A femtosecond laser-based preparation method for cracked nano-gap structure

A femtosecond laser and nano-slit technology, applied in the field of laser applications, can solve the problems of high cost, cumbersome process, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

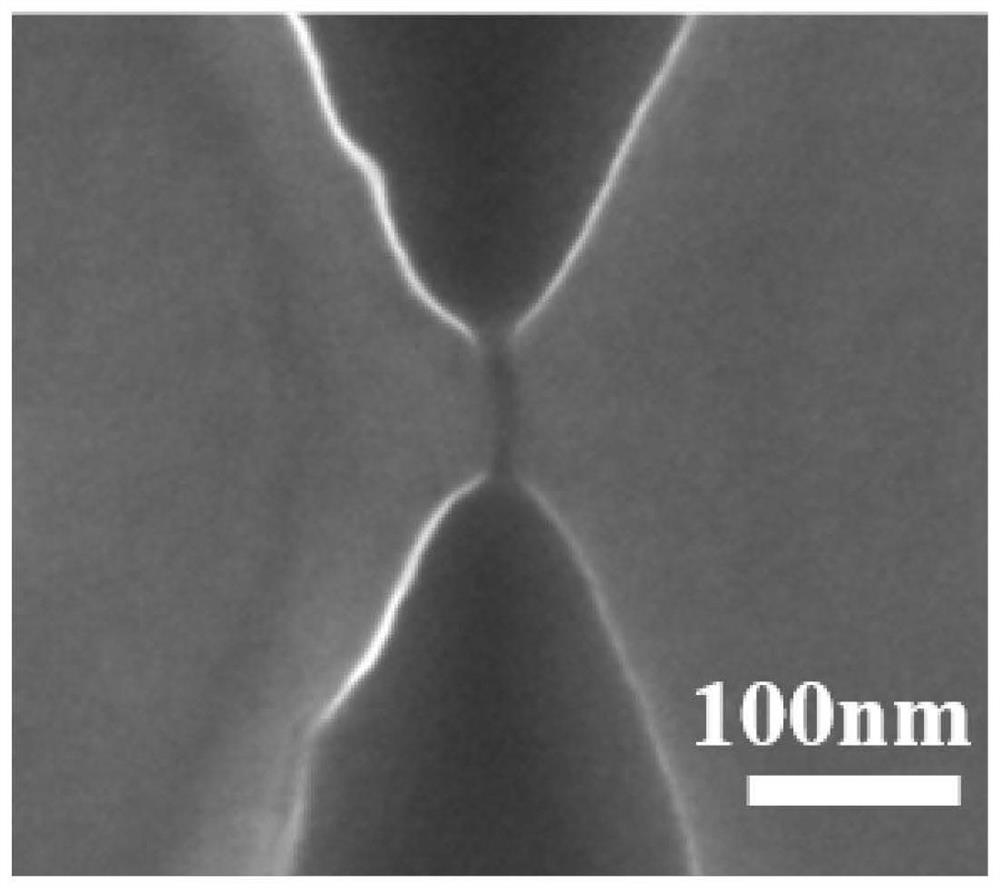

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0030] like figure 1 , a femtosecond laser-based fabrication method for cracked nano-slits. First, a linearly polarized femtosecond laser (center wavelength 800 nm) was irradiated to a liquid crystal spatial light modulator (SLM) at a small angle. In this example, a spatial shaper is used to transform the light field intensity profile of the incident laser from a Gaussian to a bimodal beam, and its phase is expressed as follows:

[0031]

[0032] The spatially shaped femtosecond laser passes through two equal focal lengths (f 1 =f 2 = 500mm) optical lens composed of 4f optical system to carry out beam phase transfer, to avoid the diffraction and distortion of the laser phase due to long-distance propagation. In the 4f system, the distance from the SLM liquid crystal surface to the lens 1 should be equal to the focal length of the lens, the distance bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com