Aluminum alloy lead frame and manufacturing method thereof

A technology of aluminum alloy wire and manufacturing method, which is applied in the field of lead frames, can solve the problems of weakening the bonding force between the reflective layer and aluminum, the decrease of the bonding force of the plating layer, and the falling off of the welding wire, so as to improve the application value, improve the adhesion, and reduce the weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1: Aluminum Alloy Lead Frame

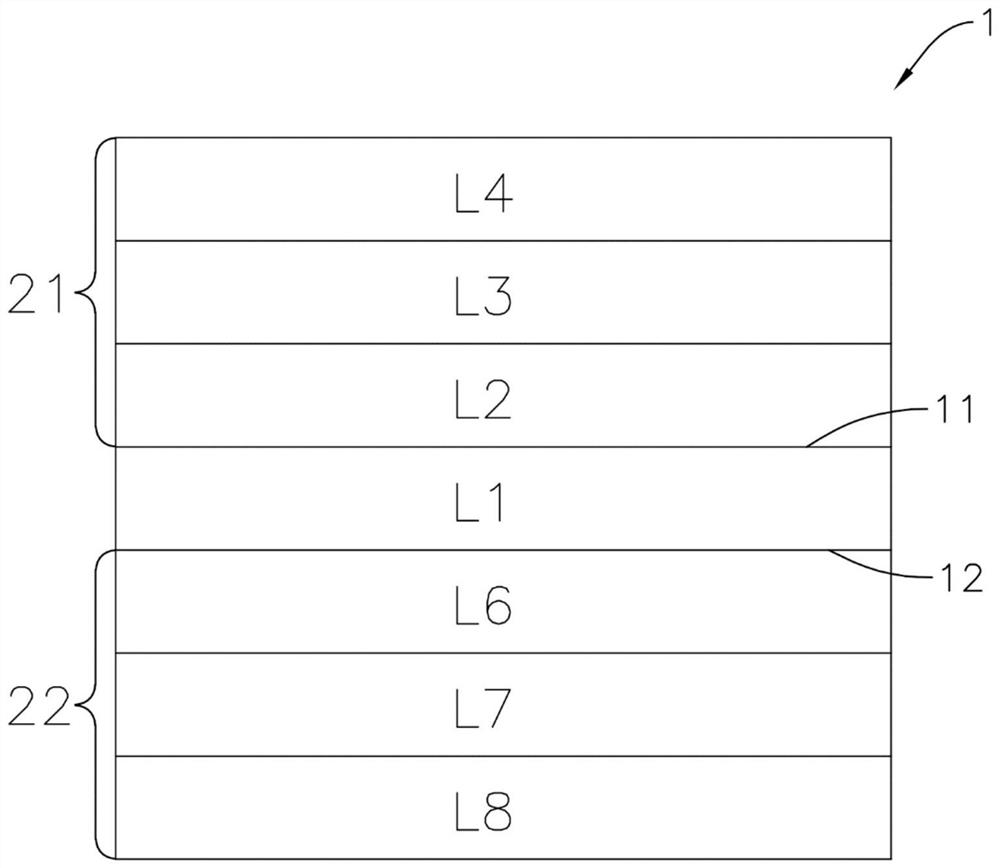

[0055] Such as figure 1 As shown, the aluminum alloy lead frame of Example 1 was prepared by the following method. First of all, 5005 series aluminum-magnesium alloy is selected as the aluminum alloy substrate L1, and its thickness is 0.3mm; the substrate can be in the form of a coil and manufactured by a continuous process. Using vacuum coating technology, a first intermediate layer L2 is formed on the upper surface 11 of the aluminum alloy substrate L1. The first intermediate layer L2 is a titanium metal layer with a thickness of 20 nm; A functional layer L3 is formed on the upper surface, the functional layer L3 is a copper layer with a thickness of 800nm; and then a second intermediate layer L6 is formed on the lower surface 12 of the aluminum alloy substrate L1 by vacuum coating technology, and the second intermediate layer L6 is a titanium metal layer , with a thickness of 20nm; in the next step, a welding layer L7 is fo...

Embodiment 2

[0057] Embodiment 2: Aluminum Alloy Lead Frame

[0058] Such as figure 2 As shown, the aluminum alloy substrate of Example 2 is manufactured by using the vacuum coating technology throughout the manufacturing process through the following method. First, 1085 series aluminum alloy is selected as the aluminum alloy substrate L1, and its thickness is 0.2mm; the substrate can be in the form of a coil and manufactured by a continuous process. A first intermediate layer L2 is formed on the upper surface 11 of the aluminum alloy substrate L1, and the first intermediate layer L2 is a titanium oxide layer (TiO x ), its thickness is 10nm; Then, form functional layer L3 on the first intermediate layer L2, functional layer L3 is a copper layer, its thickness is 800nm; And form reflective layer L4 on functional layer L3, reflective layer L4 is silver layer , its thickness 1000nm; Form the first protective layer L5 on the reflective layer L4 again, the first protective layer L5 is a sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com