Flame retardant low foaming polypropylene material and preparation method thereof

A polypropylene material and polypropylene technology, applied in the field of flame-retardant low-foaming polypropylene material and its preparation, can solve problems such as difficult control of cell size and human health damage, and achieve wide environmental adaptability, product safety, and improved The effect of flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

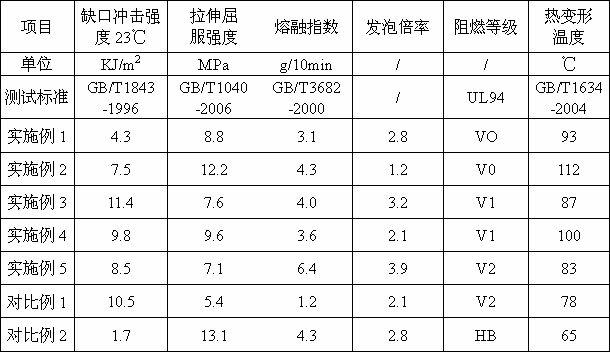

Examples

Embodiment 1

[0032] Proportion according to the following mass percentage composition: polypropylene copolymer (MI: 7.5g / 10min) 45.6%, aluminum hydroxide (particle size 1.5um) 35%, red phosphorus 10%, ethylene-octene copolymer 8%, anti- Oxygen 1010 and antioxidant 168 each 0.1%, zinc stearate 0.2%, color masterbatch 1%. Add the above materials into a high-speed mixer and stir for 10 minutes, then add the uniformly stirred materials into the hopper of a parallel twin-screw extruder with a length-to-diameter ratio of L / D of 38:1 and a screw diameter of 30 mm. The temperature of each section of the machine from the hopper to the die head is (a total of six zones): 150°C, 160°C, 170°C, 170°C, 175°C, 180°C. The rotation speed is 28r / min, and then the materials are blended and melted and extruded; the above-mentioned pellets are cooled in a water tank, air-dried, and then enter a pelletizer for pelletizing to obtain a flame-retardant low-foaming polypropylene material. Some samples were taken f...

Embodiment 2

[0035] Proportion according to the following mass percentage composition: polypropylene copolymer (MI: 7.5g / 10min) 48.6%, aluminum hydroxide (particle size 1.5um) 25%, red phosphorus (microcapsule coated red phosphorus) 15%, ethylene- Octene copolymer 10%, antioxidant 1010 and antioxidant 168 each 0.1%, calcium stearate 0.2%, color masterbatch 1%. Add the above materials into a high-speed mixer and stir for 10 minutes, then add the uniformly stirred materials into the hopper of a parallel twin-screw extruder with a length-to-diameter ratio of L / D of 38:1 and a screw diameter of 30 mm. The temperature of each section of the machine from the hopper to the die head is (a total of six zones): 150°C, 160°C, 170°C, 170°C, 180°C, 180°C. The rotation speed is 28r / min, and then the materials are blended and melted and extruded; the above-mentioned pellets are cooled in a water tank, air-dried, and then enter a pelletizer for pelletizing to obtain a flame-retardant low-foaming polypropy...

Embodiment 3

[0038] Proportion according to the following mass percentage composition: recycled polypropylene regenerated pellets (MI: 5.3g / 10min) 58.6%, aluminum hydroxide (particle size 0.7um) 15%, triphenyl phosphate 20%, ethylene-octene copolymer 5%, antioxidant 1010 and antioxidant 168 each 0.1%, calcium stearate 0.2%, color masterbatch 1%. Add the above materials into a high-speed mixer and stir for 10 minutes, then add the uniformly stirred materials into the hopper of a parallel twin-screw extruder with an aspect ratio L / D of 38:1 and a screw diameter of 30mm, and set the extrusion The temperature of each section of the machine from the hopper to the die head is (a total of six zones): 150°C, 160°C, 170°C, 170°C, 180°C, 180°C, the screw speed of the main engine is 280r / min, and the speed of the hopper feed screw The rotation speed is 27r / min, and then the materials are blended and melted and extruded; the above-mentioned pellets are cooled in a water tank, air-dried, and then enter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com