Method and system for processing nanocone arrays on silk film using femtosecond laser

A femtosecond laser and nanocone technology, which is applied in the field of femtosecond laser application, can solve the problem of lack of processing nanoscale cone-shaped convex arrays.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

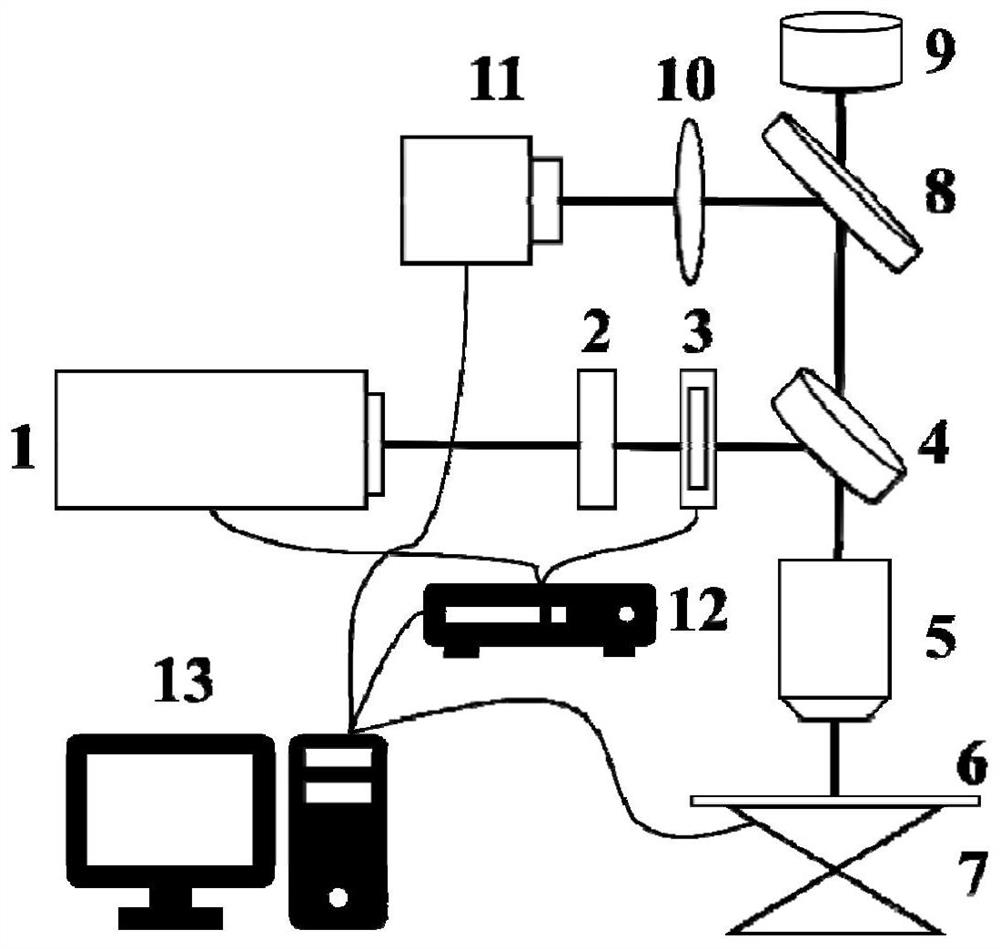

Image

Examples

Embodiment 1

[0053] Adjust the neutral density attenuator 2, and set the energy flux of a single pulse to 6.2J / cm 2 , the moving speed of the translation stage is 800 μm / s, and the scanning interval is 800 nm, and a nanocone array with a diameter of 210 nm, a height of 17.55 nm, and a pitch of 800 nm is obtained on the silk film 6 .

Embodiment 2

[0055] Adjust the neutral density attenuator 2, and set the energy flux of a single pulse to 7J / cm 2 , the moving speed of the translation stage is 1000 μm / s, the scanning interval is 1000 nm, and a nanocone array with a diameter of 320 nm, a height of 44.4 nm, and a pitch of 1000 nm is obtained on the silk film 6 .

Embodiment 3

[0057] Adjust the neutral density attenuator 2 and set the energy flux of a single pulse to 7.7J / cm 2 , the moving speed of the translation stage is 1500 μm / s, the scanning interval is 1500 nm, and a nanocone array with a diameter of 420 nm, a height of 168 nm, and a pitch of 1500 nm is obtained on the silk film 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com