Indirect brazing method for aluminum nitride ceramic copper-clad plate

A technology of aluminum nitride ceramics and brazing method, which is applied in the field of indirect brazing manufacturing of aluminum nitride ceramic copper-clad laminates, can solve the problems of large connection area and residual stress accumulation of ceramic copper-clad laminates, and reduce the level of residual stress and Effect of thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

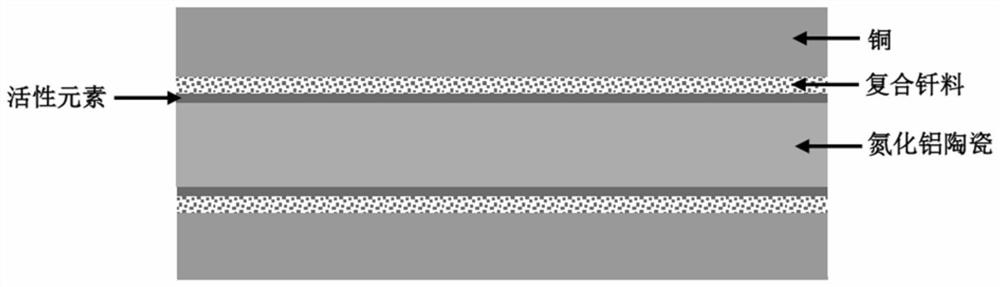

Image

Examples

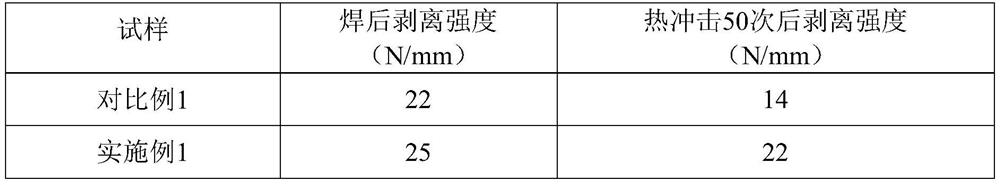

Embodiment 1

[0029] 1) The aluminum nitride ceramic substrate was ultrasonically cleaned in acetone for 20 minutes to remove surface oil, and then dried with a hair dryer for later use. Oxygen-free copper sheet with 15wt.% H 2 SO 4 Pickle for 5 minutes to remove the oxide film on the surface, then perform ultrasonic cleaning in acetone for 20 minutes, and use a hair dryer to dry it for later use.

[0030] 2) Prepare composite solder (percentage by weight) according to the following composition: Ag powder: 66%, Cu powder: 24%, copper-plated aluminum nitride powder: 10%, copper-plated graphene powder: 0.2%, aluminum nitride used wherein The diameter of the powder was 1 μm. A mechanical ball milling method is used to fully mix the above-mentioned components to prepare a composite solder. The ball milling speed is 200r / min, and the ball milling time is 4h. A binder whose weight is 5wt.% of the composite solder is added to the composite solder to prepare a slurry.

[0031] The copper-plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com