Polyamide, polyamide composition, and molded article

A polyamide composition and polyamide technology, which are used in polyamide compositions and molded products, and polyamide fields, can solve problems such as difficulty in obtaining molded products, and achieve low water absorption, vibration fatigue properties, excellent surface appearance, and polymerization yield. excellent rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

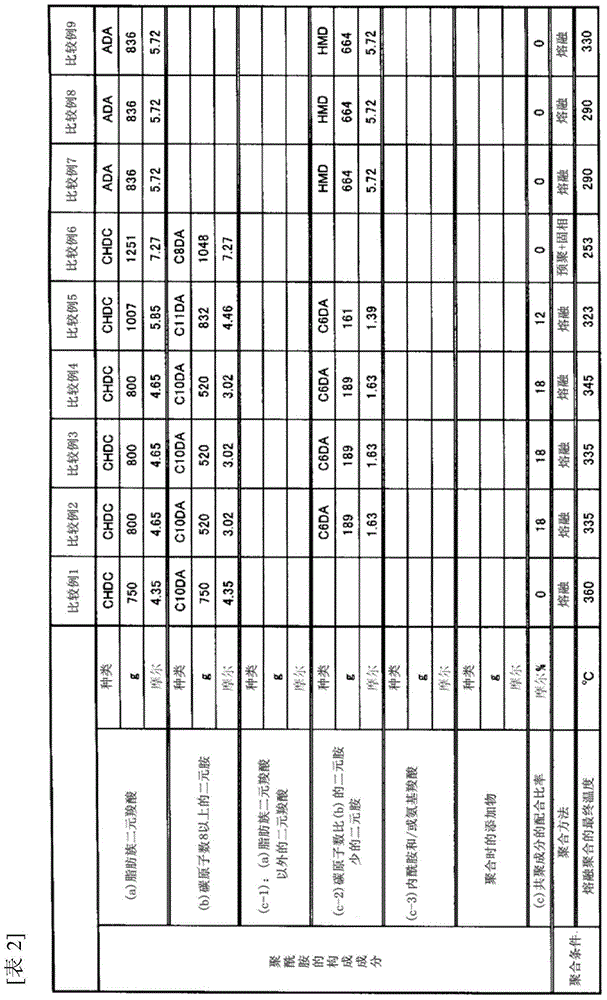

[0419] Hereinafter, the present embodiment will be described more specifically with examples and comparative examples, but the present embodiment is not limited to these examples.

[0420] The raw materials and measurement methods used in the examples and comparative examples are described below.

[0421] It should be noted that in this embodiment, 1kg / cm 2 Refers to 0.098MPa.

[0422] [Raw materials]

[0423] In this example and comparative example, the following compounds were used.

[0424]

[0425] (1) 1,4-Cyclohexanedicarboxylic acid (CHDC)

[0426] Trade name: 1,4-CHDA HP grade (trans form / cis form=25 / 75) (manufactured by Eastman Chemical)

[0427] (2) Sebacic acid (C10DC)

[0428] Trade name: Sebacic acid TA (manufactured by Ito Oil Co., Ltd.)

[0429] (3) Isophthalic acid (IPA) (manufactured by Wako Pure Chemical Industries, Ltd.)

[0430] (4) Adipic acid (ADA) (manufactured by Wako Pure Chemical Industries, Ltd.)

[0431]

[0432] (1) 1,10-Diaminodecane (1,10-decamethylene diamine) (...

manufacture example

[0448]

[0449] First, it is diluted with water to a solid content of 2% by mass of polyurethane resin, 4% by mass of maleic anhydride-butadiene copolymer, 0.6% by mass of γ-aminopropyltriethoxysilane, and 0.1% by mass of carnauba wax. Thus, a glass fiber sizing agent is obtained.

[0450] The obtained glass fiber sizing agent was adhered to the glass fiber having a number average fiber diameter of 7 μm obtained by melt spinning by a coater installed on the way to the rotating drum.

[0451] Then, the glass fiber to which the glass fiber sizing agent is adhered is dried, thereby obtaining a roving of the glass fiber bundle surface-treated with the glass fiber sizing agent.

[0452] At this time, the glass fiber is made into 1,000 pieces per bundle. The adhesion amount of the glass fiber sizing agent to the glass fibers was 0.6% by mass. This was cut into a length of 3 mm to obtain a chopped strand (hereinafter also abbreviated as "GF-2").

[0453] In addition, in this example, the a...

Embodiment 1

[0553] (Production of polyamide)

[0554] The polymerization reaction of polyamide is carried out by the "hot melt polymerization method" as described below.

[0555] 750 g (4.35 moles) of CHDC as (a) alicyclic dicarboxylic acid and 750 g (4.35 moles) of C10DA as (b) diamine with 8 or more carbon atoms were dissolved in 1500 g of distilled water to prepare a raw material list The body is equimolar about 50% by mass homogeneous aqueous solution.

[0556] The obtained aqueous solution and 17g (0.10 mol) of (b) C10DA as an additive during melt polymerization were put into an autoclave (manufactured by Nitto High Pressure) with an internal volume of 5.4L, and kept until the liquid temperature (internal temperature) reaches 50°C , Nitrogen replacement in the autoclave. Continue heating to bring the liquid temperature from about 50°C to the tank of the autoclave (hereinafter also abbreviated as "in the tank"). The pressure is about 2.5kg / in gauge (hereinafter, the pressure in the tank i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com