Detecting method and sensor for cracks of civil structure based on optical fiber long chirped grating frequency domain reflection technology

A technology of chirped grating and frequency domain reflection, which is applied in the direction of transmitting sensing components, instruments, measuring devices, etc. by using optical devices, can solve the problem of failure of strain gauge sensors, insufficient accurate detection of structural cracks and accurate position information, and inability to obtain overall Information and other issues, to achieve the effect of high spatial positioning accuracy, high cost performance, and good system stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

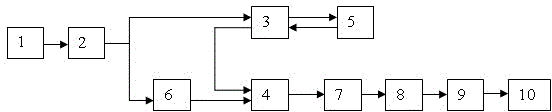

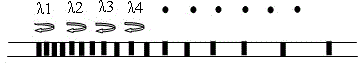

[0012] Specific implementation mode one: the following combination figure 1 , 2 This embodiment will be specifically described. The tunable laser 1 emits a narrow linewidth laser whose wavelength changes with time, enters the coupler 2 and is divided into two paths. One path of light is used as a reference light and passes through the polarization controller 5 and the coupler 4 before entering the photodetector 7, and the other path is used as a transmission path. The photosensitive light enters the long chirped grating sensor 6 through the coupler 3 and is reflected by the grating. The reflected light passes through coupler 3 into coupler 4 and then into photodetector 7 . The current signal output by the optical signal after passing through the photodetector 7 is collected by the data acquisition card 8, and then the signal is analyzed by the signal processing part 9 to obtain the change of the reflected light signal of the optical fiber long chirped grating contained in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com