Patents

Literature

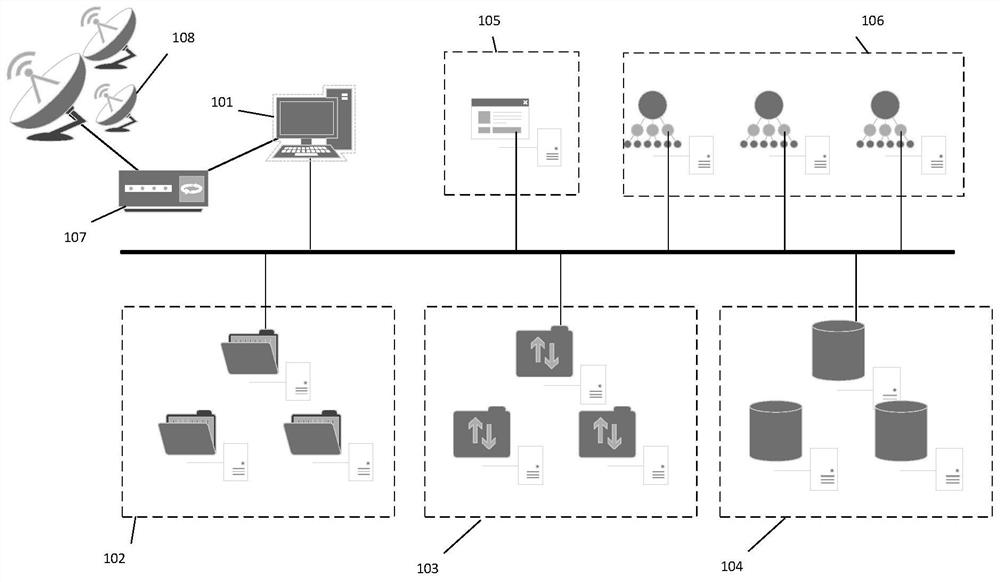

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Reliable processing method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for making northern oolong tea

InactiveCN1911057AImprove qualityReliable processing methodPre-extraction tea treatmentClimate change adaptationTea leafChemistry

A process for preparing the northern oolong tea includes such steps as picking fresh tea leaves, spreading, sunning, rocking for cooling, parching, kneading, and baking. Its advantage is high quality of tea product.

Owner:江崇焕 +1

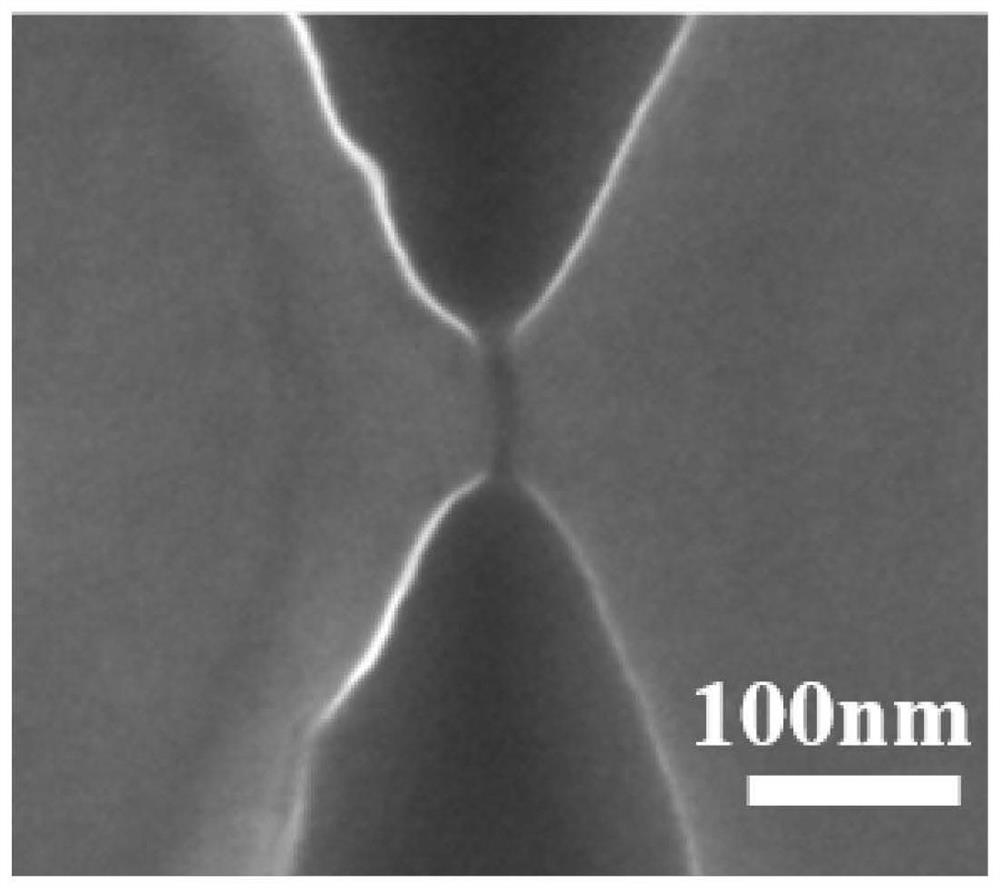

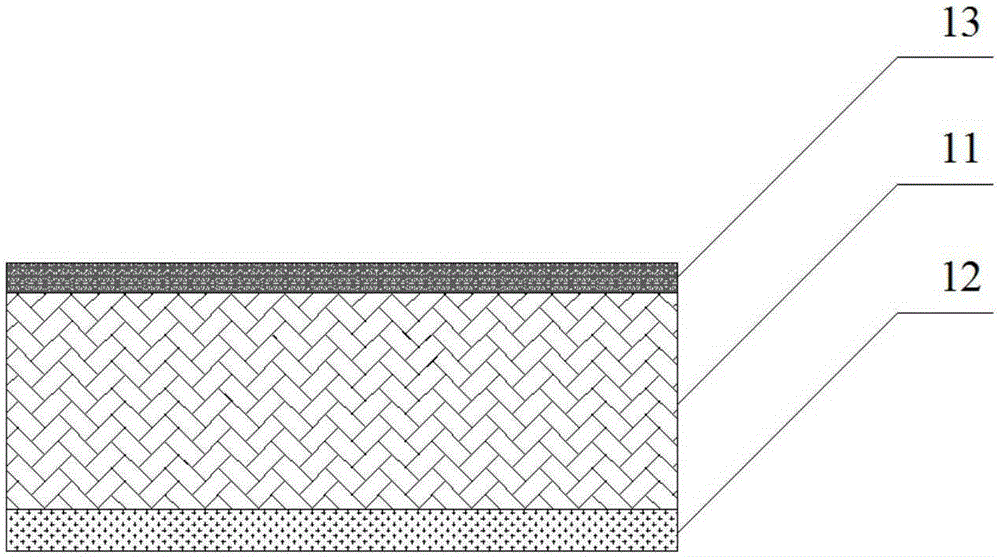

Nano-pore apparatus used for single-molecule sequencing, and application method and manufacturing method thereof

InactiveCN103820311AHigh capture rateSolve the problem of piercing too fastBioreactor/fermenter combinationsBiological substance pretreatmentsTemporal resolutionLow voltage

The invention provides a nano-pore apparatus used for single-molecule sequencing and an application method and a manufacturing method thereof. The nano-pore apparatus is used in a single-molecule sequencing device. The single-molecule sequencing device comprises a positive electrolytic bath and a negative electrolytic bath, and the nano-pore apparatus is used for separating the positive electrolytic bath from the negative electrolytic bath. Solid nano-pore structures and a graphene nano-pore structure are combined so as to obtain a sandwich structure; since a solid wine-glass-shaped groove exists in the sandwich structure, the diameter of a graphene nano-pore can be extended, which guarantees that biomolecules have a high capture rate at a low voltage, so the speed of a single molecule passing through the graphene nano-pore can be controlled by lowering down voltage, thereby overcoming the problem of a fast pore passing speed of biomolecules during nano-pore single-molecule sequencing in the prior art and improving temporal resolution during pore passing of the single molecule; the apparatus eventually detects the graphene nano-pore, thereby guaranteeing a good resolution effect of single-molecule detection.

Owner:TSINGHUA UNIV

NANDFLASH bad sector dynamic label processing method based on blocks

InactiveCN103268267AProcessing speedReduce occupancyFault responseMemory adressing/allocation/relocationBad sectorComputer science

The invention discloses a NANDFLASH bad sector dynamic label processing method based on blocks. A NANDFLASH chip is detected firstly, and then normal read-write using is carried out. Valid information of each block is labeled with one block as a unit rather than with one page as a unit, so that a system does not need to read labeling value before operation is carried out on each page of flash memory, the system only needs to read labels before a new block is operated, the system does not need to label the state of each page after the operation is finished, and the system only needs to mark the valid state of each block before the block is used or when the block is needed.

Owner:BEIJING AEROSPACE AUTOMATIC CONTROL RES INST +1

Furong plum juice and preparation method thereof

The invention discloses furong plum juice and a preparation method thereof and belongs to a drinking beverage in daily life and a preparation method thereof. The method is characterized by comprising the following steps of: 1, material preparation: A, picking fresh furong plums, cleaning and sterilizing the furong plums; B, preparing furong plum pectin esterifying enzyme; and C, preparing 50-degree rice white spirit; and 2, fermentation process: adding 2.5 to 3.5 weight percent of the prepared furong plum pectin esterifying enzyme and 5 to 10 weight percent of the 50-degree rice white spirit into every 100 kilograms of fresh furong plums and performing fermentation; and filtering the fermented product to obtain the juice and bottling the juice for delivery. The method is characterized in that: the furong plum juice is supplied by a microorganism fermentation method and no addition agent or additive is added in an entire technical process, so that the original taste and flavor of an original fruit are kept, a processing method is simple and reliable and the processed furong juice is stable and reliable and never degenerate.

Owner:章礼岳

Blade air film hole machining quality tracing system and method

PendingCN111340339AImprove processing efficiencyGuaranteed processing needsDatabase management systemsCo-operative working arrangementsAviationProcess engineering

The invention discloses a blade air film hole machining quality tracing system and method. The system comprises a code generation module, a production management module, a quality analysis module anda data storage module. The code generation module is used for generating and managing all codes used in the production process of the blade air film holes; the production management module collects production data and detection data in real time in the machining process. The quality analysis module analyzes the quality of the blade by receiving the data provided by the production management moduleand combining the product quality requirements to form a quality report; the data storage module is used for storing data and reports in the production process. According to the blade air film hole machining quality tracing system, full-closed-loop quality tracing of blade air film hole production from entering a factory, leaving the factory to being used by a client can be achieved; a reliable machining mode and a quality management systematization system can be provided for large-batch rapid production of the aero-engine blades, the delivery time can be greatly shortened, the production cost is saved, and high economic benefits are achieved.

Owner:SONGSHAN LAKE MATERIALS LAB +1

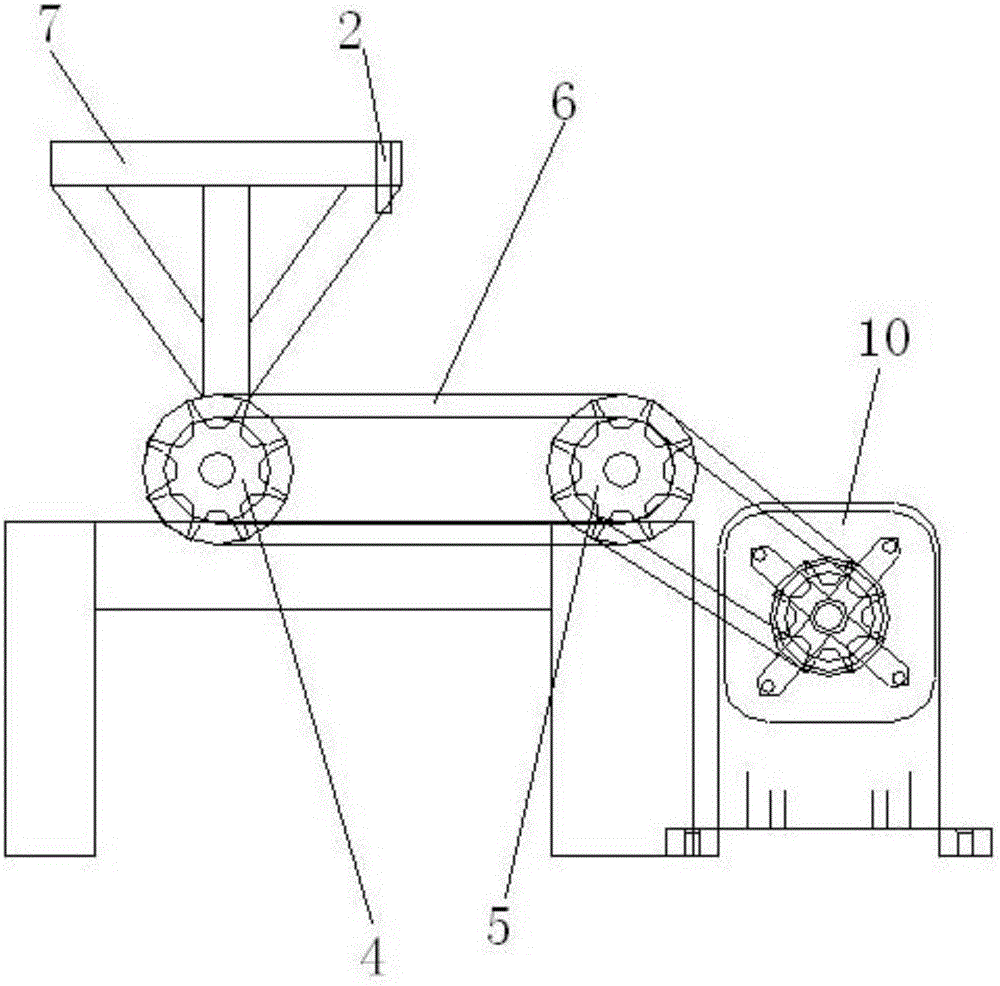

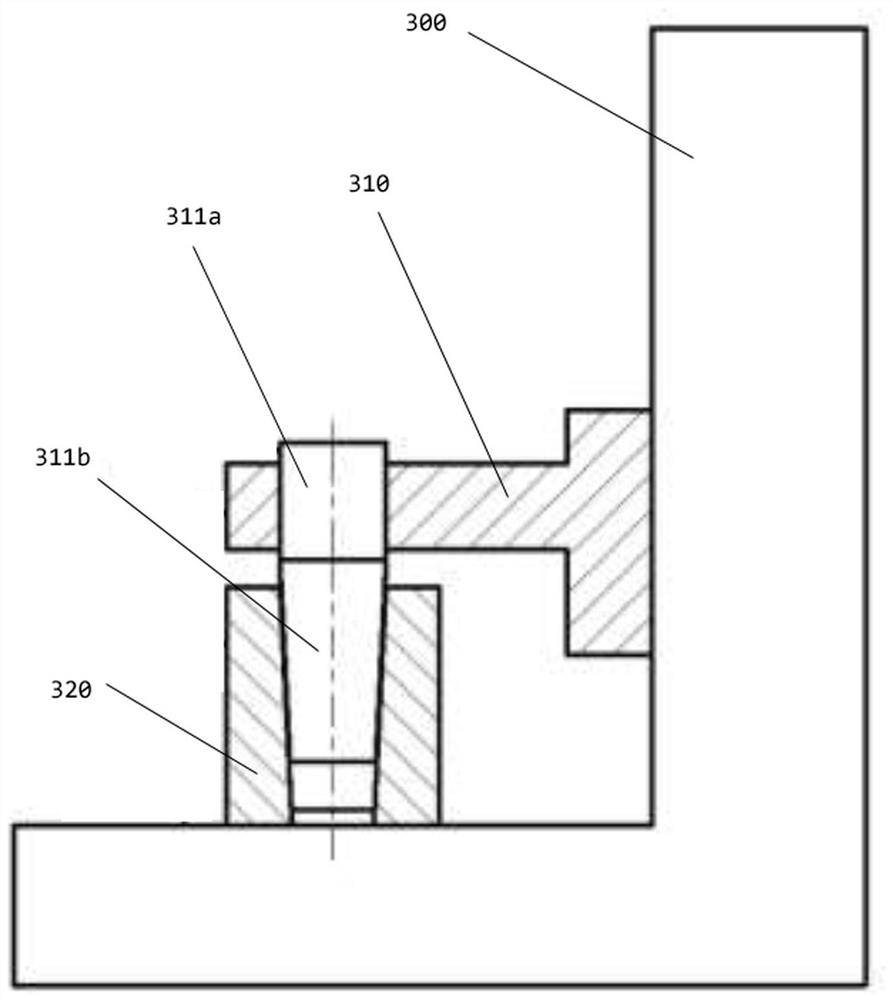

Full-automatic high-temperature mummification machine for animal innocent treatment

ActiveCN105013804AAchieve mechatronic processingAvoid secondary pollutionSolid waste disposalEngineeringPollution

The invention discloses a full-automatic high-temperature mummification machine for animal innocent treatment. The full-automatic high-temperature mummification machine is characterized by comprising a box (1), a plurality of scraper blades (2) which are perpendicular to the lower surface of the box (1) and are used for driving materials to move forwards are evenly arranged in the box (1), and extruding devices (3) are arranged between every two adjacent scraper blades (2). The full-automatic high-temperature mummification machine for animal innocent treatment can effectively achieve environment-friendly animal innocent treatment; and the scraper blades, an adjustor and the extruding devices work in an accurate and cooperative mode, mechatronics of animal carcasses is achieved, the working efficiency is high, a treatment method is reliable, and secondary pollution to the environment and propagation of pathogenic microorganism are avoided.

Owner:湖州欣宇环保科技有限公司

Metal energy storage spring machining method

The invention relates to a metal energy storage spring machining method. The metal energy storage spring machining method includes the following steps that S1, firstly, a steel belt is horizontally bent to be a circular-arc steel belt; S2, the circular-arc steel belt is spirally wound in the longitudinal direction to form a plurality of conical cylinders; S3, every two adjacent conical cylinders in the conical cylinders are connected in a lap joint mode to form a long cylinder; S4, single-piece steel belts are pulled out of the head end of the long cylinder and the tail end of the long cylinder respectively and subjected to butt welding to form an annular cylinder; S5, the two single-piece steel belts generated after butt welding is conducted are wound back into the adjacent conical cylinders respectively after restoring to the conical cylinders. S6, punch forming is conducted on the annular cylinder obtained in S5, and thus the annular cylinder can meet the drawing requirement. The method is used for machining metal energy storage springs.

Owner:HARBIN DONGAN IND DEV

Roof unsupported area detection and roadway repair method based on radar detection technology

InactiveCN106121678ASimple processing methodSafe handlingUnderground chambersTunnel liningRadar detectionRepair method

The invention discloses a roof unsupported area detection and roadway repair method based on the radar detection technology. The fracture situation of the rock stratum above roof falling gangue is detected through the radar detection technology, and grouting holes are formed according to the detected situation; and the aim of roadway repair is achieved through the steps of grouting, tunneling, supporting and the like. According to the roof unsupported area detection and roadway repair method based on the radar detection technology, the unsupported area and part of the roof falling gangue are reinforced through grouting falling, and the roof unsupported area detection and roadway repair method based on the radar detection technology provides a simple, safe and reliable processing method for roadway roof collapse.

Owner:ANHUI UNIV OF SCI & TECH

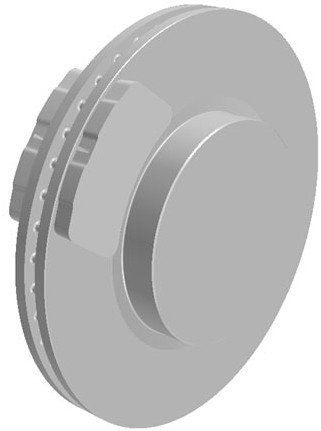

Method for processing brake friction heat load data of automobile brake disc

ActiveCN111611645APrecise capture of frictional heatImprove calculation accuracyGeometric CADSustainable transportationHeat fluxEngineering

The invention discloses a method for processing brake friction heat load data of an automobile brake disc. The method comprises the following steps: establishing a functional relationship between thesurface heat flux qt on the friction surface of the automobile brake disc and the speed vt, the whole automobile mass M, the road slope angle theta, the rolling friction coefficient f, the braking force distribution coefficient beta, the wheel slip rate s, the braking acceleration a, the wind drag coefficient Cd, the lift coefficient Cl and the position r under the central polar coordinate of thefriction surface of the brake disc; and accurately capturing the friction heat generated on the brake disc, and obtaining the temperature field on the brake disc through accurate simulation. Accordingto the method, the simulation calculation result of the temperature field on the automobile brake disc is accurate and reliable, and the simulation calculation result can be used for guidance designof the automobile brake disc.

Owner:JIANGLING MOTORS

Method for continuously removing dioxin from natural vitamin E

The invention discloses a method for continuously removing dioxin from natural vitamin E. The method comprises the following steps of: dissolving the natural vitamin E in a solvent of which the volume is 2-6 times that of the natural vitamin E; heating to 40-70 DEG C under the protection of nitrogen; uniformly mixing, and then continuously introducing the mixture into a fixed bed in which a filler is filled from the top end of the fixed bed; collecting effluent liquid after the solution stays for 0.5-5 hours; filtering; distilling and concentrating the filtrate; and refining through molecular distillation. The quality of a vitamin E product treated by the method can reach a limit standard to the dioxin by the European Union, the technological process is simple, and the running cost is low, so that the method is a relatively reliable treatment method and is suitable for industrial bulk production.

Owner:ZHONGGU TIANKE TIANJIN BIOENG

Separate collection, reuse and treatment method for SCR denitration catalyst cleaning wastewater

ActiveCN106517575ASimple processing methodReliable processing methodWater contaminantsTreatment involving filtrationWater resourcesHigh pressure water

The invention provides a separate collection, reuse and treatment method for SCR denitration catalyst cleaning wastewater. An SCR denitration catalyst is cleaned with high-pressure water and in a first cleaning tank, a second cleaning tank, a third cleaning tank, a fourth cleaning tank and a fifth cleaning tank, and the wastewater is generated, wherein the wastewater of the first cleaning tank and the second cleaning tank is drained into a first wastewater collecting tank, the wastewater of the third cleaning tank, the fourth cleaning tank and the fifth cleaning tank is drained into a second wastewater collecting tank, after the wastewater in the second wastewater collecting tank is standing, supernatant is reused into the third cleaning tank or the fourth cleaning tank or the fifth cleaning tank, after the wastewater in the second waste water collecting tank is reused 5-7 times, the wastewater is reused in the first cleaning tank or the second cleaning tank, the wastewater in the first wastewater collecting tank is dosed, neutralized, precipitated and filtered, and clear water is obtained. The cleaning method on the basis of achieving SCR denitration catalyst cleaning aims at the cleaning process, collection, separate reuse and treatment of the wastewater are reasonably arranged, the wastewater treatment method is simple, reliable and efficient, and water resources are saved.

Owner:SUZHOU XIRE ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

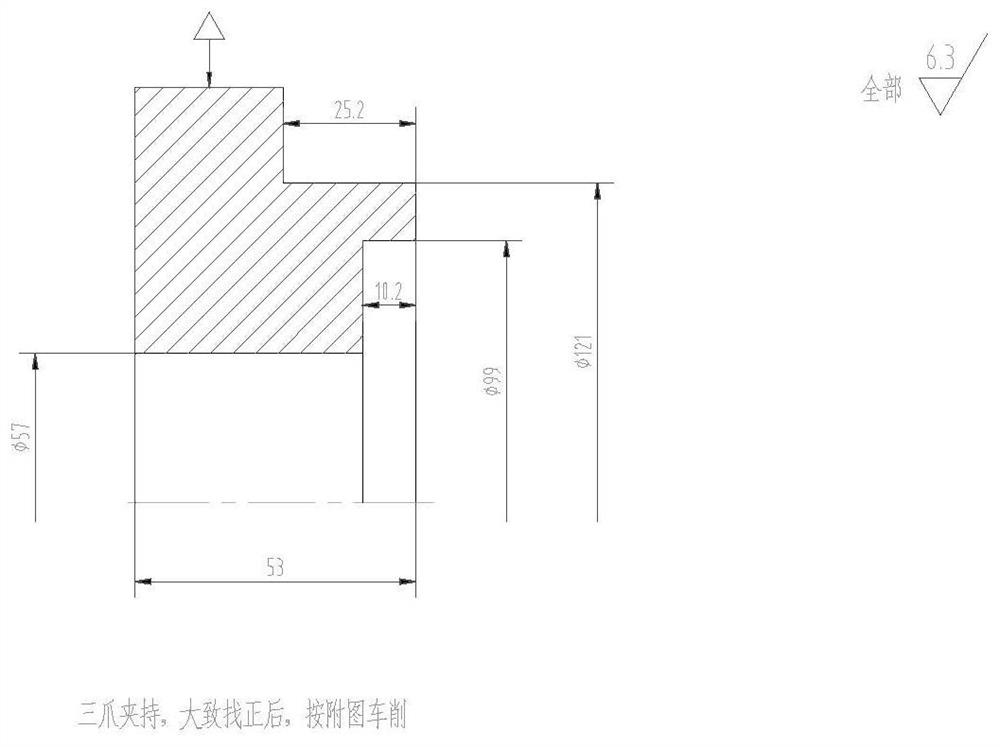

A processing method for compressor impeller of VTR series supercharger

ActiveCN110102989BGuaranteed flatnessGuaranteed parallelWork clamping meansChucksImpellerEngineering

The invention provides a method for processing the compressor impeller of a VTR series supercharger, comprising the steps of: a. the inner hole of the shaft of the impeller center; b. heat treatment; c. turning the end surface and outer circle of the impeller; d. turning the small end of the impeller and the impeller shaft Facing the inner hole, take the sample ring on the impeller at the same time; e. Inspection; f. Rough turning the small end of the impeller; g. Blades and runners; i. The outer circle of the large end of the finishing impeller; j. The large end of the finishing impeller and the axial inner hole of the impeller; k. Clamping and positioning the impeller on the turning tool, the impeller positioning surface used in the next process of finishing turning ; l. The large end of the impeller and the axial inner hole of the impeller; m. The small end face of the impeller; n. The meridian surface of the impeller and the end face of the blade. This method improves the matching accuracy and sealing performance between the large end surface of the impeller and the air seal, and solves the problem that the original sample ring and the impeller are separated and then heat treated, and the sample ring cannot truly reflect the performance status of the part after heat treatment.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

Radio astronomical data storage consistency guaranteeing method, device and system and storage medium

ActiveCN112637268ASolving Consistency Guarantee ProblemsSimple processing methodInput/output to record carriersDigital data information retrievalData segmentTelecommunications

The invention discloses a radio astronomical data storage consistency guaranteeing method, device and system and a storage medium, and the method comprises the steps: receiving radio astronomical data of a digital receiver, and connecting the radio astronomical data with a Zookeeper server; obtaining an available metadata server and a data server through a load balancing module; according to the filled UVFITS header information, obtaining a globally unique ID through a Zookeeper; sending the ID and the UVFITS header information to a metadata server and a data server; according to the state configuration node of the metadata server and the ID value of the state configuration node of the data server, judging whether the UVFITS header information and the data segment of the unified data exist or not, and marking; and if the UVFITS header information and the data segment of the unified data are not judged, performing corresponding processing according to the marking result. The consistency problem of radio astronomical data metadata, original data and processed data can be solved, and basic support is provided for upper-layer application services of various radio observation application systems.

Owner:GUANGZHOU UNIVERSITY

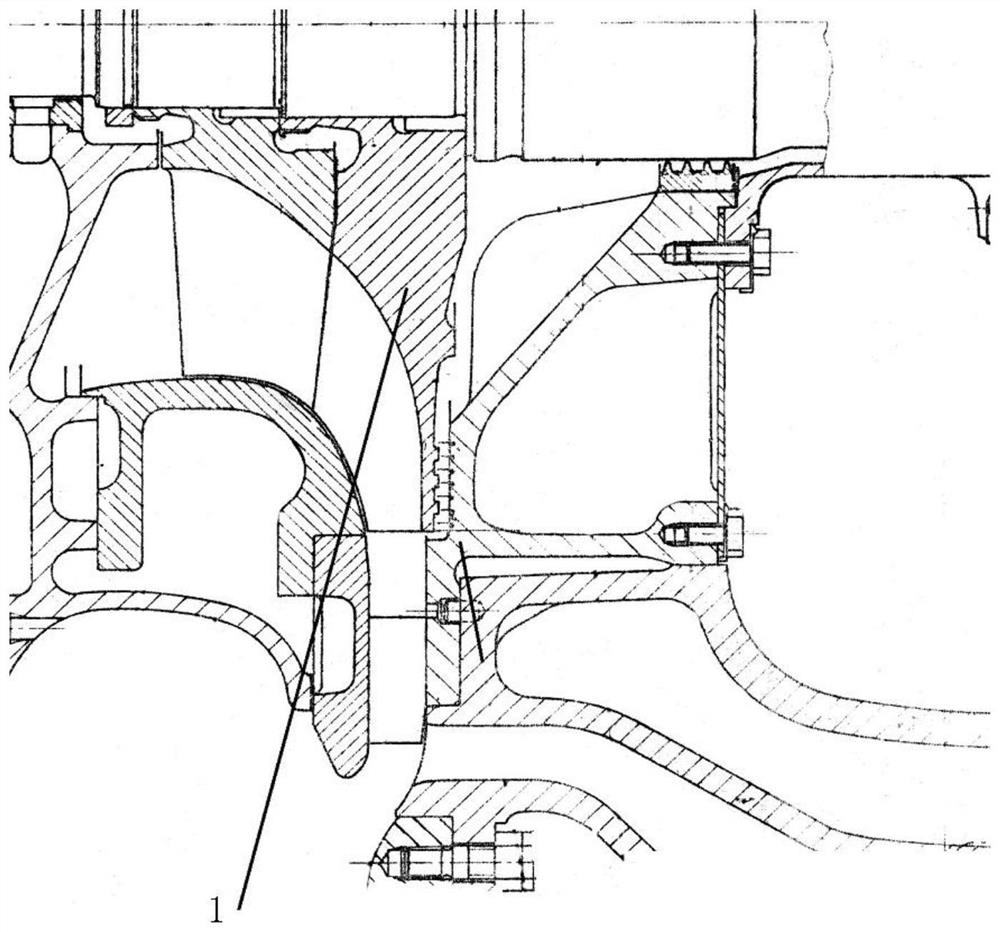

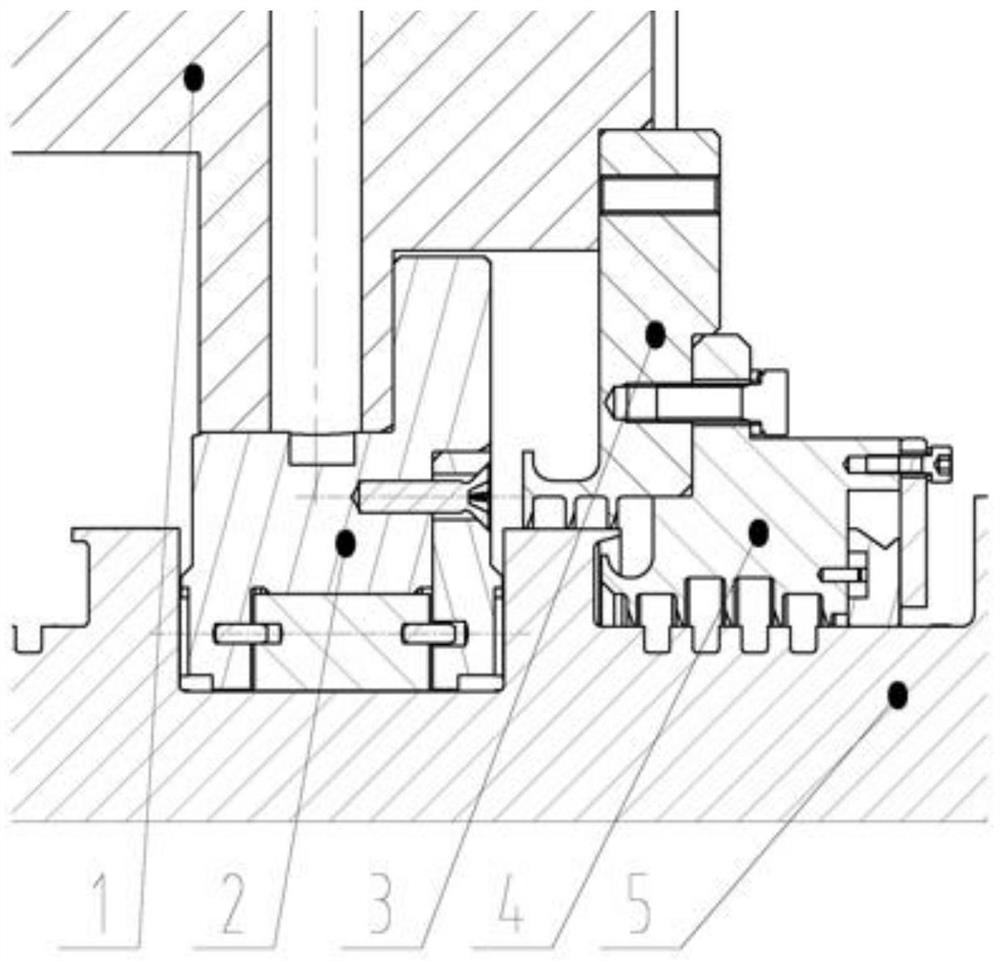

Split type DM inner layer oil seal part machining method

The invention discloses a split type DM inner layer oil seal part machining method. The machining precision is higher. The invention discloses a split type DM inner layer oil seal part machining method comprises the following working procedures that 10, a center hole of a workpiece is drilled and roughly turned; 20, heat treatment is conducted; 30, rough turning is conducted; 40, rough turning is conducted; 50, the workpiece is cut into two halves; 60, stress removing is conducted; 70, the positioning face is milled to be flat and used for grinding and clamping; 80, the positioning face is flattened; 90, four symmetrical points in the four directions of a split are aligned, and the split is ground out; 100, a connecting hole in the split of the workpiece is milled; 110, a chambering platform for a connection hole is milled; 120, chambering is conducted, an orifice is chamfered, the connecting hole is tapped, and the two halves are combined and assembled; 130, the small end and the outer circle of the workpiece are subjected to semi-finish turning; 140, the large end of the workpiece and the small-diameter section of a stepped hole are subjected to finish turning; 150, the small end and the stepped hole of the workpiece are subjected to the finish turning; 160, digital drilling is carried out; 170, digital drilling is conducted; 180, clamping is conducted; 190, digital drilling is carried out; and 200, clamping is conducted.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

Method for treating water leakage of cooler in chloroacetic acid production

InactiveCN101798262ASimple processing methodReliable processing methodOrganic compound preparationCarboxylic compound preparationAcetic acidWater leakage

The invention discloses a method for treating the water leakage of a cooler in chloroacetic acid production, which comprises the following steps: adding glacial acetic acid and catalyst to react so as to generate chlorine and chloroacetic acid liquid; and carrying out crystallization on the obtained chloroacetic acid liquid so as to get the finished product; meanwhile, the method also comprises the steps of catalyst refilling and water leakage detection. By using the method, the catalyst can be supplemented in time in case of water leakage of the cooler in production, therefore, the normal reaction of the chlorinated acid in a reaction kettle is ensured, and the product quality and yield are ensured.

Owner:HENAN HDF CHEM CO LTD

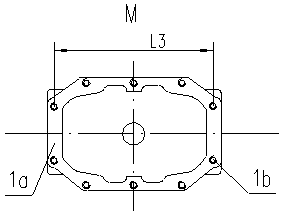

Processing and preparation method for multi-variety surface pin positioning axle housing cleaning consignment trolley

ActiveCN106624623BAvoid the phenomenon of "forced demolition and re-soldering"Avoid forced demolition and re-soldering" phenomenonAxle unitsEngineeringMulti species

The invention relates to a processing and configuring method for a multi-species face pin positioning axle housing cleaning tow trolley, which belongs to the field of machine manufacturing. The processing and configuring method provided by the invention is a simultaneous supporting research applied while researching a technical scheme of the cleaning tow trolley for multi-species 'face pin positioning' axle housing parts, so that not only can the multi-species 'face pin positioning' axle housing parts be ensured to be used on the cleaning tow trolley, the application range is broadened, but also positioning components involved during species conversion are processed and configured feasibly, reliably, conveniently and accurately, the occurrence of the phenomenon of 'forced disassembling and welding again' during conversion can be avoided, and the requirement on fast conversion during practical production is met. The processing and configuring method for the multi-species face pin positioning axle housing cleaning tow trolley provided by the invention is clear, simple, practical, and easy to configure, and has a popularized application value.

Owner:YTO LUOYANG WIT TOOLS & EQUIP

Method for continuously removing dioxin from natural vitamin E

The invention discloses a method for continuously removing dioxin from natural vitamin E. The method comprises the following steps of: dissolving the natural vitamin E in a solvent of which the volume is 2-6 times that of the natural vitamin E; heating to 40-70 DEG C under the protection of nitrogen; uniformly mixing, and then continuously introducing the mixture into a fixed bed in which a filler is filled from the top end of the fixed bed; collecting effluent liquid after the solution stays for 0.5-5 hours; filtering; distilling and concentrating the filtrate; and refining through molecular distillation. The quality of a vitamin E product treated by the method can reach a limit standard to the dioxin by the European Union, the technological process is simple, and the running cost is low, so that the method is a relatively reliable treatment method and is suitable for industrial bulk production.

Owner:ZHONGGU TIANKE TIANJIN BIOENG

Fixture processing method

Owner:BOSCH AUTOMOTIVE PROD SUZHOU

A processing method of square anchor lip and square anchor lip

ActiveCN111590215BReliable processing methodFirmly connectedWaterborne vesselsPlasma welding apparatusEngineeringSS - Stainless steel

The invention discloses a processing method of a square anchor lip and the square anchor lip, belonging to the technical field of shipbuilding. The processing method of the square anchor lip includes the following steps: S1, processing the first bevel on the edge of the stainless steel plate, and evenly opening a plurality of plug welding holes on the stainless steel plate; S2, pasting the stainless steel plate on the lower end of the square anchor lip ; S3, from the center of the stainless steel plate to the outward symmetrical welding of the plug holes in order to form a plug welding seam; S4, welding the joint between the first groove and the square anchor lip to form a groove weld. The square anchor lip is made by the above-mentioned processing method of the square anchor lip. The processing method of the square anchor lip of the present invention has simple processing technology, reliable connection and low manufacturing cost. The square anchor lip of the invention has simple structure, good strength, hardness and corrosion resistance, prolongs the service life of the square anchor lip and improves the aesthetics.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

Method for eliminating wax smoke during firing of ceramic products molded through doping wax

InactiveCN102019643AEliminate pollutionEliminate odorCeramic shaping apparatusThermal energyWax removal

The invention relates to a method for eliminating wax smoke during firing of ceramic products molded through doping wax. The method is characterized in that the wax smoke is produced by hot dewaxing, cooled by liquid sprinkling, and then discharged after being cooled below 28 DEG C through heat exchange. Wax and smoke in the discharged wax smoke can be simply, conveniently and completely separated, the wax is recovered in the form of solid wax, pollution and odour are eliminated, and the processing method is economic, simple, convenient and reliable. In particular, the wax smoke discharged by dewaxing is first introduced into and burnt in a furnace, therefore, not only can subsequent processing burden be reduced, but also combustion heat energy can be utilized. Wax smoke pollution can be stably eliminated with the method at low cost, the wax can be recovered, and the longstanding unsolved problem of wax pollution in the industry is solved.

Owner:宜兴市正大特种瓷件有限公司

Animal harmless treatment automatic high temperature drying machine

ActiveCN105013804BAchieve mechatronic processingAvoid secondary pollutionSolid waste disposalPathogenic microorganismDead body

The invention discloses a full-automatic high-temperature mummification machine for animal innocent treatment. The full-automatic high-temperature mummification machine is characterized by comprising a box (1), a plurality of scraper blades (2) which are perpendicular to the lower surface of the box (1) and are used for driving materials to move forwards are evenly arranged in the box (1), and extruding devices (3) are arranged between every two adjacent scraper blades (2). The full-automatic high-temperature mummification machine for animal innocent treatment can effectively achieve environment-friendly animal innocent treatment; and the scraper blades, an adjustor and the extruding devices work in an accurate and cooperative mode, mechatronics of animal carcasses is achieved, the working efficiency is high, a treatment method is reliable, and secondary pollution to the environment and propagation of pathogenic microorganism are avoided.

Owner:湖州欣宇环保科技有限公司

A femtosecond laser-based preparation method for cracked nano-gap structure

ActiveCN113247859BNo maskEfficient processing methodDecorative surface effectsNanotechnologyStress concentrationEtching

The invention relates to a preparation method of a crack-type nano-slit structure based on a femtosecond laser, and belongs to the technical field of laser application. The invention transforms the traditional Gaussian femtosecond laser beam into a double-peak or multi-peak beam through the space domain shaping technology. Based on the femtosecond laser-induced material amorphization and the femtosecond laser-induced shock wave phenomenon, a structure with multiple stress concentrations is induced on the silicon surface. Amorphous silicon etch mask. Such an etching mask with a stress-concentrating structure is the key to the formation of nanocrack propagation during wet etching. In the subsequent wet etching process, under the influence of solution undercutting, the etching mask with stress concentration structure releases the stress due to being etched into a suspended state, and at the same time, nanometers are generated at the stress concentration place under the action of the surface tension of the solution. The cracks propagate, forming nano-gap structures of extremely small size (below 10 nm).

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Nanopore device for single-molecule sequencing, method of use thereof, and manufacturing method thereof

InactiveCN103820311BHigh capture rateSolve the problem of piercing too fastBioreactor/fermenter combinationsBiological substance pretreatmentsTemporal resolutionImage resolution

Owner:TSINGHUA UNIV

Processing method of high-precision thin-walled copper parts

The invention discloses a processing method of high-precision thin-walled copper parts. The copper parts are installed on a special processing positioning tool and installed on a deep hole drilling and boring machine - a boring head is installed and a wooden key is installed on the boring head, and then semi-finish boring The hole-boring head is retracted, the sharp knife is disassembled, and the boring head is returned to the boring head after the light knife row is finished. The special processing and positioning tooling has good clamping performance, and at the same time provides sufficient clamping force to ensure that there will be no displacement between the workpiece and the tooling. The processing method is convenient and reliable, can effectively reduce the deformation caused by clamping, metal cutting heat and cutting internal stress in the process of processing the inner hole of thin-walled copper parts, and eliminate processing errors at the same time, and has high processing efficiency and stable quality; the processing method of the present invention It can process the inner hole of thin-walled copper parts with a length of more than 3m and an inner hole diameter of more than φ600, and copper parts whose inner hole cylindricity can reach 0.05mm.

Owner:武汉重工铸锻有限责任公司

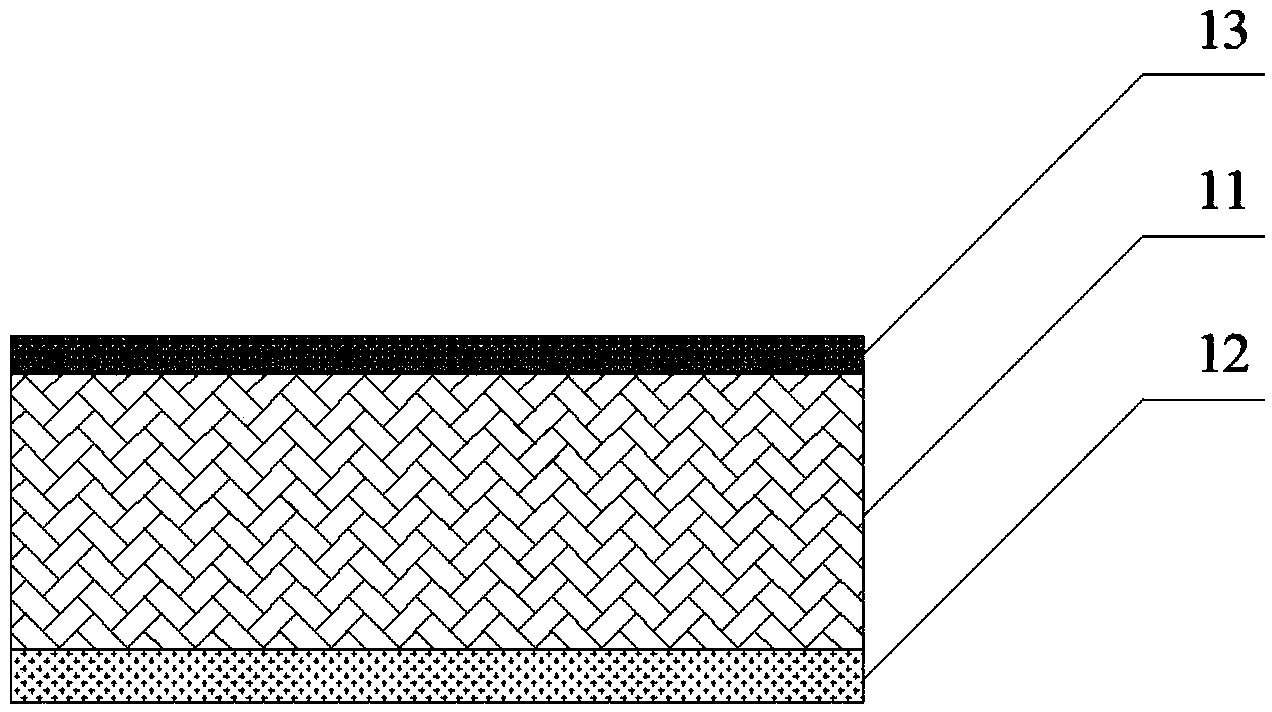

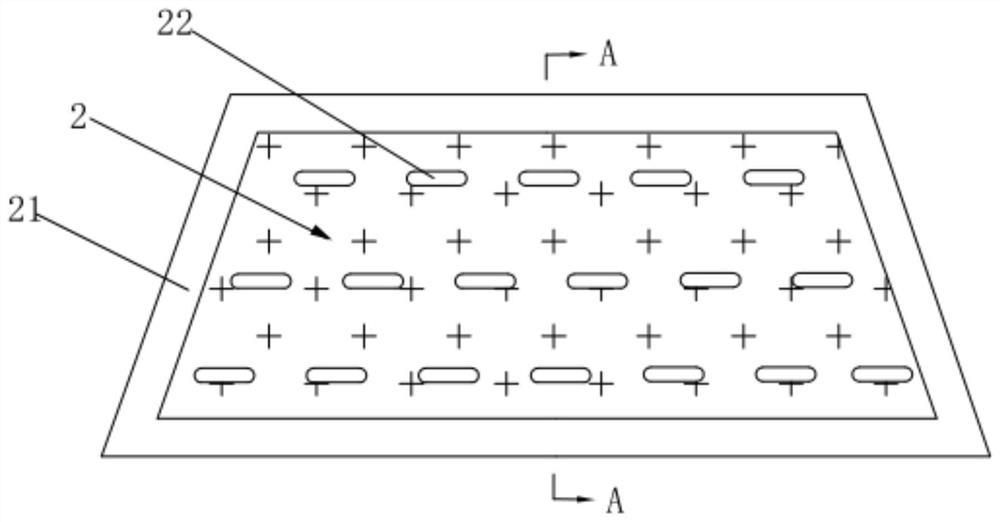

Oxygen barrier layer and self-flat-topped lattice point digital flexible resin plate comprising same and provided with convex parts with gritted surfaces

PendingCN114474959AImprove restoration qualityHigh reduction levelPlate printingFoil printingPrinting inkCarboxylic group

The invention provides an oxygen barrier layer and a self-flat-topped lattice point digital flexible resin plate containing the oxygen barrier layer, wherein the surface of a convex part of the self-flat-topped lattice point digital flexible resin plate is sanded. The oxygen barrier layer contains particles with the size of 0.01-10 microns; the particles in the oxygen barrier layer are formed by reacting amido-containing water-soluble resin and carboxyl-containing polymer resin in water, that is, the particles are directly formed in the oxygen barrier layer coating liquid, the process of dispersing solid particles is omitted, and the purpose that the particles are contained in the oxygen barrier layer is achieved. The oxygen barrier layer coating liquid is coated on the photosensitive elastomer, namely the ultraviolet polymerization relief printing plate forming layer, the surface of the sand mesh has higher printing ink transfer capability, the ink layer of the printed matter is thicker, and the color rendition is more vivid.

Owner:LUCKY HUAGUANG GRAPHICS

A processing method for metal energy storage spring used in U-shaped polytetrafluoroethylene shell

The invention relates to a metal energy storage spring machining method. The metal energy storage spring machining method includes the following steps that S1, firstly, a steel belt is horizontally bent to be a circular-arc steel belt; S2, the circular-arc steel belt is spirally wound in the longitudinal direction to form a plurality of conical cylinders; S3, every two adjacent conical cylinders in the conical cylinders are connected in a lap joint mode to form a long cylinder; S4, single-piece steel belts are pulled out of the head end of the long cylinder and the tail end of the long cylinder respectively and subjected to butt welding to form an annular cylinder; S5, the two single-piece steel belts generated after butt welding is conducted are wound back into the adjacent conical cylinders respectively after restoring to the conical cylinders. S6, punch forming is conducted on the annular cylinder obtained in S5, and thus the annular cylinder can meet the drawing requirement. The method is used for machining metal energy storage springs.

Owner:HARBIN DONGAN IND DEV

A deep reddish-brown and high-gloss baked food skin coating liquid and a method for processing baked food using the skin coating liquid

ActiveCN103875754BIncrease brightnessHigh transparencyPre-baking dough treatmentCooking & bakingMaillard reaction

The invention relates to surface coating liquid of a dark-red-brown high-glossiness bakery product. The surface coating liquid comprises, by weight, the components of 40 parts-70 parts of water, 0.5 part-6 parts of alkali and 30 parts-60 parts of egg white liquid. During baking of the bakery product, hot alkali liquid in the surface coating liquid is used for surface coating first, the proper Maillard reaction condition is controlled, so that the product has attractive dark-red-brown color, the color can be kept for a long time, when the bakery product is fully baked and goes out of an oven, protein liquid is placed in a coating mode, and accordingly the surface of the bakery product has higher brightness and higher transparency.

Owner:山东乐利事食品有限公司

A household automatic food waste microbial treatment integrated machine

ActiveCN106964630BReduce zero emissionsGuaranteed zero emissionsSolid waste disposalDomestic plumbingBiotechnologyHome use

The invention discloses a domestic full-automatic kitchen garbage microbiological treatment all-in-one machine. The domestic full-automatic kitchen garbage microbiological treatment all-in-one machine comprises a mechanical smashing system, a microbiological degradation system and a PLC online monitoring system. Kitchen garbage can be rapidly degraded into liquid and carbon dioxide through a compound microbiological preparation, and the degradation rate of organic garbage is high; and in the degradation process, no toxicity or off flavor is generated, and reduction and harmless treatment of the kitchen garbage can be achieved from the source. According to the domestic full-automatic kitchen garbage microbiological treatment all-in-one machine, a family is used as a unit, the kitchen garbage can be treated from the source, and installation and use are convenient and safe; the designed working life of the domestic full-automatic kitchen garbage microbiological treatment all-in-one machine is over 10 years, the microbiological degradation system is replaced once every year, the yearly average maintenance cost is hundreds of yuan and lower than that of other kitchen garbage treatment manners, and therefore the domestic full-automatic kitchen garbage microbiological treatment all-in-one machine can be accepted by ordinary families.

Owner:浙江金环宝生物技术有限公司

Processing and preparation method for multi-variety v-shaped positioning axle housing cleaning consignment trolley

ActiveCN106563928BAvoid the phenomenon of "forced demolition and re-soldering"Avoid forced demolition and re-soldering" phenomenonAxle unitsEngineeringMachining

The invention discloses a machining and preparing method for a cleaning and conveying trolley for multiple varieties of V-shaped positioning axle housings, and belongs to the field of mechanical manufacturing. According to the machining and preparing method, a same-period matched study is implemented while a technical scheme of the cleaning and conveying trolley for multiple varieties of V-shaped positioning axle housing components is studied, it can be ensured that the multiple varieties of V-shaped positioning axle housing components are used on the cleaning and conveying trolley, and the application range is widened; and during variety changing, involved positioning and limiting assembly machining and preparing are feasible and reliable, and convenience and accuracy are achieved; and the phenomenon of forced demounting and rewelding during changing can be avoided, and the rapid changing needed during actual production is met. The method is clear, simple and practical, preparing is easy, and the popularized application value is achieved.

Owner:FIRST TRACTOR

A treatment device and treatment method for fluorine-containing waste gas

ActiveCN106268232BEfficient purification treatmentStable purification treatmentDispersed particle separationLiquid storage tankTherapeutic effect

Owner:HENGLI ELETEK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com