Air spring with stepless-adjustable volume and control method thereof

An air spring and volume technology, applied in the direction of springs, springs/shock absorbers, shock absorbers, etc., can solve the problems of shortening the service life of solenoid valves and other components, the external shape of the base cannot be dynamically adjusted, and wasting suspension installation space. , to save the installation space of the suspension, the volume change is steplessly adjustable, and the performance is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

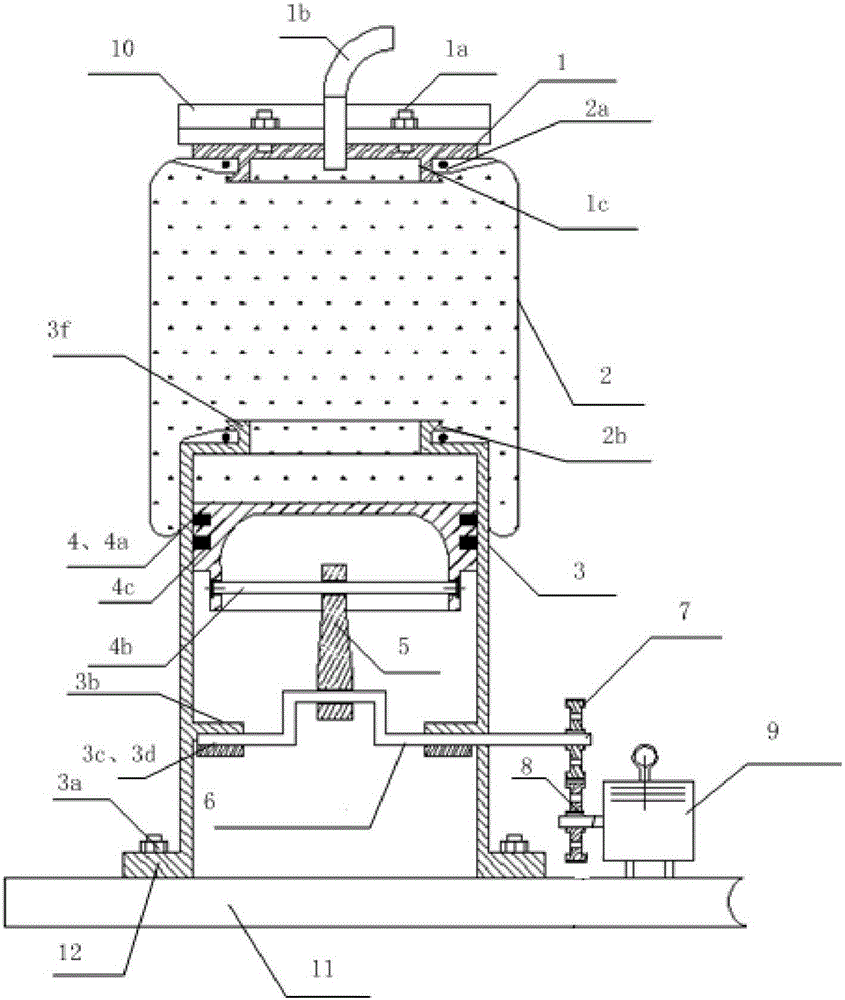

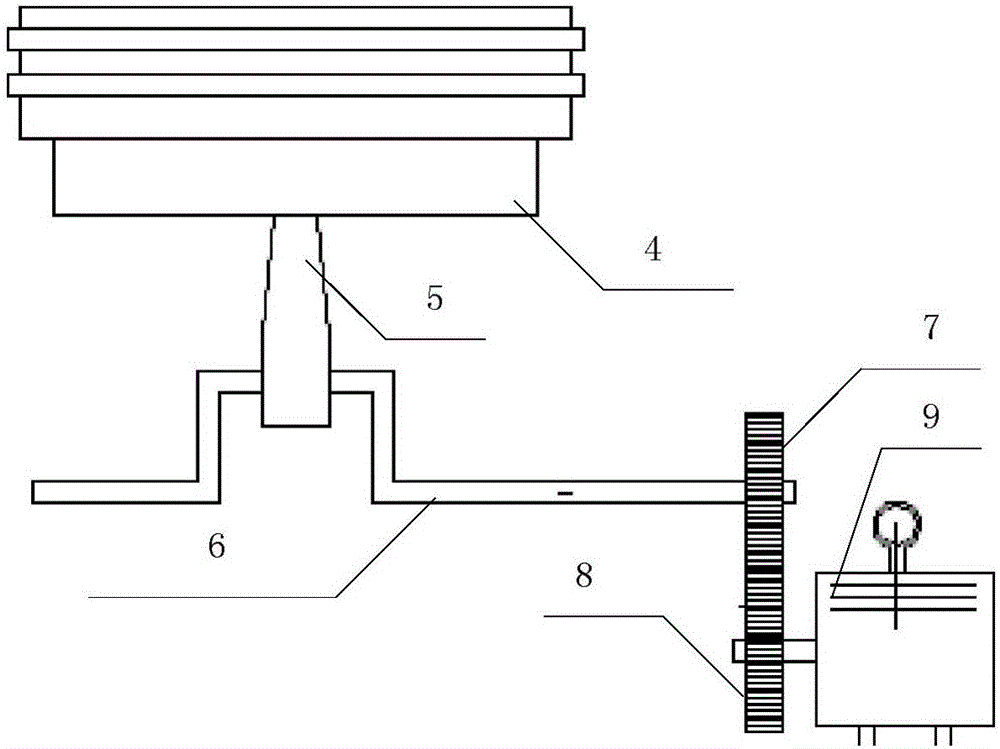

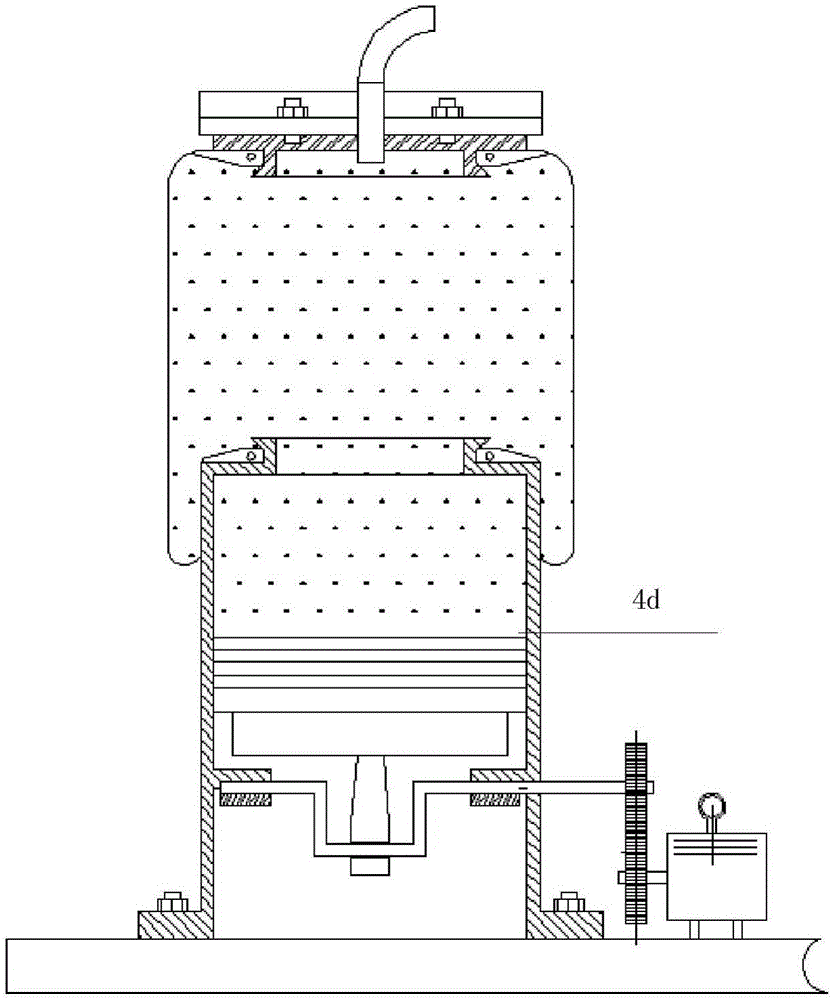

[0029] Embodiment: a kind of air spring whose volume is steplessly adjustable, such as figure 1 , 2 As shown, it includes a cover plate 1, a rubber air bag 2, a base 3, a piston 4, a connecting rod 5, a crankshaft 6, a driven gear 7, a driving gear 8 and a stepping motor 9. The top surface of cover plate 1 is fixedly connected on the vehicle frame 10 by bolt 1a, and the bottom surface of cover plate 1 is a connection cylinder 1c, and the outer surface of cylinder 1c is interference fit with the inner circle surface of seal 2a on rubber airbag 2. The base 3 is a cylindrical frame structure, the bottom is a hollow ring 3f penetrating along the axis, the outer circular surface of the ring 3f is in interference fit with the inner circular surface of the lower seal 2b of the rubber airbag 2, and the bottom end of the base 3 passes through the base bolts 3d is fixed on the spring seat 12 of the axle 11.

[0030] The piston 4 is composed of the piston body 4a, the piston pin 4b and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com