High-speed cyclic gas-liquid mixed micro-nano foam generating device

A foam generating device, micro-nano technology, applied in the direction of mixers, mixing methods, fluid mixers, etc., can solve the problems of slow rotation speed, increased air flow, and insufficient consideration of the internal volume gas-liquid discharge hole ratio, etc. , to achieve the effect of large amount of bubbles and increased rotation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

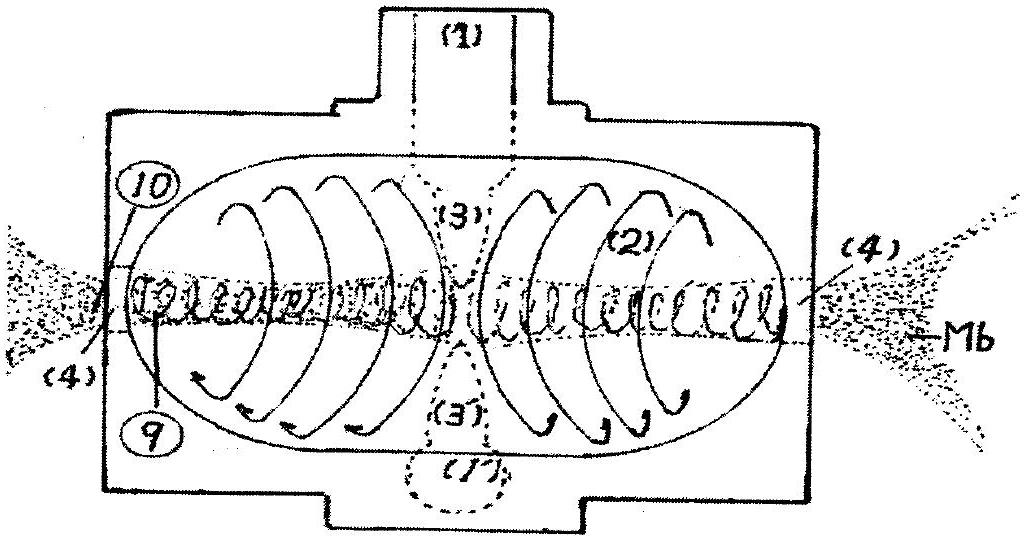

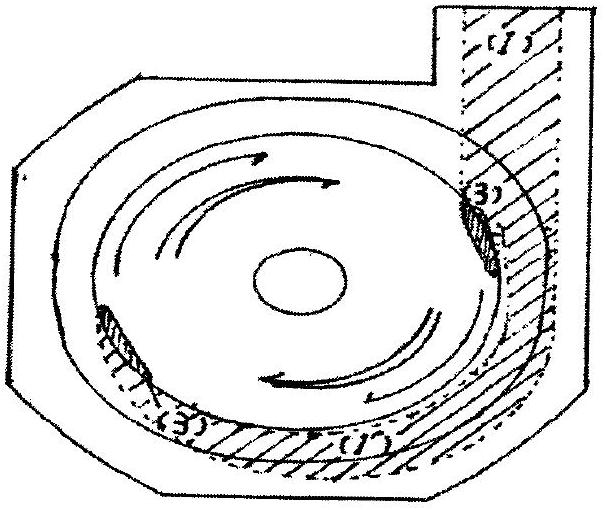

[0015] FIG. 1 is an explanatory diagram of the principle of a manufacturing apparatus.

[0016] Figure 1-(A) is a side view, and Figure 1-(B) is a cross-sectional view of Figure 1-(A).

[0017] Due to the high-speed hovering conditions and the gas, the specific gravity of the liquid is poor, the liquid generates a strong centrifugal force, and the gas generates a strong centripetal force so that the liquid and gas can be separated. Also, due to the huge speed difference between the front and rear parts of Figure 1-(A) ⑩, the strip-shaped gas part ⑨ is cut off continuously and stably. As a result, a large number of micro-nanofoam MNBs occurred. Bubbles with a diameter of 50nm to 20um occur near (4) in Fig. 1-(A), and are discharged out of the container.

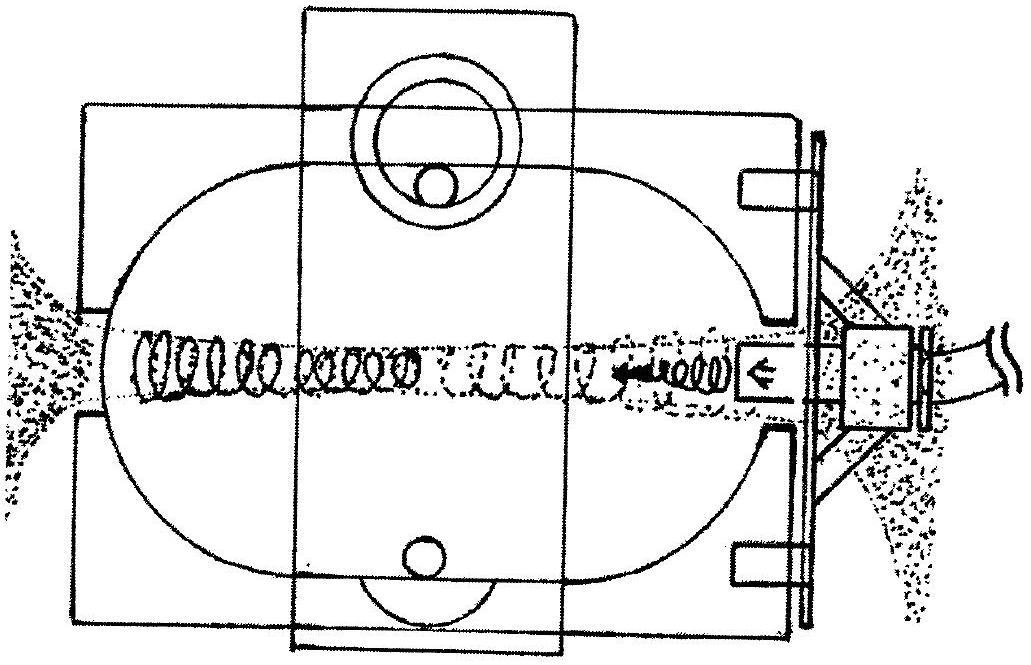

[0018] figure 2 This is a schematic diagram and an explanatory diagram of using the gas discharge hole as the gas input hole.

[0019] Explanation of use and application range

[0020] Small, medium, and large devices can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com