High-toughness wear-resistant steel with excellent cold bending performance and manufacturing method thereof

A technology of cold-bending performance and wear-resistant steel, applied in the field of metal materials, can solve problems such as poor impact toughness, reduced impact energy, poor low-temperature impact performance, etc., and achieve good structural uniformity and mechanical uniformity, and low residual stress level , Enhance the effect of grain boundary strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

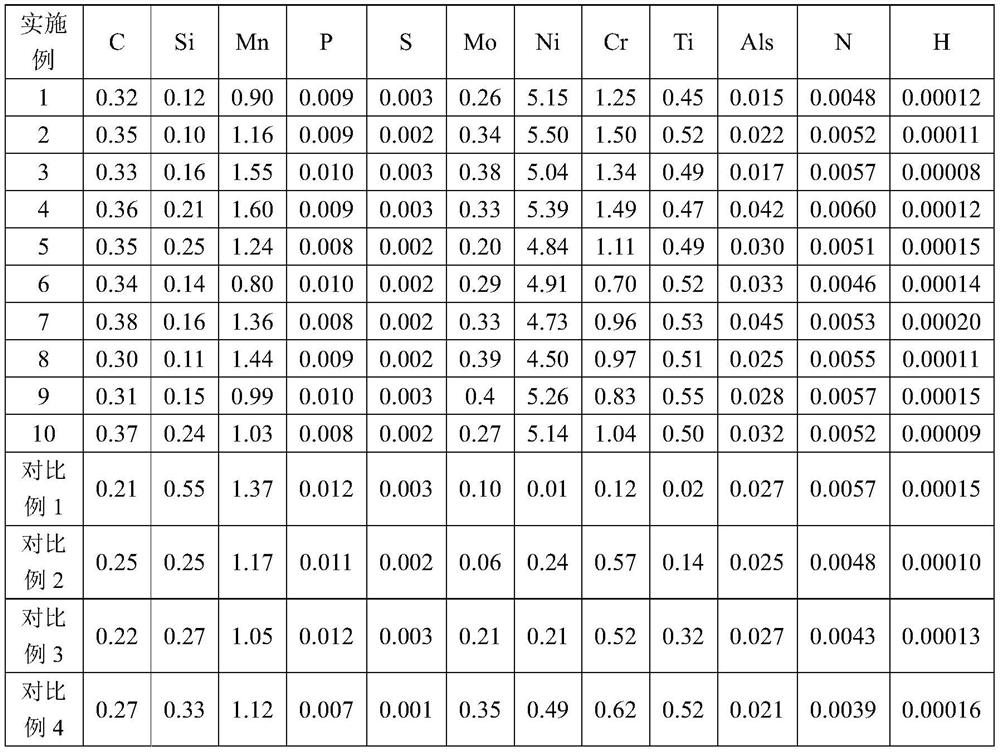

[0045] Below by embodiment the present invention will be further described.

[0046] In the embodiments of the present invention, according to the component ratio of the technical solution, pretreatment of molten iron, converter smelting, refining outside the furnace, die casting or continuous casting, and rolling are performed.

[0047] Rolling: The rough rolling start temperature is 1120~1050℃, the rough rolling finish temperature is 1000~1070℃, the average reduction rate in the rough rolling stage is ≥15%, and the thickness of the intermediate billet is 2.0t~3.0t, where t is the finished steel plate Thickness, finish rolling start temperature is 860-900°C, finish rolling finish temperature is 820-880°C, the reduction rate of the first pass of finish rolling is ≥12%, air cooling or stack cooling to room temperature after rolling;

[0048] Heat treatment: the normalizing temperature of the steel plate is 810-850°C, the time in the furnace is 2.5-3.5min / mm, and it is air-coole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com