Floor drain having waste hot water rocovery mouthpiece

A waste hot water and floor drain technology, applied in the field of floor drains, can solve the problems of increased environmental pollution, large discharge of domestic waste hot water, waste of energy, etc., and achieve the effects of energy saving, good economic and social benefits, and reduction of thermal pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

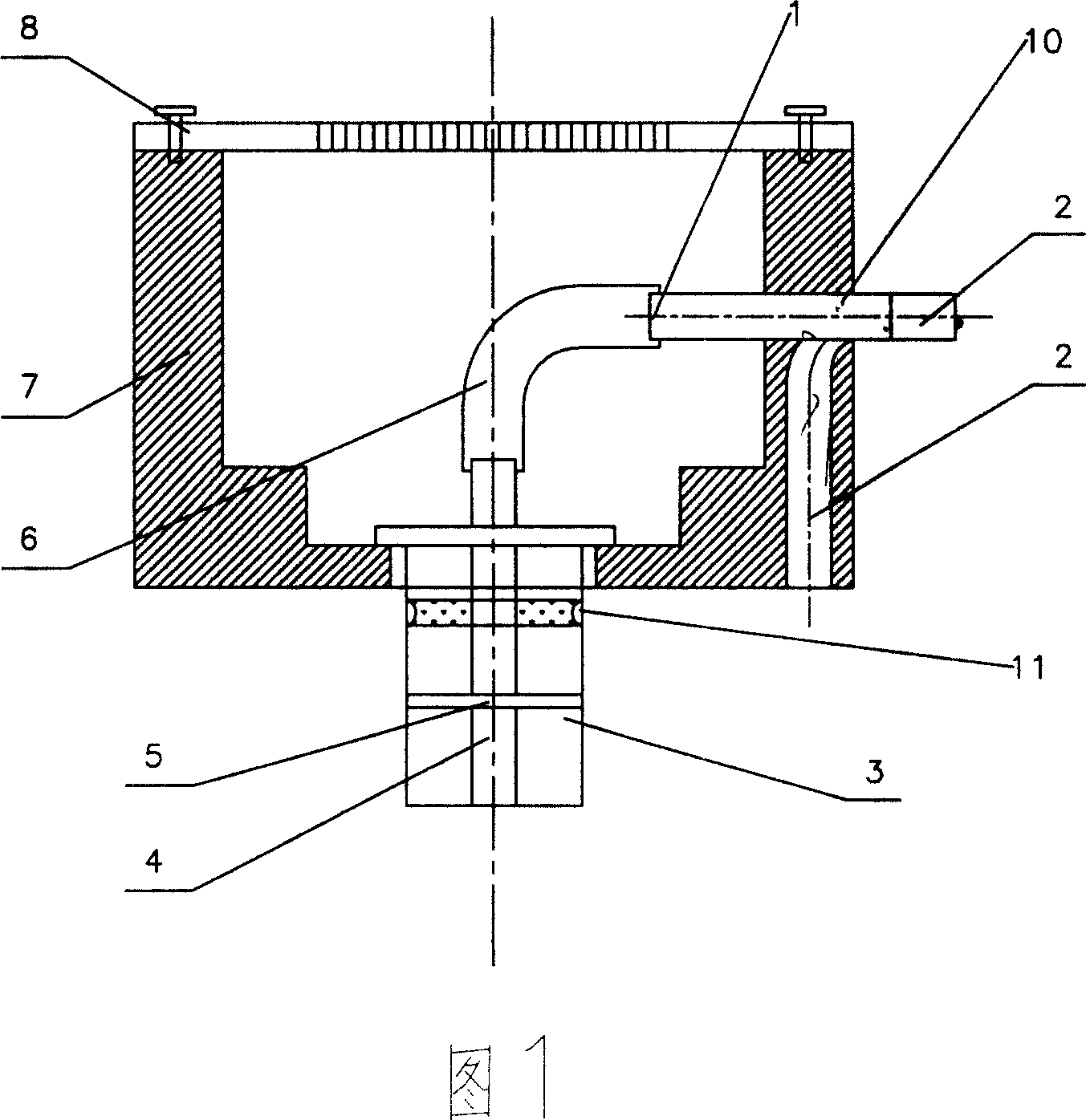

[0012] As shown in Figure 1, a floor drain with a waste hot water recovery interface described in this embodiment is mainly composed of a floor drain body 7, a cover plate 8, a waste hot water extraction channel 1, a waste hot water transition chamber 3, and a filter screen 5 The waste hot water transition chamber 3 is arranged at the bottom of the floor drain main body 7, the nozzle of the water suction pipe 4 of the waste water hot water extraction passage 1 is arranged at the bottom of the waste water hot water transition chamber 3, and the water intake pipe 10 of the waste water hot water extraction passage 1 passes through the floor drain main body 7 Leading to the outside, the filter screen 5 is set on the waste hot water transition chamber 3, the cover plate 8 is connected to the floor drain main body 7, the upper part of the waste water hot water transition chamber 3 is provided with an overflow hole 11, and the floor drain main body 7 is provided with a waste water drai...

Embodiment 2

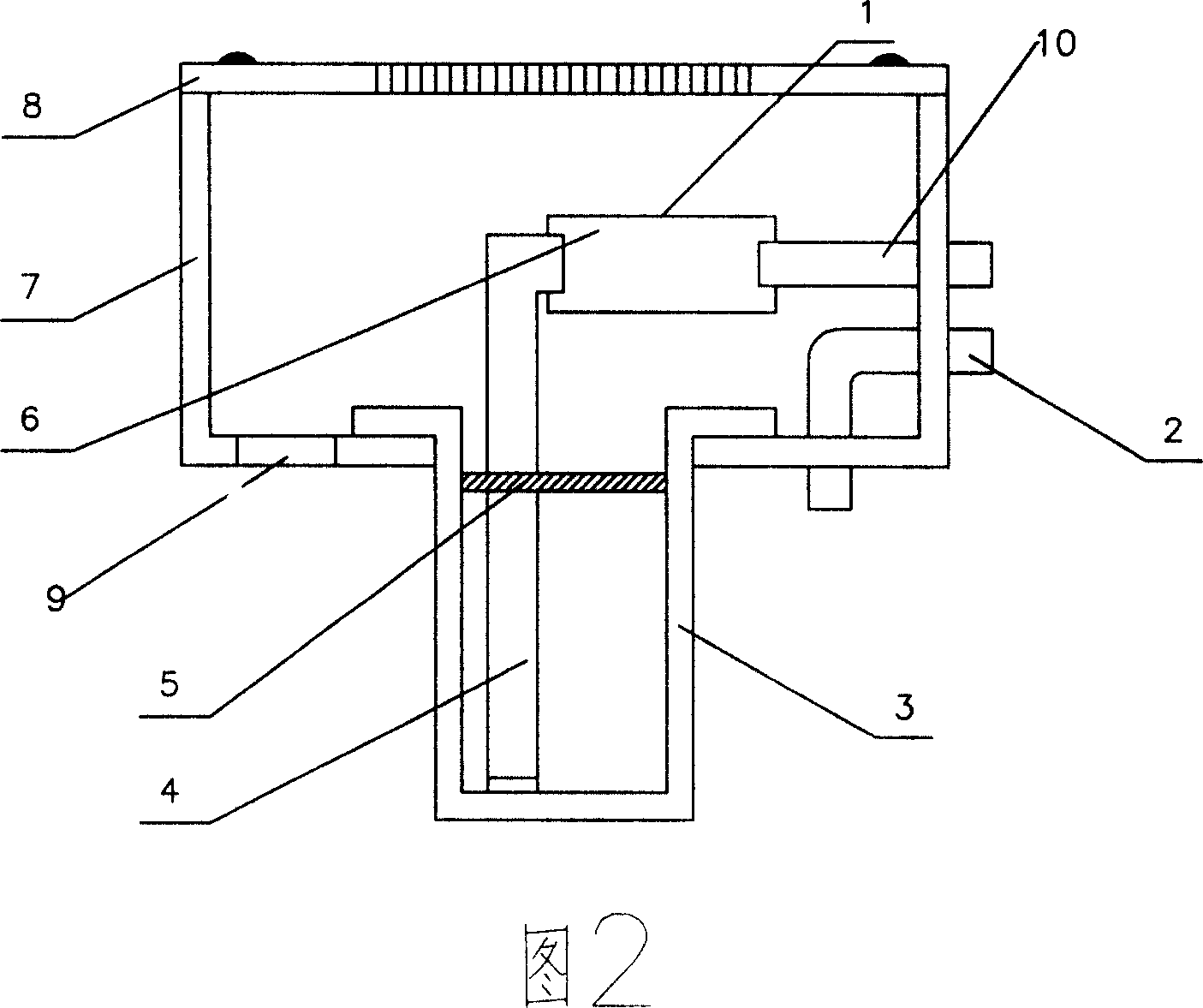

[0016] As shown in FIG. 2 , this embodiment describes a floor drain with a waste water recovery interface, and the floor drain main body 7 is made of thin-walled metal material. There are two through-hole structures on its surface, which are respectively used to install the waste hot water extraction passage 1 and the drainage channel 2. An overflow hole 9 is provided on the floor drain main body 7. The waste hot water transition chamber 3 is set on the steps of the floor drain main body 7. The water suction pipe 4 is socketed with the filter screen 5 as a filter and a water intake interface functional part. As shown in FIG. 2 , the drainage channel 2 is realized by setting a pipeline channel outside the wall of the floor drain main body, and is installed on the floor drain main body 7 . The waste hot water extraction channel 1 is composed of a water suction pipe 4, a hose 6 and a water intake connection 10, and the drainage channel 2 passes through the floor drain main body 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com