Diamond NV color center prepared through laser direct writing assisted by spatial light modulation technology, preparation method and application of diamond NV color center

A technology of spatial light modulation and auxiliary laser, applied in diamond, laser welding equipment, manufacturing tools, etc., can solve the problems of destroying focus energy density, complicated preparation process, limited positioning accuracy, etc., achieving high positioning accuracy and simple preparation process. , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

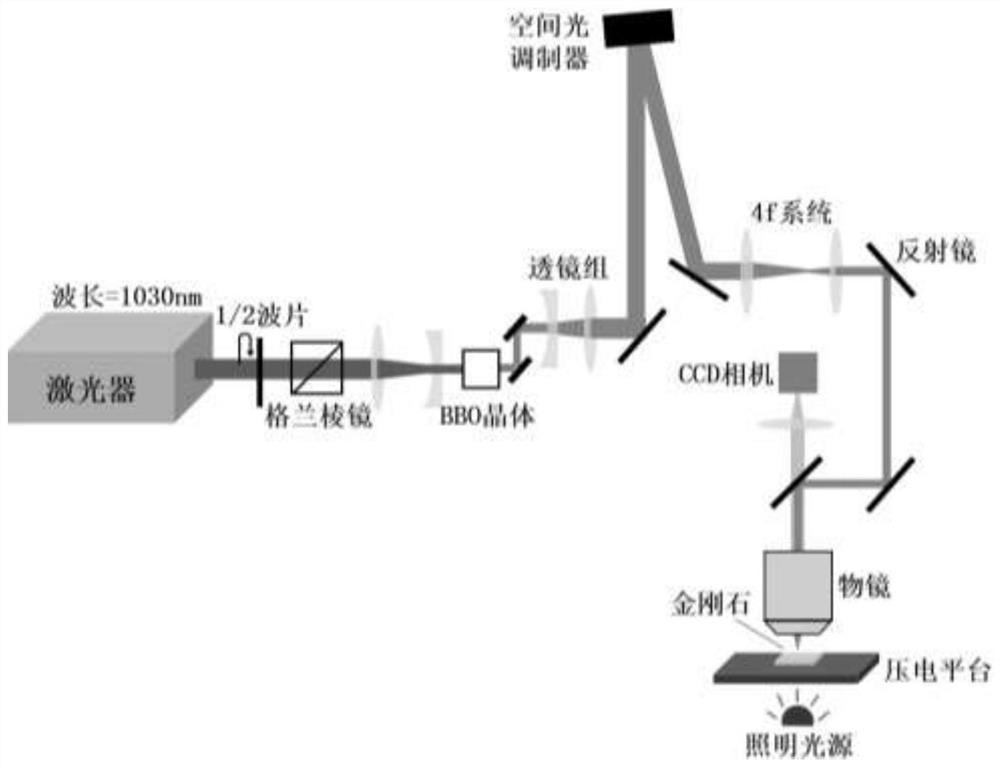

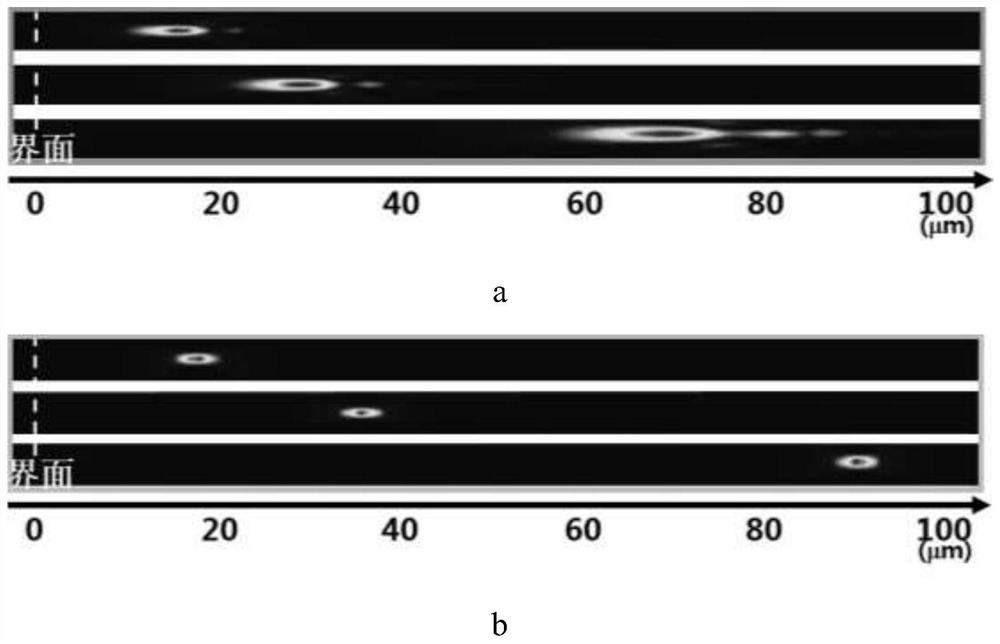

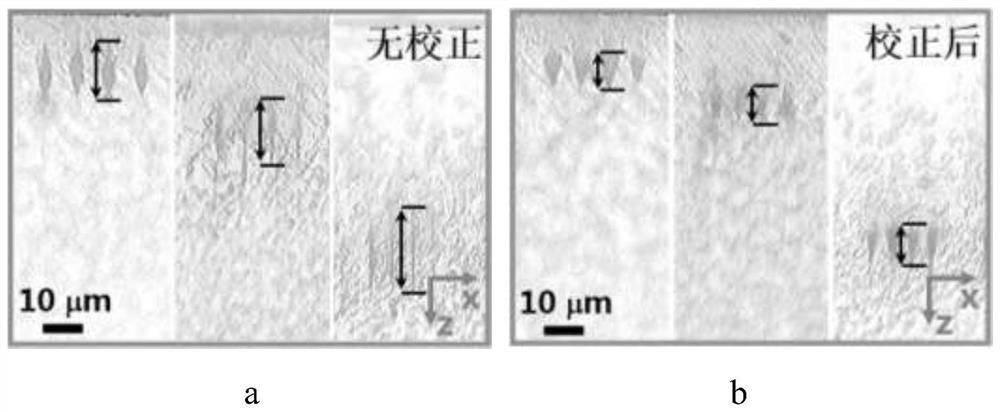

[0040] Preparation of diamond NV color centers by laser direct writing assisted by spatial light modulation technology.

[0041] After correcting the aberration by using the frequency-doubled femtosecond laser reflected by the spatial light modulator, the diamond sample after laser direct writing is placed in a high-temperature annealing furnace for annealing according to a certain temperature gradient and time length, and then the sample is placed in the prepared The mixed acid solution is heated in a hydrothermal reaction oven, and then the diamond sample is taken out and cleaned thoroughly, and finally a single NV color center inside the diamond is obtained.

[0042] A method for preparing diamond NV color centers assisted by laser direct writing with spatial light modulation technology, the specific steps are as follows:

[0043] (1) Preparation of diamond samples: The purchased double-sided polished commercial CVD diamond has a side length of 2 mm, a thickness of 500 μm, ...

Embodiment 2

[0053] The embodiment of the present invention also provides an application of diamond NV color centers prepared by laser direct writing assisted by spatial light modulation technology in the preparation of quantum optical devices.

[0054] The NV color center prepared in Example 1 shows the anti-bunching phenomenon through the photon correlation test, which proves that it is a single NV color center, which only emits one photon in one excitation-deexcitation process when excited by the excitation light. Therefore, it can be used as a single photon source. An ideal single photon source often needs to meet several requirements of stability at room temperature, long coherence time, and narrow optical linewidth close to the excited state lifetime. The ground state electrons of the NV color center are excited to transition and radiate fluorescence under the irradiation of excitation light, and the "excitation-emission" process occurs many times, and the generated photons will main...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com