Expansion polymerization imprinting glue for nano-imprinting

A technology of nano-imprinting and imprinting glue, applied in the field of nano-imprinting, can solve the problems of decreased fidelity of imprinted patterns, delamination of imprinted glue, and cannot be completely eliminated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

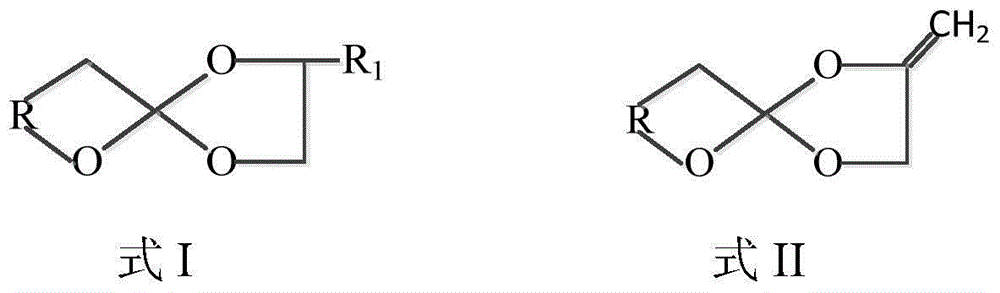

Method used

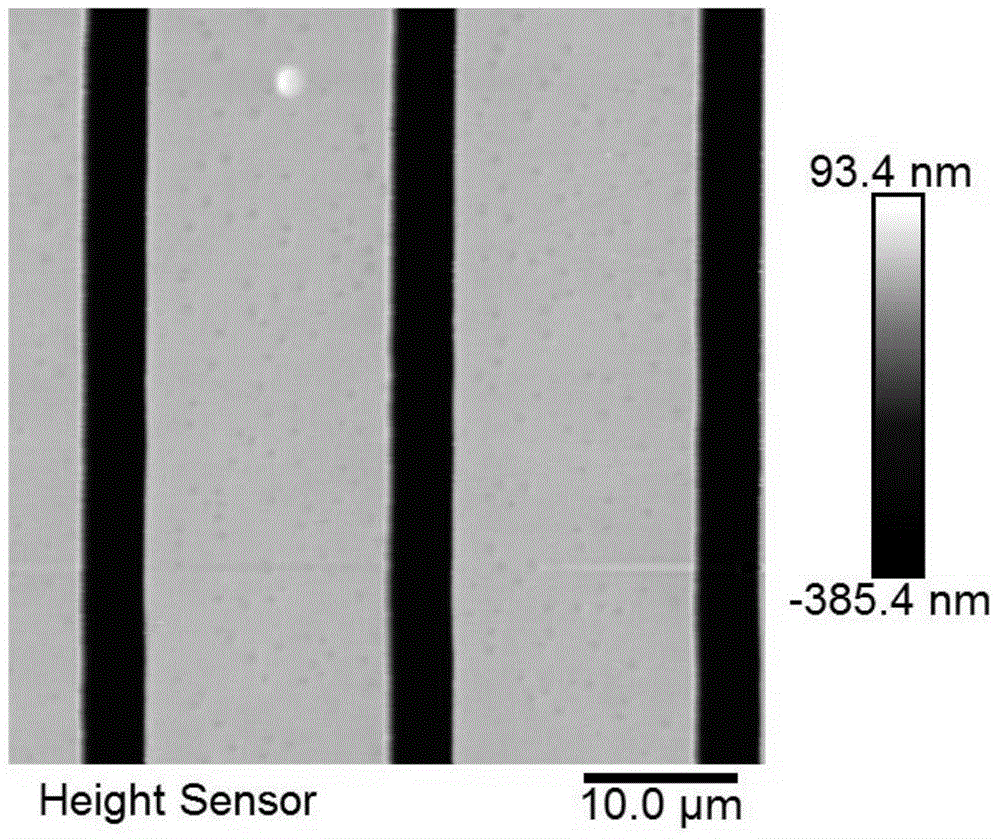

Image

Examples

Embodiment 1

[0068] Embodiment 1: A kind of spiro ring orthocarbonate, epoxy resin mixed embossing glue system

[0069] The raw materials required for the preparation of the expanded polymeric embossing glue for nanoimprinting in this embodiment include oligomers, expansion monomers, and photoinitiators, wherein the oligomers are epoxy resin monomers, and the expansion monomers are spirogen Carbonate compounds, specifically 2,4,8,10-tetramethyl-1,5,7,11-tetraoxaspiro[5,5]undecane, the structure is shown in formula VI, and the photoinitiator is Triaryliodonium salts.

[0070]

[0071] The preparation process of the expansion polymer imprinting glue for nanoimprinting in this embodiment is as follows: epoxy resin oligomer, expansion monomer 2,4,8,10-tetramethyl-1,5,7,11-tetramethyl-1,5,7,11-tetra Oxyspiro[5,5]undecane and triaryliodonium salt photoinitiator were evenly mixed in the dark. The weight percent of oligomer, expansion monomer and photoinitiator are 90wt%, 9wt%, 1wt% respectiv...

Embodiment 2

[0073] Embodiment 2: A kind of spiro ring orthocarbonate, silicon-containing epoxy resin mixed embossing adhesive system

[0074] The raw materials required for the preparation of the expanded polymeric imprinting glue for nanoimprinting in this embodiment include oligomers, expansion monomers, photoinitiators, and diluents, wherein the oligomers are silicon-containing epoxy resin monomers, and the expansion monomers The body is a spiro ring orthocarbonate compound, specifically 1,5,7,11-tetraoxaspiro[5,5]undecane, the structure is shown in formula VII, the photoinitiator is a triaryl iodonium salt, dilute The agent is PGMEA.

[0075]

[0076] The preparation process of the expansion polymer imprint glue for nanoimprinting in this embodiment is as follows: the silicon-containing epoxy resin oligomer, the expansion monomer 1,5,7,11-tetraoxaspiro[5,5]undecane , photoinitiator and diluent PGMEA were evenly mixed in the dark. The weight percentages of oligomer, expansion mono...

Embodiment 3

[0079] Embodiment 3: A kind of spiro ring orthocarbonate, silicon-containing epoxy resin mixed embossing adhesive system

[0080]The raw materials required for the preparation of the expanded polymeric imprinting glue for nanoimprinting in this embodiment include oligomers, expansion monomers, photoinitiators, and diluents, wherein the oligomers are silicon-containing epoxy resin monomers, and the expansion monomers The body is a spiro ring orthocarbonate compound, specifically 1,5,7,11-tetraoxaspiro[5,5]undecane, the structure is shown in formula VII, the photoinitiator is a triaryl iodonium salt, dilute The agent is an epoxy cationic reactive diluent.

[0081] The preparation process of the expansion polymer imprint glue for nanoimprinting in this embodiment is as follows: the silicon-containing epoxy resin oligomer, the expansion monomer 1,5,7,11-tetraoxaspiro[5,5]undecane , photoinitiator and diluent were evenly mixed in the dark. The weight percentages of oligomer, expa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com