Brazing method capable of reducing residual stress on ceramic and metal joints

A technology of metal joints and residual stress, applied in metal processing equipment, welding media, welding equipment, etc., can solve the problems of large residual stress of brazed joints, difficult brazing connection, and can only be completed under high temperature vacuum or protective atmosphere , to achieve the effect of low brazing temperature and low residual stress level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

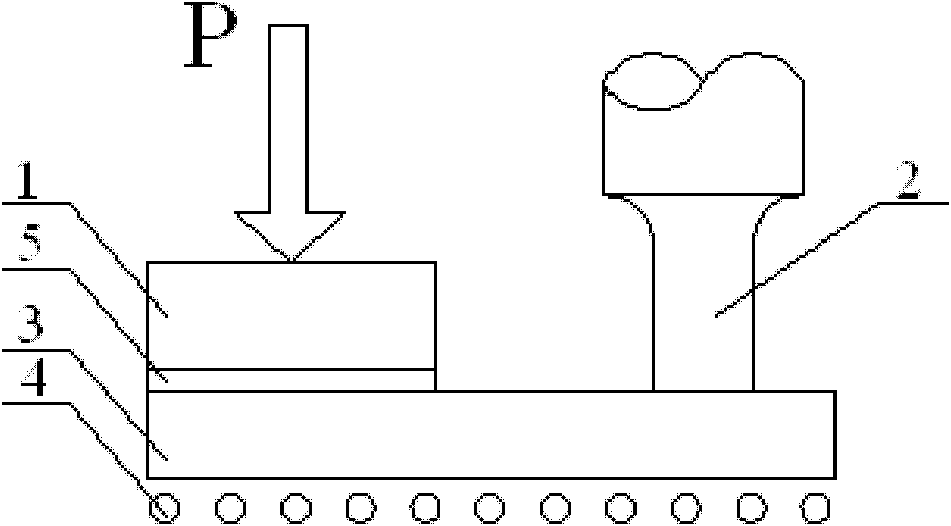

[0015] Specific embodiment one: the brazing method of reducing the residual stress of ceramics and metal joints in this embodiment is carried out according to the following steps: one, the parts to be welded are cleaned on the surface of ceramics and metals, and Al-Sn-Si-Zn The solder foil is placed between the ceramic and the metal surface to be connected or the Al-Sn-Si-Zn solder block is placed on the edge of the ceramic and metal lap gap to obtain the workpiece to be welded; 2. At an ultrasonic frequency of 20~ Under the conditions of 100kHz, amplitude 1-10μm, and brazing temperature 600-620°C, perform ultrasonic brazing on the brazing part for 4-30s, keep warm for 0-30min, then cool down with the furnace or air-cool to 300-500°C, and weld the joint Apply a longitudinal pressure of 0-100N, and continue to cool to room temperature with the furnace; that is, the reduction of the residual stress of the ceramic and metal joint is realized.

[0016] The joint shear strength can...

specific Embodiment approach 2

[0017] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the ceramics described in step one are SiC, Al 2 o 3 、Si 3 N 4 or TiC. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0018] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the metal in step 1 is TC4 or stainless steel. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com