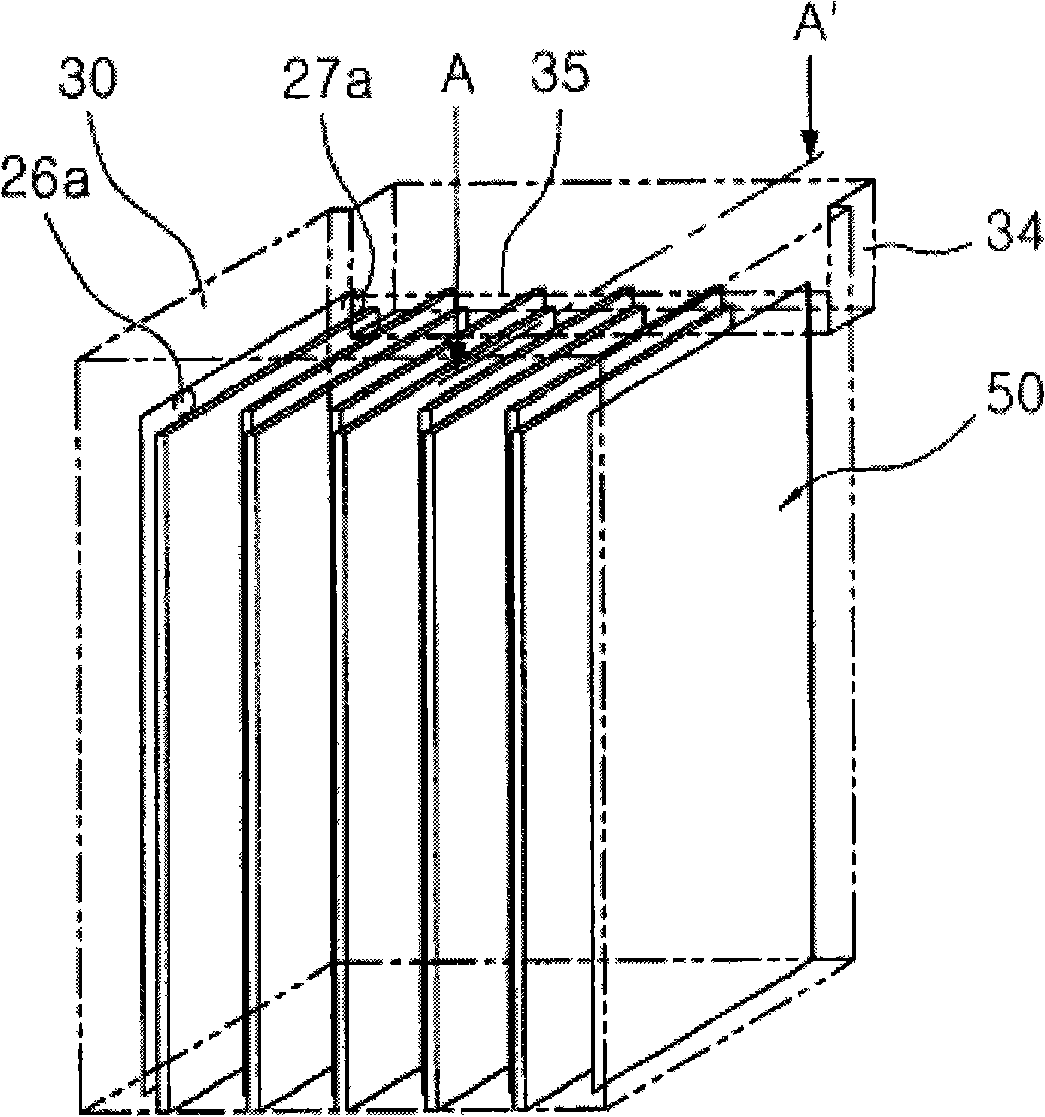

Electro-chemical water processing apparatus and method thereof

InactiveCN101573299AEasy to separateLow costWater treatment parameter controlSpecific water treatment objectivesElectrolysisHydrogen-Ion Concentrations

The present invention provides an electro-chemical water treatment apparatus and method for removing total nitrogen ingredients of ammonia nitrogen, nitrous acid nitrogen, nitrate nitrogen etc., organic materials of BOD and COD induction ingredients, and cyanogen included in wastewater and dirty water. The apparatus includes: a wastewater collection reservoir that contains wastewater; a wastewaterstorage retention reservoir that controls a hydrogen ion concentration (pH), an electrical conductivity and an amount of flow of wastewater; an electrolyte tank which makes the electrical conductivity of the wastewater as an electrical conductivity at which an electrolysis can be achieved; a pH conditioner tank that supplies a pH conditioner for the wastewater; an electrolyzer including an anodeplate and a cathode plate, and a number of electrodes which are arranged as an electrification body between the anode plate and the cathode plate; and a controller which grasps state of wastewater andwhich is connected to the anode plate and the cathode plate to thereby control the electrolysis.

Owner:田致重

Artificial intelligence home environment management system based on big data

PendingCN108873729AImprove comfortGuarantee air qualityComputer controlProgramme total factory controlHome environmentTerminal system

The present invention discloses an artificial intelligence home environment management system based on big data. The system comprises an identification system, an intelligent integration communicationsystem, a sensor system, a home environment terminal system, an artificial intelligence operation management system and a cloud center processor. The identification system identifies resident information and then upload resident environment data collected by the sensor system to a data analysis layer in the artificial intelligence operation management system through the intelligent integration communication system so as to establish a unique 'temperature and humidity' model of the residents in a model layer in the artificial intelligence operation management system. The artificial intelligence home environment management system is employed to improve the comfort level when the users are living, ensure the air quality safety of the home space and greatly save the energy cost in the home environmental unit usage process.

Owner:上海晶友智家节能电子设备有限公司

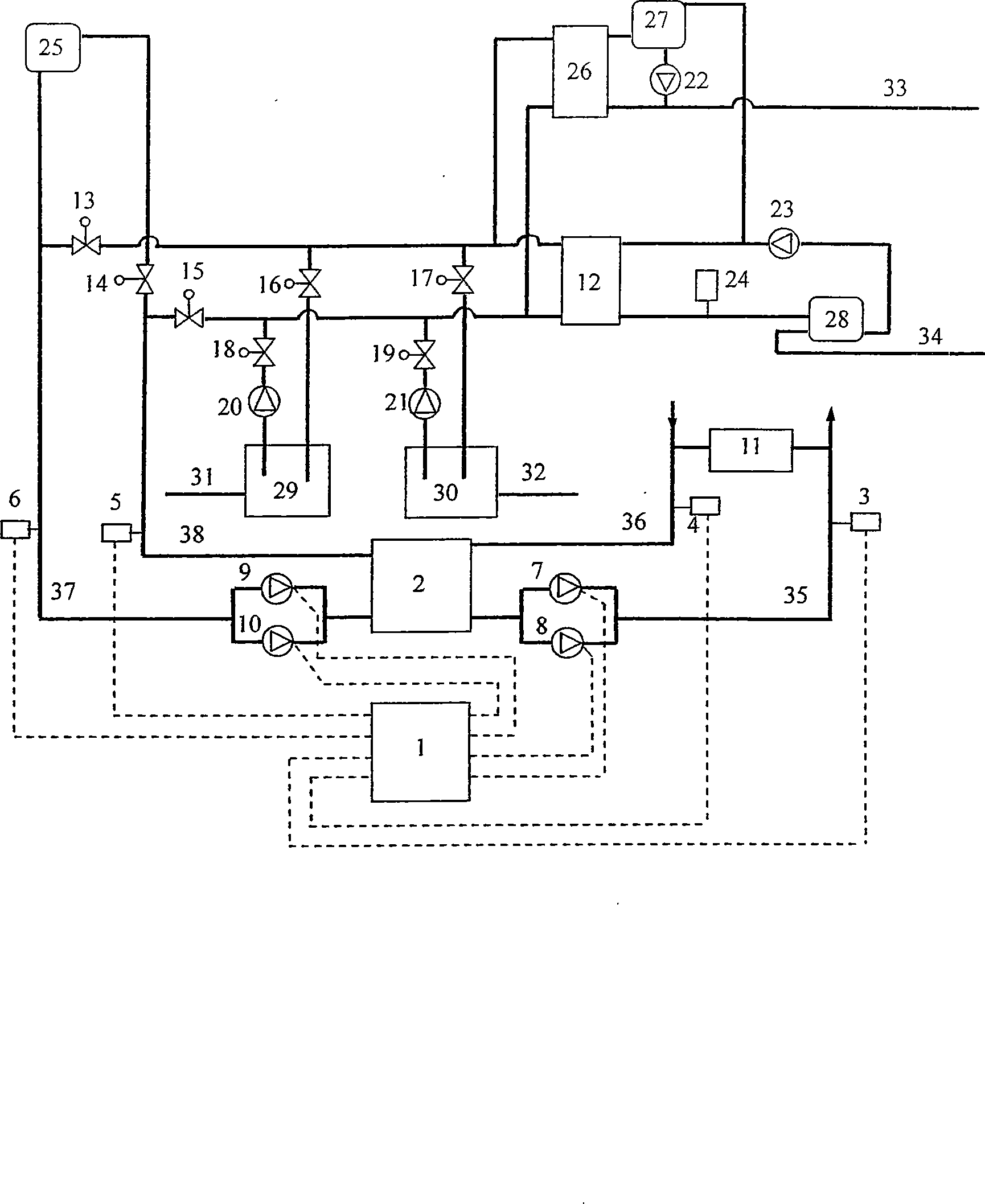

Free energy heat pump multiple-effect evaporation device and process

InactiveCN102527070AReduce work efficiencySimple equipment installationHeat pumpsMultiple-effect evaporationEngineeringOperating energy

The invention belongs to the technical field of energy conservation and environment friendliness, and relates to a free energy heat pump multiple-effect evaporation device which integrates a heat pump and a multiple-effect evaporation system, and a free energy heat pump multiple-effect evaporation process. The free energy heat pump multiple-effect evaporation device comprises the heat pump and the multiple-effect evaporation system which is integrated with the heat pump, wherein the heat pump is a medium- and high- temperature heat pump and is driven by a power supply system; the multiple-effect evaporation system comprises a vertical heat exchanger, a multiple-effect separator, a multiple-effect evaporator, a condenser, a heat exchanger, a delivery pump and a vacuum pump; and the medium-and high- temperature heat pump is communicated with the vertical heat exchanger and the condenser by a process pipeline. According to the free energy heat pump multiple-effect evaporation device and the free energy heat pump multiple-effect evaporation process, the running of the heat pump is adopted, and a cold source and a heat source are utilized organically, so that the aim of energy conservation can be fulfilled in the first-effect or second-effect operating state, operating energy consumption is reduced, and the simplification of equipment and the reduction of fixed investments are facilitated; and the free energy heat pump multiple-effect evaporation device can operate under the condition of lack of steam, the number of laying of steam pipelines can be reduced, a circulating cooling water system can be eliminated, and the waste heat discharge is reduced.

Owner:KESHENG ENVIRONMENTAL PROTECTION TECH CO LTD

Warp-knitted base sun shading material and preparation method thereof

The invention relates to a warp-knitted base sun shading material and a preparation method thereof. The preparation method comprises the following steps of: (1) providing polyester warp-knitted base cloth; (2) coating PVC slurry on the polyester warp-knitted base cloth, and drying the polyester warp-knitted base cloth to obtain an intermediate material; and (3) coating surface treatment slurry to the surface of the intermediate material obtained in the step (2), and drying the intermediate material to obtain the finished sun shading material. The PVC slurry and the surface treatment slurry in the preparation method are special slurry of the invention. The sun shading material has high mechanical function, fireproof function, insulating performance, self-cleaning performance and weather resistance besides the functions of appearance, visual effect and the like of a common curtain material.

Owner:FOSHAN GAOMING YILONG PLASTICS & RUBBER IND

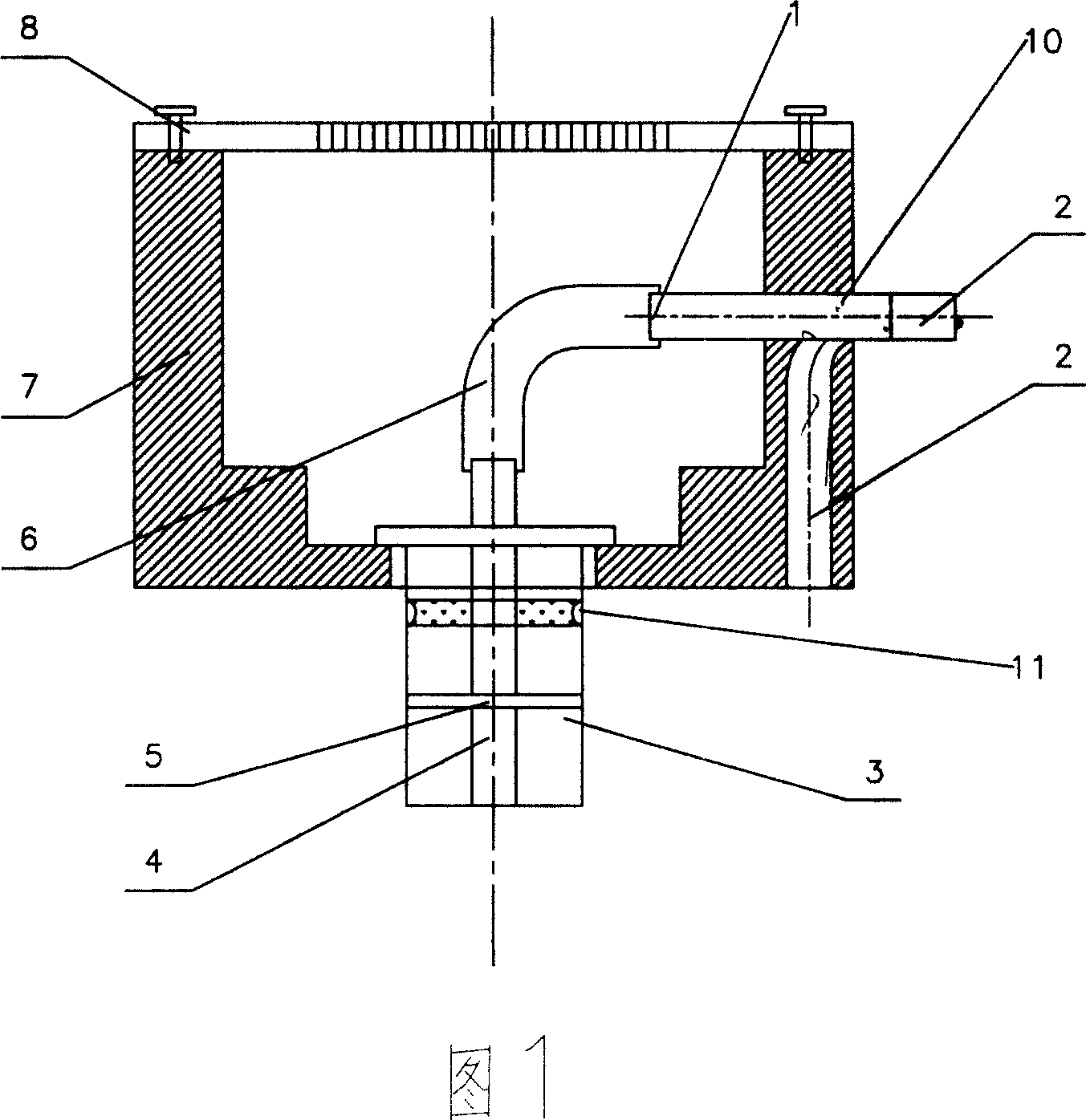

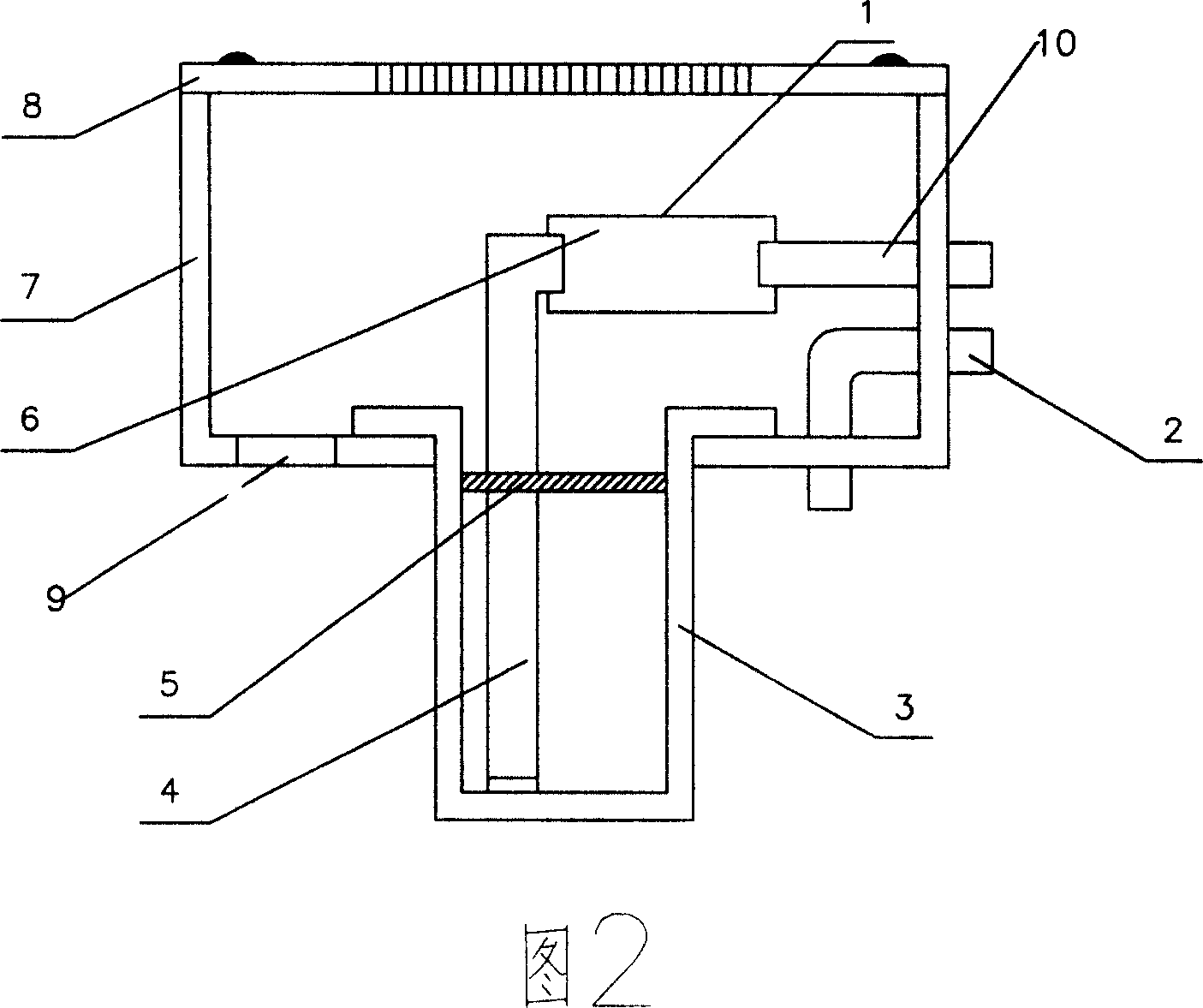

Floor drain having waste hot water rocovery mouthpiece

InactiveCN1948645AReduce heat pollutionSave energyOther heat production devicesDomestic plumbingSocial benefitsPlate heat exchanger

This invention discloses a floor drain with the waste water recycling interface. It mainly consists of the floor drain, the cover board, the waste heat water extraction path, the waste heat water transition cavity and the strainer. The waste water transition cavity is set in the bottom of the floor drain, the suction duct mouth waste heat water extraction path is set in the bottom of the waste heat water transition cavity which the water intake pipe is connected to the outside though the floor drain. The strainer is set on the waste water transition cavity, the cover board covers on the floor drain. The floor drain with the waste water recycling interface matched with the heat exchanger can use the heat energy in the waste heat water, so it can save energy for the family and decrease the heat pollution to the environment and has the good economic and social benefits.

Owner:HANGZHOU DIANZI UNIV

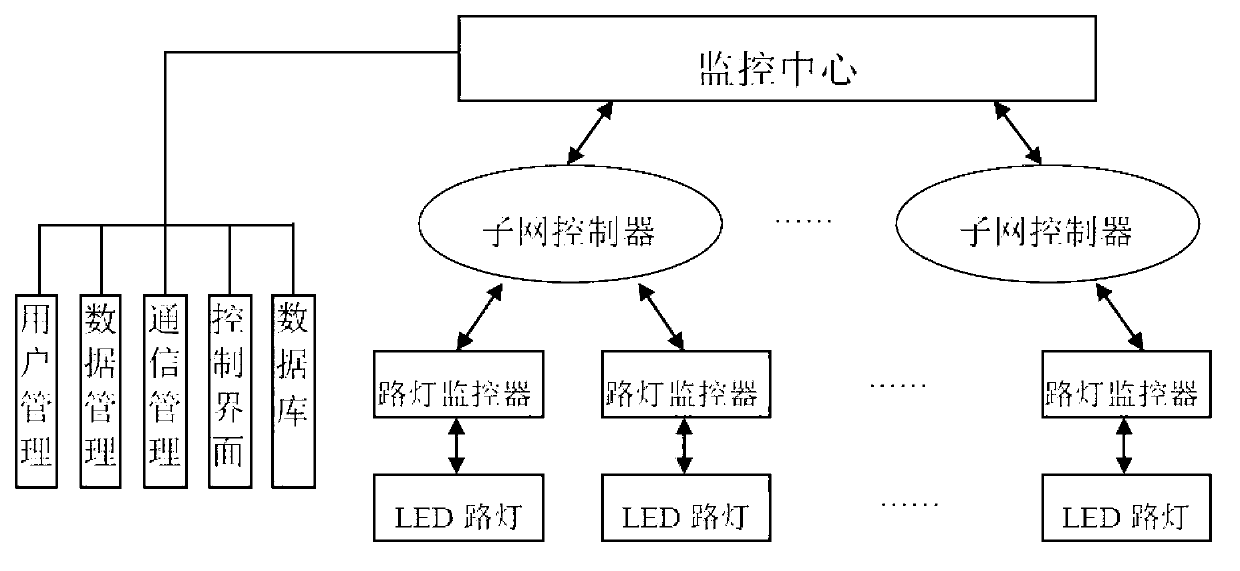

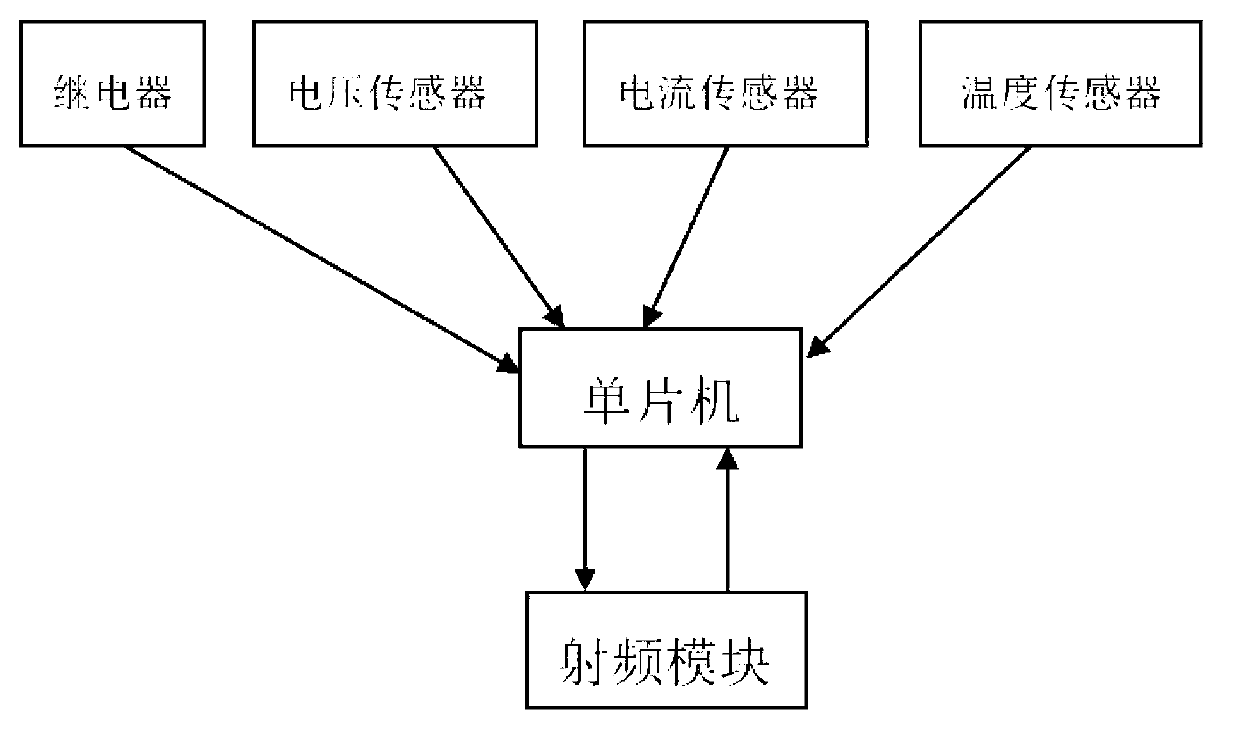

Light-emitting diode (LED) streetlight wireless energy-saving control system

InactiveCN103139984AImprove management efficiencyImprove troubleshooting efficiencyEnergy efficient ICTElectric light circuit arrangementEngineeringLight-emitting diode

The invention provides a light-emitting diode (LED) streetlight wireless energy-saving control system. The light-emitting diode streetlight wireless energy-saving control system comprises an LED streetlight monitor, subnet controllers and a monitoring center. The streetlight monitor is connected with an LED streetlight, a plurality of streetlight monitors keep in touch with corresponding subnet controllers through wireless protocol, and each subnet controller keeps in touch with the monitoring center through an intelligent network. The monitoring center comprises a data management module, a control panel module, a data base module, a user management module and a communication management module. The LED streetlight energy-saving control system based on a wireless sensing technology improves efficiency of streetlight management and efficiency of streetlight failure processing, reduces energy consumption of the streetlight, saves electric power, prolongs service life of an illuminating lamp, saves energy cost and illumination cost, simple to network, flexible to expand and high-efficient, convenient and fast to supervise.

Owner:WUXI ZHONGBO ELECTRONICS

Greenhouse animal breeding and plant cultivation method and device

InactiveCN104082070AEmission reductionImprove growth qualityManure treatmentMethane captureZoologyAnimal waste

The invention relates to a greenhouse animal breeding and plant cultivation method and device. Plants are planted in the middle of a greenhouse, animals are bred on the upper portion and the lower portion of the greenhouse, carbon dioxide produced by the animals are absorbed by the plants, animal waste on the upper portion and on the lower portion and plant waste in the middle are collected and thoroughly decomposed to be efficiently transformed to organic fertilizer and biogas fuel, organic fertilizer can be applied to the plants, and biogas and solar combined power generation is used for warming of the greenhouse, electrical appliance auxiliary device power supply and lighting power supply. According to the device, a breeding pen cage is arranged on a top layer slide way of a slide way type movable breeding and movable planting device, pen cage sliding wheels are installed on the breeding pen cage, and a movable excrement receiving disk is arranged below the breeding pen cage and connected with a dirt discharge pipe; a movable planting bed with sliding wheels is arranged on a middle slide way; a bottom layer breeding pen is arranged below a bottom layer slide way; a planting bed is arranged in an outer protection and light collection cover and can move out of the outer protection cover to collect light. According to the greenhouse animal breeding and plant cultivation method and device, a multi-layer three-dimensional breeding and multi-layer three-dimensional planting structure is adopted, the breeding area and the planting area are greatly increased, income is large, and the rate of multipurpose utilization of land is fully increased.

Owner:骆常青 +1

Building internal thermal energy circulation utilizing system integrated energy-saving device

InactiveCN101067528AReduce evaporated waterLow costHeat pumpsDomestic hot-water supply systemEngineeringEnergy conservation

The invention discloses an integration energy conservation installment of building internal heat energy circulation use system, including frequency conversion velocity modulation intelligence control device, central air-conditioning system equipment, disc heat interchanger and heat pump unit, among: after parallel connected with the one side feed-water end of the heat pump unit (12), the disc heat interchanger (26) one side feed-water end through the one feed-water motorized valve (15) of the heat pump unit (12) connects the cooling water discharging piping(38), after parallel connected with the one side water exit end of the heat pump unit (12), the disc heat interchanger (26) one side water exit end through the one water exit motorized valve (13) of the heat pump unit (12) connects the cooling water feed-water piping(37); the input end of the frequency conversion velocity modulation intelligence control device connects the related sensor of the air conditioning main engine(2), the output end connects the related working pump and the stand-by pump of the air conditioning main engine(2). The invention can raises the lower order heat energy of building internal cooling water, center water, fire control water to the higher order heat energy, shifts and uses this kind of heat energy, directly prepared the hygienic hot water which is used for the user.

Owner:贵州华城楼宇科技有限公司

Automatic cable deicing device based on cam transmission principle

ActiveCN111628467AProtection securityImprove cleanlinessOverhead installationBatteries circuit arrangementsGear wheelEngineering

The invention relates to the technical field of cables, and further discloses an automatic cable deicing device based on the cam transmission principle. The device comprises a frame, the top of the frame is fixedly connected with a solar panel, and a main gear is movably connected in the frame. The outer portion of the main gear is connected with a connecting gear in an engaged manner, the outer portion of the connecting gear is fixedly connected with a convex block, and the outer portion of the convex block is movably connected with a driving lever. The outer portion of the driving lever is fixedly connected with a tension spring, the outer portion of the driving lever is fixedly connected with a concave hammer, and the inner portion of the frame is movably connected with a power wheel. Through the cooperative use of the main gear, the connecting gear, the convex block, the driving lever, the tension spring and the concave hammer, the effect of hammering the cable is achieved, and theice on the surface of the cable falls off, so that the cleanness of the surface of the cable is ensured, pole falling caused by the overweight of the cable is avoided, and the safety of a circuit iseffectively protected. Moreover, according to the automatic cable deicing device, the operation is simple, the energy effect is less, and the energy cost is effectively saved.

Owner:台州壹品工业设计有限公司

Sintering-free ceramic body material and preparation method thereof

InactiveCN104261791AShorten the production cycleRealize large-scale industrial productionSolid waste managementSlagSodium silicate

The invention discloses a sintering-free ceramic body material and a preparation method thereof. The ceramic body material is prepared from metakaolin or blast furnace slag, sodium silicate and water, wherein a weight ratio of the metakaolin or blast furnace slag to sodium silicate is (1-1.5):1, and the addition amount of water accounts for 10-20 percent of the total weight of the metakaolin or blast furnace slag and the sodium silicate. The sintering-free ceramic body material disclosed by the invention has the innovative characteristics that the green body is sintering-free, a low-temperature fired glaze at the temperature of about 600-800 DEG C can be applied to the surface and the production period is short. Meanwhile, the conventional universal green body paste of the traditional high-temperature ceramics can be replaced, large-scale industrial production is realized, millions of energy cost even more money can be saved for ceramic enterprises, and the ceramic body material has high significance for protecting the environmental resources.

Owner:ZHONGLI CERAMICS

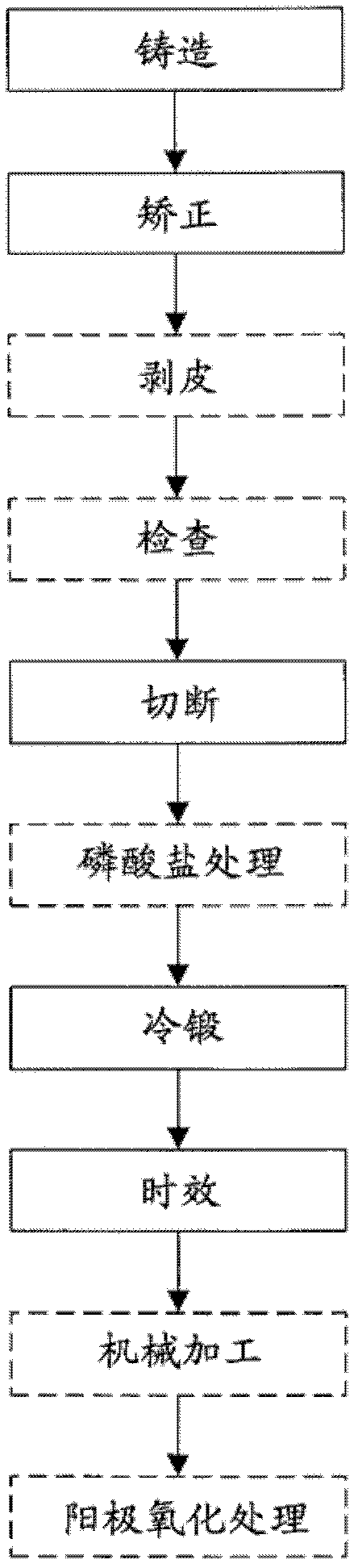

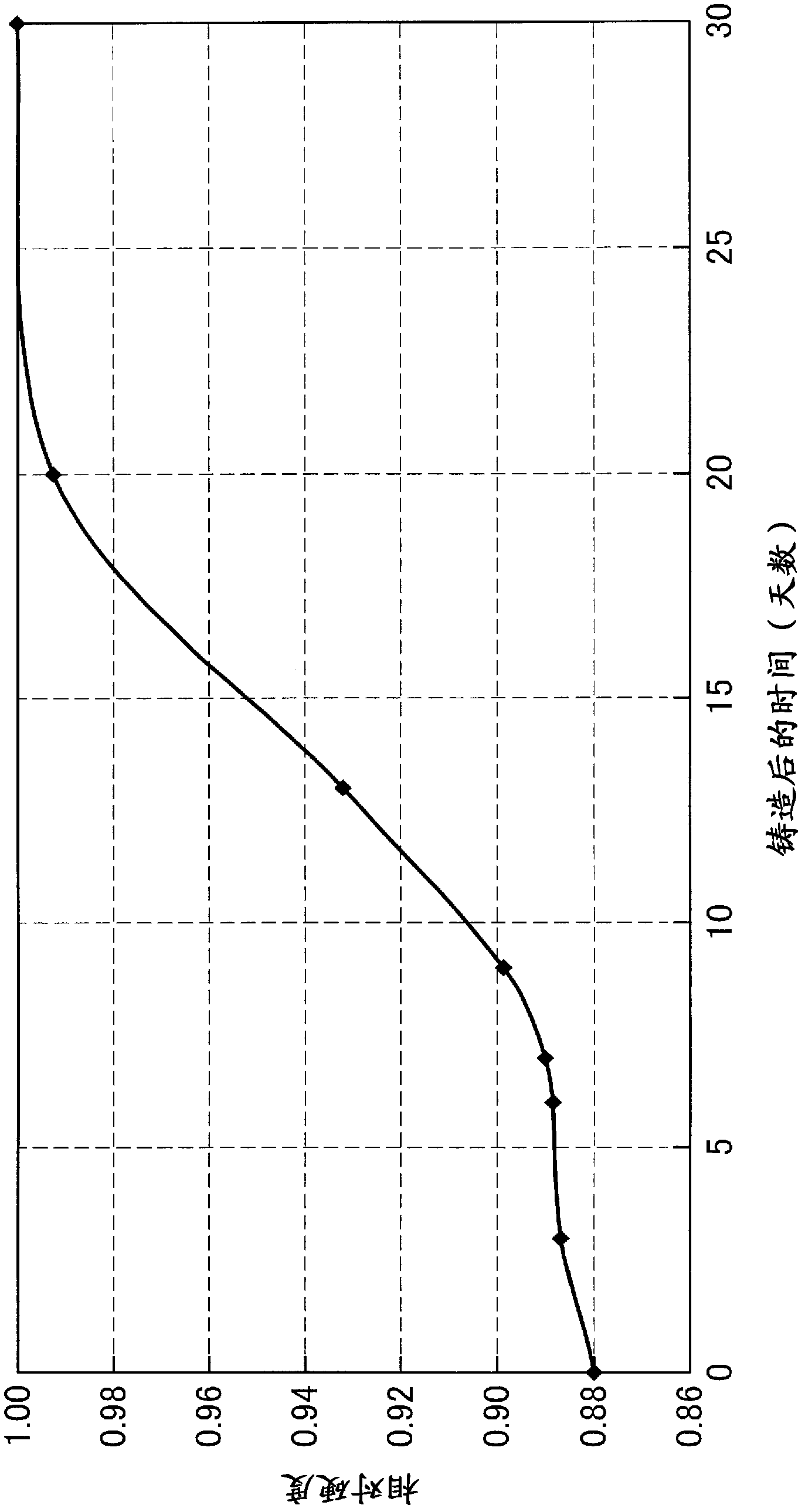

Process for producing brake piston

InactiveCN102686763AReduce wasteReduce hardnessMetal-working apparatusFurnace typesReduction rateIngot

A brake piston having required mechanical strength is produced through fewer steps than in conventional processes. An aluminum alloy containing Si and Mg, wherein the aluminum alloy has a Si concentration (CSi mass%) and a Mg concentration (CMg mass%) falling within a range surrounded by four points A (0.75, 1.25), B (1.4, 1), C (1.4, 0.6), and D (0.75, 0.85) in terms of a relationship thereof (CSi , CMg ), and further has a Cu concentration of 0.07 to 0.9 mass%, a Mn concentration of 0.1 to 0.9 mass%, a Ti concentration of 0.005 to 0.15 mass%, a Cr concentration of 0.2 mass% or less, and a Fe concentration of 0.5 mass%, the balance being Al and inevitable impurities is cast to obtain a rod-shaped ingot. The rod-shaped ingot, without being subjected to a homogenization treatment, is straightened within 3 (three) days after the casting. The straightened rod-shaped ingot is cut into a given thickness to obtain a forging raw material. This forging raw material, without being subjected to annealing, is cold-forged at a reduction rate of 25 to 90% within 7 (seven) days after the casting of the rod-shaped ingot into a cup shape, which is subjected to age-hardening without being subjected to a solution heat treatment.

Owner:SHOWA DENKO KK

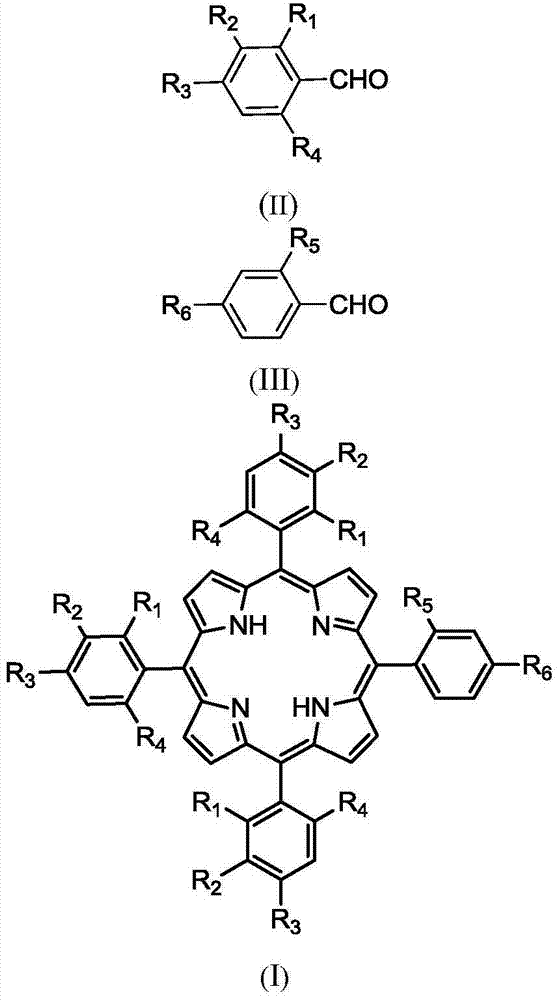

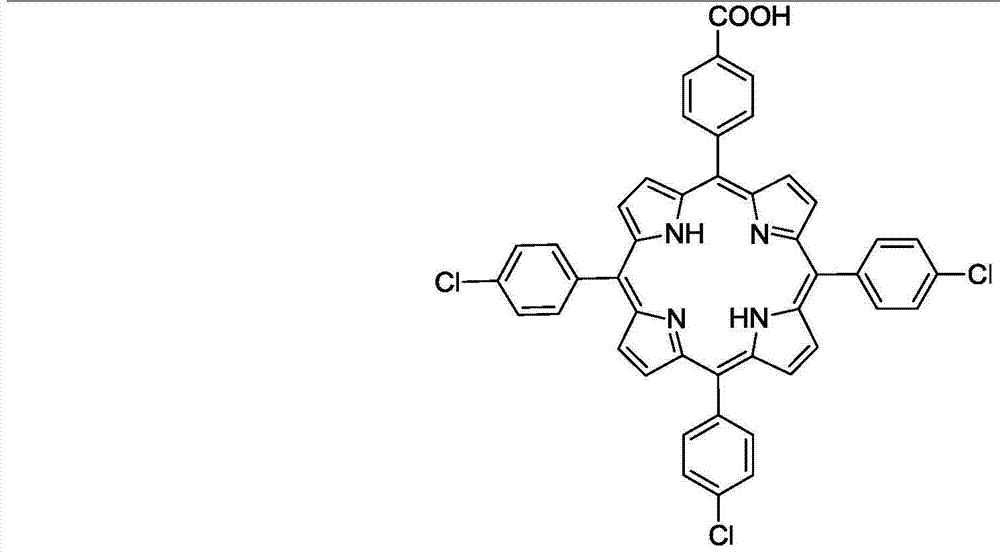

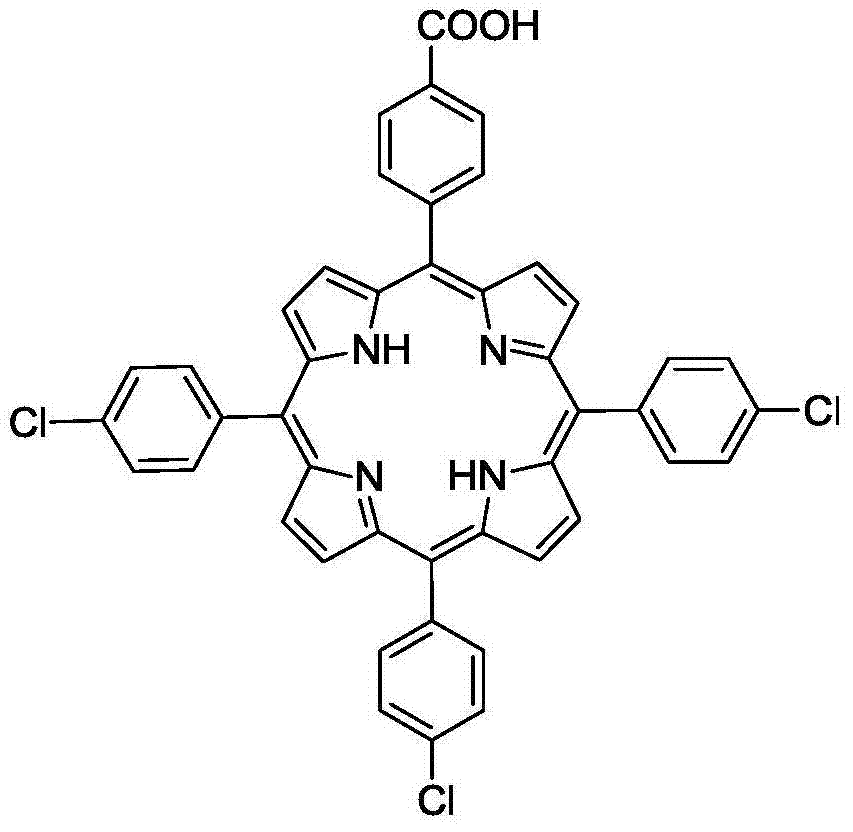

Preparation method of A3B type asymmetric porphyrin compounds

InactiveCN103694246AShort reaction timeSave on energy billsOrganic chemistrySynthesis methodsPorphyrin

The invention relates to a preparation method of A3B type asymmetric porphyrin compounds, which comprises the steps of mixing aldehyde A and pyrrole, adding into a solution containing C2-8 straight-chain fatty acid, xylene and water removal agent, reacting at 120-140 DEG C for 1-5 minutes, simultaneously adding aldehyde A and aldehyde B, and further reacting for 0.5-2 hours, thus obtaining the A3B type asymmetric porphyrin compounds. The yield of the method is 10-20%. According to the method, a small amount of trifluoroacetic acid and water removal agent are added, so that the reaction time is shortened, the preparation steps are simplified, the yield of an intermediate compound dipyrrolidine is increased, and the damage of the generated moisture to the intermediate compound is reduced, thereby increasing the product yield and further simplifying the separation and purification steps. Besides, low-toxicity xylene is used instead of nitrobenzene with high toxicity, thus reducing the environmental pollution. The method provided by the invention effectively utilizes the resources, reduces the environmental pollution and realizes energy saving and emission reduction in a true sense. Thus, compared with the existing synthesis method, the method provided by the invention has wider industrial application prospects.

Owner:BEIJING UNIV OF TECH

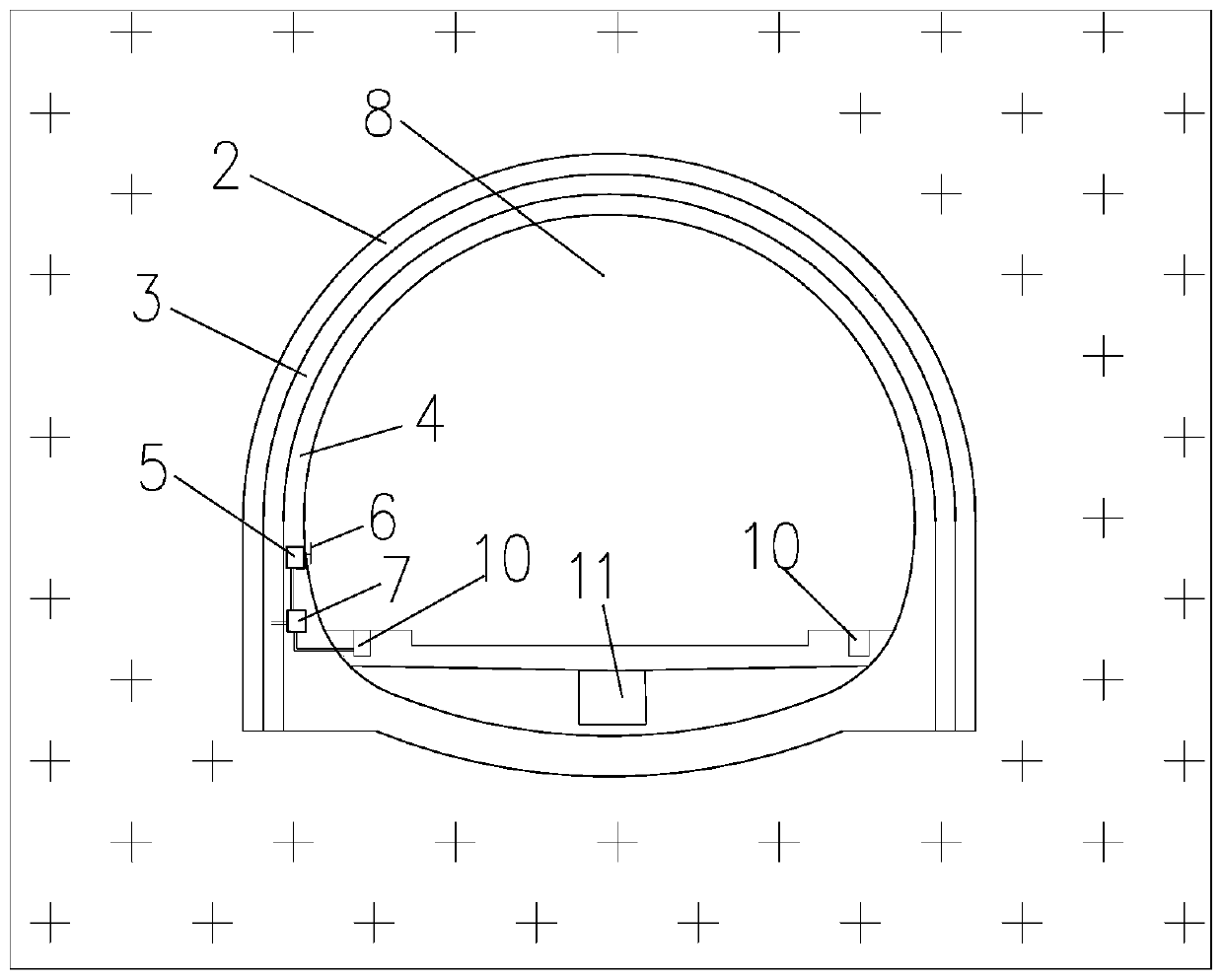

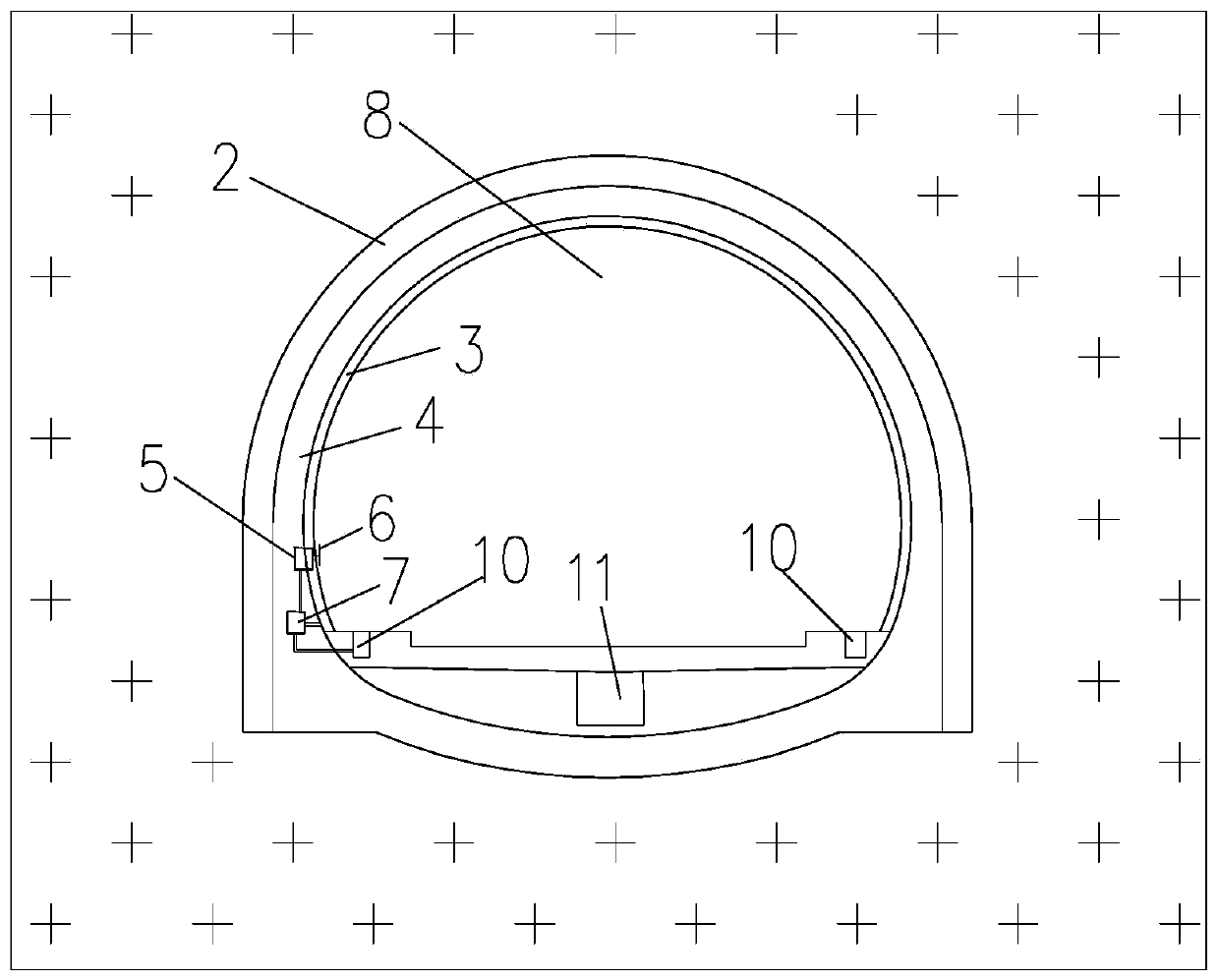

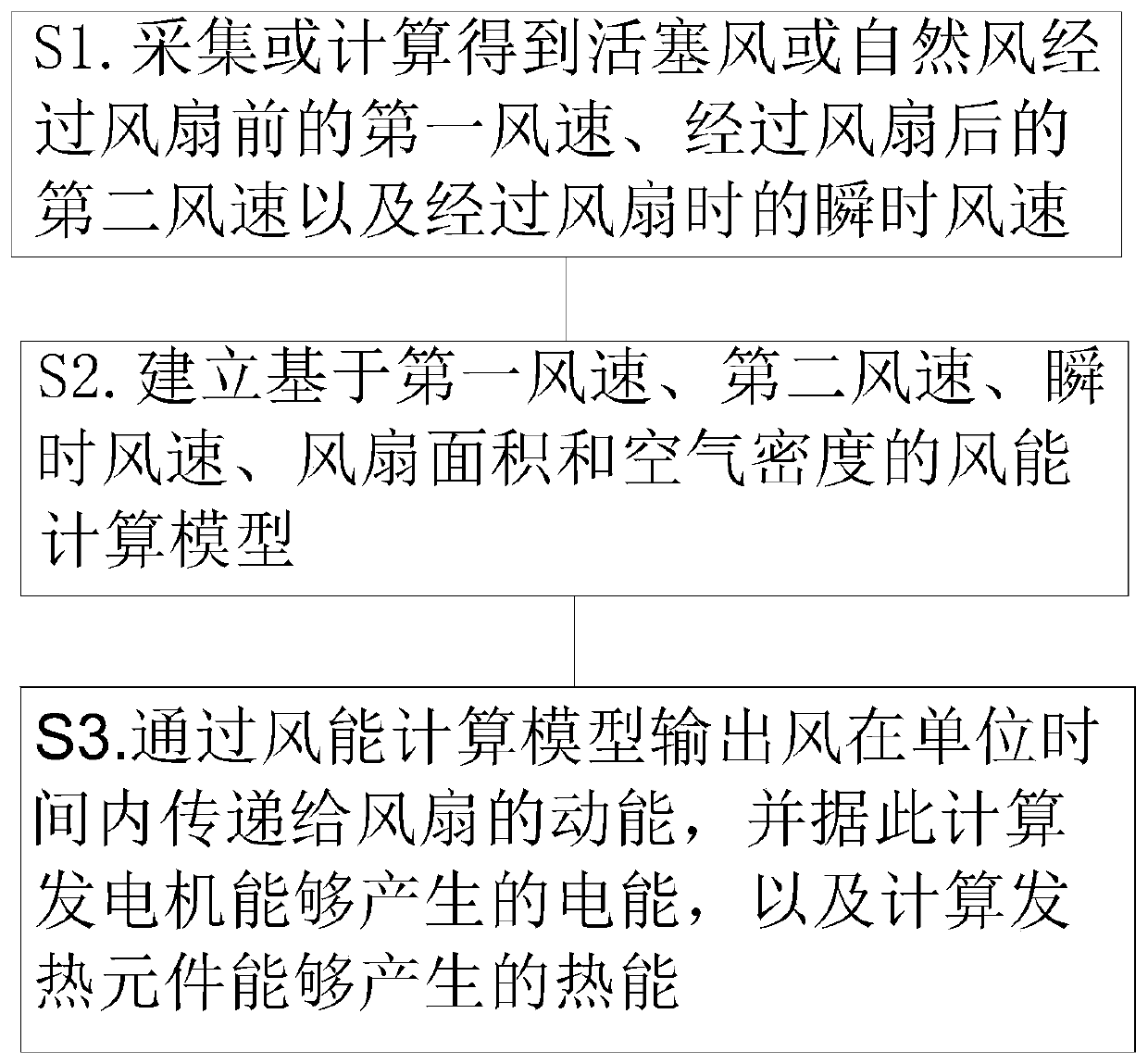

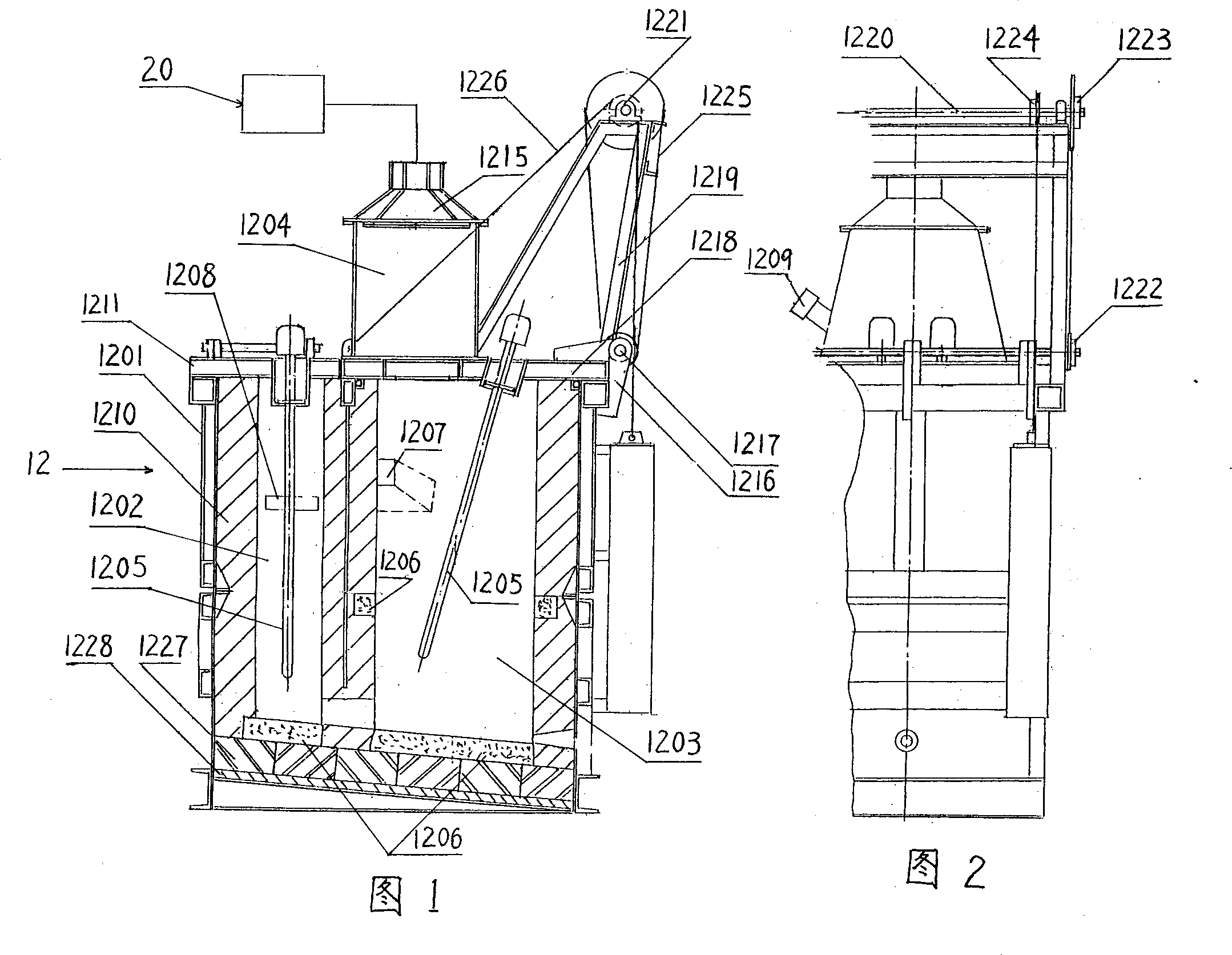

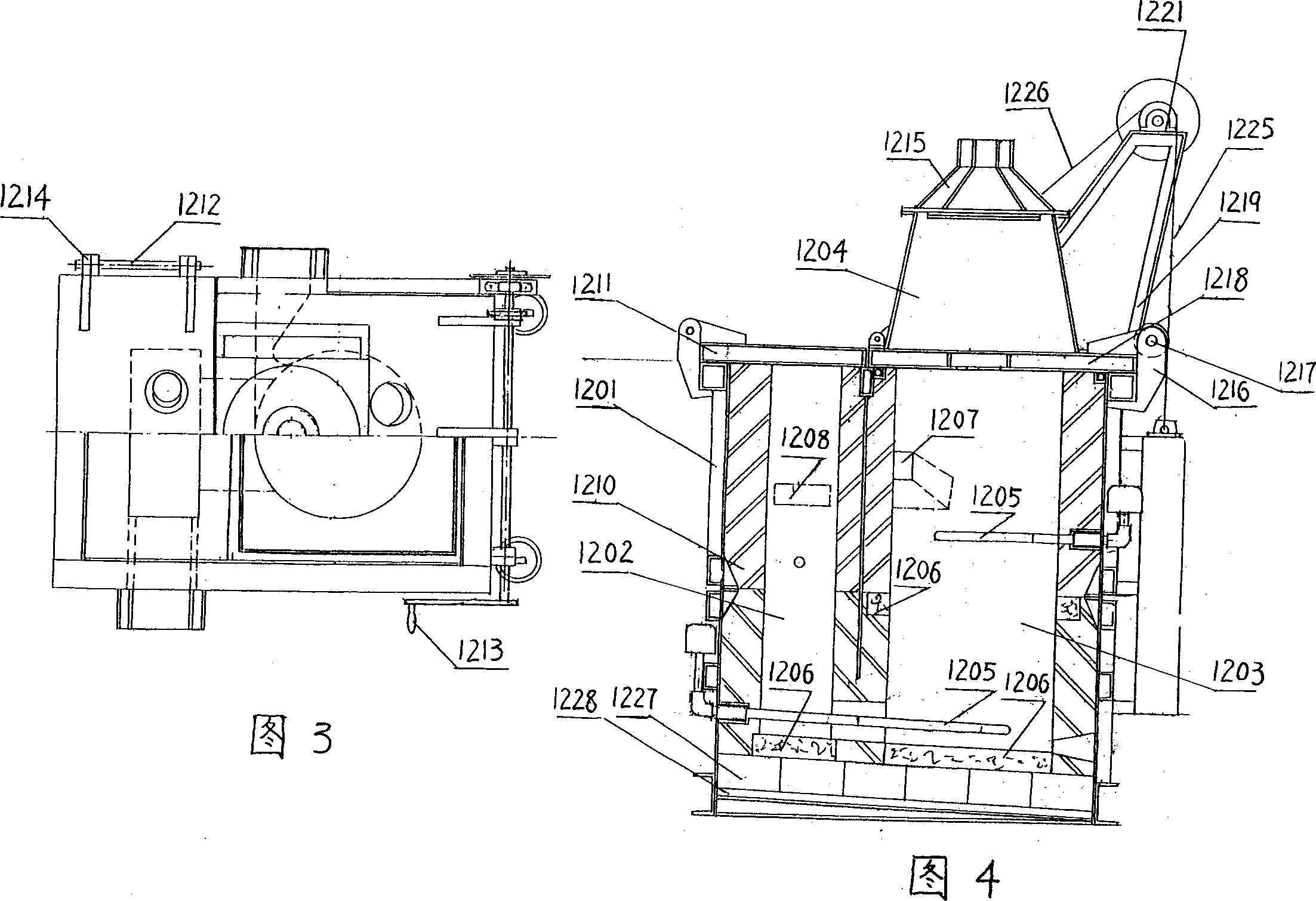

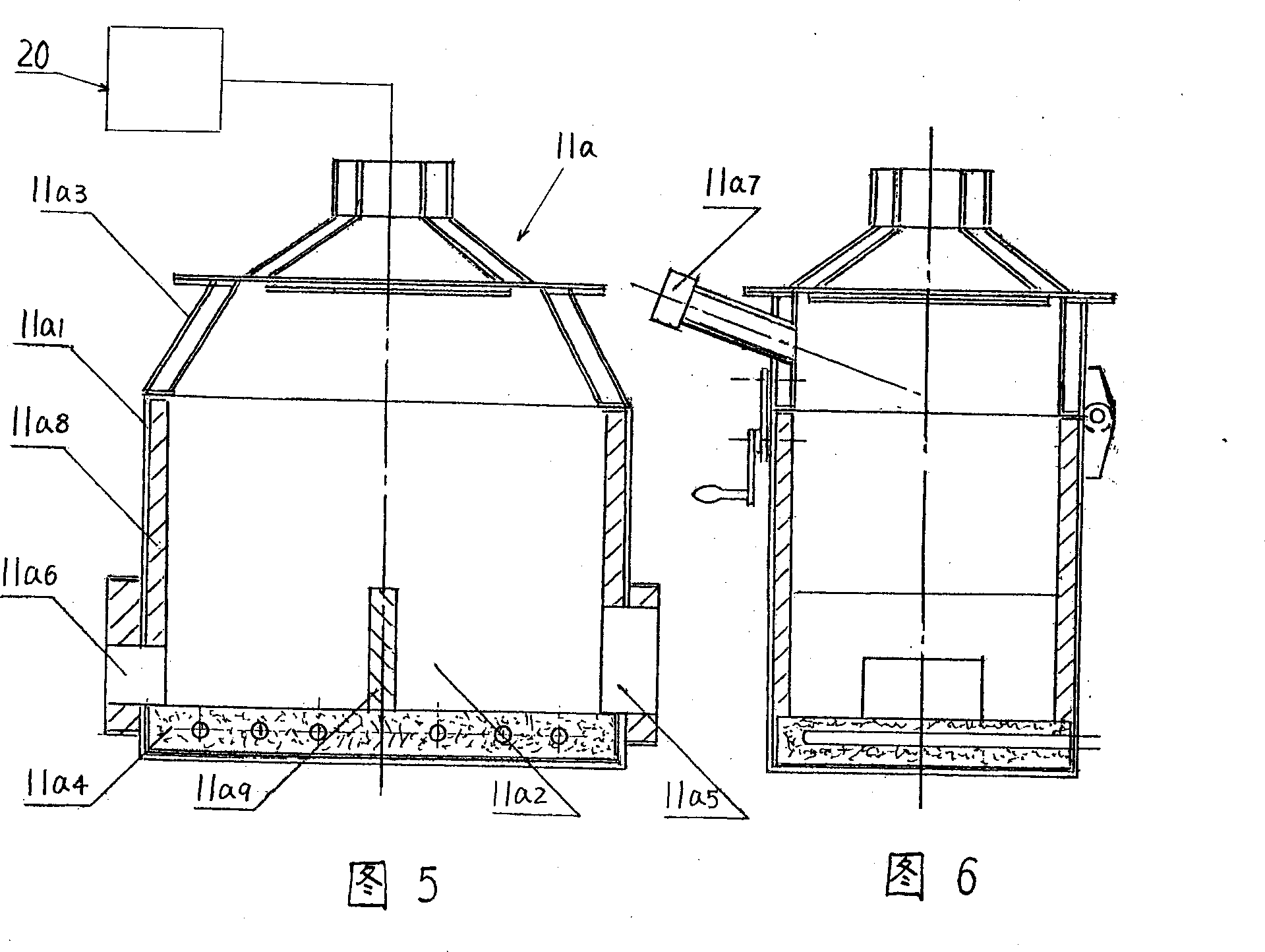

Tunnel cold-proof and freezing-proof system in alpine regions

InactiveCN111365040APrevent frostbiteNo pollution in the processUnderground chambersWind energy with electric storageTunnel engineeringElectric heating

The invention relates to the field of tunnel engineering, in particular to a tunnel cold-proof and freezing-proof system in alpine regions. The tunnel cold-proof and freezing-proof system comprises afan, a generator, a freezing-proof layer and an electric heating element, wherein the fan is arranged in a tunnel; the generator is connected with the fan; the freezing-proof layer is arranged betweena primary support and a secondary lining of the tunnel or arranged on the side, close to the center of the tunnel, of the secondary lining; and the electric heating element is electrically connectedwith the generator, and the electric heating element is arranged in a drainage system and / or the freezing-proof layer of the tunnel. The tunnel cold-proof and freezing-proof method and the heat energycalculation method are based on the system. According to the tunnel cold-proof and freezing-proof system, clean energy wind energy generated in the tunnel is utilized, extra manual energy applicationis not needed, freezing damage is avoided, and meanwhile the beneficial effects of being capable of saving energy, free of pollution and high in working frequency are achieved.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Method for cleaning molten non-ferrous metal and its equipment

The present invention relates to a method for purifying molten non-ferrous metal liquid and its equipment. Its method includes adsorptive purification by using purification gas and making it pass through molten non-ferrous metal liquid. The invention is characterized by that at the same time of making adsorptive purification by using gas, the evacuation is made over the molten non-ferrous metal liquid so as to form negative pressure to suck the molten liquid. Its equipment is formed from non-ferrous metal purification device and evacuation device that is connected with the space over the molten liquid in the purification device. Said purification device can be in monochamber structure, several chamber structure and chamber-free structure. Said method is high in efficiency, low in energy consumption and can save energy.

Owner:黄德盛

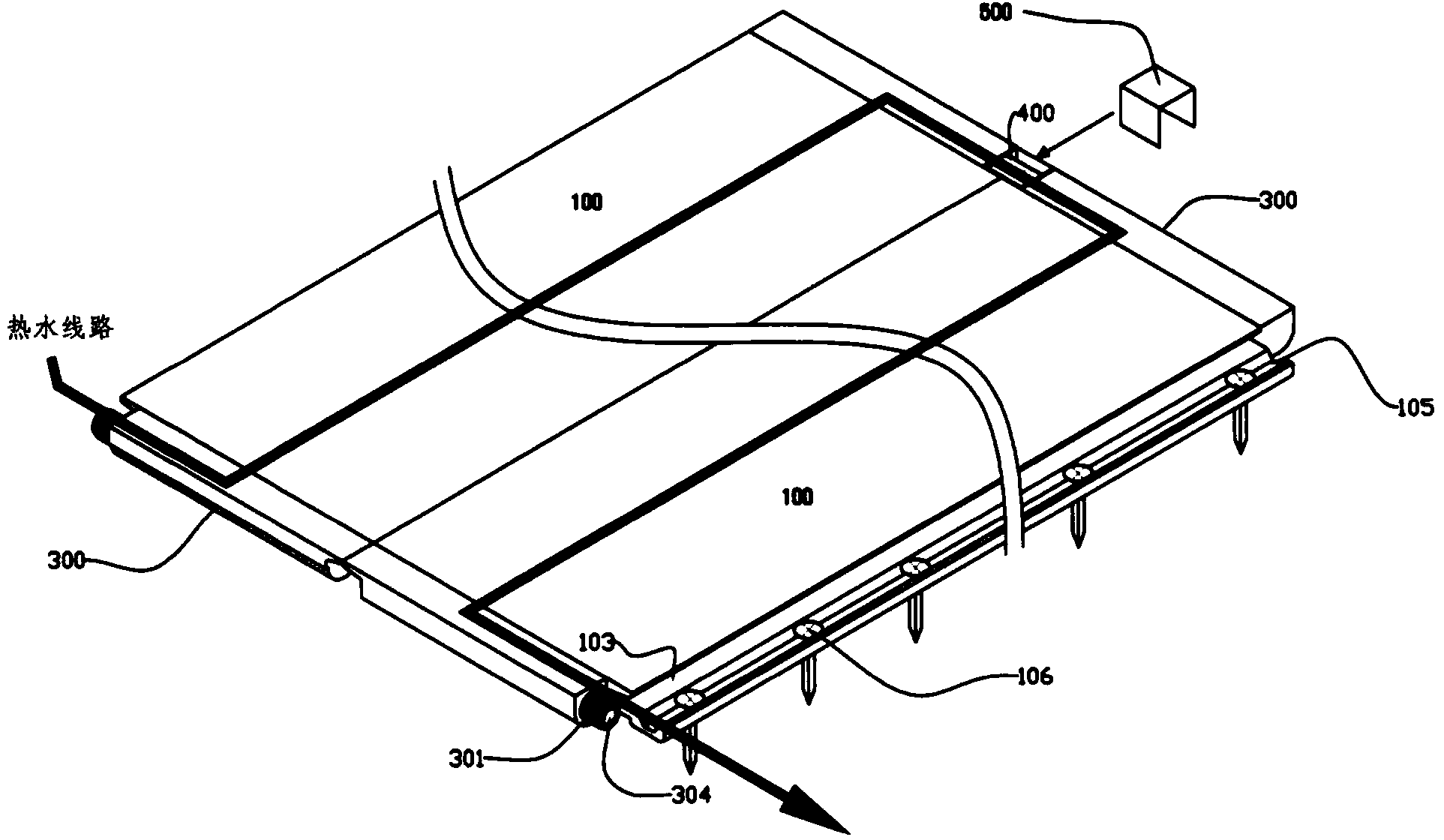

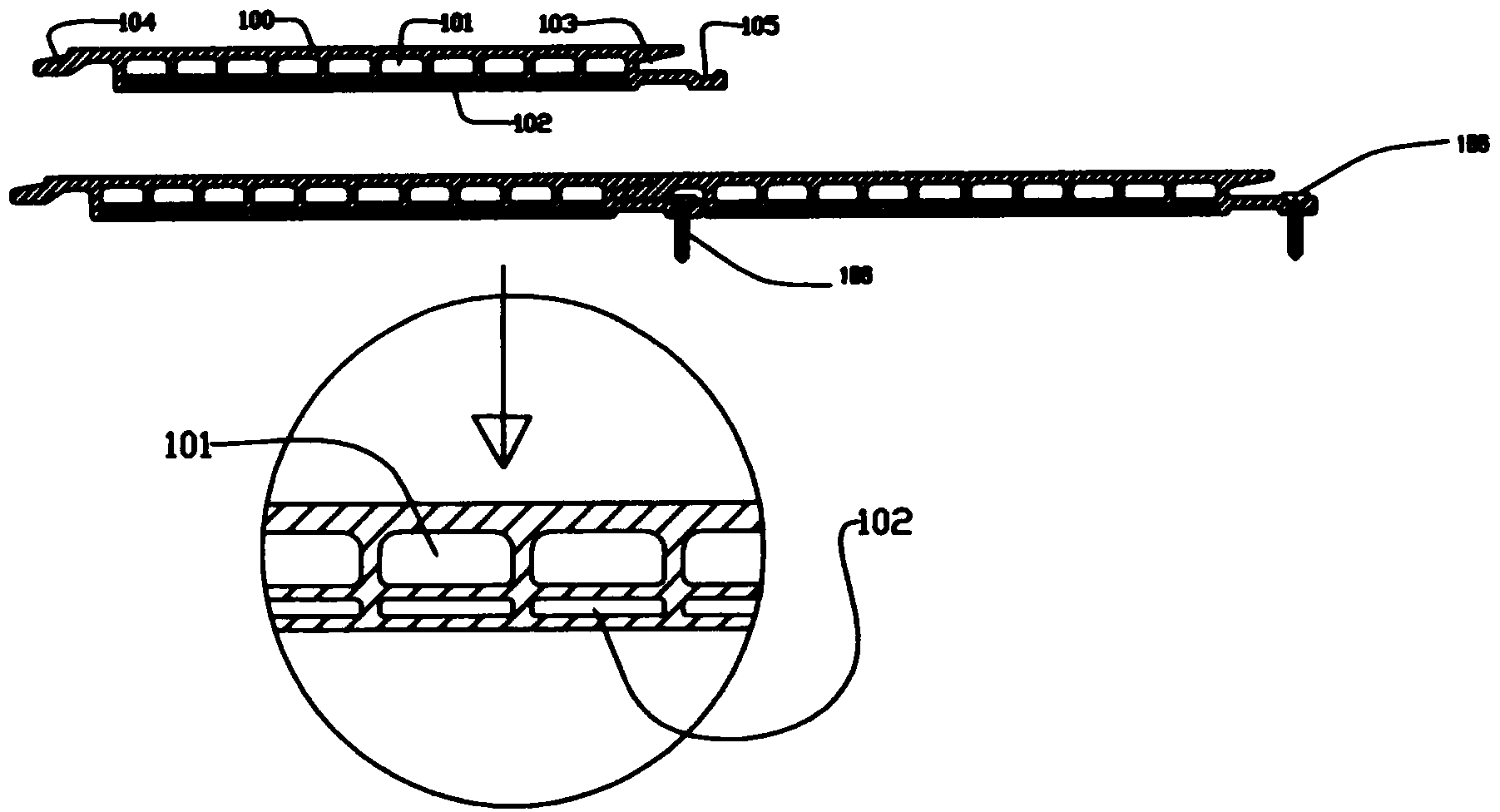

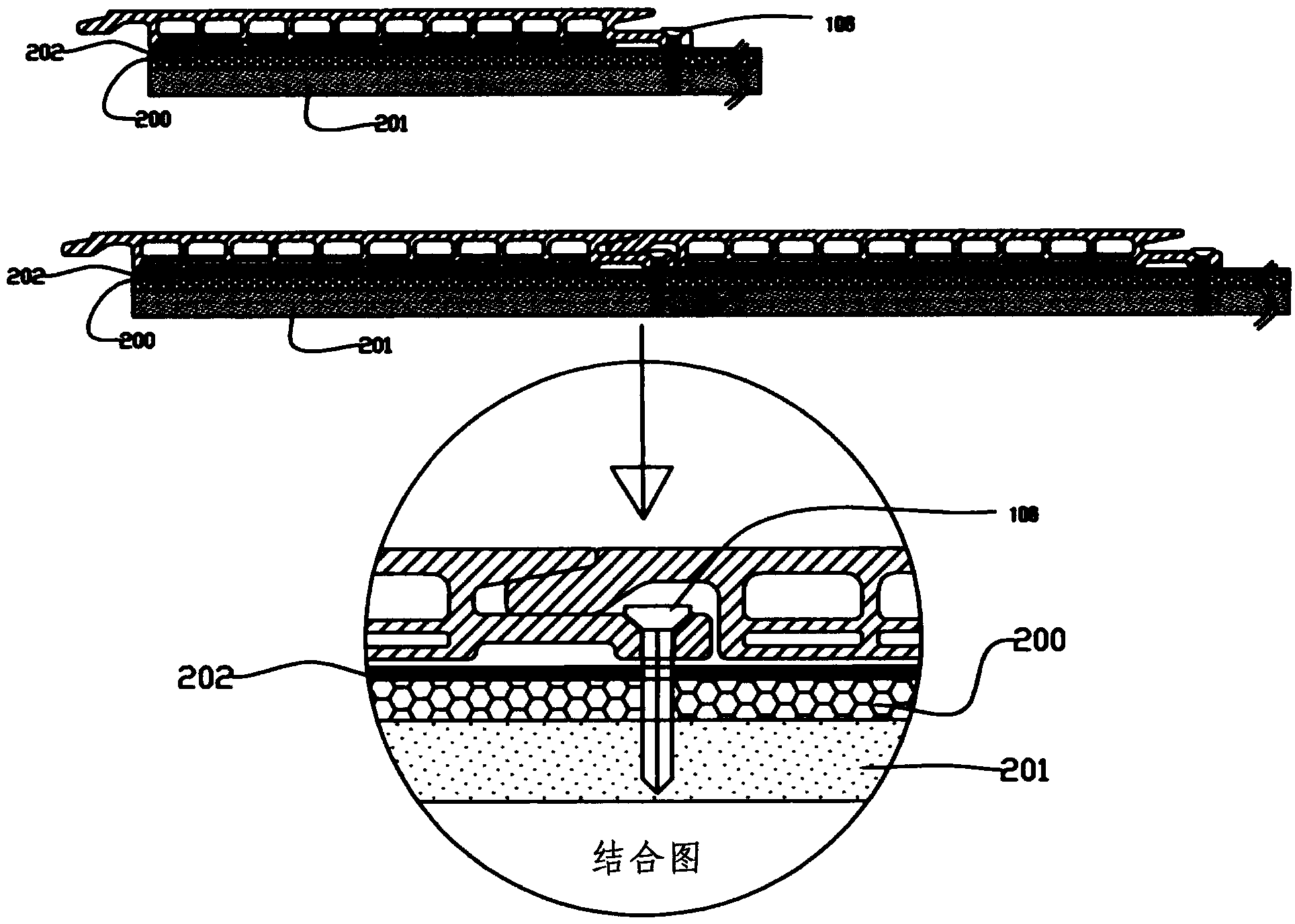

Air pocket-type hot-water flooring panel

InactiveCN103492811AThermal insulationReduce interlayer noiseHot-air central heatingLighting and heating apparatusCouplingUnderfloor heating

The present invention relates to a flooring material for a Korean underfloor heating system, and more particularly, to a flooring panel consisting of an extruded resin plate. A plurality of passages and air pockets are integrally formed in a lattice shape in the flooring panel, and hot water is caused to flow through passage joints so as to effectively perform cooling and heating. By forming air pockets, heat-insulation effects can be achieved, and noise between the floors of a building, which causes problems between the floors of a building, can also be reduced. The passage joints are formed into two different types, and screw threads are formed opposite one another, so as to enable two sheets of panels to be coupled together or separated using one nut, thereby minimizing the risk of leakage. A concavo-convex coupling structure is formed for coupling one panel to another, and a drill bit groove is formed in a recessed surface so as to enable the panel to be fixed to a plywood board thereunder using a drill bit, such that assembly and construction can be simply and quickly carried out, thereby significantly reducing costs.

Owner:朴相彦

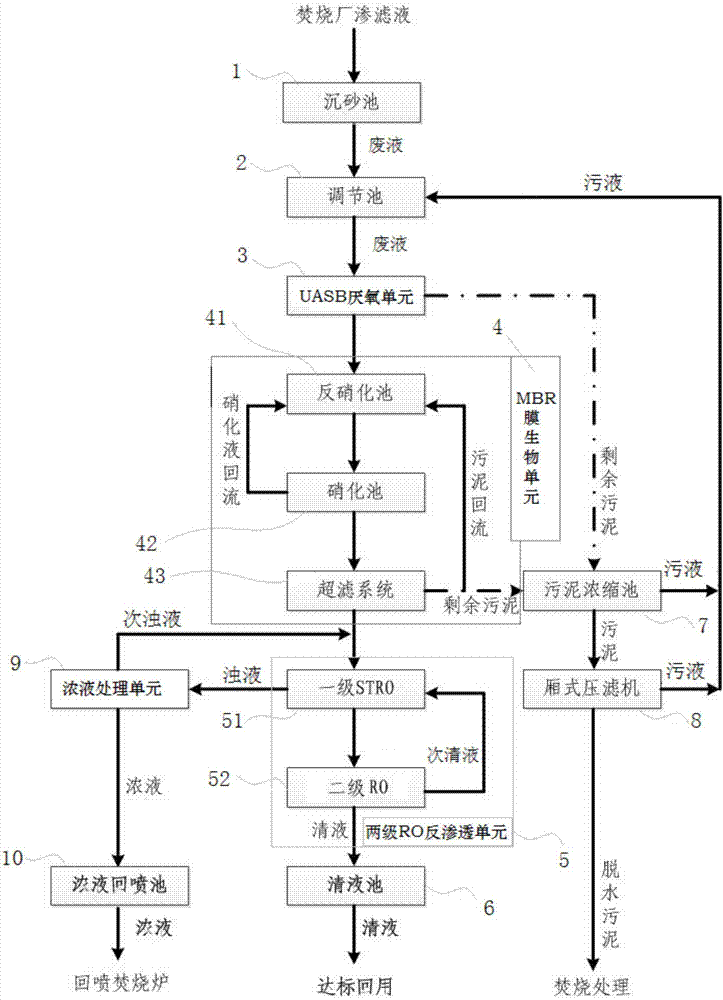

Zero discharging system and method for landfill leachate

InactiveCN108002646AIncrease water production rateAchieving Zero Emissions GoalMultistage water/sewage treatmentTreatment involving sedimentationBiological unitReverse osmosis

The invention discloses a zero discharging system and method for landfill leachate, and belongs to the field of wastewater treatment. The system is provided with a settling tank, an adjustment basin,a UASB (upflow anaerobic sludge blanket) anaerobic unit, an MBR (membrane bioreactor) membrane biological unit, a two-stage RO (reverse osmosis) unit and a clear liquid basin in sequence according toa zero discharging treatment sequence of the landfill leachate. The settling tank is connected with the leachate of an incineration plant, and is used for performing solid-liquid separation on the landfill leachate; the adjustment basin is used for homogenizing separated waste liquid; the UASB anaerobic unit is used for performing an anaerobic reaction on the homogenized waste liquid; the MBR membrane biological unit is used for performing a membrane biological reaction on the waste liquid subjected to the anaerobic reaction; and clear liquid filtered by the two-stage RO unit enters the clearliquid basin for storage for repeated use again. The zero discharging system disclosed by the invention is high in water yield and low in concentrated liquid yield, has a strict requirement on an effluent index, and cannot be affected by received water body; by reuse of the clear liquid, a large amount of energy is saved; and the operation is stable, and the environmental friendliness risk for leachate treatment is reduced.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

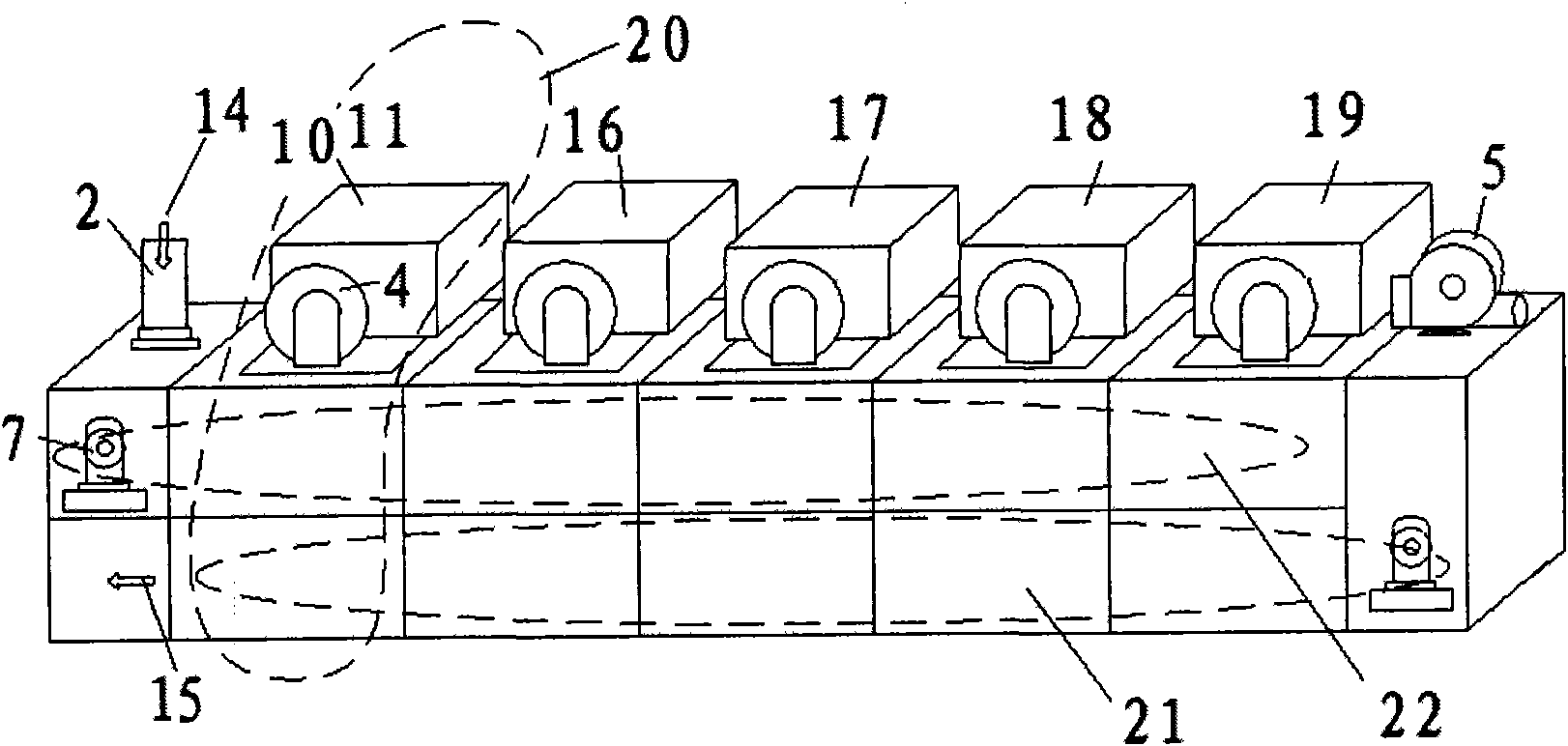

Molybdenum wire production continuous rolling and continuous forging cogging equipment and production method thereof

InactiveCN102615510AAvoid adding ancillary projectsLess investmentOther manufacturing equipments/toolsAutomatic controlWorking environment

The invention relates to molybdenum wire production continuous rolling and continuous forging cogging equipment, which comprises a heating furnace, a rolling machine, a first rotary forcing unit, a butt-welding machine and a second rotary forging unit arranged in sequence. The invention further relates to a method for producing a molybdenum wire with the equipment. By adopting a continuous rolling and continuous forcing process in which the advantages of cogging of the rolling machine and a plurality of rotary fogging machines are combined, the investment cost is greatly reduced, production efficiency is increased, consumption is lowered, and yield is increased. Meanwhile, the automatic control degree is high, noise is small, a good dust collecting effect is achieved, working environment conditions can meet relevant industrial sanitation and environment requirement standards, and the product quality can reach the world advanced level.

Owner:ZIGONG CEMENTED CARBIDE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com