Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Reduce mold release" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyfunctional vinyl aromatic copolymer, process for producing the same, and resin composition

InactiveUS8404797B2Improve the heating effectIncrease resistanceSurgical adhesivesPhotomechanical apparatusPolymer scienceEnd-group

Owner:NIPPON STEEL CHEMICAL CO LTD

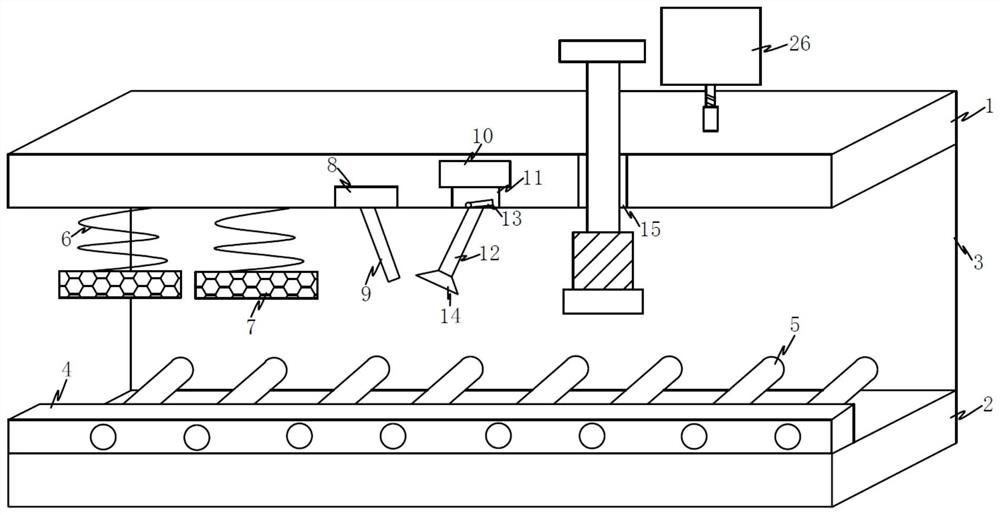

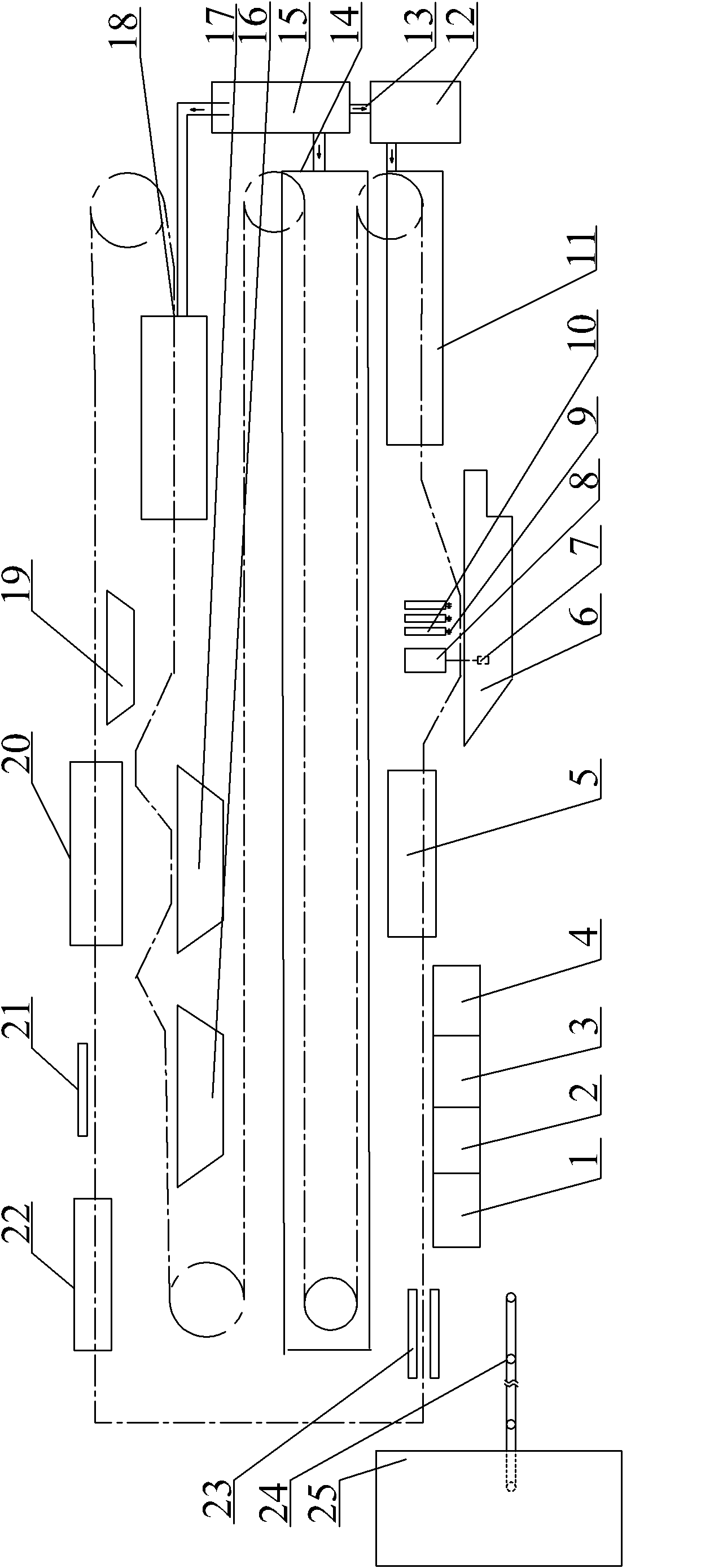

Polyvinyl chloride (PVC) glove production device

ActiveCN102173017ARapid coolingGood release effectDomestic articlesCoatingsPolyvinyl chlorideEngineering

The invention belongs to the field of polyvinyl chloride (PVC) glove production and relates to a PVC glove production device. The device comprises a hand mold rail line and a glove production device, wherein the hand mold rail line is positioned above the glove production device; the glove production device comprises a PVC material groove, a PVC material dripping section, a PVC plasticizing forming device, a polyurethane (PU) material groove, a PU drying device, a PVC glove hemming device and a demolding device in turn; and the PVC plasticizing forming device and the PU drying device are connected with a heat supply boiler. The device is characterized in that: a hand mold cleaning device and a hand mold drying device are arranged in turn between the demolding device and the PVC material groove; the PVC material groove is provided with a viscosity detection adjusting device; and a PU washing device and a washing drying device are arranged in turn between the PU drying device and the PVC glove hemming device. The device has high automation degree and good effect of forming PVC gloves; moreover, the product is easy to demold, and stickness or damage hardly appears in the demolding process, so that the glove quality is ensured.

Owner:SHANDONG INTCO MEDICAL SUPPLY CO LTD

Polyfunctional vinyl aromatic copolymer, process for producing the same, and resin composition

InactiveUS20110105638A1High efficiencyResist secondary processingSurgical adhesivesPhotomechanical apparatusSolventChemistry

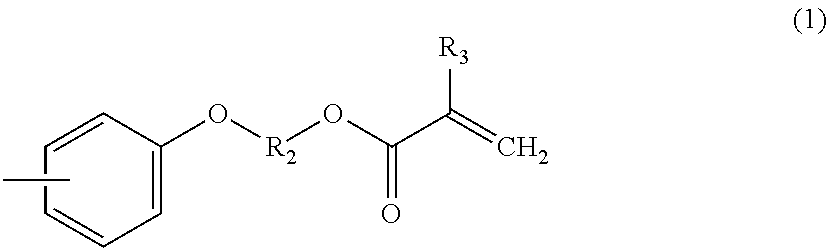

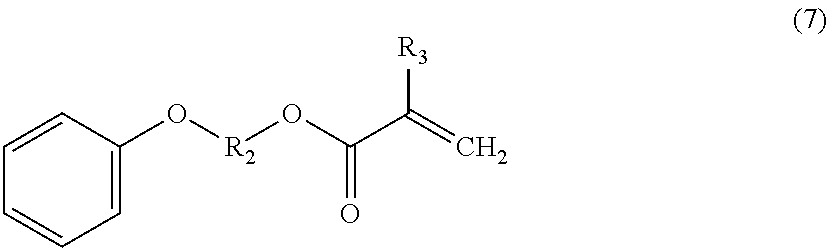

An end-modified soluble polyfunctional vinyl aromatic copolymer, which is improved in heat resistance, thermal stability, solvent solubility, and compatibility with acrylate compounds, and a curable resin composition using the same are disclosed. The end-modified soluble polyfunctional vinyl aromatic copolymer is obtained by allowing a divinyl aromatic compound (a), a monovinyl aromatic compound (b), and an aromatic ether compound (c) to react with each other, and has, at an end, an end group derived from the aromatic ether compound and having an acrylate bond. The copolymer has a number average molecular weight Mn of 500 to 100,000, an introduction amount (c1) of the end group derived from the aromatic ether compound satisfies (c1)≧1.0 (group / molecule), a molar fraction a′ of a structural unit derived from the divinyl aromatic compound and a molar fraction b′ of a structural unit derived from the monovinyl aromatic compound in the copolymer satisfy 0.05≦a′ / (a′+b′)≦0.95. Besides, the curable resin composition includes the copolymer and an unsaturated acrylate monomer.

Owner:NIPPON STEEL AND SUMIKIN CHEMICAL CO LTD

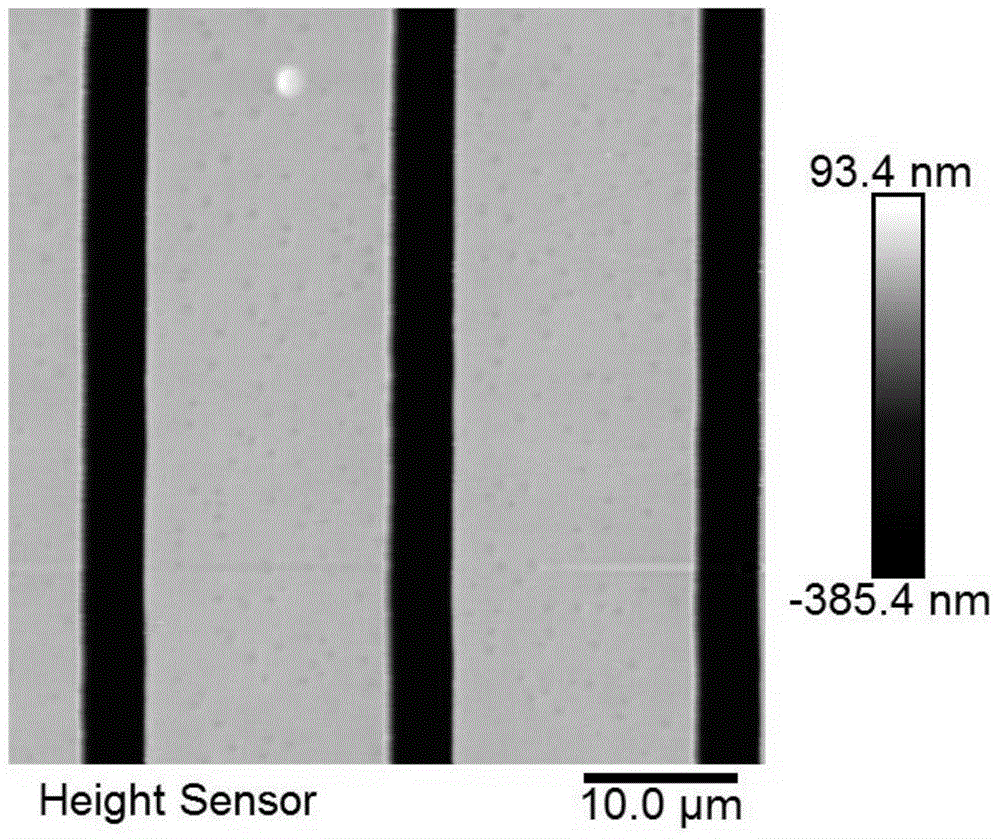

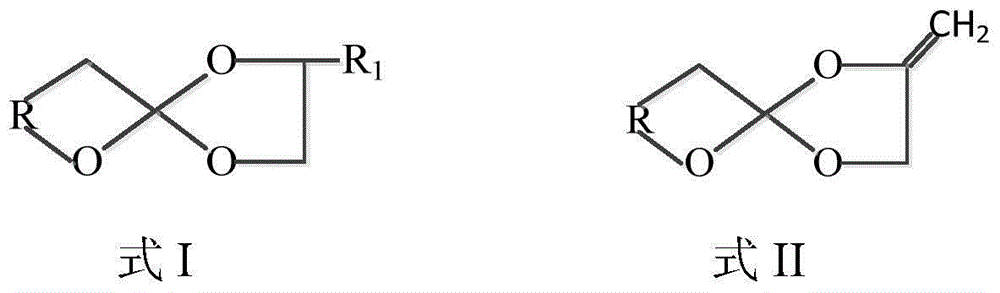

Expansion polymerization imprinting glue for nano-imprinting

ActiveCN104932197AAdjustable volume changeSmall volume shrinkagePhotosensitive materials for photomechanical apparatusMicro nanoPolymer science

The invention discloses an expansion polymerization imprinting glue for nano-imprinting. Raw materials required for the preparation of the expansion polymerization imprinting glue comprise a low polymer and an expansion monomer. Compared with the prior art, after the expansion polymerization imprinting glue for nano-imprinting is introduced in the expansion monomer, the expansion monomer can be polymerized with the low polymer, the volume change of the impressing glue after polymerization can be adjusted, and thus the volume shrinkage after the imprinting glue is cured is reduced or even eliminated; and the imprinting glue with zero curing shrinkage or volume expansion can be obtained by adjusting the content of the expansion monomer. The imprinting glue can effectively reduce the residual stress in a micro-nano figure, and the generation of figure defects in the nano-imprinting demolding process caused by the residual stress is reduced while accurate figure copying is realized.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

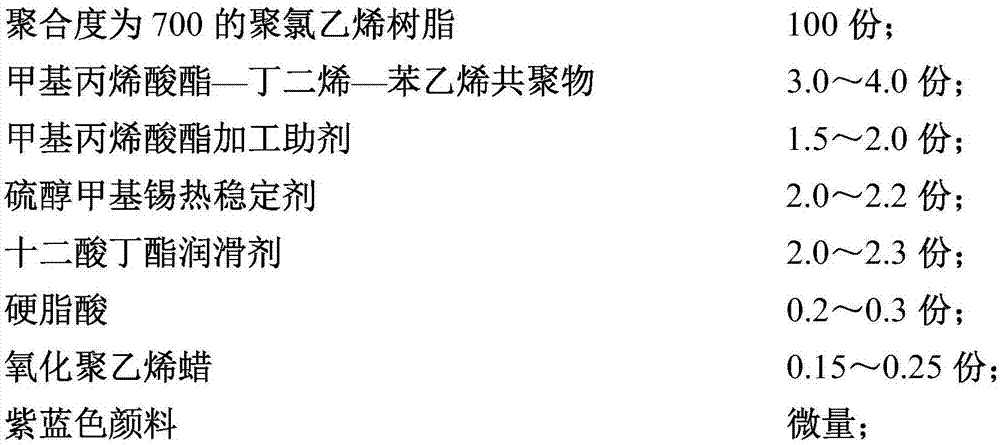

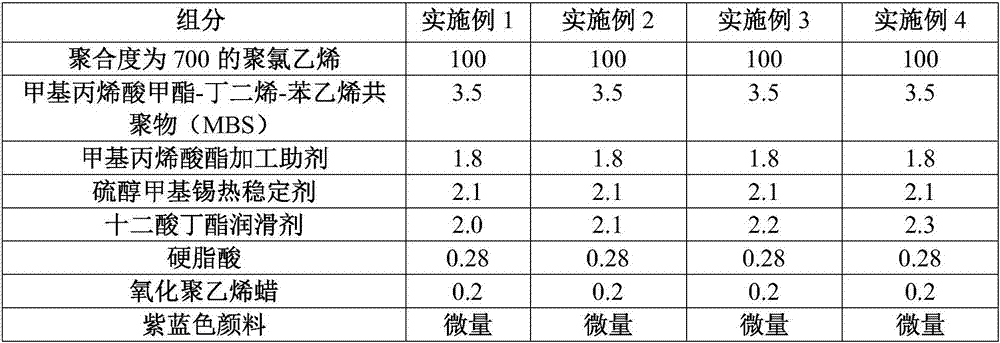

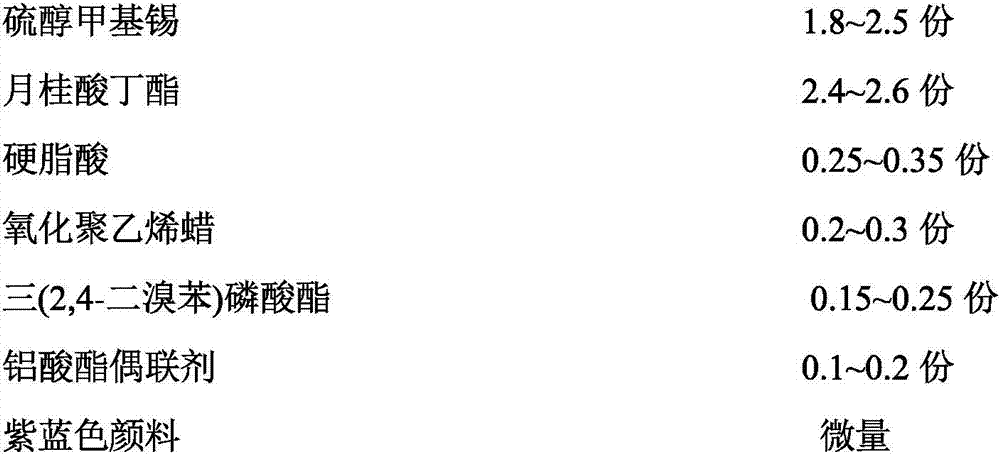

PVC (polyvinyl chloride) pellets special for ultrahigh-transparency hard medical injection molding apparatuses

ActiveCN107141646AImprove thermal stabilityTransparency has little effectMethacrylateProcedure Agents

The invention discloses PVC (polyvinyl chloride) pellets special for ultrahigh-transparency hard medical injection molding apparatuses. The PVC pallets comprise, by weight, 100 parts of polyvinyl chloride resin with the degree of polymerization being 700, 3.0-4.0 parts of methacryIate-Butadiene-Styrene copolymer, 1.5-2.0 parts of methacrylate processing aid, 2.0-2.2 parts of methyltin mercaptide heat stabilizer, 2.0-2.3 parts of butyl dodecanoate lubricant, 0.2-0.3 part of stearic acid, 0.1-0.25 part of oxidized polyethlene wax and trace indigo pigment. The finished products are prepared by means of feeding the components into a high-speed heating mixer according to the proportion for high-speed mixing, performing kneading to the temperature of 123-125 DEG C prior to discharging, putting the discharged material into a low-speed cooling mixer to be cooled to room temperature to obtain mixed powder, feeding the mixed powder into a pelletizer for pelletizing, and cooling the pellets to the temperature lower than 40 DEG C prior to packaging. The medical injection molding apparatuses made of the PVC pellets have ultrahigh transparency and surface glossiness.

Owner:WUXI JIAHONG PLASTICS TECH

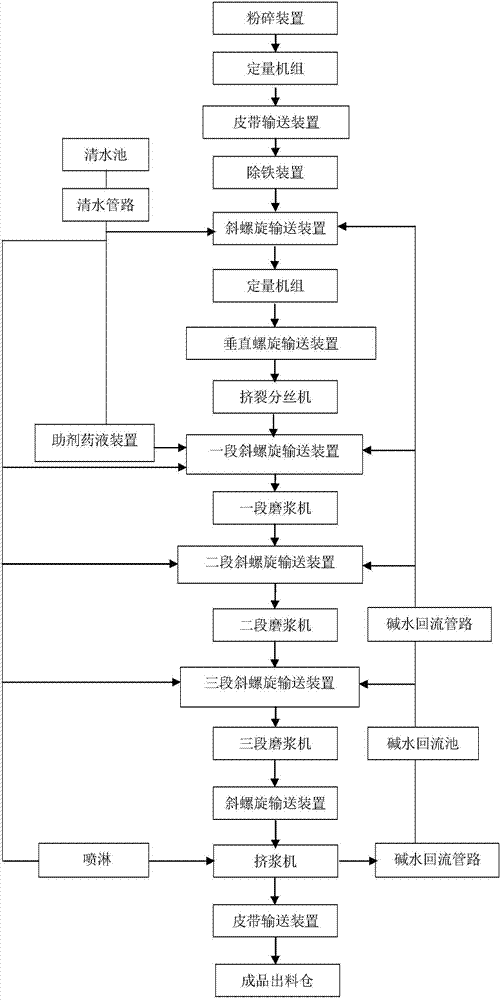

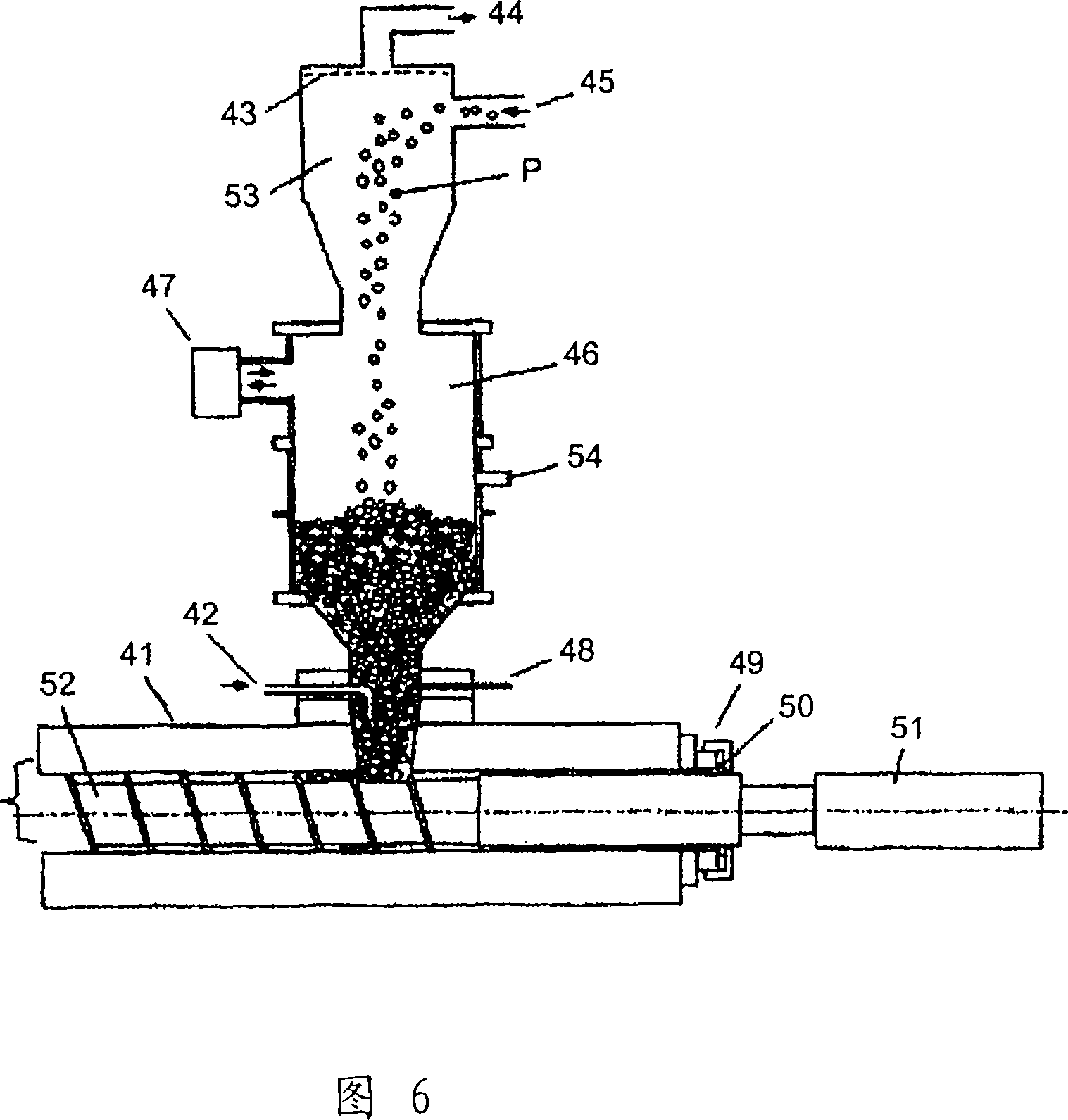

Unbleached pulp, and preparation process, application and preparation device of unbleached pulp

InactiveCN107268327AImprove insulation effectEfficient power savingPretreatment with alkaline reacting compoundsMultistage pulping processElectricityBlack liquor

The invention provides an unbleached pulp, and a preparation process, an application and a preparation device of the unbleached pulp, and relates to the technical field of pulping by utilizing a straw. The choices for the raw material of the unbleached pulp are wide, a wheat straw, a rice straw, a reed straw or a waste wood chip are used efficiently as the pulping raw material, so that the pulping cost is obviously lowered. The preparation process of the unbleached pulp uses the new technique to replace steam heating to soften the raw material, the problem of a pulp black liquor existing in the pulping process is solved while the heating cost is obviously reduced. The flow of the production process is simplified, the electricity and the water are efficiently saved, the resource utilization rate is effectively increased, and the production of no wastewater or waste materials is guaranteed in the production process. The special production process is used to pulp, the beating degree is high, the quality is better, the performance of a pulp product is stable, the pulp product is widely applied to the functional degradable material, and the functional applicability and the material quality are obviously strengthened in the application fields of preparation of corrugated paper, industrial packaging materials, preparation of plates, and preparation of tableware.

Owner:北京泽鑫荣创秸秆科技开发有限公司

Glass film coating device

The invention discloses a glass film coating device. The device comprises an upper horizontal plate, a lower horizontal plate and a vertical support plate. One end, far away from a suction ventilator,of the upper horizontal plate is provided with a film coating processing device. A film coating roller is fixed between connecting blocks. A film coating liquid adding device is disposed above the film coating roller. A receiving plate is provided with brush hair. One end, far away from the receiving plate, of a film coating liquid pipe is connected to a film coating liquid tank. A threaded ringlayer is arranged in the film coating liquid tank. A threaded extrusion plate is movably disposed in the threaded ring layer. A rotating plate is provided with a rotating electric machine. A supporting column is provided with a plurality of telescopic stirring rods. The invention provides the glass film coating device. A built-in cleaning dust removing device can ensure that the glass has no adhered impurities before coating and reduce pinholes or demolding after coating. A device for controlling the uniform liquid discharge is arranged in the film coating liquid tank and the film coating liquid is stirred white being uniformly discharged so that sedimentation is prevented, the operation linkage is simple and the effect is good.

Owner:CHONGQING LYUSEN TEMPERING HOLLOW GLASS

Thermosetting mold release coating agent, a mold releasing film, and a mold release polyethylene terephthalate film

ActiveCN106867004AReduce mold releaseLow residual adhesionSynthetic resin layered productsPolyether coatingsPolyethylene terephthalate glycolPolyethylene terephthalate

The present invention provides a heat-curable release coating composition which can form a cured film excellent in releasability and residual adhesion at a relatively low temperature while the film is formed by film formation. The thermosetting release coating agent contains a methylated melamine resin (A), a polyol (B) having a molecular weight of 100 to 3000, and an acid catalyst (C).

Owner:ARAKAWA CHEM IND LTD

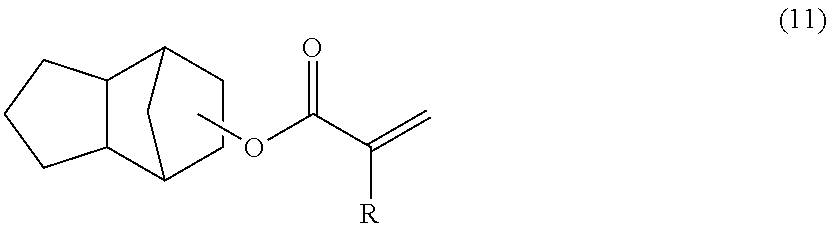

Process for producing molded object of curable resin and molded cured resin

A process for producing a molded object of a curable resin. In the process, transferability and mold releasability are kept intact. Also provided is a cured resin molding obtained by the process. The process for producing a molding of a curable resin comprises the following steps: (i) a resin die for curable resins obtained by molding a resin composition comprising a polymer having an alicyclic structure and a hindered phenol compound is used to form a first cured-resin molding, (ii) the resin die for curable resins which has been used for the molding is heated for 30 seconds to 100 hours at a temperature lower by 5-60 DEG C than the glass transition temperature of the resin composition, and (iii) the resin die heated is used to form a second cured-resin molding.

Owner:ZEON CORP

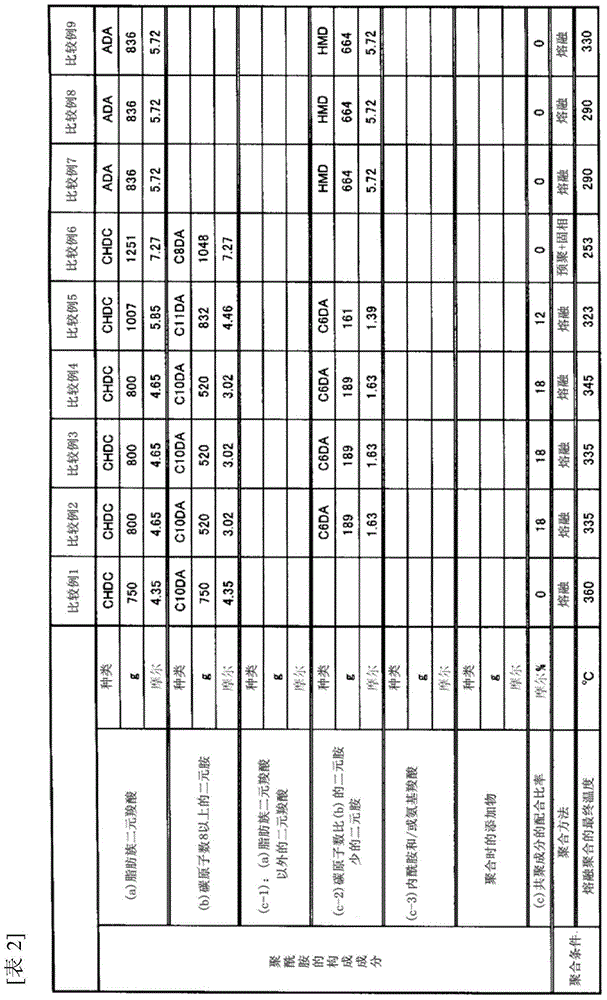

Polyamide, polyamide composition, and molded article

A polyamide containing (a) a unit comprising at least one species of alicyclic dicarboxylic acid and (b) a unit comprising a C8 or higher diamine, and satisfying conditions (1) and (2). (1) The sulfuric acid relative viscosity etar at 25°C is 2.3 or higher. (2) The weight-average molecular weight (Mw) / the number-average molecular weight (Mn) is 4.0 or less.

Owner:ASAHI KASEI KK

High-strength high-transparency thermal-resistant hard plastic alloy granular material

The invention relates to a high-strength high-transparency thermal-resistant hard plastic alloy granular material which comprises the following components in parts by weight: 100 parts of polyvinyl chloride resin of which the polymerization degree is 700, 15-25 parts of a polyvinyl chloride resin of which the polymerization degree is 400, 7-9 parts of a methacrylate-butadiene-styrene copolymer, 10-15 parts of a maleic anhydride grafted ethylene-octylene copolymer elastomer, 1.5-2.0 parts of amino modified graphene oxide, 1.5-2.2 parts of a methacrylate processing additive, 1.8-2.5 parts of methyl tin mercaptide, 2.4-2.6 parts of butyl laurate, 0.25-0.35 part of stearic acid, 0.2-0.3 part of oxidized polyethlene wax, 0.15-0.2 part of tri(2,4-dibromo-benzene)phosphate, 0.1-0.2 part of an aluminic acid ester coupling agent and a trace amount of a purple blue pigment. The material is high in transparency, excellent in physical mechanical property and use processing property, and high in market application prospect.

Owner:WUXI JIAHONG PLASTICS TECH

Imprint material having low mold release property

InactiveUS9533467B2Reduce mold releaseImprove scratch resistanceLayered productsNanoinformaticsPolymer chemistryFingerprint

Owner:NISSAN CHEM CORP

Environment-friendly heat-resistant high-toughness PVC transparent granular material, and preparation and application thereof

The invention relates to an environment-friendly heat-resistant high-toughness PVC transparent granular material, and preparation and application thereof. The granular material is prepared from, by weight, 90-120 parts of PVC resin, 15-30 parts of modified filled butadiene styrene rubber, 0.2-0.5 parts of an anti-aging agent, 2-4 parts of a thermal stabilizer, 0.8-1.2 parts of organic silicon modified plant oil, 1-4 parts of oxidized polyethlene wax, and 1-3 parts of phytosterol rice bran oleate. The granular material can be used for producing electrical tubular parts. Compared with the priorart, an electrical tube prepared from the PVC transparent granular material has great transparency with light transmittance reaching 92.4%; the material is excellent in compressive property, processability and anti-aging performance, can effectively overcome defects that a PVC composition tube material is liable to be aged and is poor in appearance. The material can improve anti-aging performanceand appearance and prolong the service life of the tube material, broadens application range of products, satisfies market demands, and has excellent application prospect.

Owner:AKAN ENTERPRISE GROUP SHANGHAI

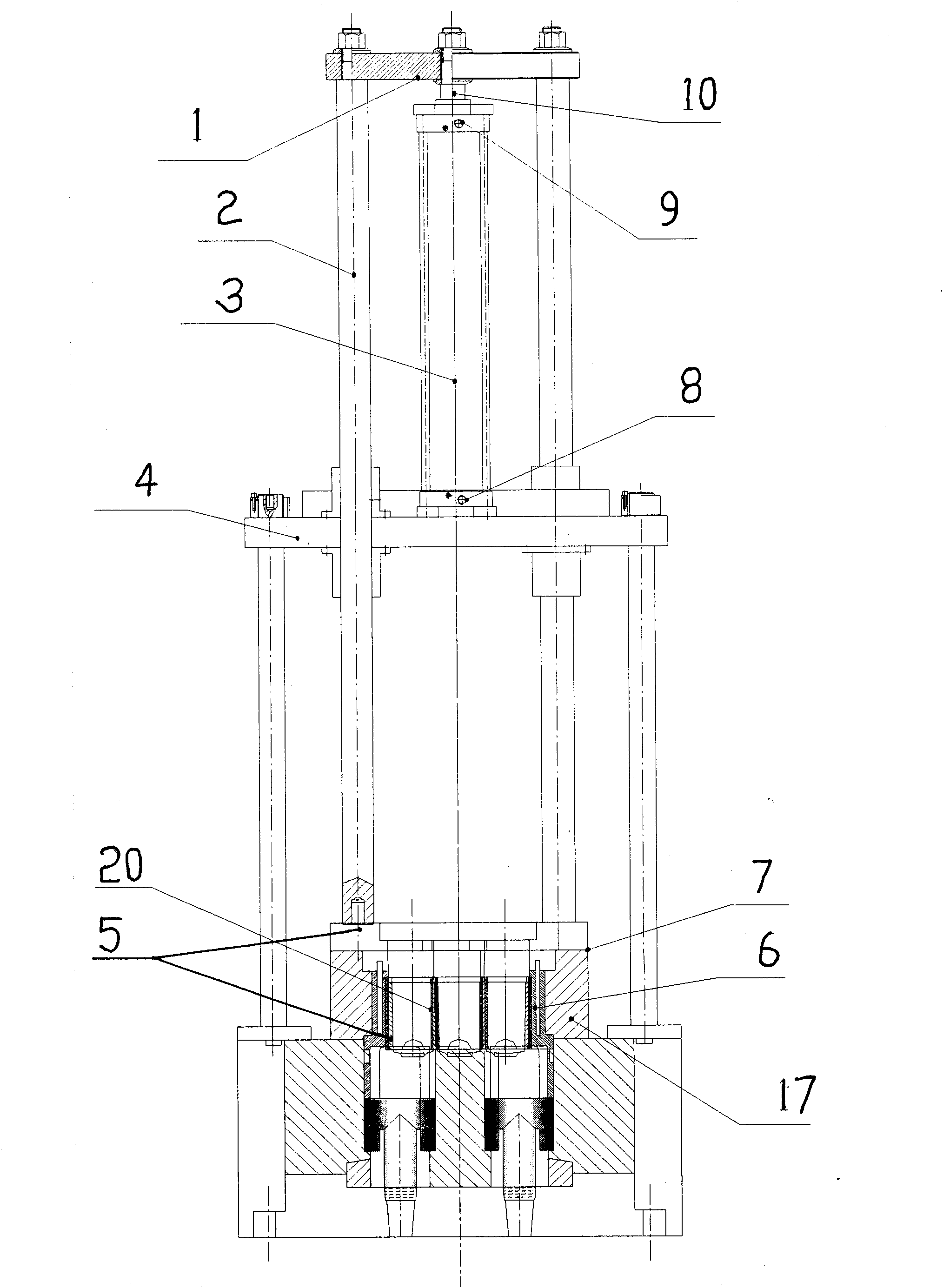

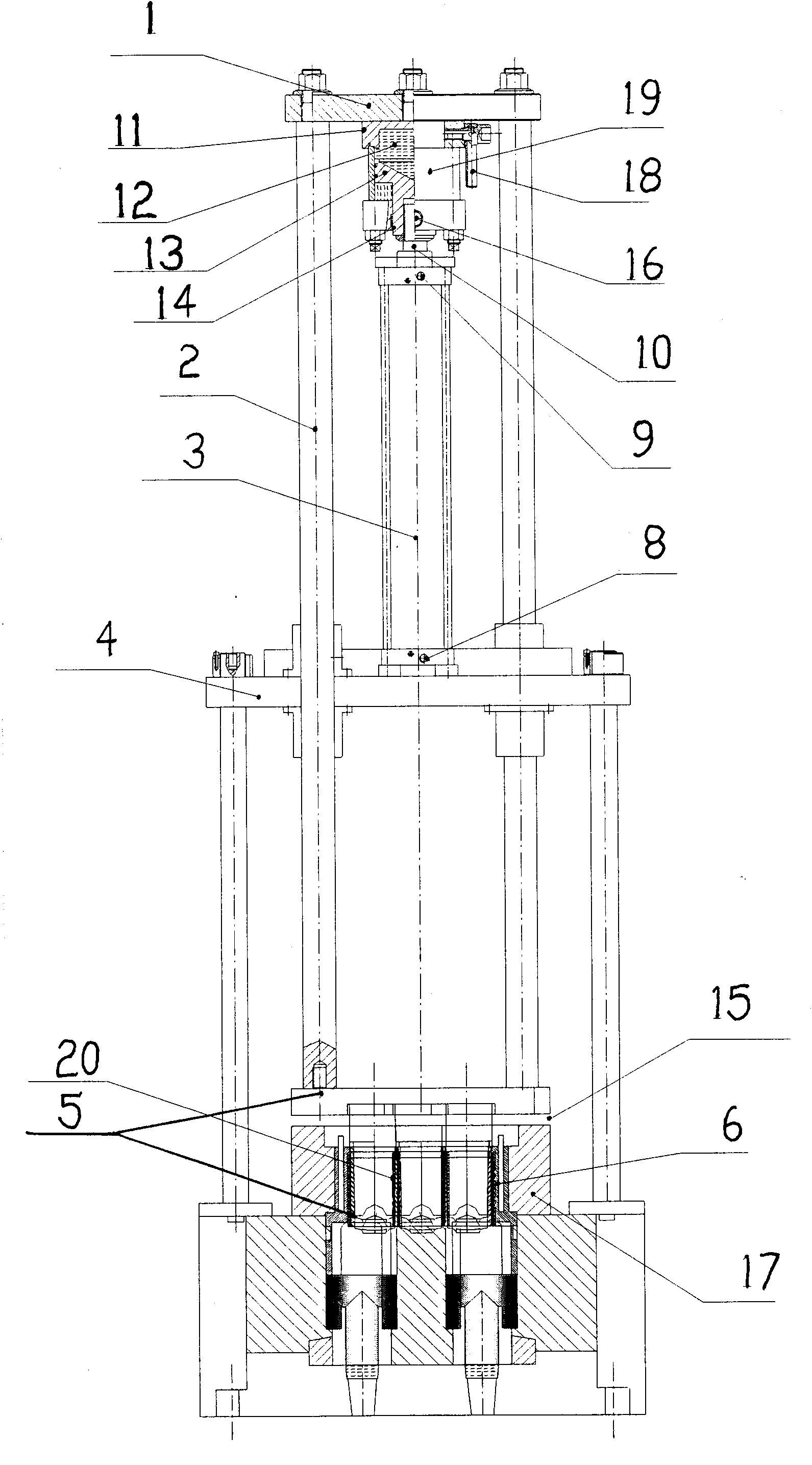

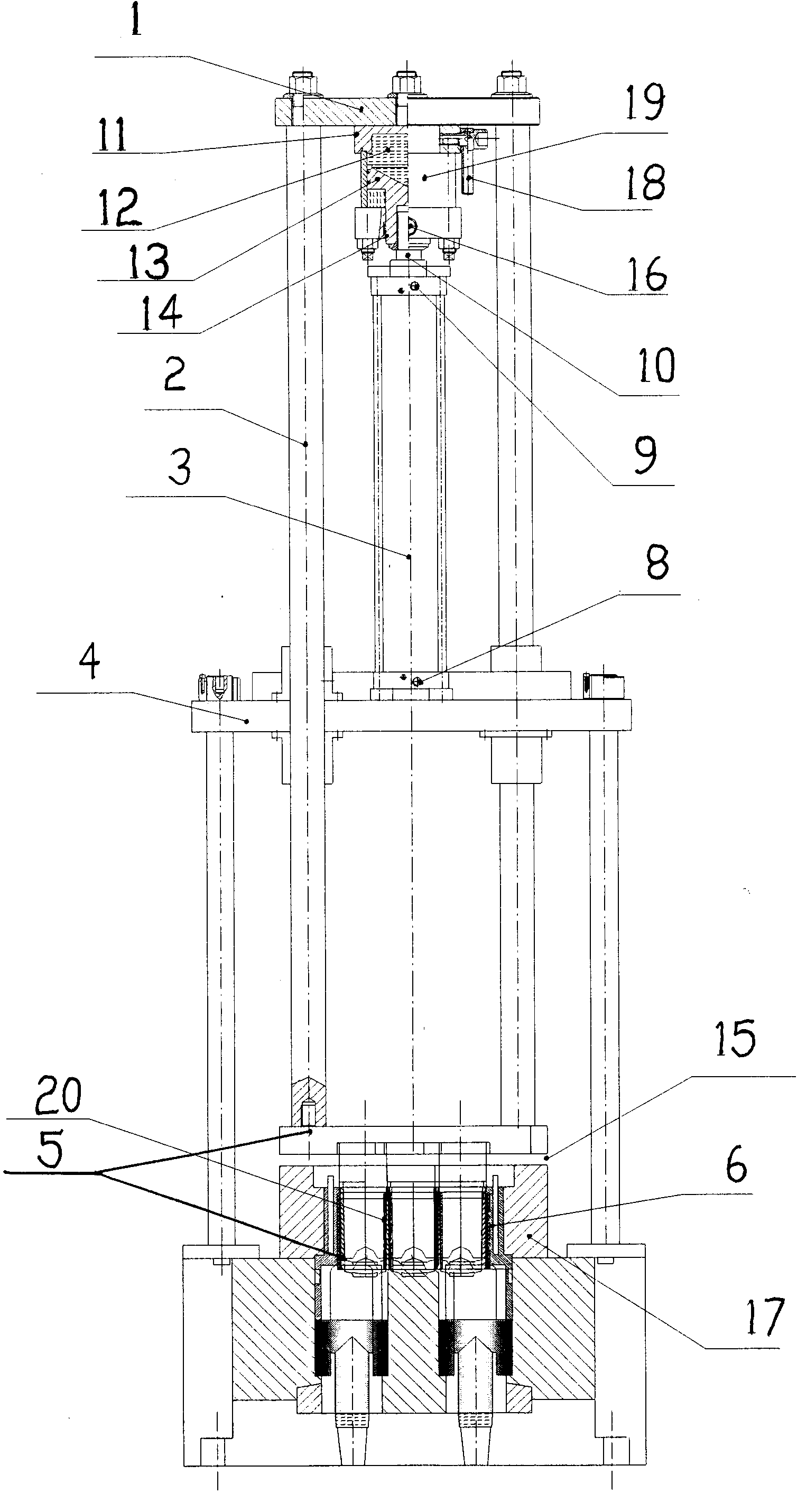

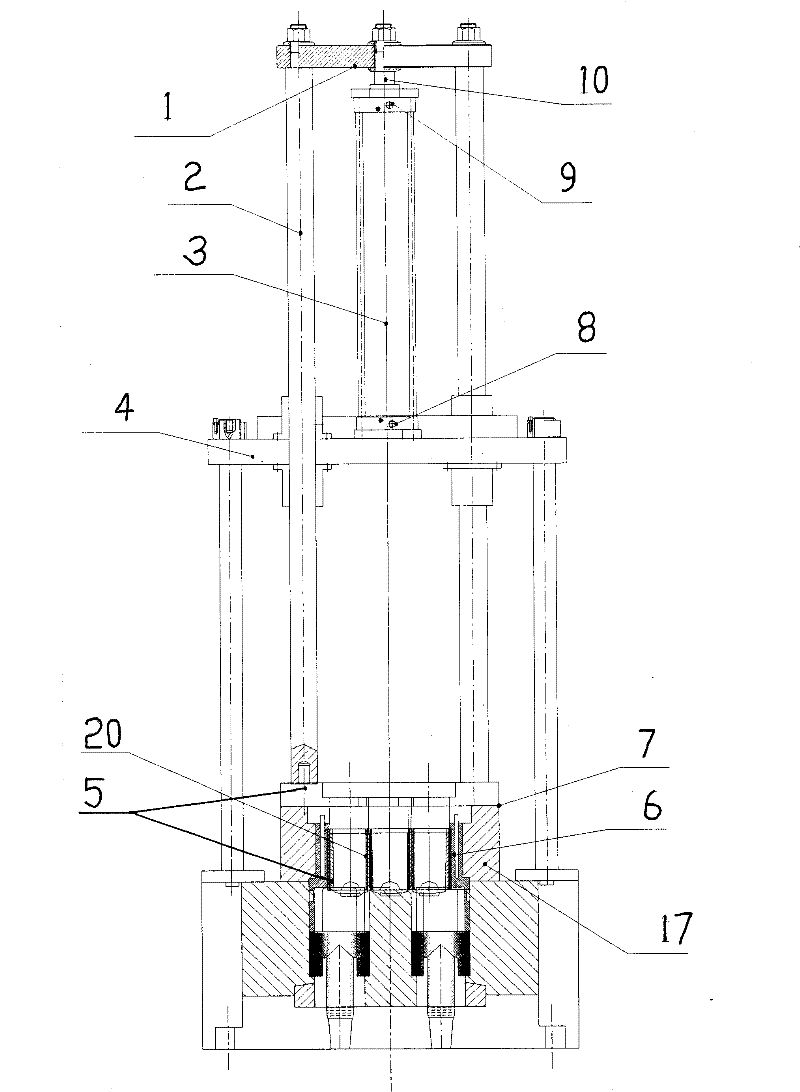

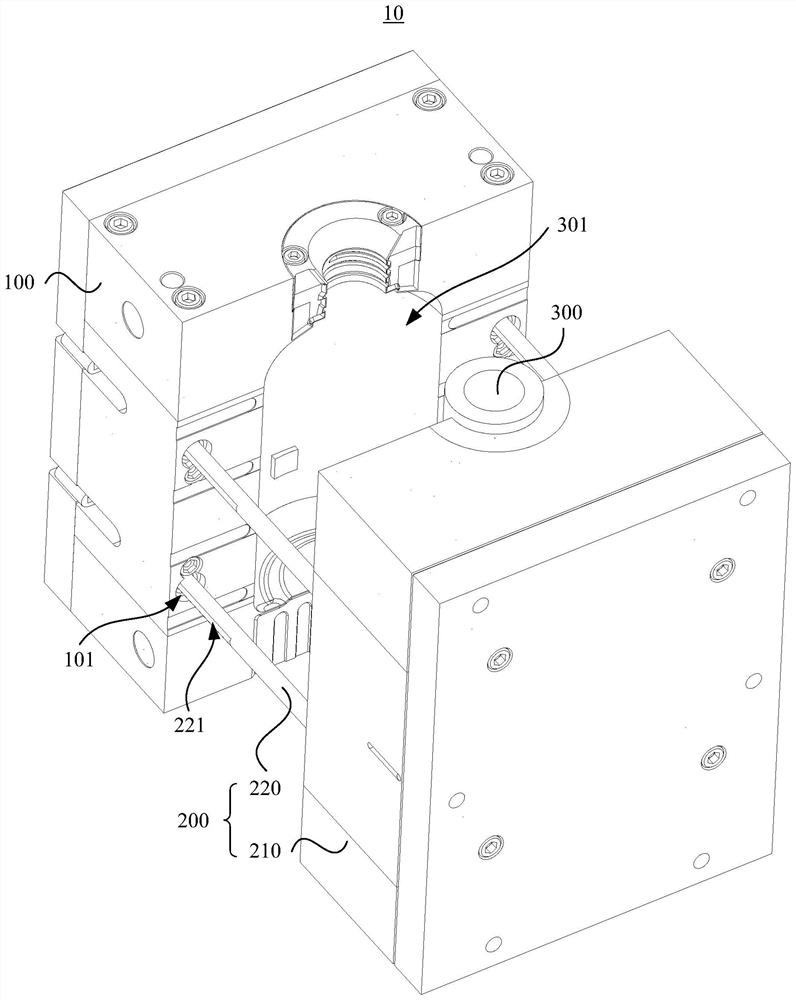

Reducing piled force-expanding type oil cylinder opening-closing device and using method thereof

The invention relates to a reducing piled force-expanding type oil cylinder opening-closing device. In the invention, a short-stroke large-cylinder-diameter flat oil cylinder is connected between a piston rod and a cross arm of a power oil cylinder, wherein the piston rod of the flat oil cylinder is connected with the piston rod of the power oil cylinder, and a close hole end cover of the flat oil cylinder is connected with the cross arm. The using method comprises the following steps of: filling hydraulic oil into an inlet-outlet oil hole of a piston cavity of the flat oil cylinder to ensure that oil enters the piston cavity and the piston rod is in a fixed state; acting on the close hole end cover of the flat oil cylinder by the piston cavity after the oil enters the piston cavity to ensure that the close hole end cover pushes the cross arm and a pull rod pulls a metal die core, wherein because the sectional area of the piston cavity of the flat oil cylinder is an odd number times that of the piston cavity of the power oil cylinder, under the action of several times of pulling force, the metal die core and an outer die of a metal die form a die opening and core pulling distance space; and then filling oil into the piston cavity of the power oil cylinder to finish the overall die opening and core pulling action of the metal mold. The invention is applied to a metal die core pulling and demoulding casting process, reduces the shut-down waste caused by the braking of the metal die core, saves the resources and improves the working efficiency.

Owner:WENZHOU RUIMING IND

Glass coating equipment

The invention discloses a glass coating equipment, which comprises an upper horizontal plate, a lower horizontal plate and a vertical support plate, a coating processing device is arranged on the end of the upper horizontal plate away from the suction fan; a coating roller is fixed between the connecting blocks, A coating solution adding device is provided above the coating roller; bristles are provided on the receiving plate, and the end of the coating solution tube away from the receiving plate is connected to a coating solution tank, and a threaded ring layer is arranged in the coating solution tank. A thread extruding plate is movably arranged in the thread circle layer, a rotating motor is arranged on the rotating plate, and a plurality of telescopic stirring rods are arranged on the support column. The invention provides glass coating equipment. The built-in cleaning and dust removal device can ensure that there is no impurity on the glass before coating, and reduce the phenomenon of pinholes or demoulding after coating. Stir the coating solution while discharging the liquid evenly to prevent precipitation. The operation linkage is simple and the effect is good.

Owner:CHONGQING LYUSEN TEMPERING HOLLOW GLASS

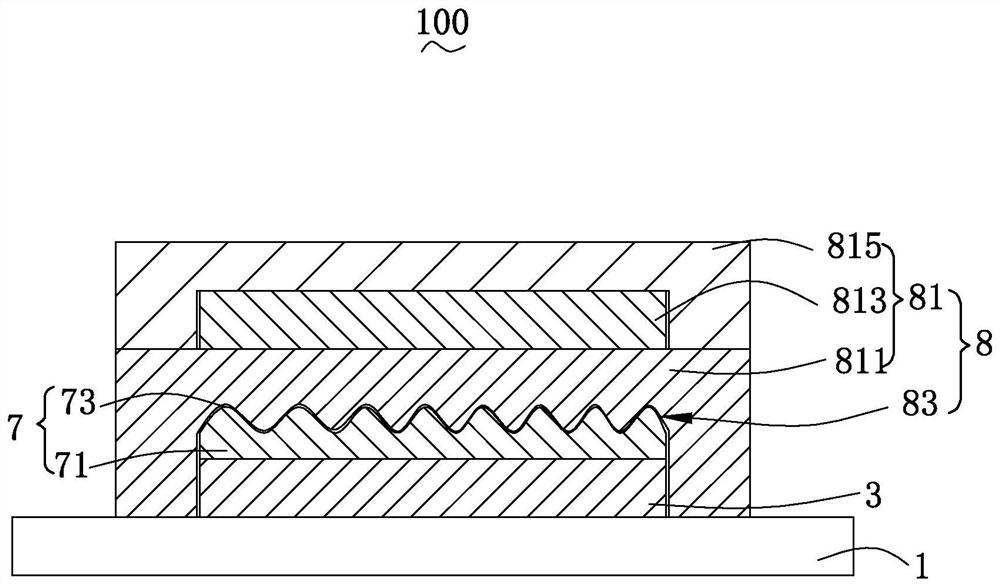

Fiber-reinforced composite material molding apparatus and method for manufacturing fiber-reinforced composite material molded article

ActiveCN111886125AGood release effectReduce mold releaseCoatingsFree energiesFiber-reinforced composite

Provided are a molding apparatus and method for manufacturing a fiber-reinforced composite material molded article that exhibits superior molded article releasability and superior abrasion resistancein areas of molded surfaces that have been imparted with releasability, and are capable of suppressing reductions in releasability. The fiber-reinforced composite material molding apparatus (101) comprises a mold (130) for molding a fiber-reinforced composite material, in which a fiber-reinforced base material is impregnated with a resin composition, to obtain a fiber-reinforced composite materialmolded article. Some or all cavity surfaces (113a), (123a) of the mold (13) have a surface free energy of 25.0 mJ / m<2> or less as measured via a three-liquid method. It is preferable that some or allof the cavity surfaces (113a), (123a) be injection surfaces through which fluorine and / or silicon are injected.

Owner:MITSUBISHI CHEM CORP

Spray-type release agent for production of artificial stone and preparation method and use method of spray-type release agent

ActiveCN110065149ASolve the problem of paper clippingSolve the blockageCeramic shaping apparatusAluminum silicatePolytetrafluoroethylene

The invention discloses a spray-type release agent for production of artificial stone and a preparation method and a use method of the spray-type release agent. The spray-type release agent comprisesthe following raw materials: polyvinyl alcohol, paraffin, hydrotalcite powder, magnesium silicate, magnesium aluminum silicate, zinc oxide, magnesium hydroxide, polytetrafluoroethylene, cellulose, xanthan gum, sodium tripolyphosphate, sodium carbonate, modified camellia oil, 1-dodecyl-3-methylimidazolium nitrate and dipotassium N-octadecyl sulfosuccinamate. The release agent is prepared by the steps of dissolving polyvinyl alcohol, mixing with an additive and the like. The use method comprises the following steps: spraying the release agent onto the surface of an artificial-stone production mold; performing natural drying and curing; and forming an anti-sticking coating on the surface of the mold. Polyvinyl alcohol, paraffin, modified camellia oil, 1-dodecyl-3-methylimidazolium nitrate anddipotassium N-octadecyl sulfosuccinamate are taken as a reinforcing system to take a synergistic effect. Thus, the drying filming time is shortened synergistically, the production cycle is shortenedand the efficiency is improved.

Owner:GUANGXI LISHENG STONE CO LTD

Mold release composition and surface protective film

ActiveCN102414278AReduce mold releasePhotomechanical apparatusOriginals for photomechanical treatmentResistHydrolysis

Provided is a mold release composition, with which it is possible to form a transparent coating on the surface of which a photoresist cannot be readily deposited. Also provided is a surface protective film having a coating formed from the cured product of the mold release composition. The mold release composition comprises a binder resin, a silicone oil, and a metal alkoxide hydrolysis product. Preferably the metal alkoxide hydrolysis product content is 50 to 500 parts by weight per 100 parts by weight of binder resin. Preferably the metal alkoxide consists of tetraethoxysilane or tetramethoxysilane. The surface protective film is obtained by forming a coating of the cured product of the mold release composition on a substrate.

Owner:KIMOTO CO LTD

Polyvinyl chloride (PVC) glove production device

ActiveCN102173017BRapid coolingGood release effectDomestic articlesCoatingsPolyvinyl chlorideEngineering

The invention belongs to the field of polyvinyl chloride (PVC) glove production and relates to a PVC glove production device. The device comprises a hand mold rail line and a glove production device, wherein the hand mold rail line is positioned above the glove production device; the glove production device comprises a PVC material groove, a PVC material dripping section, a PVC plasticizing forming device, a polyurethane (PU) material groove, a PU drying device, a PVC glove hemming device and a demolding device in turn; and the PVC plasticizing forming device and the PU drying device are connected with a heat supply boiler. The device is characterized in that: a hand mold cleaning device and a hand mold drying device are arranged in turn between the demolding device and the PVC material groove; the PVC material groove is provided with a viscosity detection adjusting device; and a PU washing device and a washing drying device are arranged in turn between the PU drying device and the PVC glove hemming device. The device has high automation degree and good effect of forming PVC gloves; moreover, the product is easy to demold, and stickness or damage hardly appears in the demolding process, so that the glove quality is ensured.

Owner:SHANDONG INTCO MEDICAL SUPPLY CO LTD

Environment-friendly release agent for autoclaved aerated concrete block and preparation method of environment-friendly release agent

InactiveCN112852533AGood release effectExcellent mold releaseCeramic shaping apparatusLubricant compositionVegetable oilPolyethylene glycol

The invention discloses an environment-friendly release agent for autoclaved aerated concrete blocks. The environment-friendly release agent is prepared from the following raw materials in parts by weight: vegetable oil, a POSS-phosphorylated vegetable oil polymer, polyethylene glycol, nano calcium carbonate, ammonium polycarboxylate, a compound emulsifier, C12 alcohol ester, emulsified silicone oil, xanthan gum and water. The invention also discloses a preparation method of the environment-friendly release agent for autoclaved aerated concrete blocks, which comprises the following steps: dispersing the POSS-phosphorylated vegetable oil polymer into the vegetable oil containing polyethylene glycol to obtain a dispersion liquid; dissolving a compound emulsifier, emulsified silicone oil and xanthan gum in hot water to obtain emulsified water; and adding nano calcium carbonate, ammonium polycarboxylate and emulsified water into the dispersion liquid, adding the C12 alcohol ester and adding water for dilution, and uniformly stirring all the components to obtain the modified vegetable oil environment-friendly release agent. The release agent disclosed by the invention has the advantages of high film forming speed, small adhesion amount, low cost, no toxicity, no pollution and good release effect.

Owner:广西建工集团建筑产业投资有限公司

Imprint material having low mold release property

InactiveUS20150321445A1Reduce mold releaseImprove scratch resistanceLayered productsDecorative surface effectsPolymer chemistryFingerprint

There is provided an imprint material that allows a resin film to be readily released from a mold at the time of mold release after curing, that is, an imprint material that forms a film having a low mold release property as well as high transparency, high scratch resistance, and a high fingerprint wiping-off property; and a film which is formed from the material and to which a pattern is transferred. An imprint material including: a (A) component: a compound having a propylene oxide unit and two polymerizable groups or a compound having a propylene oxide unit, an ethylene oxide unit, and two polymerizable groups; a (B) component: a silicone compound; and a (C) component: a photopolymerization initiator.

Owner:NISSAN CHEM IND LTD

Spraying type release agent for producing artificial stone, preparation method and application method thereof

ActiveCN110065149BShorter drying and film forming timeExcellent drying and film forming timeNon-fibrous pulp additionCeramic shaping apparatusCellulosePolyvinyl alcohol

The invention discloses a spray-coating release agent for artificial stone production, a preparation method and a use method thereof, which comprise the following raw materials: polyvinyl alcohol, paraffin, hydrotalcite powder, magnesium silicate, aluminum magnesium silicate, zinc oxide, Magnesium Hydroxide, Teflon, Cellulose, Xanthan Gum, Sodium Tripolyphosphate, Sodium Carbonate, Modified Camellia Oil, 1-Dodecyl-3-Methylimidazole Nitrate, Octadecylsuccinic Acid Dipotassium monoamide sulfonate, the release agent is made through steps such as dissolving polyvinyl alcohol and mixing with additives. The method of use is to spray the mold release agent on the surface of the artificial stone production mold, and after natural drying and curing, an anti-bonding coating is formed on the surface of the mold. The present invention uses polyvinyl alcohol, paraffin, modified camellia oil, 1-dodecyl-3-methylimidazole sodium nitrate, and dipotassium octadecylsuccinic acid monoamide sulfonate as the reinforcement system, which has a synergistic effect , synergistically shorten the drying and film forming time, shorten the production cycle and improve the efficiency.

Owner:GUANGXI LISHENG STONE CO LTD

Environment-friendly high-efficiency nylon demoulding master batch and preparation method thereof

The invention discloses an environment-friendly high-efficiency nylon demoulding master batch and a preparation method thereof. The environment-friendly high-efficiency nylon demoulding master batch is prepared from the following raw materials in parts by mass: 60 to 80 parts of nylon slices, 10 to 20 parts of nano silicon dioxide, 5 to 10 parts of EBS and 0.2 to 0.5 part of an antioxidant. Nylon6 slices are used as a matrix, nano silicon dioxide, a lubricant and an antioxidant are added, and a parallel twin-screw extruder is used for mixing to obtain the master batch. The nylon demoulding master batch prepared by utilizing the nucleating effect of nano silicon dioxide and the lubricating and dispersing effects of EBS can remarkably improve the demoulding effect of a product during injection molding by adding a small amount of the nylon demoulding master batch into nylon 6, and the forming period is shortened.

Owner:FUJIAN ZHONGJIN NEW MATERIALS

Cleaning method for outer side wall of arc glass

The invention discloses a cleaning method applied to the outer wall of curved glass, which includes the following steps: the curved glass is placed in the curved groove and moved to the curved hole, and after the curved glass enters the adsorption cavity through the curved hole, the adsorption soft The cleaning agent is put into the tube, and after the cleaning and drying process is completed, the curved glass is sent out from the rear end of the adsorption chamber to facilitate the cleaning of the upper surface of the curved glass before ultrasonic spraying; the top of the adsorption chamber is equipped with an adsorption soft The tube has arc-shaped holes at the front and rear ends of the adsorption chamber, an arc-shaped groove is fixed at the lower end of the arc-shaped hole, a groove is opened on the adsorption chamber, and a baffle is hinged at the upper end of the groove. When working, the upper and lower ends of the curved glass are placed in the functional area of the adsorption cavity. There are grooves on the inner wall of the front end of the adsorption cavity and the outer wall of the rear end. The baffle can close the adsorption cavity. While the curved glass passes through normally, the phenomenon of glass demoulding is reduced.

Owner:CHENGDU HENGTONG ZHAOYE PRECISION MACHINERY

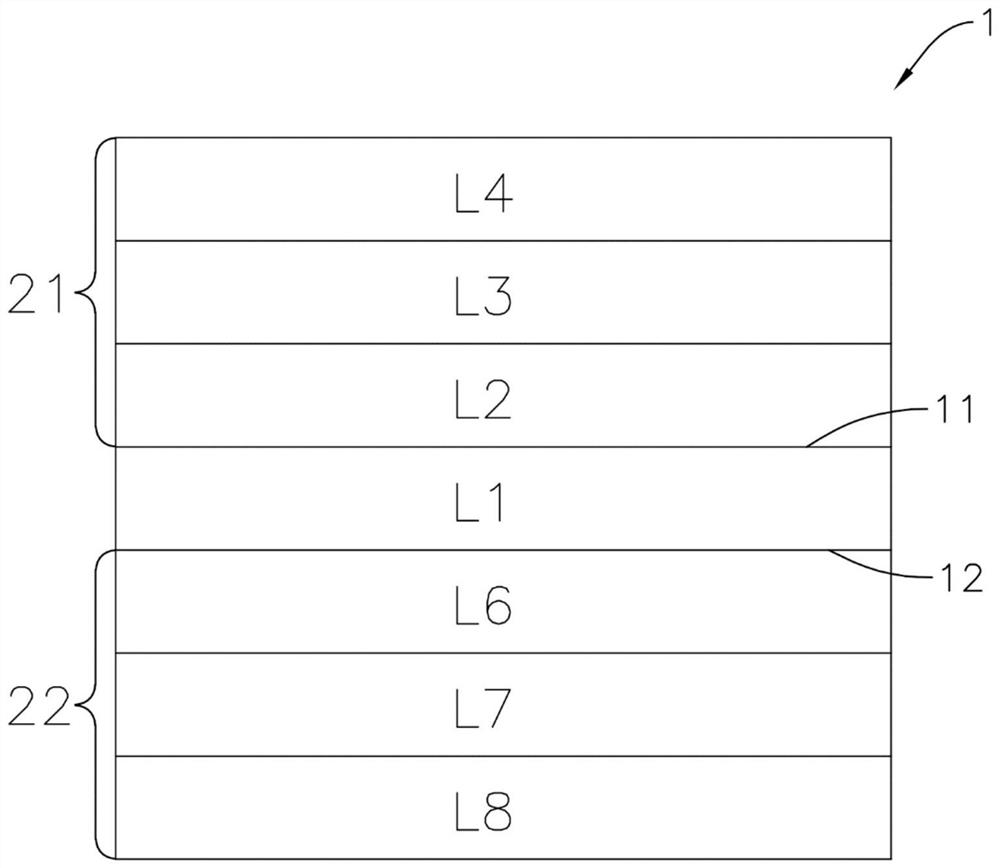

OLED display device and method for manufacturing OLED display device

ActiveCN109427997BImprove bending reliabilitySolve vulnerableSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

An OLED display device, comprising a sequentially stacked substrate, an OLED unit, an optical coupling layer, and an encapsulation layer for encapsulating the OLED unit, the optical coupling layer is made of an inorganic material suitable for light extraction, and is directly formed on the on the OLED unit. A method for preparing an OLED display device includes: S1, preparing an OLED unit on a substrate; S2, forming an optical coupling layer on the OLED unit by depositing an inorganic material; S3, forming an encapsulation layer on the optical coupling layer to encapsulate the OLED unit. The OLED display device and the preparation method of the OLED display device provided in this embodiment increase the adhesion between the optical coupling layer and the encapsulation layer by preparing the optical coupling layer from inorganic materials, and solve the problem that the optical coupling layer is easily damaged, so that When the OLED display device is bent, the phenomenon of defilming of the optical coupling layer and the encapsulation layer is reduced, and the bending reliability of the OLED display device is improved.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT

Polycarbonate resin composition and molded article thereof

A polycarbonate resin composition (1) comprising (B) 0.01 to 0.25 parts by mass of a silicone compound and (C) an aliphatic compound having 12 to 22 carbon atoms with respect to 100 parts by mass of the (A) polycarbonate resin. 0.015 to 0.25 parts by mass of ester of carboxylic acid and glycerin, the sodium content in the above-mentioned component (B) is 15 mass ppm or less, or the polycarbonate resin composition (2), wherein, with respect to 100 parts by mass of (A), contains (B) 0.01 to 0.25 parts by mass and (C) 0.015 to 0.25 parts by mass, the modification rate of component (C) is 30% or less; and the molded polycarbonate resin composition (1) or (2) obtained Taste.

Owner:IDEMITSU KOSAN CO LTD

Reducing piled force-expanding type oil cylinder opening-closing device and using method thereof

The invention relates to a reducing piled force-expanding type oil cylinder opening-closing device. In the invention, a short-stroke large-cylinder-diameter flat oil cylinder is connected between a piston rod and a cross arm of a power oil cylinder, wherein the piston rod of the flat oil cylinder is connected with the piston rod of the power oil cylinder, and a close hole end cover of the flat oil cylinder is connected with the cross arm. The using method comprises the following steps of: filling hydraulic oil into an inlet-outlet oil hole of a piston cavity of the flat oil cylinder to ensure that oil enters the piston cavity and the piston rod is in a fixed state; acting on the close hole end cover of the flat oil cylinder by the piston cavity after the oil enters the piston cavity to ensure that the close hole end cover pushes the cross arm and a pull rod pulls a metal die core, wherein because the sectional area of the piston cavity of the flat oil cylinder is an odd number times that of the piston cavity of the power oil cylinder, under the action of several times of pulling force, the metal die core and an outer die of a metal die form a die opening and core pulling distance space; and then filling oil into the piston cavity of the power oil cylinder to finish the overall die opening and core pulling action of the metal mold. The invention is applied to a metal die core pulling and demoulding casting process, reduces the shut-down waste caused by the braking of the metal die core, saves the resources and improves the working efficiency.

Owner:WENZHOU RUIMING IND

Aluminum alloy lead frame and manufacturing method thereof

ActiveCN110690338BGood adhesionGood can improve adhesionSemiconductor/solid-state device detailsSolid-state devicesInter layerAlloy substrate

The invention provides an aluminum alloy lead frame and a manufacturing method thereof. The lead frame provides an aluminum alloy substrate with an upper surface and a lower surface opposite to each other. A reflective composite layer is arranged on the upper surface. The reflective composite layer comprises a first intermediate layer, a functional layer, and a reflective layer in order. The firstintermediate layer is arranged between the aluminum alloy substrate and the functional layer, and a welding composite layer is arranged on the lower surface thereof. The welding composite layer comprises a second intermediate layer, a welding layer, and a second protective layer in order. The second intermediate layer is arranged between the aluminum alloy substrate and the welding layer to acquire an aluminum alloy lead frame. According to the invention, the binding force of the functional layer and the welding layer with the aluminum alloy substrate is improved, so that the problems of pooradhesion of the film layers of a general aluminum alloy substrate and poor reflectivity of the existing copper alloy lead frame are improved; the application value is improved; and furthermore, the lead frame with advantages in price and weight is provided.

Owner:安森科技材料股份有限公司

PC/ABS composite material and preparation method thereof, blow mold and blow molding method

ActiveCN113980418BImprove low temperature toughnessHigh heat distortion temperatureBlow moldingPolymer science

The application provides a PC / ABS composite material, a preparation method thereof, a blow mold and a blow molding method. The above-mentioned PC / ABS composite material includes PC resin, ABS resin, compatibilizer, toughening agent, melt reinforcing agent, ionic dispersant and halogen-free flame retardant. The above-mentioned PC / ABS composite material has good flame retardant effect, good compatibility and good processing performance stability.

Owner:东莞市千晋塑料科技有限公司

A special pvc granule for ultra-high transparency rigid medical injection molding equipment

The invention discloses PVC (polyvinyl chloride) pellets special for ultrahigh-transparency hard medical injection molding apparatuses. The PVC pallets comprise, by weight, 100 parts of polyvinyl chloride resin with the degree of polymerization being 700, 3.0-4.0 parts of methacryIate-Butadiene-Styrene copolymer, 1.5-2.0 parts of methacrylate processing aid, 2.0-2.2 parts of methyltin mercaptide heat stabilizer, 2.0-2.3 parts of butyl dodecanoate lubricant, 0.2-0.3 part of stearic acid, 0.1-0.25 part of oxidized polyethlene wax and trace indigo pigment. The finished products are prepared by means of feeding the components into a high-speed heating mixer according to the proportion for high-speed mixing, performing kneading to the temperature of 123-125 DEG C prior to discharging, putting the discharged material into a low-speed cooling mixer to be cooled to room temperature to obtain mixed powder, feeding the mixed powder into a pelletizer for pelletizing, and cooling the pellets to the temperature lower than 40 DEG C prior to packaging. The medical injection molding apparatuses made of the PVC pellets have ultrahigh transparency and surface glossiness.

Owner:WUXI JIAHONG PLASTICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com