Air pocket-type hot-water flooring panel

A floor and air bag technology, used in hot water central heating systems, household heating, heating methods, etc., can solve the problems of complex construction process, reduced thermal efficiency, long time required, etc., to achieve convenient construction and reduce interlayer noise. , the effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail with reference to the drawings.

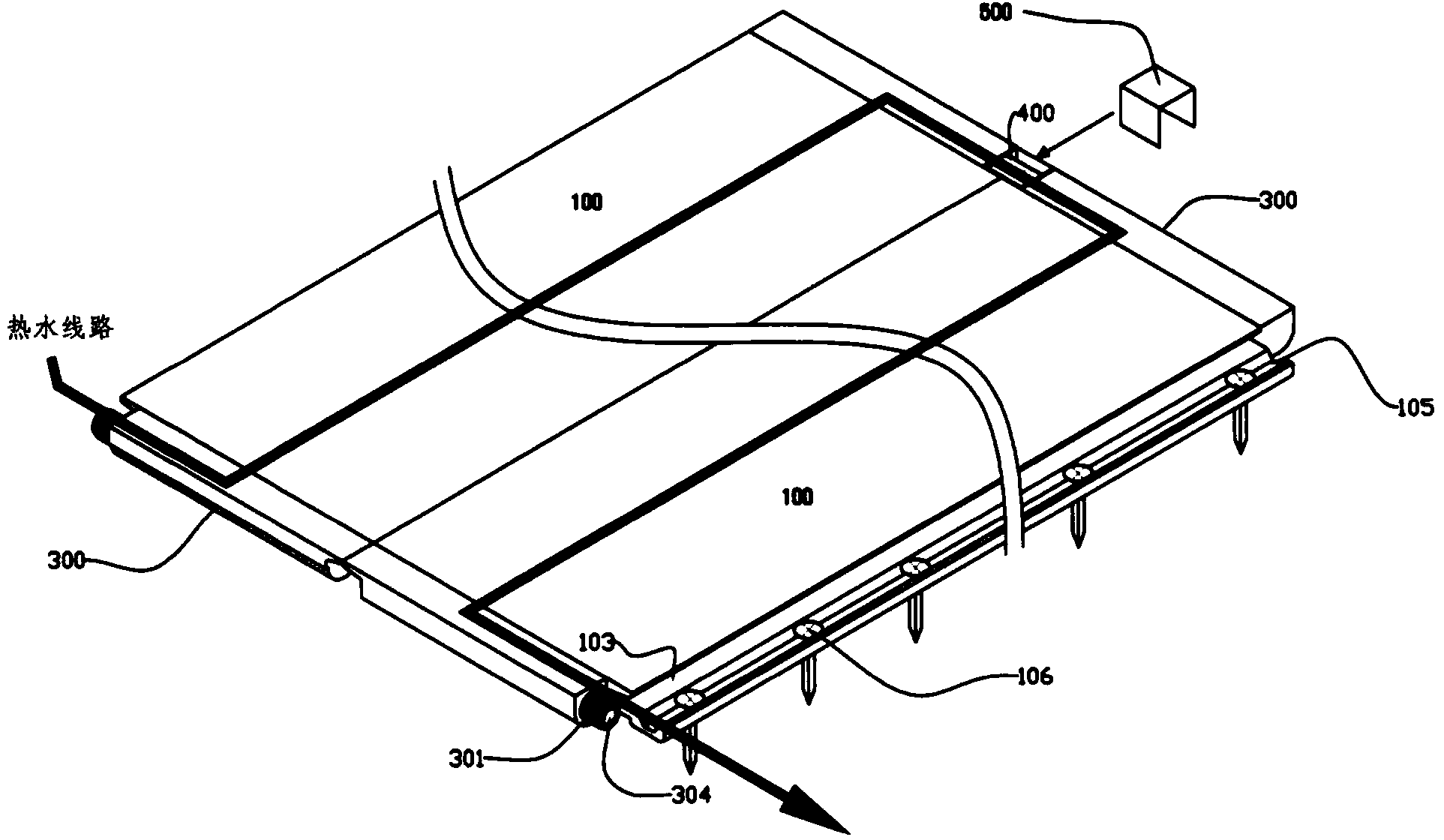

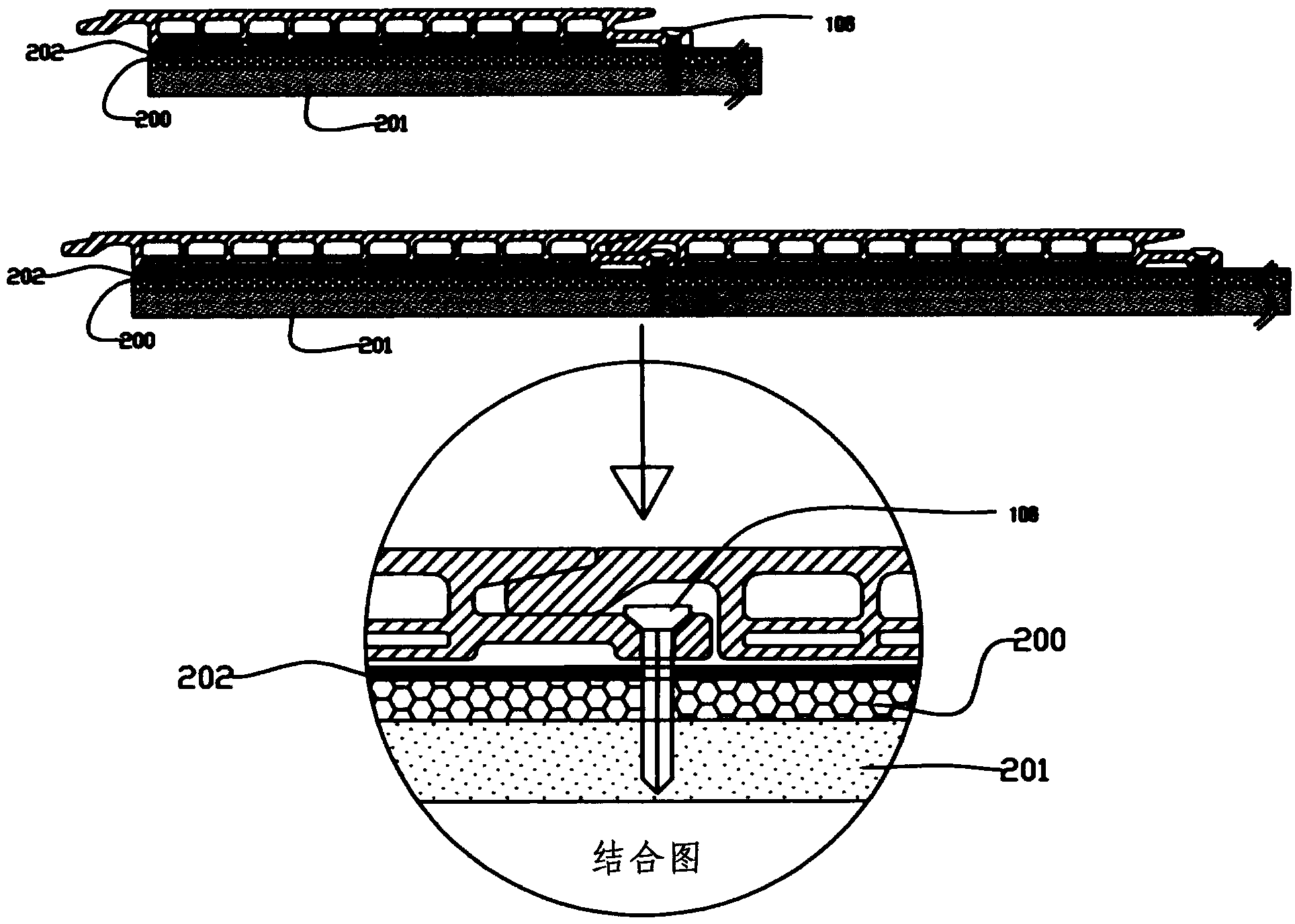

[0027] figure 1 It shows the structure of bonding the fluid path connector 300 on the floor 100, the fluid path connector 300 connected to the next board through a nut 400 and the structure of fixing the joint part 103 to the bottom through the drill block 106 A drawing of the construction of the plywood 200 .

[0028] Block grooves 105 for drilling are formed in the joint portion 103 of the floor 100, and can be fixed to the plywood 200 under the floor at predetermined intervals by drill blocks 106.

[0029] The nut 400 connected with two flow path connectors 300 is covered with The surface treatment material 500 of the plastic or metal plate of the shape is surface treated.

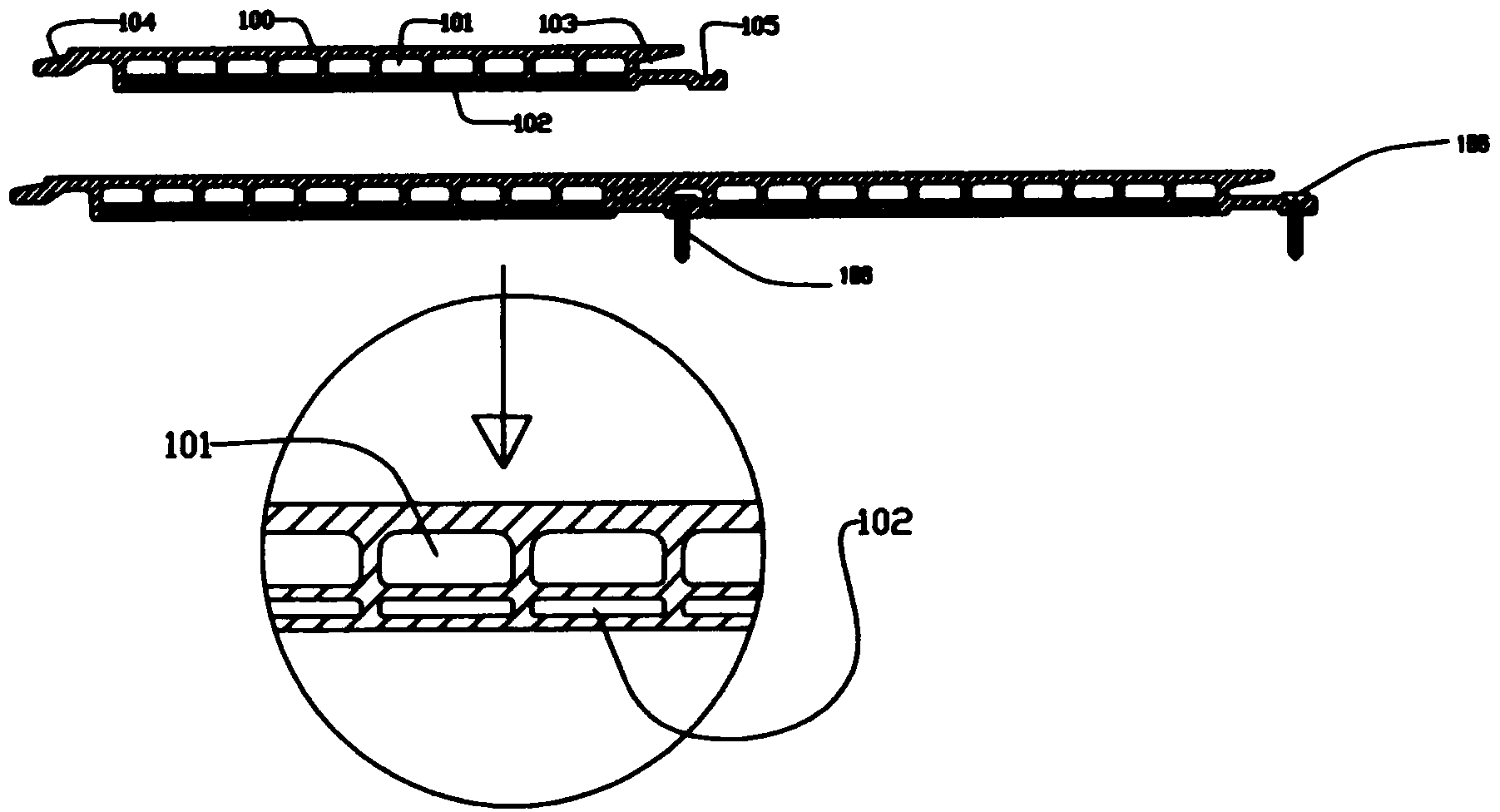

[0030] figure 2 is a structural diagram of the floor 100. The floor 100 is formed by extruding ABS, PVC, AS and other resins. A plurality of flow channels 101 are formed in a grid pattern on the floor 100 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com