Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Reduce residual stress levels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

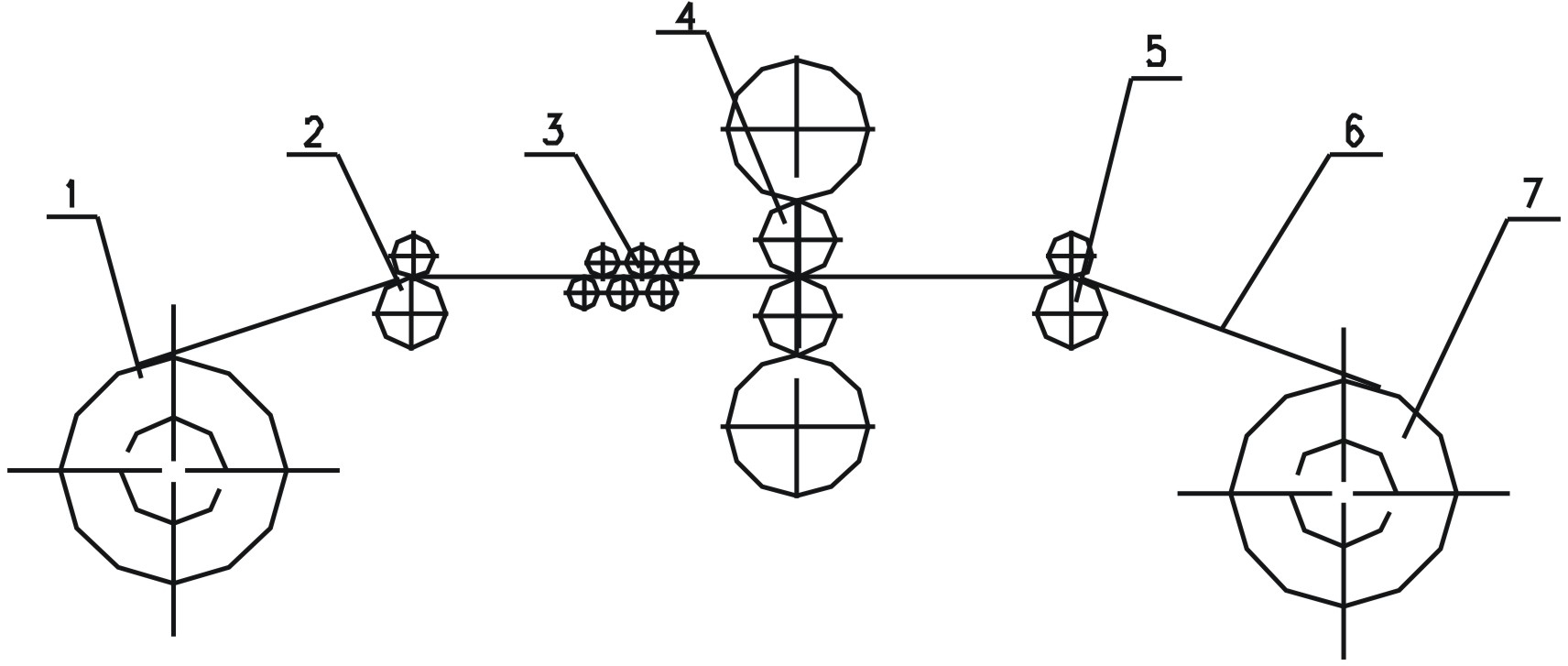

Straightening and leveling process for hot-rolled high-strength steel

ActiveCN102626726AReduce residual stress levelsResidual Stress Level GuaranteeMetal rolling arrangementsUltimate tensile strengthMechanical engineering

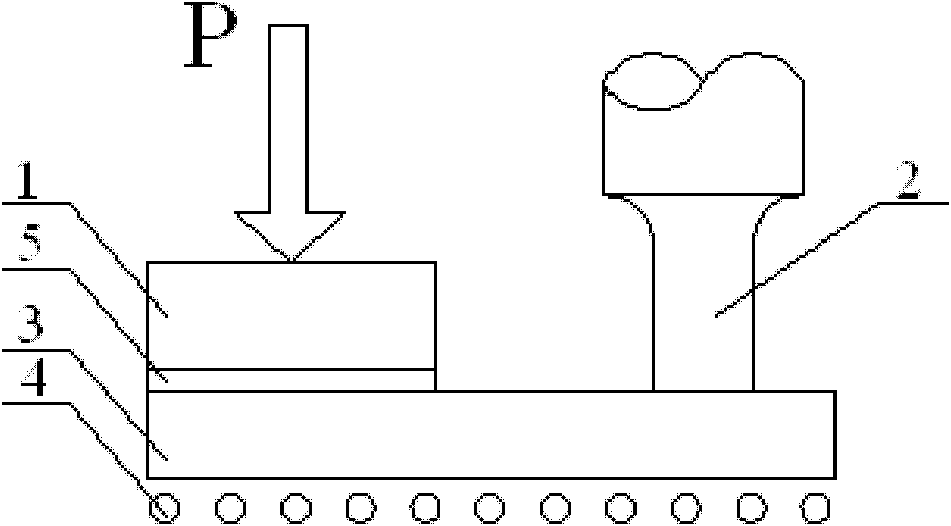

The invention relates to a straightening and leveling process for hot-rolled high-strength steel. The straightening and leveling process is characterized in that: hot-rolled high-strength band steel is fed into a straitening machine and a leveling machine in sequence. The process comprises the following specific steps of: firstly, setting the total elongation rate of a unit according to yield strength needed by a band steel product on the tail of a process section; secondly, distributing a total elongation rate set value to the straitening machine and the leveling machine for presetting the straightening and leveling process; thirdly, detecting the total elongation of detected and processed band steel in real time; and lastly, comparing the total elongation of the detected and processed band steel with the total elongation rate set value, dynamically adjusting the rolling force of the leveling machine in real time to ensure that the total elongation rate of a band steel product on the tail of the process section is constant, lowering the residual stress level of the band steel by using the straightening machine, and ensuring the performance quality of the band steel product on the tail of the process section. Due to the adoption of the process, the internal residual stress level of the hot-rolled band steel can be lowered fully, and the performance quality of a hot-rolled high-strength steel product is improved effectively.

Owner:WISDRI ENG & RES INC LTD

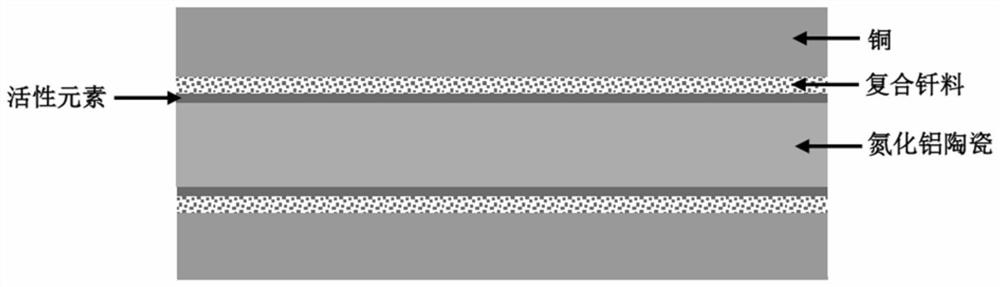

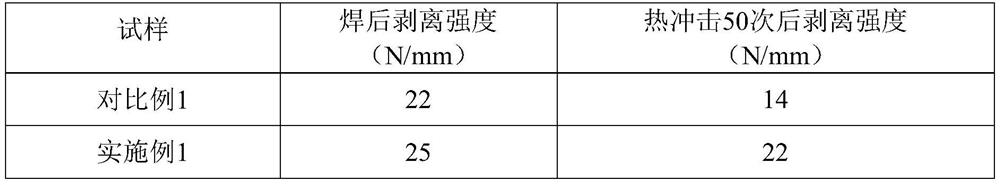

Indirect brazing method for aluminum nitride ceramic copper-clad plate

ActiveCN113307647ASmall coefficient of thermal expansionReduce residual stress levelsThermal dilatationSlurry

The invention discloses an indirect brazing method for an aluminum nitride ceramic copper-clad plate, and belongs to the technical field of ceramic copper-clad plate manufacturing. The preparation process comprises the following steps: uniformly mixing Ag powder, Cu powder, copper-plated low-expansion ceramic powder and copper-plated graphene powder to prepare composite brazing filler metal, and adding an organic binder into the composite brazing filler metal to prepare composite brazing filler metal slurry; depositing an active metal element Ti, Zr, Hf or Cr on the surface of the aluminum nitride ceramic; and after the composite brazing filler metal is coated on the surface of the aluminum nitride ceramic substrate sputtered with the active elements, making oxygen-free copper sheets compounded on two sides, and making an obtained assembly dried and then put into a vacuum furnace to be brazed. The ceramic particles with the low expansion coefficient are introduced into the brazing filler metal, the thermal expansion coefficient of a connector is in gradient transition, and then the residual stress level of the connector is remarkably reduced. Graphene with high thermal conductivity and high strength is introduced into the composite brazing filler metal, so that the strength of the brazing filler metal can be improved, and the thermal conductivity of the brazing filler metal can be improved.

Owner:CHANGCHUN UNIV OF TECH

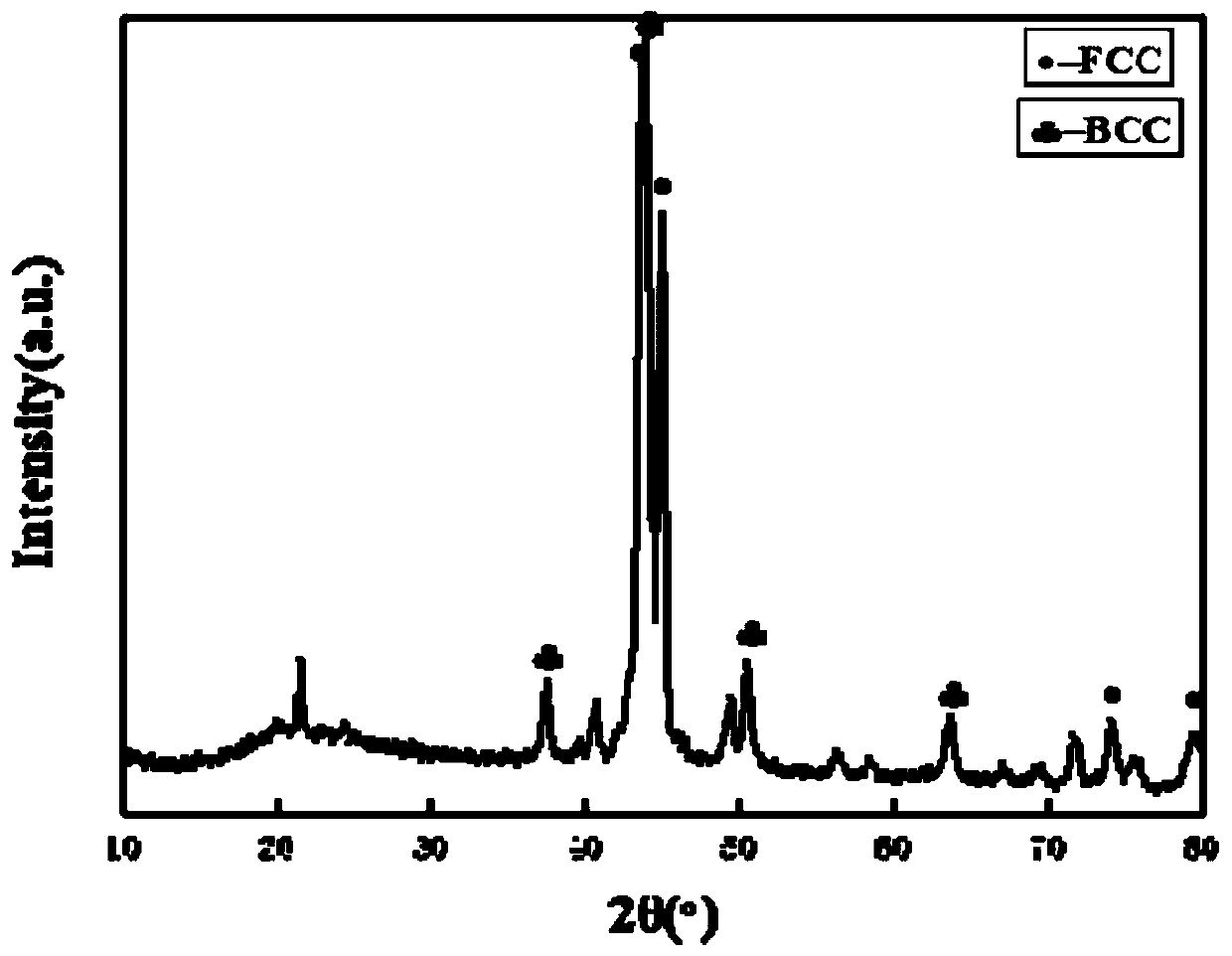

FeCrCuTiV high-entropy alloy powder for laser melting deposition manufacturing and preparation method of FeCrCuTiV high-entropy alloy powder

ActiveCN109957700AModerated coefficient of thermal expansionModerate differences in modulus of elasticity, etc.Additive manufacturing apparatusTransportation and packagingHigh entropy alloysThermal expansion

The invention discloses FeCrCuTiV high-entropy alloy powder for laser melting deposition manufacturing and a preparation method of the FeCrCuTiV high-entropy alloy powder. The high-entropy alloy powder is prepared from the following components in percentage by weight: 17-20% of Cr, 22-25% of Cu, 16-19% of Ti, 17-20% of V and 19-22% of Fe. The differences of the thermal expansion coefficient, the melting point, the elastic modulus and the like of a tungsten / steel interface can be effectively relieved through the solid solution effect of alloy elements such as Ti, V and Cu of a high-entropy alloy, the level of residual stress at a heterogeneous interface in the laser melting deposition preparation process can be reduced, precipitation of a Laves phase is avoided, and the manufacturing requirements of tungsten steel heterogeneous parts for a fusion reactor can be met.

Owner:SUZHOU UNIV

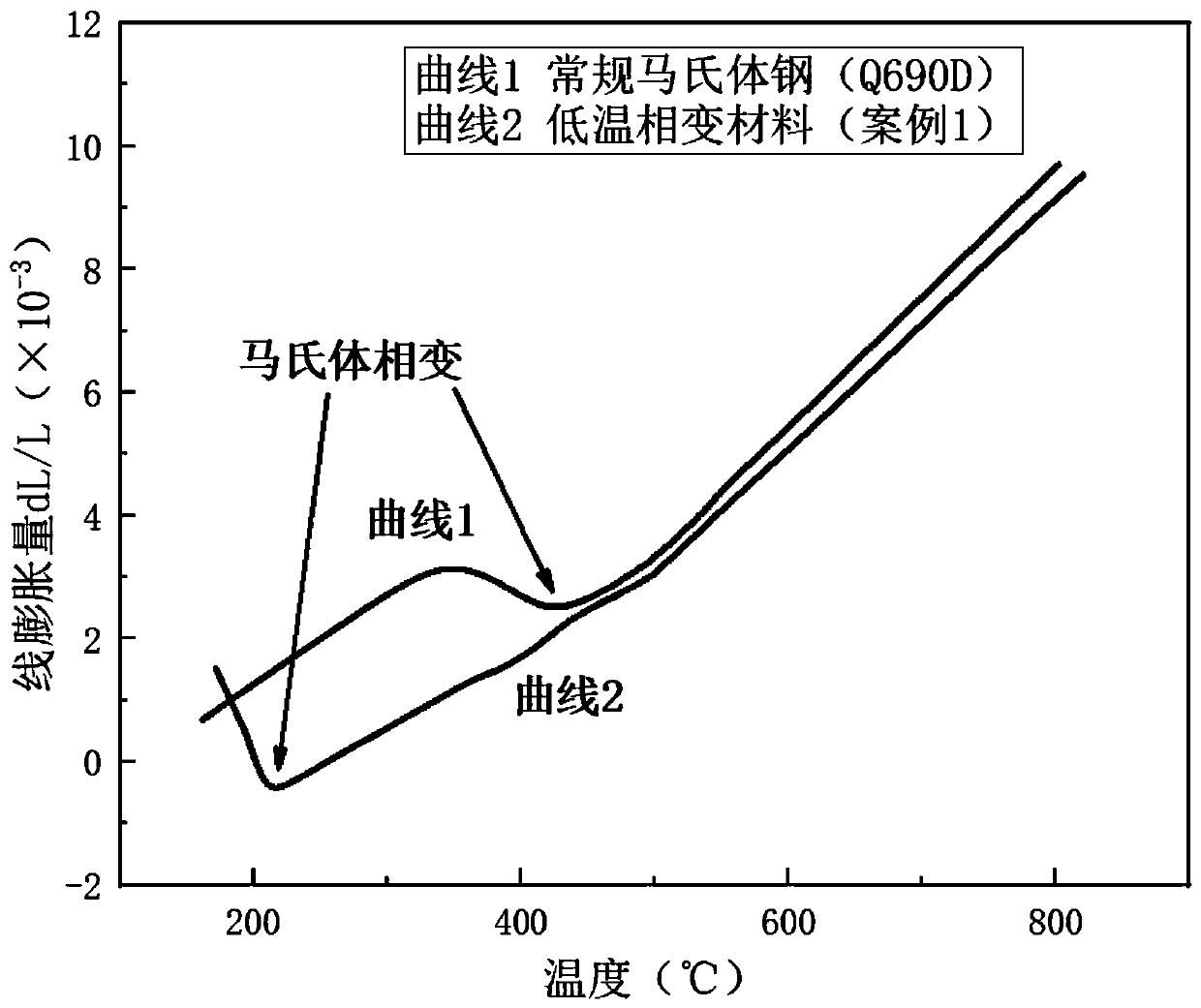

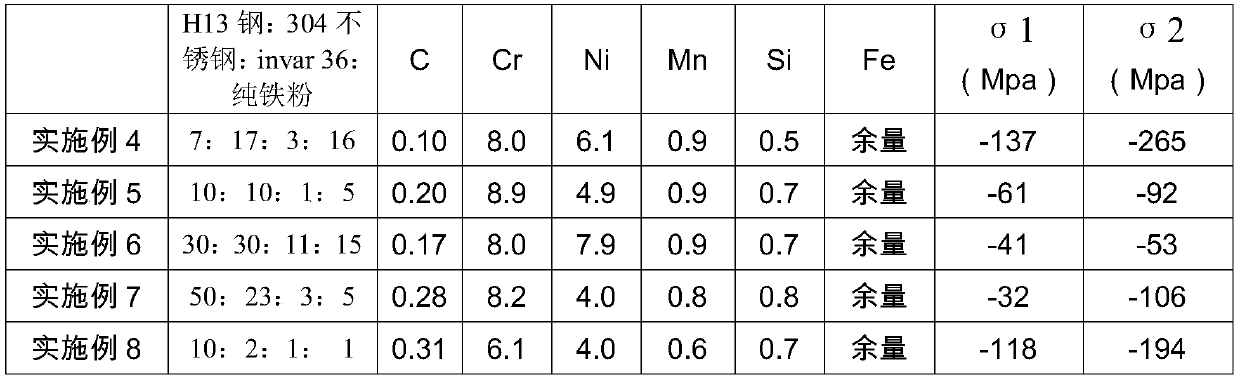

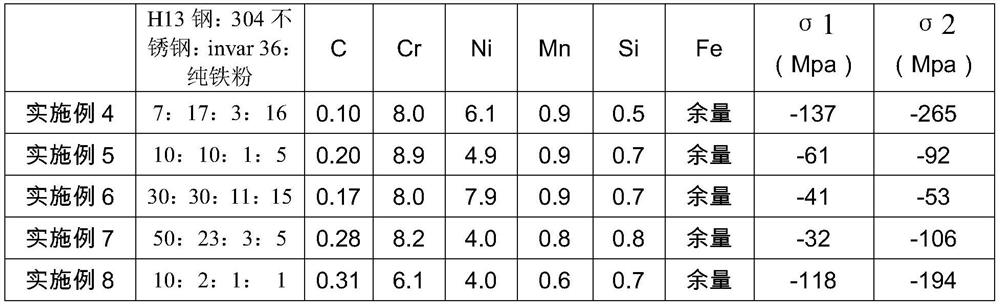

Alloy powder for repairing martensitic steel through laser additive manufacturing and preparation and application of alloy powder

ActiveCN111390159AMs points loweredTensile stress is obtainedAdditive manufacturing apparatusIncreasing energy efficiencyMartensite transformationAlloy

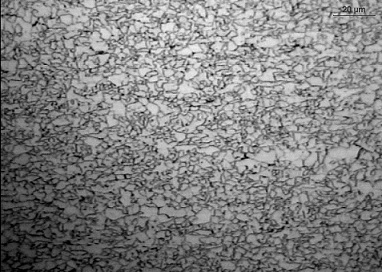

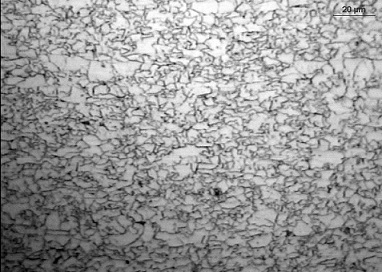

The invention belongs to the field of laser additive manufacturing repair, and particularly relates to alloy powder for repairing martensitic steel through laser additive manufacturing and preparationand application of the alloy powder. The alloy powder contains the following components of, in percentage by mass, 0.03%-0.4% of C, 6%-10% of Cr, 4%-8% of Ni, 0.5%-1.5% of Mn, 0.6%-1.2% of Si and thebalance Fe and inevitable impurities, so that the alloy powder has a relatively low martensite phase transformation point. The alloy powder is used for repairing the martensitic steel through laser additive manufacturing, a martensitic structure is formed in a repaired area, the volume expansion effect of martensitic phase transformation is used for counteracting heat shrinkage generated by cooling of the repaired area, residual compressive stress is generated in the repaired area, the defects of deformation, fatigue cracks and the like of repaired parts are avoided, timeliness and reliability of part repairing are improved, and the damaged part can be used immediately after being repaired.

Owner:HUAZHONG UNIV OF SCI & TECH

Method of manufacturing aluminum alloy sheet product with low residual stress level

The present invention relates to a method of manufacturing thick gauge aluminum alloy plates with low residual stress levels, said method comprising: (a) providing a solution heat treated and quenched aluminum alloy plate having a thickness of at least 80 mm; (b) by adding said Cold rolling of the plate stress relieves it, resulting in a reduction of up to 8% in the thickness direction of the plate product.

Owner:ALERIS ALUMINUM KOBLENZ GMBH

Molding method for high-strength high-modulus aluminum based composite material

InactiveCN101429635AReduce the chance of machining cracksImprove microstructureAluminum matrix compositesSolution treatment

Owner:苏州有色金属研究院有限公司

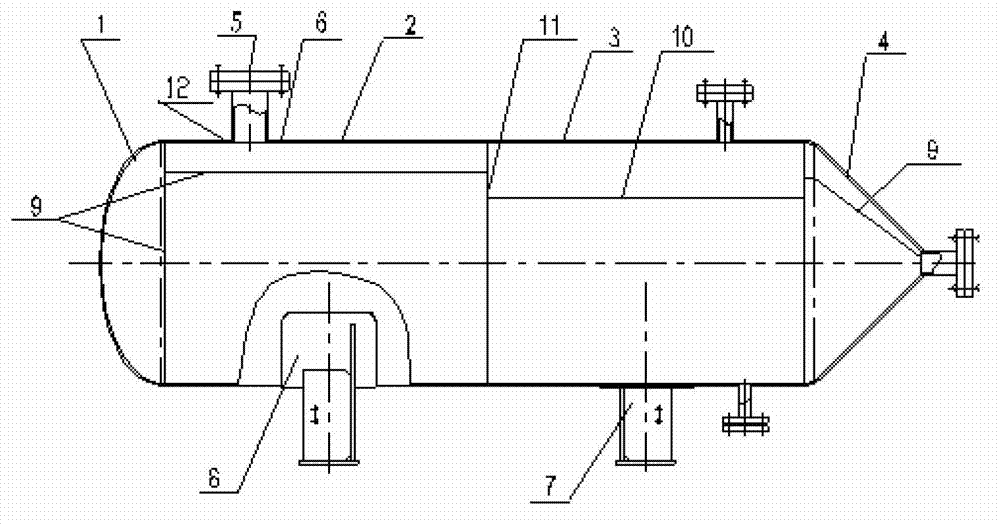

Elongation rate distribution method for high-strength steel straightening and leveling unit

ActiveCN102626717AControl yield strengthReduce residual stress levelsMetal rolling arrangementsElongation control deviceStructural engineeringUltimate tensile strength

The invention relates to an elongation rate distribution method for a high-strength steel straightening and leveling unit. The method is characterized by comprising the following steps of: controlling the total elongation rate of high-strength steel at a process section of the straightening and leveling unit according to the product deformation characteristic in a hot-rolling processing process and the processing characteristics and control stability of the straightening machine and the leveling machine; proportionally distributing a total elongation rate set value to the straightening machine and the leveling machine for presetting straightening and leveling processes; fully lowering the residual stress level of hot-rolled high-strength steel under the reciprocating bending action of the straightening machine; and effectively controlling the final performance of the high-strength steel by using the real-time dynamic adjusting capability of the leveling machine. According to the method, the internal residual stress level of band steel after hot rolling can be lowered fully, the yield strength of the hot-rolled high-strength steel is controlled effectively, and the performance quality of a product is ensured.

Owner:WISDRI ENG & RES INC LTD

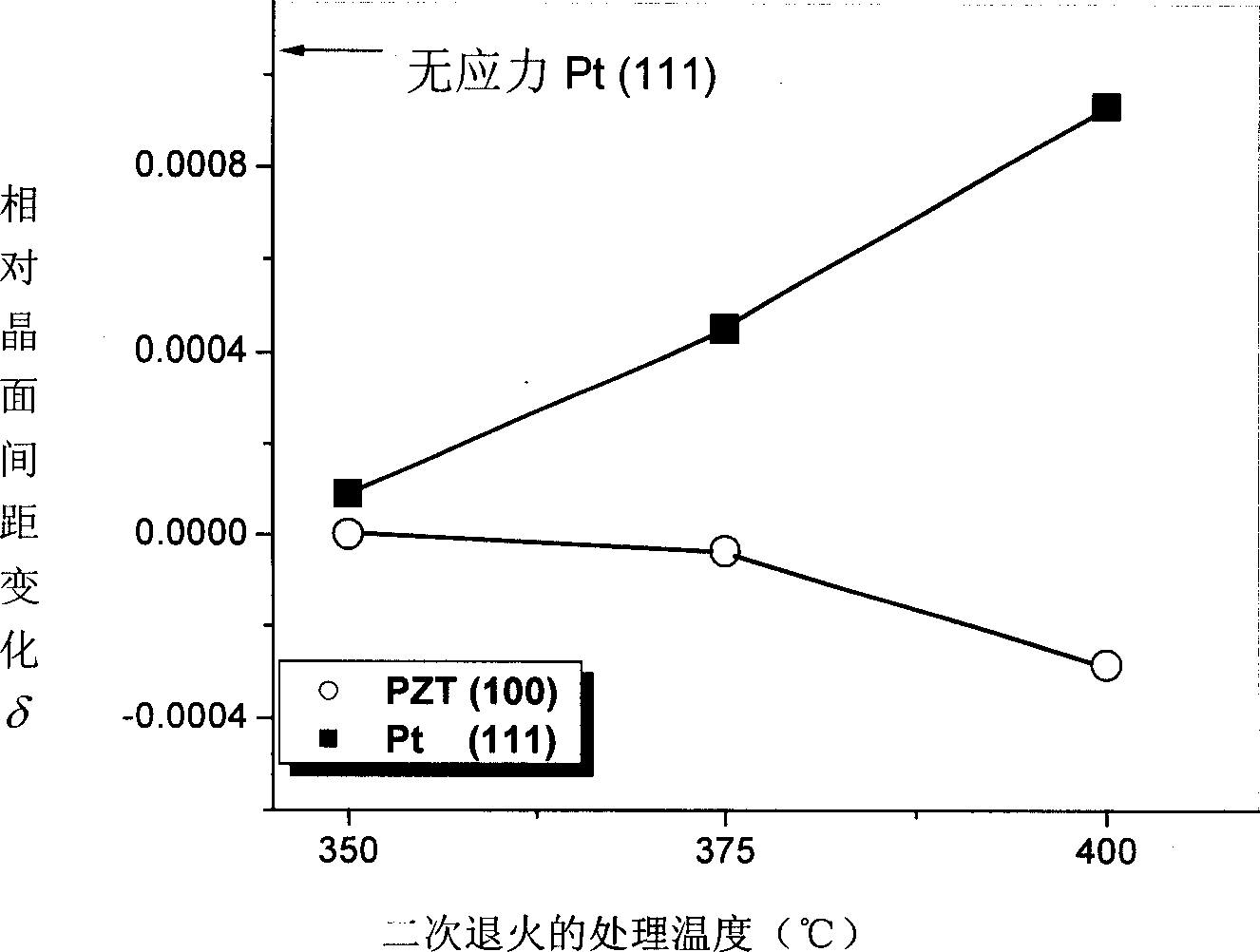

Ferroelectric film alternating electric field heat treatment method

InactiveCN1765830AExcellent ElectricalImprove ferroelectric propertiesCurie temperatureThermal treatment

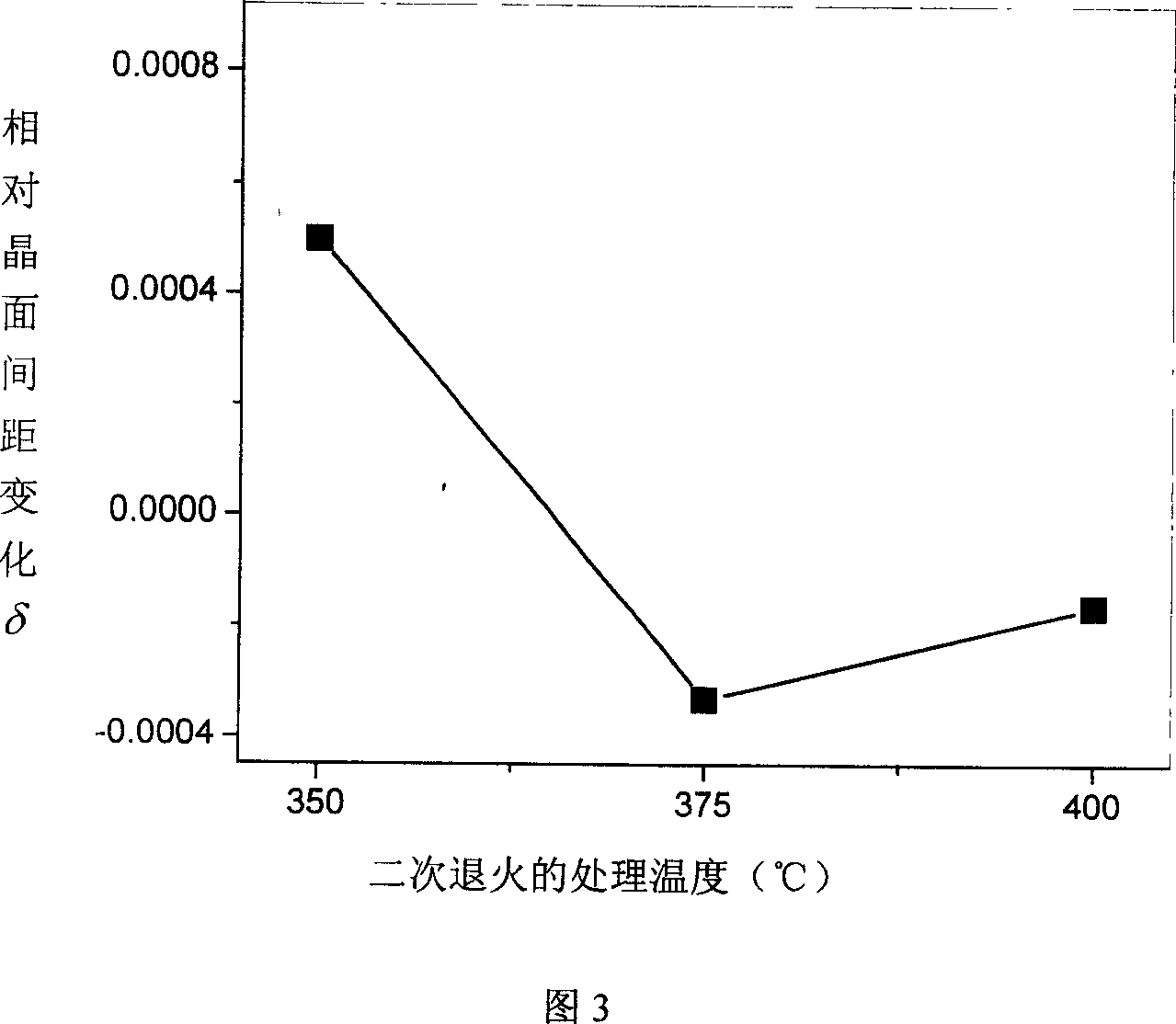

The alternating electric field thermal treatment method for ferroelectric film, special to reduce residual stress in ferroelectric ceramics film, comprises: 1. depositing ferroelectric film material on Pt / Ti / SiO2 / Si base, annealing and crystallizing at high temperature to form film 1; 2.taking secondary anneal to the film 1 with alternating electrc field. This invention is used to ferroelectric ceramics film material with 300~800Deg Curie temperature, can decrease residual stress and process cost.

Owner:HARBIN INST OF TECH

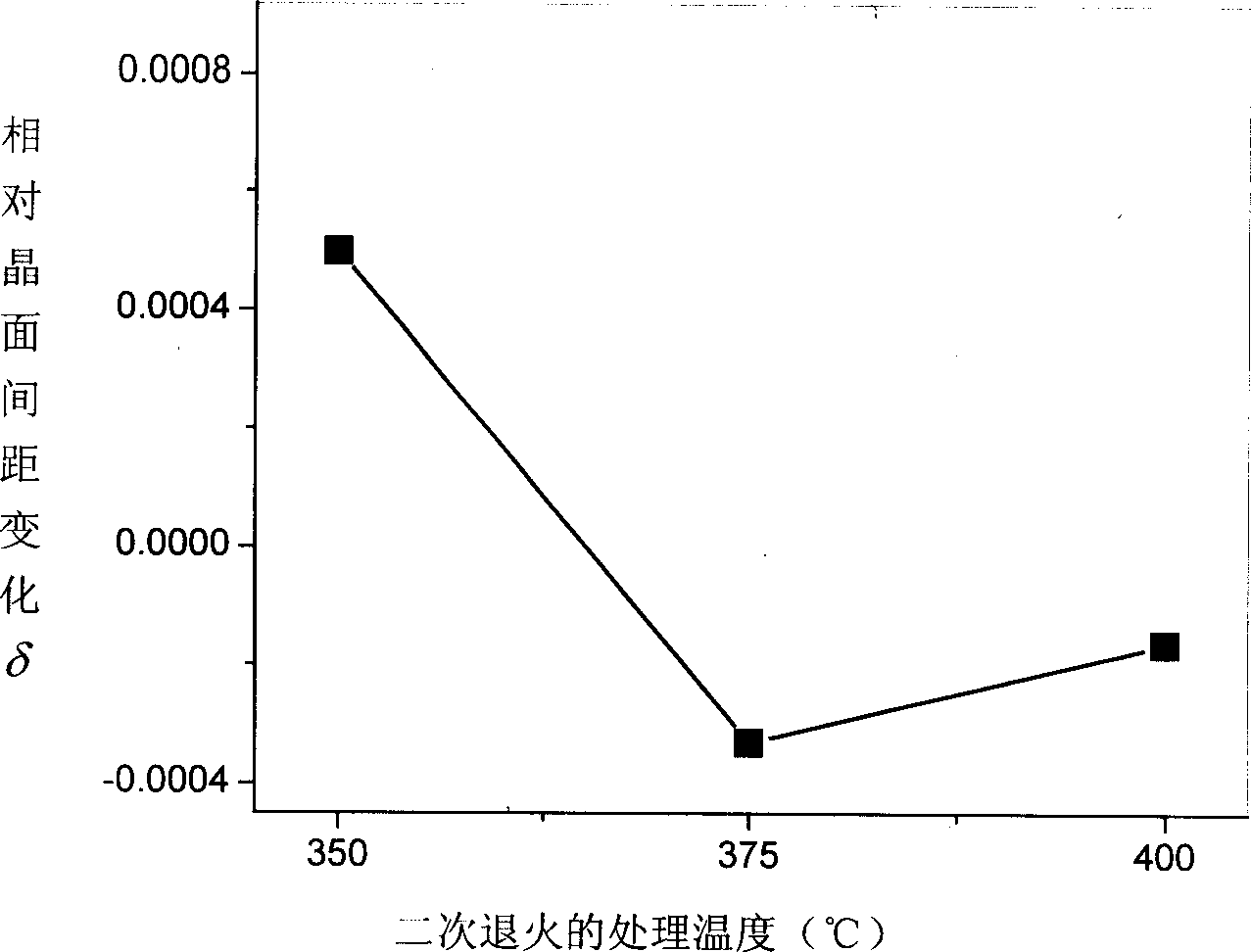

Best strain of austenitic stainless steel container welding residual stress overload reducing method

ActiveCN103160663AExtensiveVersatilityProcess efficiency improvementPrincipal stressAutomatic control

The invention provides best strain of an austenitic stainless steel container welding residual stress overload reducing method. The best strain of the austenitic stainless steel container welding residual stress overload reducing method comprises: (1) a best value exists in overload dependent variable for reducing welding residual stress, the dependent variable corresponding to first major principal stress in direction in a continuous structure zone serves as an evaluation index and overload plastic strain is in a range of 2%-5%; (2) in the process of overload, boosting speed is controlled through a variable frequency pump or an automatic control reflux valve, uploading speed is in a range of 0.2 MPa / min-0.4 MPa / min and the dependent variable is controlled through deformation measurement or strain measurement; and (3) when a container is manufactured, a tensile test is firstly performed to materials, design stress and overload stress are determined according to an actual single tensile curve of the materials and design pressure and overload pressure are calculated through a simplified method. Numerical modeling has universality and generality, evaluation stress is corroded, first tensile welding residual stress is reduced to a great extent and the residual stress after reduction is in the same level with residual stress of a cold rolling plate rear base material and residual stress after stress relief heat treatment.

Owner:北京市朝阳区特种设备检测所

Control method for high-strength steel straightening and leveling unit

ActiveCN102626718AControl yield strengthReduce residual stress levelsMetal rolling arrangementsElongation control deviceStructural engineeringUltimate tensile strength

The invention relates to a control method for a high-strength steel straightening and leveling unit. The unit mainly comprises a straightening machine and a leveling machine. The method is characterized by comprising the following steps of: dynamically controlling the total elongation rate of high-strength steel at a process section of the straightening and leveling unit; fully lowering the residual stress level of hot-rolled high-strength steel under the reciprocating bending action of the straightening machine; and effectively controlling the yield strength of the hot-rolled high-strength steel by using the real-time dynamic adjusting capability of the leveling machine, and lowering the residual stress level of the high-strength steel by using the straightening machine. According to the method, the performance quality of a high-strength steel product on the tail of the process section is ensured.

Owner:WISDRI ENG & RES INC LTD

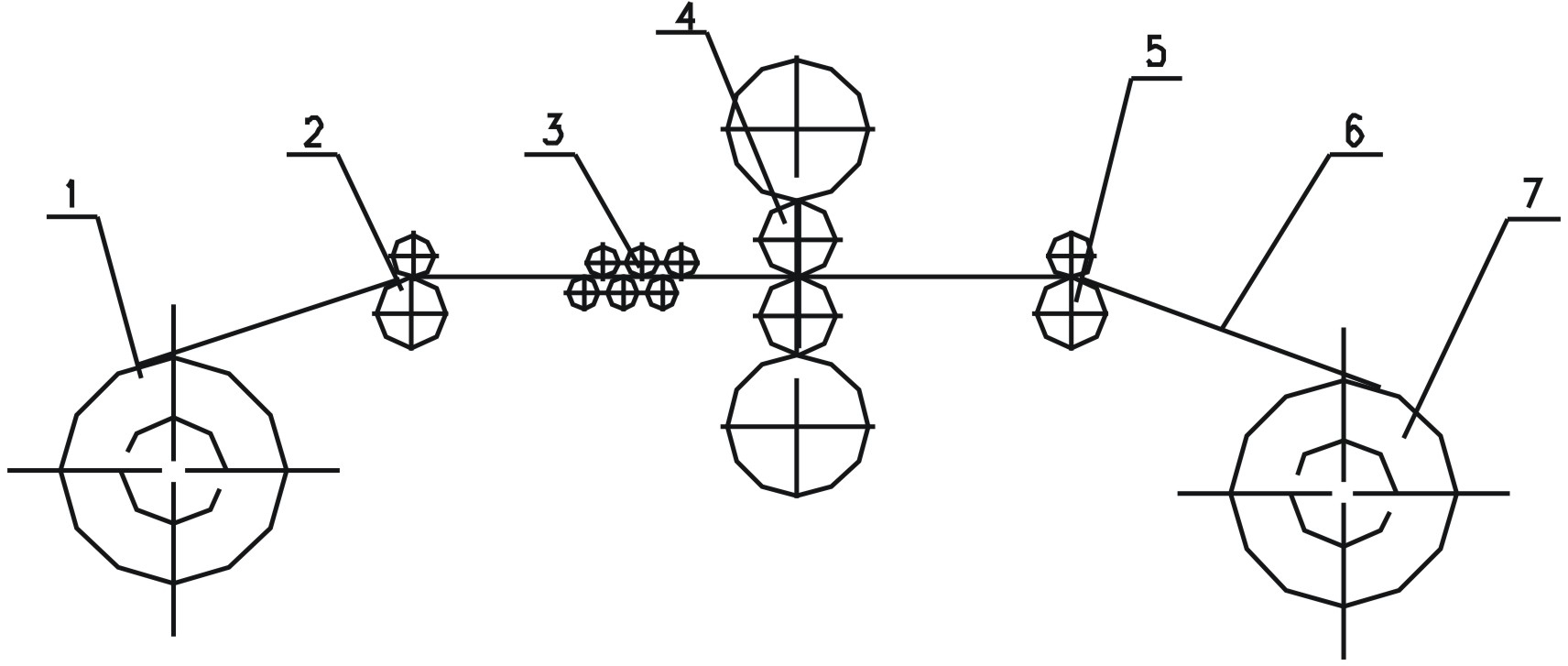

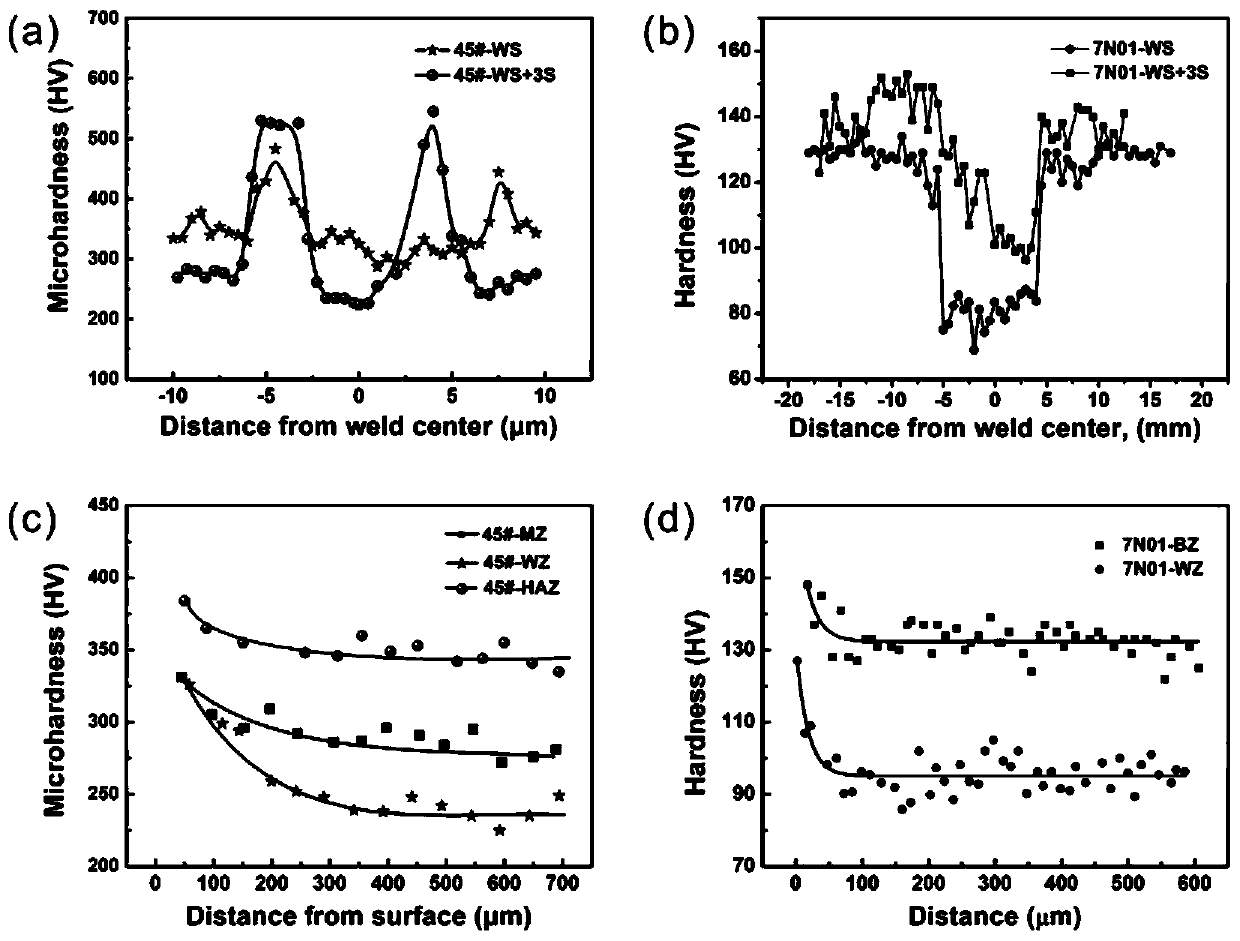

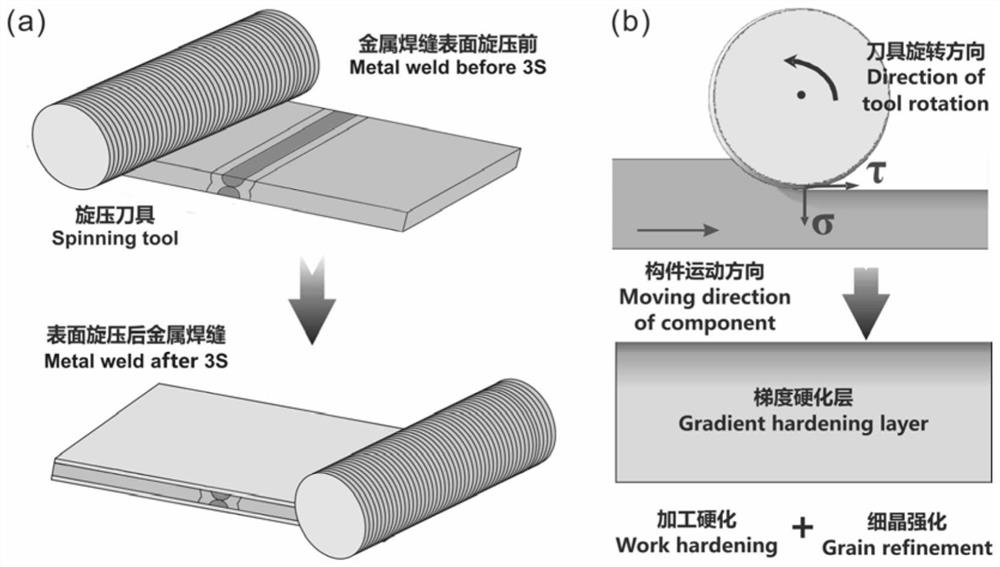

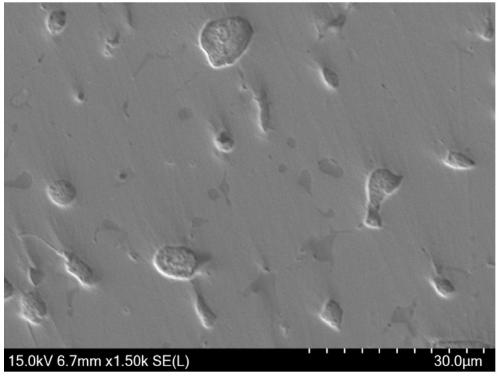

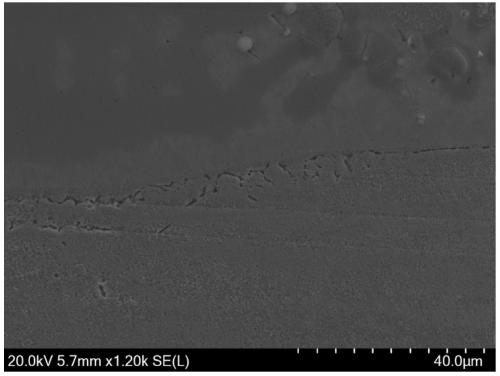

Welded joint fatigue life prolonging method

ActiveCN111069703AAchieving grain refinementAchieve refinementMachined surfaceStructural engineering

The invention discloses a welded joint fatigue life prolonging method and belongs to the technical field of surface strengthening processing for improving the fatigue property of a metal welding seam.According to the welded joint fatigue life prolonging method, the surface spinning strengthening technology is adopted to carry out surface strengthening processing on a welded joint so as to obtaina metal surface layer microstructure with hardness gradient, so that surface strengthening and hardening of the metal welded joint are realized; and in addition, the processing surface is smooth, so that the surface stress concentration level and the postwelding residual stress level of a welded component are lowered. When the metal welded component takes service under the action of cyclic load, afatigue crack can be restrained from generating on the surface of the welded joint after spinning processing to improve the fatigue property of the metal welded joint.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A method for prolonging fatigue life of welded joints

The invention discloses a method for prolonging fatigue life of welded joints, and belongs to the technical field of surface strengthening processing for improving the fatigue performance of metal welds. This method adopts surface spinning strengthening technology to carry out surface strengthening processing on welded joints to obtain metal surface structure with hardness gradient, realize surface strengthening and hardening of metal welded joints, and process smooth surface at the same time, which reduces the level of stress concentration and stress concentration on the surface of welded components. Post-weld residual stress levels. When metal welded components serve under cyclic loads, the initiation of fatigue cracks from the surface of welded joints can be inhibited after spinning, thereby improving the fatigue performance of metal welded joints.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

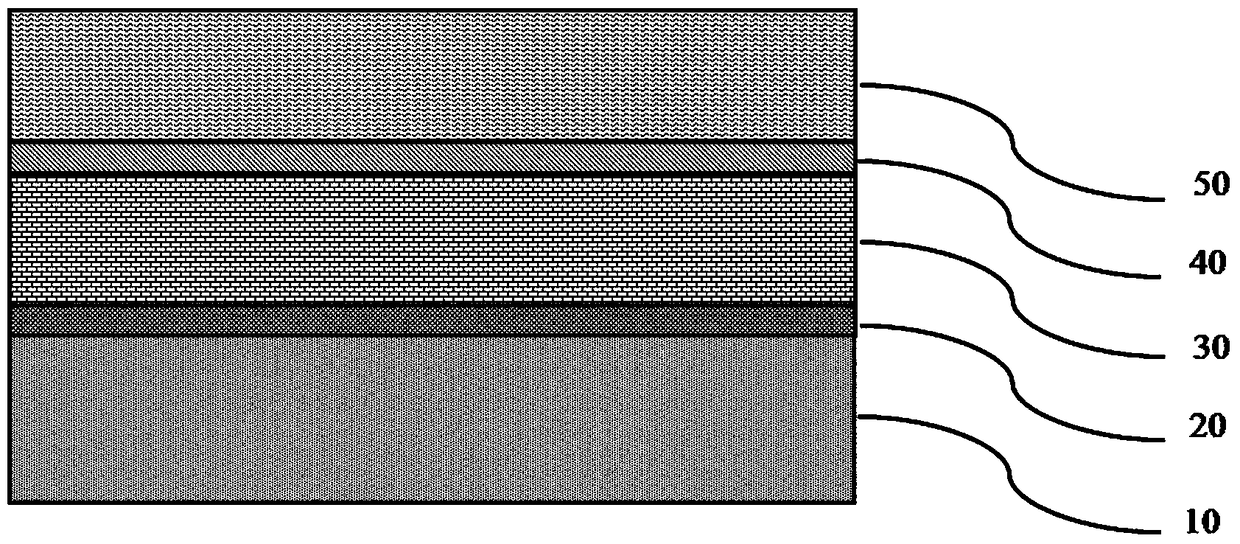

Bionic-structure cubic boron nitride coating and preparation method thereof

ActiveCN106756781AReduce residual stressImprove fracture toughnessVacuum evaporation coatingSputtering coatingBoron nitrideHardness

The invention is suitable for the technical field of vacuum coating, and provides a bionic-structure cubic boron nitride coating and a preparation method thereof. The bionic-structure cubic boron nitride coating is coated on a substrate, and consists of a bottom ductile layer and a top high-hardness layer, wherein the high-hardness layer is a cubic boron nitride layer; the ductile layer is in a multi-layer composite structure formed by alternate deposition of M2 layers and M1Bx:M2 doped composite layers; each M1Bx:M2 doped composite layer is formed by doping of M1Bx in M2; the M1 and the M2 are the same or different transition metal; and x is equal to or lager than 0.5 and equal to or smaller than 4.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

CrCuV solid solution for heterogeneous interface bonding and preparation method and application thereof

ActiveCN111560552AModerated coefficient of thermal expansionModerate melting pointAdditive manufacturing apparatusMetallic material coating processesThermal dilatationHardness

The invention discloses a CrCuV solid solution for heterogeneous interface bonding and a preparation method and application thereof. The CrCuV solid solution comprises the following components in percentage by weight: 33-42% of copper; 25-35% of vanadium; and the balance of chromium. A gradient material with the CrCuV solid solution as the transition layer is synthesized from the CrCuV solid solution by using a laser additive manufacturing or fusion welding means. The difference in thermal expansion coefficient, melting point, elastic modulus, etc. of the heterogeneous interface is effectivelyalleviated, the residual stress level at the heterogeneous interface during the additive manufacturing process can be reduced, the precipitation of hard and brittle phases is avoided, the manufacturing requirements of heterogeneous parts can be reached, and a high-strength bonding interface is created. The CrCuV solid solution used for the connection of heterogeneous materials can have high connection interface strength and hardness, and can be widely used in the bonding of heterogeneous parts such as steel-aluminum, steel-tungsten, or steel-copper.

Owner:SUZHOU UNIV

Low-cost lightweight 600mpa-grade automobile body steel and production method thereof

ActiveCN110499470BFully exert the strengthening effectReduce manufacturing costChemical compositionMechanical property

A low-cost lightweight 600MPa-grade automobile body steel, its chemical composition and mass percentage are: C: 0.050-0.090%, Si≤0.12%, Mn: 1.00-1.30%, P≤0.016%, S≤0.005%, Als: 0.015~0.045%, Ti: 0.070~0.100%, the balance is Fe and unavoidable impurities; the preparation methods include converter, refining, continuous casting, heating, rolling, cooling, coiling, feeding Storage stacking and leveling process; continuous casting process, the steel flow from the ladle to the tundish is sealed with argon gas at the long nozzle, the process adopts a dynamic light reduction of 8mm, and the solidification end increases the reduction by 0.5mm; Gas N content ≤ 0.0055wt%. The invention has the advantages of low production cost, thin product thickness specification, uniform and stable mechanical properties, good cold bending performance and excellent plate shape quality.

Owner:HANDAN IRON & STEEL GROUP +1

Ferroelectric film alternating electric field heat treatment method

InactiveCN100347131CExcellent ElectricalImprove ferroelectric propertiesCurie temperatureThermal treatment

The alternating electric field thermal treatment method for ferroelectric film, special to reduce residual stress in ferroelectric ceramics film, comprises: 1. depositing ferroelectric film material on Pt / Ti / SiO2 / Si base, annealing and crystallizing at high temperature to form film 1; 2.taking secondary anneal to the film 1 with alternating electrc field. This invention is used to ferroelectric ceramics film material with 300~800Deg Curie temperature, can decrease residual stress and process cost.

Owner:HARBIN INST OF TECH

Alloy powder for repairing martensitic steel by laser additive manufacturing and its preparation and application

ActiveCN111390159BMs points loweredTensile stress is obtainedAdditive manufacturing apparatusIncreasing energy efficiencyMartensite transformationAlloy

The invention belongs to the field of laser additive manufacturing and repairing, and more specifically relates to an alloy powder for laser additive manufacturing and repairing martensitic steel and its preparation and application. In terms of mass percentage, the alloy powder contains 0.03%-0.4% of C, 6%-10% of Cr, 4%-8% of Ni, 0.5%-1.5% of Mn, 0.6%-1.2% of Si, and the rest The amount is Fe and unavoidable impurities, so that it has a lower martensitic transformation point. Use this alloy powder to repair martensitic steel with laser additives, form martensite structure in the repaired area, and use the volume expansion effect of martensitic phase transformation to offset the thermal contraction caused by cooling the repaired area, resulting in residuals in the repaired area Compressive stress, avoid defects such as deformation and fatigue cracks in repaired parts, improve the timeliness and reliability of repaired parts, and realize "instant repair and use" of damaged parts.

Owner:HUAZHONG UNIV OF SCI & TECH

Brazing method capable of reducing residual stress on ceramic and metal joints

ActiveCN102513636BAchieving a soldered connectionReduce residual stress levelsWelding/cutting media/materialsSoldering mediaRoom temperatureHot Temperature

The invention provides a brazing method capable of reducing residual stress on ceramic and metal joints, relates to ceramic and metal brazing connection methods and solves the technical problems that low-temperature brazing connection for ceramic and metal is difficult, residual stress at the brazing joints is high, the brazing process can be completed in high-temperature vacuum or protective atmosphere only and the like. The brazing method includes: firstly, cleaning surfaces of to-be-brazed portions of ceramic and metal and placing solder foil between to-be-connected surfaces of ceramic andmetal or at the edge of a lapping gap of ceramic and metal; secondly, brazing ultrasonically, preserving heat and cooling, applying longitudinal pressure onto the brazed joints, and cooling the brazed joints along with a furnace until the temperature thereof reaches the room temperature. The brazing process is completed on the condition of atmosphere, the brazing temperature is low, and the residual stress on the ceramic / metal brazed joints is low.

Owner:HARBIN INST OF TECH

Best strain of austenitic stainless steel container welding residual stress overload reducing method

ActiveCN103160663BVersatilityGuaranteed reliabilityProcess efficiency improvementPrincipal stressAutomatic control

The invention provides best strain of an austenitic stainless steel container welding residual stress overload reducing method. The best strain of the austenitic stainless steel container welding residual stress overload reducing method comprises: (1) a best value exists in overload dependent variable for reducing welding residual stress, the dependent variable corresponding to first major principal stress in direction in a continuous structure zone serves as an evaluation index and overload plastic strain is in a range of 2%-5%; (2) in the process of overload, boosting speed is controlled through a variable frequency pump or an automatic control reflux valve, uploading speed is in a range of 0.2 MPa / min-0.4 MPa / min and the dependent variable is controlled through deformation measurement or strain measurement; and (3) when a container is manufactured, a tensile test is firstly performed to materials, design stress and overload stress are determined according to an actual single tensile curve of the materials and design pressure and overload pressure are calculated through a simplified method. Numerical modeling has universality and generality, evaluation stress is corroded, first tensile welding residual stress is reduced to a great extent and the residual stress after reduction is in the same level with residual stress of a cold rolling plate rear base material and residual stress after stress relief heat treatment.

Owner:北京市朝阳区特种设备检测所

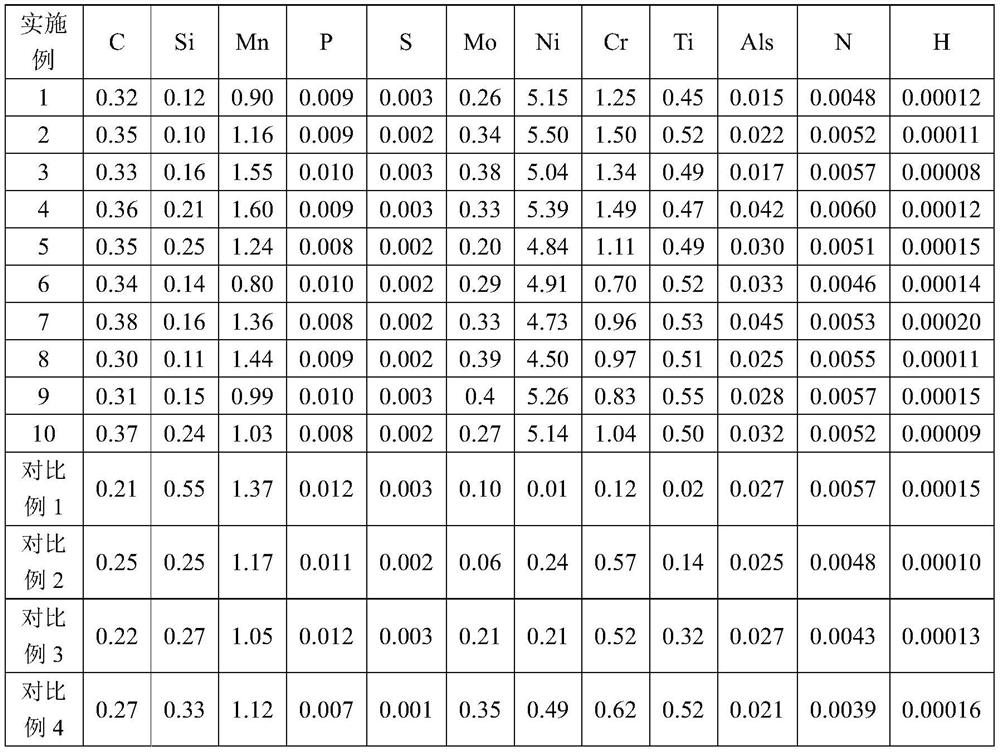

High-toughness wear-resistant steel with excellent cold bending performance and manufacturing method thereof

The invention provides high-toughness wear-resistant steel with excellent cold bending performance and a manufacturing method thereof. The steel comprises the following components in percentage by weight: 0.30%-0.38% of C, 0.10%-0.25% of Si, 0.80%-1.60% of Mn, less than or equal to 0.010% of P, less than or equal to 0.003% of S, 0.2%-0.4% of Mo, 4.5%-5.5% of Ni, 0.7%-1.5% of Cr, 0.45%-0.55% of Ti, 0.015%-0.045% of Als, less than or equal to 0.0060% of N, less than or equal to 0.0020% of H and the balance of iron and inevitable impurities. The manufacturing method comprises the steps of molten iron pretreatment, converter smelting, external refining, die casting or continuous casting, heating, rolling and heat treatment. According to the steel plate produced through the method, the yield strength reaches 967-1048 MPa, the tensile strength reaches 1248-1359 MPa, the surface hardness reaches 420-468 HBW, the core hardness reaches 417-467 HBW, the ballistic work at the temperature of-40 DEG C is larger than or equal to 44 J, and 90-degree cold bending d = 5a is qualified.

Owner:ANGANG STEEL CO LTD

A kind of biomimetic structure cubic boron nitride coating and preparation method thereof

ActiveCN106756781BImprove fracture toughnessReduce residual stressVacuum evaporation coatingSputtering coatingBoron nitrideHardness

The invention is suitable for the technical field of vacuum coating, and provides a bionic-structure cubic boron nitride coating and a preparation method thereof. The bionic-structure cubic boron nitride coating is coated on a substrate, and consists of a bottom ductile layer and a top high-hardness layer, wherein the high-hardness layer is a cubic boron nitride layer; the ductile layer is in a multi-layer composite structure formed by alternate deposition of M2 layers and M1Bx:M2 doped composite layers; each M1Bx:M2 doped composite layer is formed by doping of M1Bx in M2; the M1 and the M2 are the same or different transition metal; and x is equal to or lager than 0.5 and equal to or smaller than 4.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Elongation rate distribution method for high-strength steel straightening and leveling unit

ActiveCN102626717BControl yield strengthReduce residual stress levelsMetal rolling arrangementsElongation control deviceTemperingStructural engineering

The invention relates to a method for allocating the elongation rate of a high-strength steel straightening and leveling unit. The total elongation of high-strength steel is controlled, and the set value of the total elongation is distributed to the leveler and the tempering machine in proportion to pre-set the straightening and leveling process, and the reciprocating bending effect of the leveler is used to fully reduce the residual of hot-rolled high-strength steel Stress level, using the real-time dynamic adjustment capability of the temper machine to effectively control the final performance of high-strength steel. It can fully reduce the residual stress level inside the hot-rolled steel strip, effectively control the yield strength of the hot-rolled high-strength steel, and ensure the performance and quality of the product.

Owner:WISDRI ENG & RES INC LTD

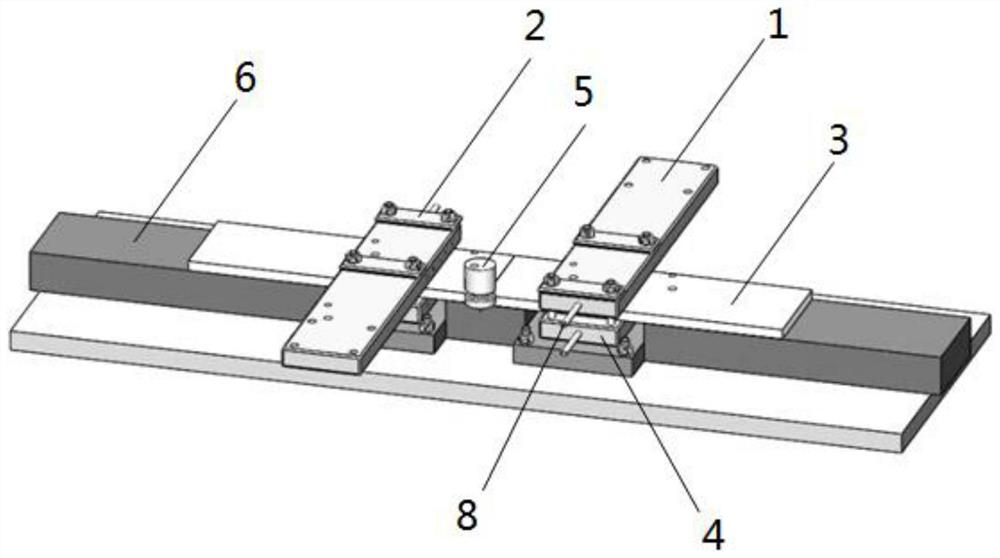

A current-assisted thermal field friction stir welding method for titanium alloy material butt joint

ActiveCN111390373BSolve the problem of soldering temperatureAvoid severe wear and tearNon-electric welding apparatusFriction weldingManufacturing technology

The invention discloses a current-assisted thermal field friction stir welding method for butt jointing of titanium alloy materials, and belongs to the technical field of material forming. The invention solves the problems that the welding seam structure is unstable under the high-temperature use state when the welding method is used to manufacture Ti-Al-based alloy and other complex-shaped hot-end thin shell components, and the plasticity of the material at room temperature is low, which leads to defects in the welding process and the like. The present invention makes the surface of the masterbatch to be welded reach the plastic deformation temperature of the material faster through the method of current assisted heating, improves the welding efficiency and effectively avoids the severe wear when the stirring head reaches a higher temperature, and obtains a material with good shape and excellent mechanical properties. welds. In addition, the present invention can also realize local stress relief annealing of the weld seam through current-assisted heating after welding, reduce the residual stress level of the weld seam, further improve the bearing service performance of the joint, and realize the integrated manufacturing process of welding-stress relief annealing.

Owner:HARBIN INST OF TECH

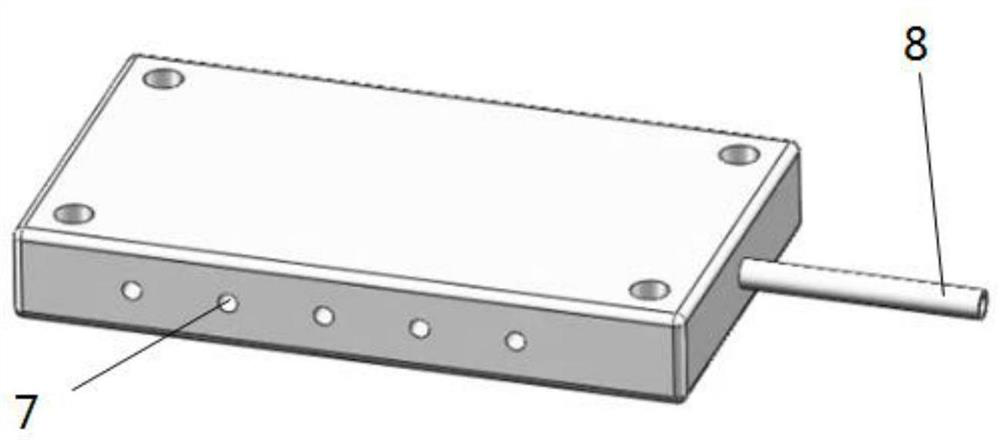

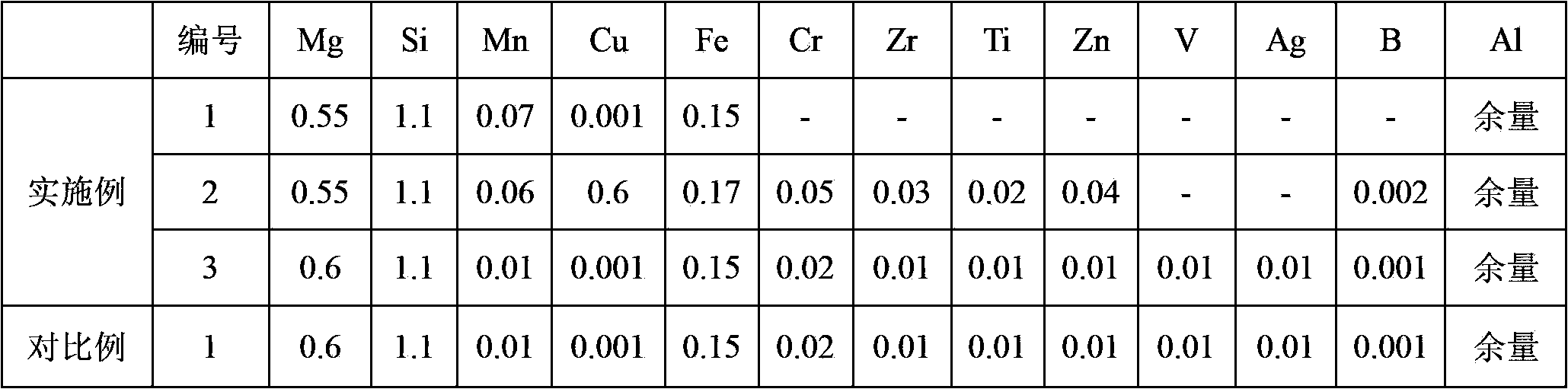

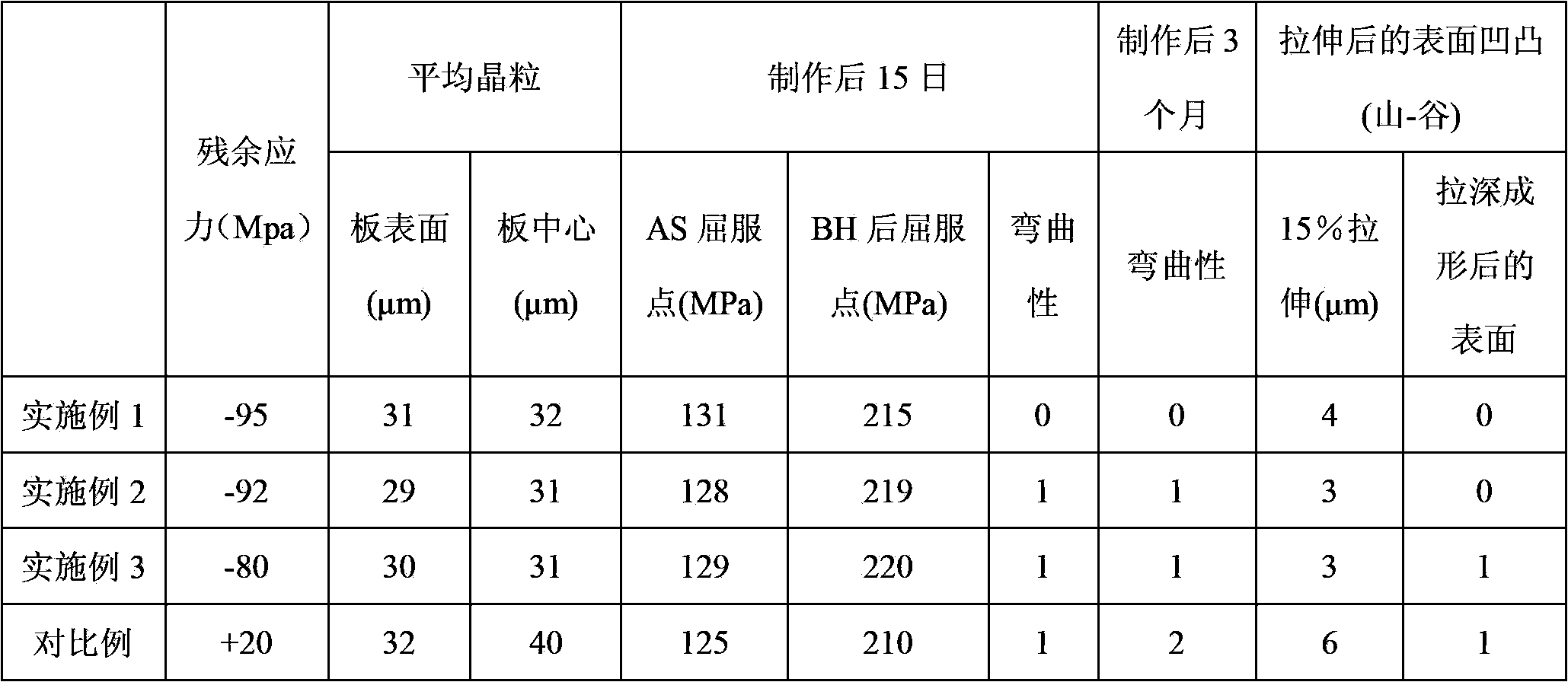

Aluminum alloy plate and production process thereof

InactiveCN102703773BGood stability at room temperatureReduce residual stress levelsMetal rolling arrangementsIngotImpurity

The invention relates to a production process of an aluminum alloy plate. The production process comprises the following steps of: (1) performing homogenization heat treatment on an aluminum alloy cast ingot, wherein the aluminum alloy cast ingot comprises 0.2-1.2% by weight of Mg, 0.35-1.7% by weight of Si, 0.01-1.0% by weight of Mn, 0.001-1.0% by weight of Cu and the balance of Al and inevitable impurities; the solid-soluted content of Si accounts for 0.45-0.80% by weight, the solid-soluted content of Mg accounts for 0.2-0.60% by weight, and the solid-soluted content of the Si / the solid-soluted content of the Mg is 1.1-2; (2) cooling, further re-heating and performing hot rolling; (3) performing first straightening; (4) performing cold rolling to reduce a plate product in the thickness direction by 0.2%-15%; and (5) performing second straightening to get an aluminum alloy finished product. The aluminum alloy plate produced by the process has the advantages of excellent stability at normal temperature and small residual stress, and is suitable for being used as an outer plate of a motor vehicle.

Owner:东莞市闻誉实业有限公司

A kind of indirect brazing method of aluminum nitride ceramic copper clad laminate

ActiveCN113307647BSmall coefficient of thermal expansionReduce residual stress levelsWelding/cutting media/materialsSoldering mediaThermal dilatationComposite solder

Owner:CHANGCHUN UNIV OF TECH

Control method for high-strength steel straightening and leveling unit

ActiveCN102626718BControl yield strengthReduce residual stress levelsMetal rolling arrangementsElongation control deviceTemperingStructural engineering

The invention relates to a control method for a high-strength steel straightening and leveling unit. The unit mainly includes a straightening machine and a leveling machine. Bending fully reduces the residual stress level of hot-rolled high-strength steel, and effectively controls the yield strength of hot-rolled high-strength steel by using the real-time dynamic adjustment capability of the tempering machine. While using the leveler to reduce the residual stress level of high-strength steel, ensure high strength at the end of the process section Performance quality of steel products.

Owner:WISDRI ENG & RES INC LTD

Straightening and leveling process for hot-rolled high-strength steel

ActiveCN102626726BReduce residual stress levelsResidual Stress Level GuaranteeMetal rolling arrangementsTemperingUltimate tensile strength

The invention relates to a hot-rolled high-strength steel straightening and leveling process, which is characterized in that the straightening and leveling process is adopted, and the hot-rolled high-strength steel strip is sequentially sent into a straightening machine and a leveling machine; the above-mentioned process specifically includes the following steps: first, according to The required yield strength of the strip product at the end of the process section sets the total elongation of the unit; then, the set value of the total elongation is assigned to the straightening machine and the tempering machine to pre-set the straightening and leveling process; after that, real-time detection of processing Finally, compare the detected total elongation of the processed strip with the set value of the total elongation, and dynamically adjust the rolling force of the temper mill in real time to ensure that the strip product at the end of the process section The total elongation is constant, and while the leveler is used to reduce the residual stress level of the strip, the performance quality of the strip product at the end of the process section is guaranteed. By adopting the process, the residual stress level inside the hot-rolled steel strip can be fully reduced, and the performance quality of the hot-rolled high-strength steel product can be effectively improved.

Owner:WISDRI ENG & RES INC LTD

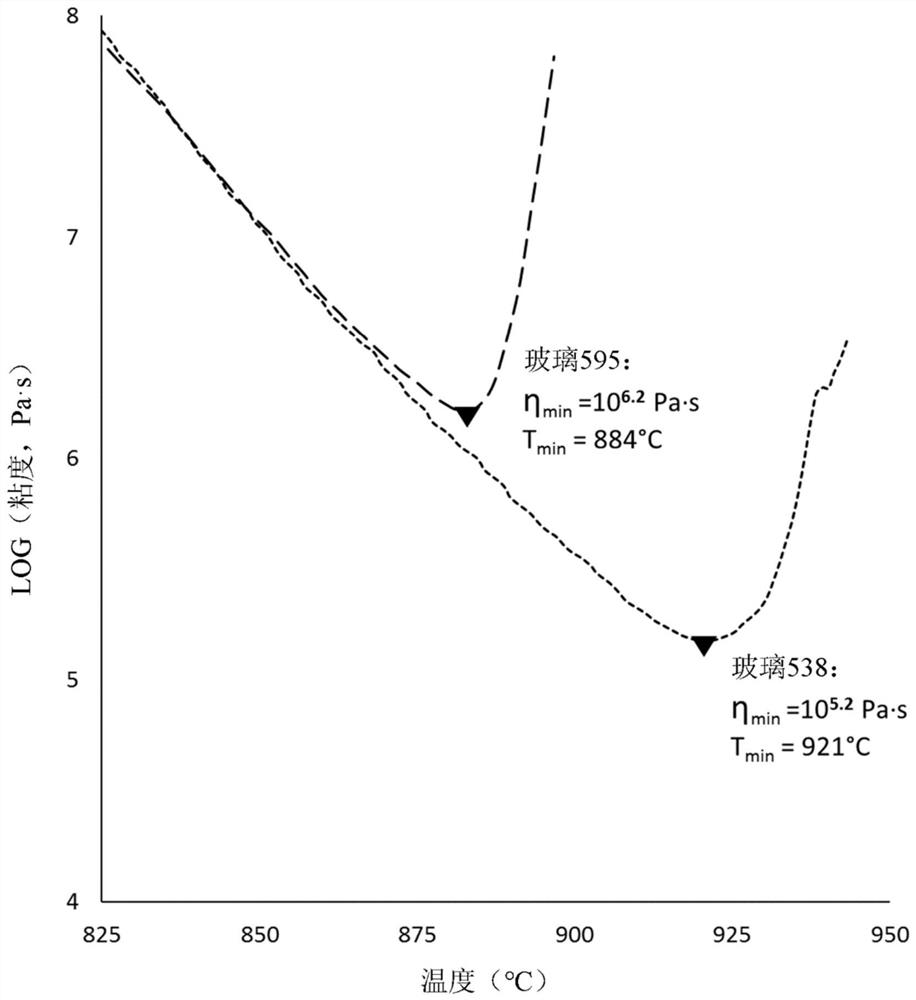

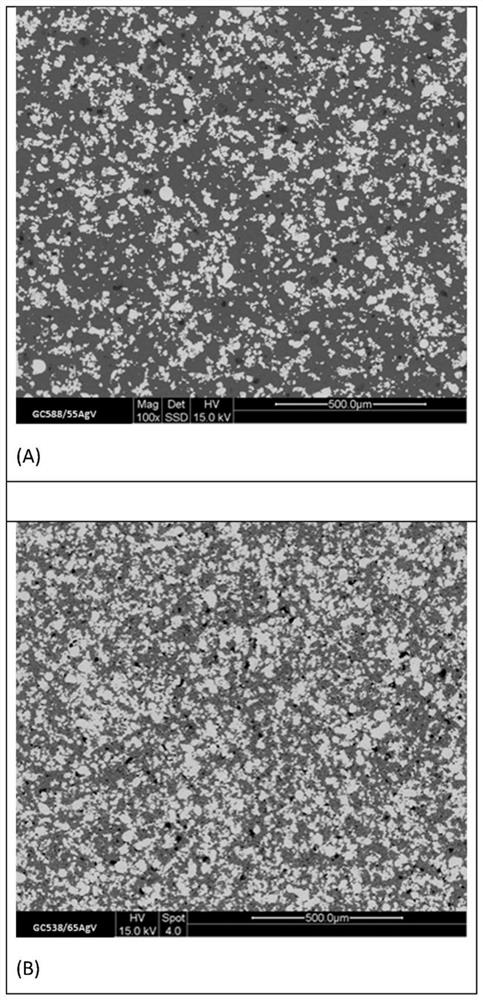

Ceramic materials

PendingCN113692662AReduce residual stress levelsImprove reliabilitySolid electrolytesFuel cellsFuel cellsElectrolysis

The present invention relates to glass-ceramic / silver composite precursor compositions in the form of powders, and to glass-ceramics / silver composite materials produced therefrom. Such materials find particular use as interconnect materials for high temperature electrochemical conversion devices such as solid oxide fuel cells (SOFCs) and solid oxide electrolysis cells (SOECs).

Owner:COORSTEK MEMBRANE SCI AS

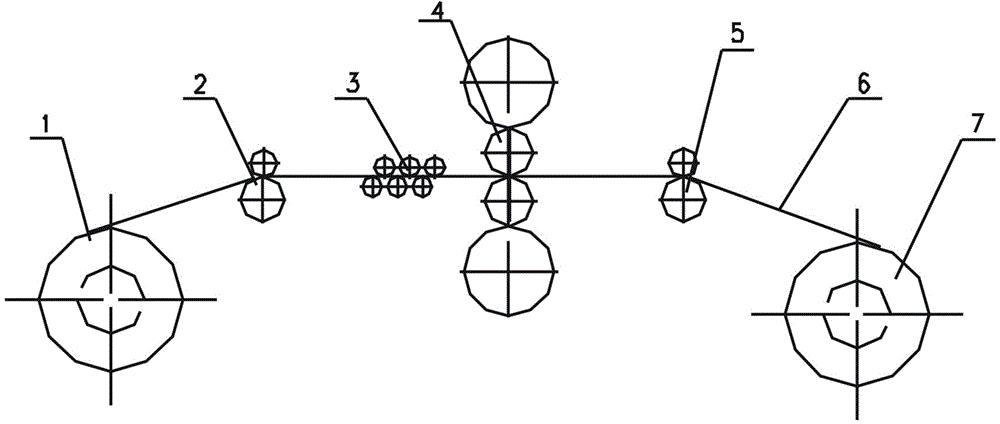

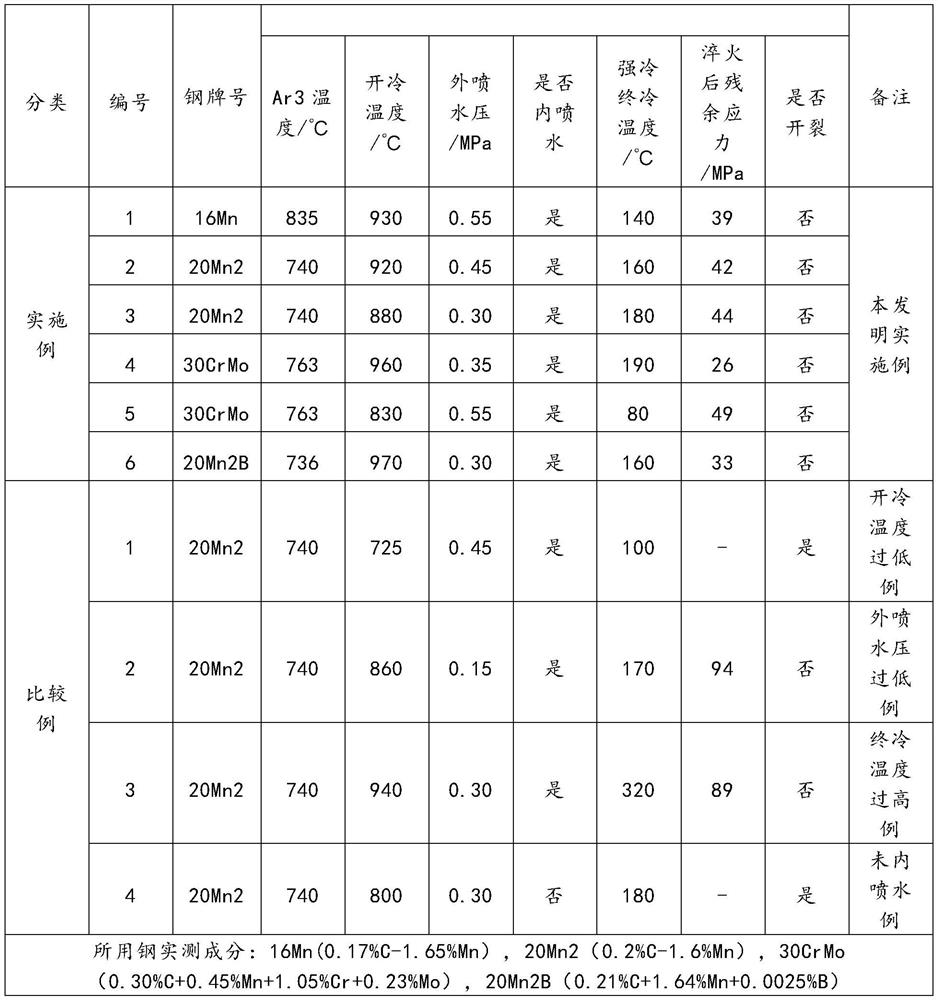

On-line quenching preparation method for reducing residual stress of hot-rolled seamless steel tube and steel tube

ActiveCN113249562AReduce residual stress levelsPrevent quenching crackingFurnace typesProcess efficiency improvementSteel tubeMetallurgy

The invention discloses an on-line quenching preparation method for reducing residual stress of a hot-rolled seamless steel tube and the steel tube. The preparation method comprises the following steps that 1, a tube blank is rolled into the steel tube in an existing hot rolling manner; 2, when the temperature of the steel tube is not lower than the Ar3 temperature of steel, cooling is conducted in the mode that water is evenly sprayed to the outer wall of the steel tube in the circumferential direction; 3, when the surface temperature of the steel tube is not reduced to the Ms point temperature, water is sprayed to the inner wall of the steel tube; and 4, when the surface temperature of the steel tube is reduced to 200 DEG C or below, water spraying is stopped, cooling is carried out, and finally the steel tube is converted into air cooling. The on-line quenching preparation method can effectively reduce the residual stress level of the seamless steel tube after quenching, and prevents the seamless steel tube from quenching cracking.

Owner:BAOSHAN IRON & STEEL CO LTD

A Method for Reducing Residual Stress of Laser Cladding Metal Coating

ActiveCN107858680BReduce residual stress buildupReduce residual stress levelsMetallic material coating processesMetal coatingLaser

The invention discloses a method for reducing the residual stress of laser cladding metal coatings. Before cladding, the invention prefabricates regularly arranged groove microstructures on the substrate, and the laser focus falls on the center of two adjacent grooves. , the melting channel and the groove are parallel to each other. The invention is suitable for laser cladding technology, and is characterized in that the residual stress of formed parts is low, effectively avoids cracks, cracks, warping and deformation phenomena, does not require additional equipment, and is easy to operate.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com