Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Reduce explosiveness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for reclaiming and reusing iron-making dust in blast furnace

InactiveCN1632136AFavorable nodulationHelps eliminate nodulesBlast furnace detailsIron powderBlast furnace smelting

A method for recycling blast furnace ironmaking dust. The bag dust, gravity ash and other iron-containing dust recovered in the blast furnace smelting process are evenly mixed with coal powder, and sprayed into the hearth from the tuyere of the blast furnace. It is required that there is no accumulation in the hearth before injection. , no nodules in the furnace throat, and its process parameters: spray bag dust, the injection amount is 6-10Kg / t iron, hot air temperature> 1000 ℃, blast furnace zinc load <0.15Kg / t iron; spray gravity ash, injection amount is 6Kg / t iron ~ 15Kg / t iron, hot air temperature > 1050°C; spray other iron-containing dust, injection amount < 8Kg / t iron, dust particle size < 0.5mm, hot air temperature > 1050°C; the present invention has the functions of increasing iron, Saving coke, benefiting silicon reduction in molten iron, promoting smooth operation of blast furnace and strengthening smelting, benefiting safe coal injection, reducing nodulation in blast furnace, protecting the environment, and clean production, etc.

Owner:INST OF METALLURGICAL TECH DONGBEI UNIV SHENYANG

System adopting high concentration CO2 flue gas as coal dust drying medium in boiler

InactiveCN101893370AInitial temperature adjustmentIncrease working temperatureDrying gas arrangementsHigh concentrationCoal dust

The invention relates to a system adopting a high concentration CO2 flue gas as a coal dust drying medium in a boiler and belongs to the technical field of energy technology application and CO2 capture. The flue gas which is dehydrated and heated to a certain temperature and contains over 95 percent of CO2 is used as the drying medium for coal dust pulverizing. The drying medium is an inert gas with low oxygen content so as to solve the problem of easy explosion of a coal pulverizing system when hot air is used as the drying medium and improve the operational safety of the coal pulverizing system. Meanwhile, compared with the temperature of the hot air, the initial temperature of the drying medium can be greatly improved so as to reduce the power consumption of a coal mill, improve the fineness of coal dust, improve combustion efficiency, reduce the exhaust gas temperature and improve the heat efficiency of the boiler.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method for improving strength of pellets

ActiveCN103451416ARaise the firing temperatureImprove crystal bridge connectionSodium BentoniteReduction treatment

The invention provides a method for improving the strength of pellets. The method comprises the following steps: respectively and independently mixing magnetite concentrates and non-magnetite concentrates with externally matched bentonite uniformly; pelletizing, wherein pellets comprise not less than 20% of magnetite concentrates and not more than 80% of non-magnetite concentrates, and in the pelletizing process, the magnetite concentrates added for the first time account for 40-80% of total addition of the magnetite concentrates, the mixture of the non-magnetite concentrates and bentonite is added for the second time, the remaining magnetite concentrates are added for the third time, and 1.3-1.5wt% of bentonite is added in the pelletizing process to serve as a binder; carrying out pressure increase and reduction treatment on the pellets. The method has the beneficial effects that the calcination temperatures of ores at the middle layer and crystal bridge connection between the pellets can be improved, the content and existing state of water in the pellets can be changed, the preheating and drying time can be shortened, the preheating and drying temperatures can be reduced, the burst properties of the pellets can be reduced, the strength of the pellets can be improved, the use proportions of hematite, limonite and siderite in the pellets can be increased, and the production cost of the pellets can be lowered.

Owner:ANGANG STEEL CO LTD

Mixed fuel for blast furnace injection

A mixed fuel for blast furnace injection belongs to the technical field of metallurgy. The average particle size of mixed coal is not more than 30 microns, and the mixed coal comprises low-temperature semi coke, and anthracite; the weight of the low-temperature semi coke accounts for 60-85% of the weight of the mixed coal, and the weight of the anthracite accounts for 15-40% of the weight of the mixed coal. The low-temperature semi coke is mixed with the anthracite, which neutralizes the low-temperature semi coke with a medium volatile content. The mixed coal has low explosibility, meets the requirements for coal injection safety, increases the ratio of medium volatile bituminite to a level of 85%, greatly decreases the ratio of expensive anthracite, and thus significantly reduces the cost. The mixed coal can be used as a fuel for blast furnace injection, and has a significantly increased combustion rate level.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Flame-retardant electrolyte of lithium ion battery and preparation method of electrolyte

The invention belongs to the technical field of battery material preparation, and specifically relates to a flame-retardant electrolyte of a lithium ion battery and a preparation method of the electrolyte. The flame-retardant electrolyte consists of a solvent, an accessory solvent, a film forming agent, a cosolvent, flame retardant and lithium salt; the preparation method comprises the steps of performing mixing on ethylene carbonate, diethyl carbonate and methyl ethyl carbonate in a glove box filled with argon to prepare a mixed solvent; next, adding the accessory solvent, the film forming agent, the cosolvent and the flame retardant into the mixed solvent to be mixed uniformly to obtain a mixed liquid; and finally, dissolving the lithium salt into the mixed liquid to obtain the flame-retardant electrolyte of the lithium ion battery. The obtained flame-retardant electrolyte has relatively high flame-retardant effect, so that the safety and reliability of the lithium ion battery can be effectively improved; meanwhile, the flame-retardant electrolyte has relatively high compatibility with a graphite carbon negative electrode; and furthermore, the lithium ion battery assembled by the flame-retardant electrolyte has high electrochemical performance.

Owner:常州市万昌化工有限公司

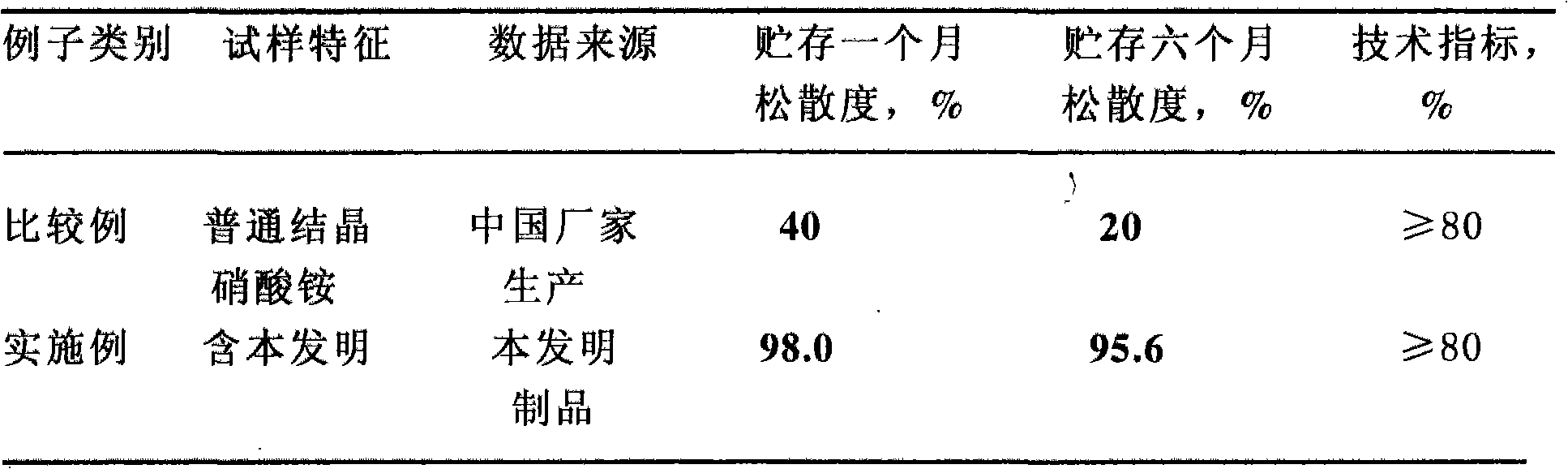

Detonation inhibitor for ammonium nitrate

ActiveCN101333120AReduce explosivenessReduce dosageOther chemical processesAmmonium nitrate fertilisersDetonationOxidation-Reduction Agent

The invention provides a modified explosion-proof agent which is used to prepare totally explosion-free crystal ammonium nitrate. The invention is characterized in that the explosion-proof agent is composed of anti-hardening agent, flame retardant, misfiring agent and flameproof agent. The invention aims to solve the problems that the existing explosion-proof agent for ammonium nitrate has large dosage and poor explosion-proof effect in the actual use, and the modification technology of the existing explosion-proof agent follows the mechanical mixing method and the products can easily get hardened in the storage period. As the invention adds long-chain fatty amine cationic surfactant as anti-hardening agent, the products can be stored for six months and the loose degree reaches more than 95%; the selection of high-heat-capacity flame retardant effectively prevents the generation of explosion hot points; the introduction of misfiring agent enables the explosion to be instantly extinguished; the flameproof agent which generates the protective film with the ammonium nitrate radically prevents the source of explosion caused by redox reaction and prevents producing weapons of terror with ammonium nitrate. The invention can also be used as the effective explosion-proof agent for preparing granular ammonium nitrate through tower granulation process. The adding concentration of the invention is 1% to 2%.

Owner:SHANXI TOND CHEMICAL CO LTD

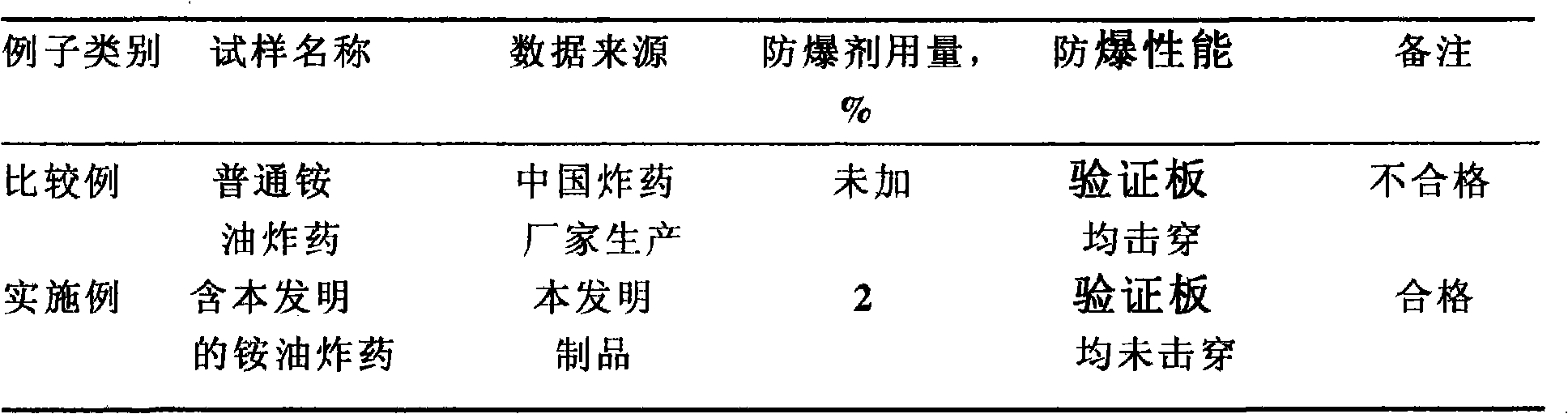

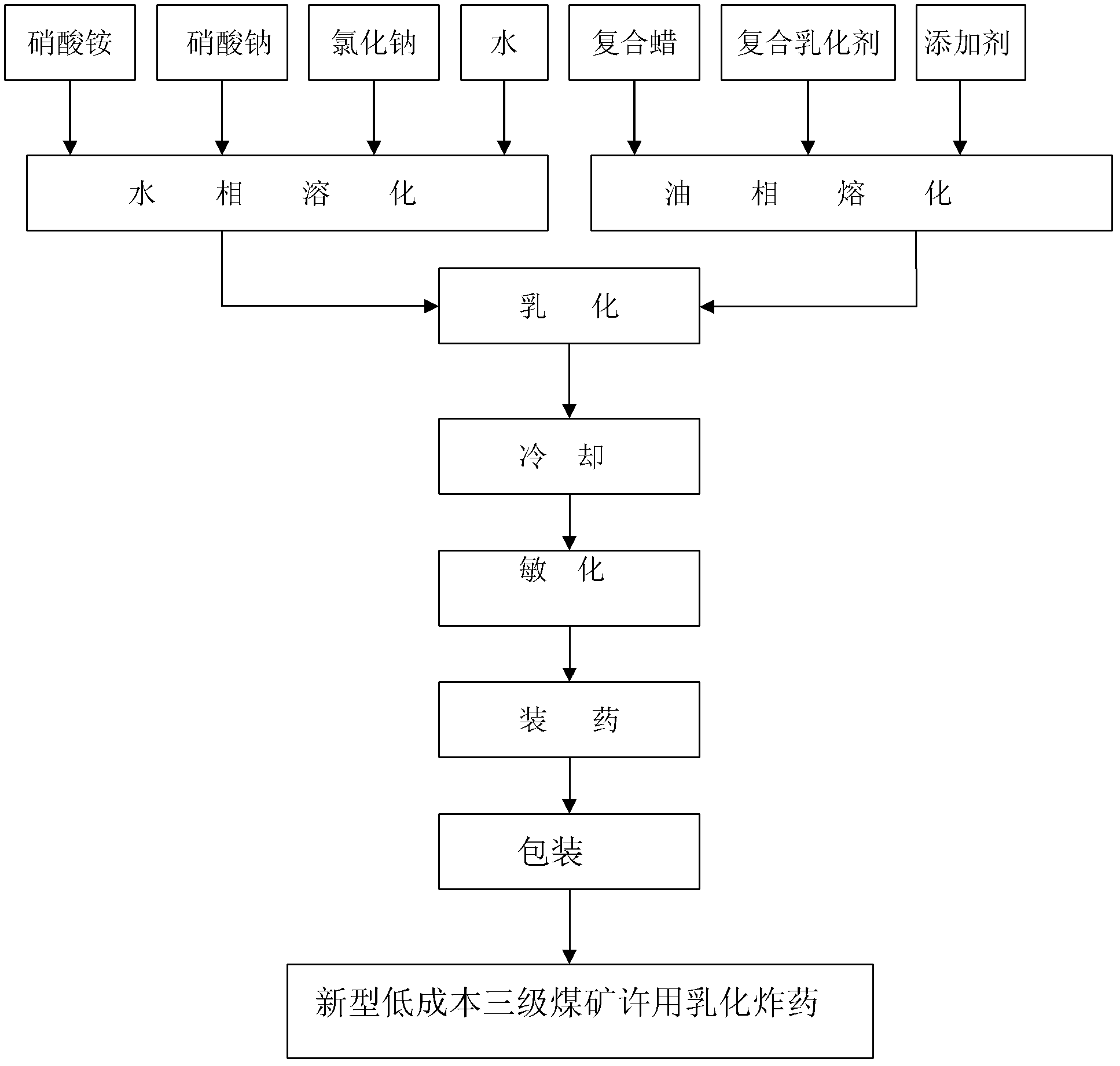

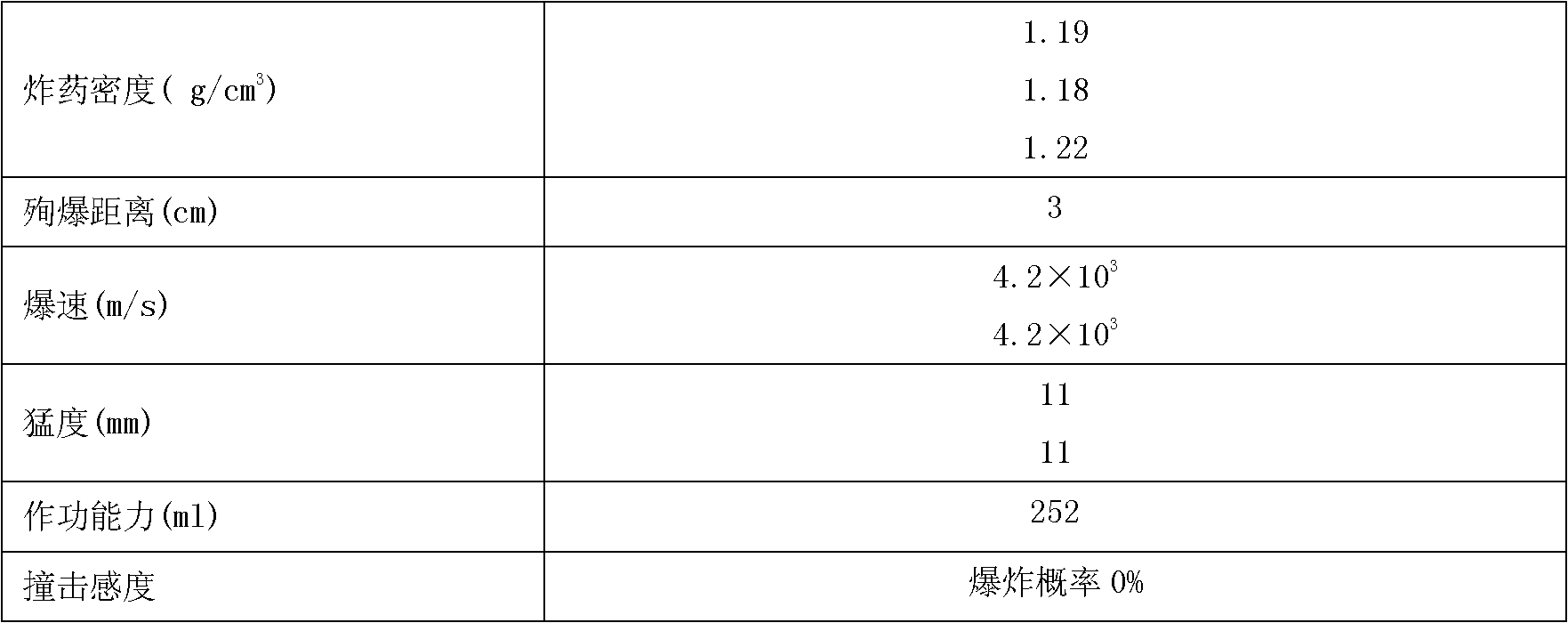

Three-grade coal mine allowable emulsified explosive and preparation method thereof

The invention discloses a three-grade coal mine allowable emulsified explosive and a preparation method thereof. The explosive comprises the following materials, by mass, 66.5-75% of ammonium nitrate, 5-12% of sodium chloride, 3-7% of sodium nitrate, 9-11% of water, 2-2.5% of a composite emulsifier, 2.5-3.5% of composite wax, and 0.5-1% of an additive. The preparation method comprises the following steps: 1, respectively melting above water phase materials and oil phase materials through heating to form a water phase solution and an oil phase solution; 2, adding the water phase solution to the oil phase solution to form a water-in-oil mixture; 3, cooling the prepared mixture, and carrying out chemical sensitization foaming on the mixture to prepare the emulsified explosive; and 4, charging the emulsified explosive to obtain the finished emulsified explosive. The explosive of the invention, which can be applied to explosive engineering operations of excavating faces of high gas mines, excavating faces of high gas zones of low gas mines and excavating faces of outburst dangers of coal dust and the gas, has enough large explosive capacities on condition that the safety reaches indexes.

Owner:云南锐达民爆有限责任公司

Flame-retardant electrolyte for lithium ion battery and preparation method thereof

InactiveCN108183259AImprove securityImprove flame retardant performanceSecondary cellsOrganic electrolytesSulfite saltHeat stability

The invention provides a flame-retardant electrolyte for a lithium ion battery and a preparation method thereof, and relates to the technical field of an electrolyte for the lithium ion battery. The flame-retardant electrolyte for the lithium ion battery is prepared from the following raw materials of adiponitrile, dimethylacetamide, diacetic acid lithium borate, sodium sulfite, propylene carbonate, trimethyl phosphite, lithium salt, a filming agent, and a flame-retardant agent. The flame-retardant electrolyte for the lithium ion battery has the advantages that the burning and firing are avoided, and the safety of the lithium ion battery is effectively improved; the heat stability is obviously improved, and the discoloring and precipitate separation-out of the electrolyte are avoided whenthe electrolyte is stored for five months or more at the temperature of 50 DEG C. The lithium ion battery prepared by the electrolyte has the advantages that the flame-retardant property is good, thecyclic property is good, and the electric conductivity is good.

Owner:广州鸿森材料有限公司

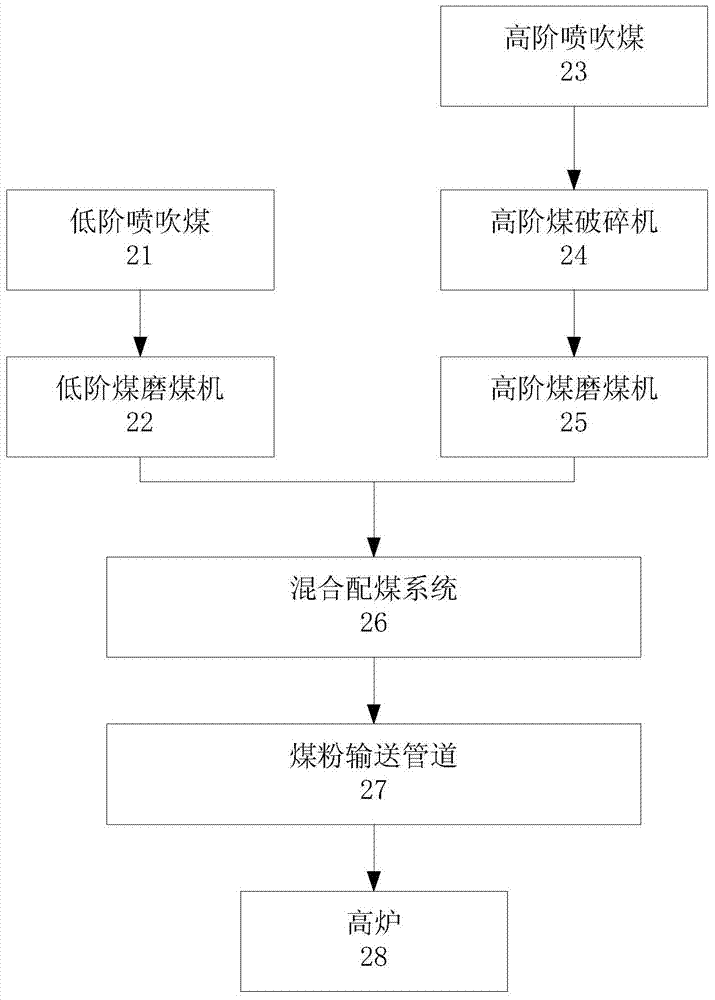

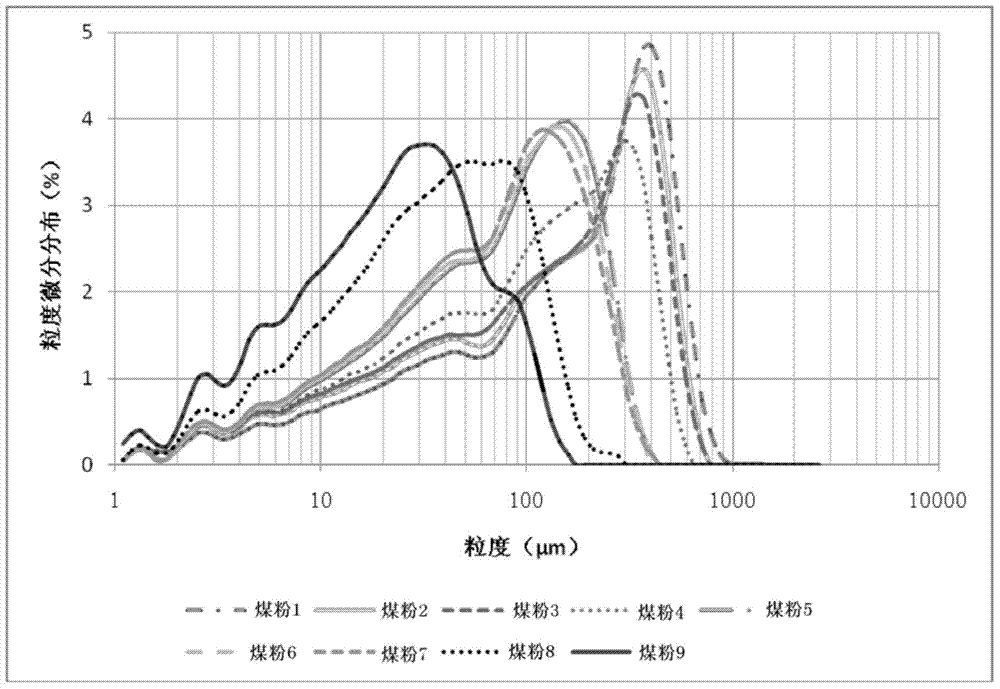

Additive amount method of low-rank coal in blast furnace injection coal

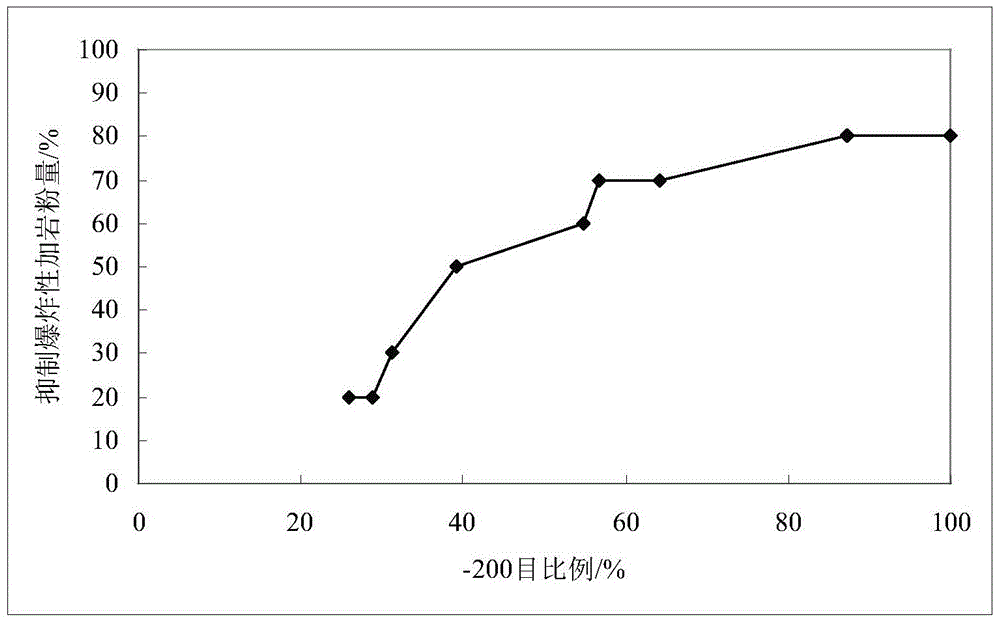

InactiveCN104762428ARelax granularityIncrease the proportion of coal blendingBlast furnace detailsGranularityEconomic benefits

The invention discloses an additive amount method of low-rank coal in blast furnace injection coal. The method is characterized by comprising the steps of grinding the low-rank coal by a coal mill to obtain the pulverized coal of the low-rank coal, wherein the weight of the pulverized coal with the particle size of less than or equal to 100 meshes in the low-rank coal accounts for 38.05-93.74% of the total weight of the pulverized coal of the low-rank coal; grinding high-rank coal by the coal mill to obtain the pulverized coal of the high-rank coal; and mixing the pulverized coal of the low-rank coal and the pulverized coal of the high-rank coal to obtain the blast furnace injection coal. According to the method, the limitation for the particle size of the low-rank coal is broadened in the pulverizing process, and the content of the pulverized coal with the particle size of less than or equal to 100-meshe aperture in the low-rank coal is increased, so that the explosiveness of the pulverized coal is reduced, the safety requirement for the blast furnace injection coal is reached, and the coal blending ratio of the high-rank coal and the low-rank coal is increased. Therefore, the consumption of the low-rank coal which is taken as the blast furnace injection coal can be increased, the production cost of iron and steel enterprises is greatly lowered, and the economic benefit of the enterprises can be improved.

Owner:CHINA SHENHUA ENERGY CO LTD +2

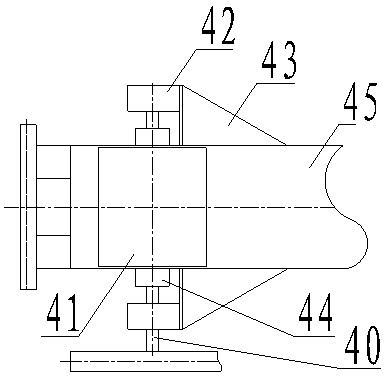

Muzzle break with supersonic nozzle

ActiveUS9163892B1Reduce recoilImproved muzzle brakeMuzzle attachmentExpansion chamberSupersonic nozzle

A muzzle brake mounts to the barrel of a gun and reduces the recoil when the gun is fired. The muzzle brake comprises a supersonic nozzle including an expansion chamber configured to accelerate the propellant gases exiting the barrel of the gun and a reverser plate to at least partially reverse the flow of the propellant gases to reduce or mitigate recoil.

Owner:BUBOLTZ DAVID C

Method for reclaiming and reusing iron-making dust in blast furnace

InactiveCN1261598CReduce caloric expenditureReduce focal ratioBlast furnace detailsIron powderBlast furnace smelting

Owner:INST OF METALLURGICAL TECH DONGBEI UNIV SHENYANG

Rotary engine

InactiveUS20100263622A1Reduce explosion capacityImprove acceleration performanceInternal combustion piston enginesEfficient propulsion technologiesCombustion chamberAirflow

A rotary engine includes one or more combustion chambers around a turbine, and a movable plate at an opening of the combustion chamber and rotated 90 degrees and protruded from the turbine. Both sides of the movable plate and the diameter of the turbine form an align straight line. The turbine comprises a slide member, a U-shape groove, a ditch with an open end coupled to the movable plate to form the explosion chamber. During explosion, the movable plate drives the turbine to rotate while eliminating the waste gases. The air current and pressure of the explosion apply forces to rotate the bottom of the combustion chamber. The volume of the explosion chamber can be extended to provide a relatively large open space since the movable plate can be moved and a higher pressure gases will be reduced rapidly so that the high-pressure gases can produce a greater force.

Owner:CHOU JUNG KUANG

Sintering method for reducing solid fuel consumption ratio

InactiveCN112094969AImprove utilization factorReduce solid fuel consumptionBlast furnace detailsCoalSupply energy

The invention discloses a sintering method for reducing a solid fuel consumption ratio. Heavy magnesium oxide is added to raw coal to prepare pulverized coal, and the pulverized coal is sprayed into afurnace from a blast furnace tuyere; the content of MgO in sintering is reduced, and the utilization coefficient of a sintering machine is increased; the solid fuel consumption of sintered ore is reduced, and the cost of the sintered ore and blast furnace molten iron is reduced; the heavy magnesium oxide is added to the raw coal according to 1.0%-10.0% of the raw coal amount, and then injected into the blast furnace; the problems that an injected carbonate alkaline flux is high in hardness and poor in grindability, and a coal injection gun is abraded; the tuyere combustion temperature is reduced due to decomposition and heat absorption in the furnace are solved; and MgO in the sintered ore can be controlled in the optimal state of 1.2%-1.6%. Through control over the granularity and the heat value of the mixed pulverized coal, stable combustion and energy supply of the pulverized coal for the blast furnace are guaranteed.

Owner:美匡冶金技术研究院(苏州)有限公司

Drip-feed type gas boriding process

InactiveCN1952216AUniform penetrationGood surface qualitySolid state diffusion coatingHeat treatment process controlAutomatic controlBoron atom

This invention involves a drip gas boronizing approach. The method contains the steps of: adopting ordinary drip gas carburizing furnace, heating the furnace to the temperature for boronizing, and dropping boriding agent containing trimethyl borate, methanol and chloridated rare earth and methanol to the furnace, decomposing and to form boride on the steel surface through adsorption and diffusion of boron atom decomposed by trimethyl borate. The invention has the advantage of uniform and compact leaking layer, good surface quality, Layer depth and surface boron content can be controlled; no need of cleaning workpiece after infiltration, with directly quenching after infiltration and low labor intensity; penetration enhancers without rank poison, non-explosive, with relatively good and safe, reliable working environment, without specialized equipments, commonly used carburizing furnace can meet the requirements, can handle all sorts of shapes and sizes workpiece, can be easy to achieve automatic control, with high efficiency, easy operation and high applicability.

Owner:JIANGSU UNIV

Perfuming or flavouring microcapsules comprising an explosion suppressant

ActiveUS20110044922A1Reduce violenceLow hygroscopicityCosmetic preparationsBiocideFlavorCarboxylic acid

A method for preparing a powder that includes perfuming or flavoring microcapsules of a perfuming or flavoring ingredient, a carrier material, and an explosion suppressant. The powder, when suspended in hot air during its preparation, has a reduced tendency for explosion. The explosion suppressant is selected from C1 to C12 carboxylic acids, their salts and mixtures of these.

Owner:FIRMENICH SA

High-energy type coal mine emulsion explosive

ActiveCN103130591BReduced security requirementsReduce explosivenessExplosive working-up apparatusInorganic saltsExplosive Agents

The invention relates to a high-energy type coal mine emulsion explosive which comprises the following materials: ammonium nitrate, sodium nitrate, flame inhibitor, water, oil phase material, organic active material and water-in-oil type emulsifying agent, wherein the ammonium nitrate, the sodium nitrate, the flame inhibitor and the water form aqueous phase; and the oil phase material, the organic active material and the water-in-oil type emulsifying agent form oil phase. The high-energy type coal mine emulsion explosive solves the problem that in order to meet the safety requirement of the existing allowable emulsion explosive technology of coal mines at home and abroad, a great deal of inert inorganic flame inhibitors such as sodium chloride, potassium chloride, ammonium chloride and the like are needed to be added into the aqueous phase, so that the explosion performance of the explosive is greatly reduced. The high-energy type coal mine emulsion explosive realizes the consistency of explosion performance, storage performance and preparation technology between the coal mine type emulsion explosive product and the rock-type emulsion explosive product.

Owner:CHINA COAL TECH & ENG GRP HUAIBEIBLASTING TECHN RES INST

Li-containing silicon oxide powder

ActiveCN108701826AReduce explosivenessSuppress battery performance degradationCell electrodesLi-accumulatorsImage resolutionSilicon oxide

The present invention relates to a Li-containing SiOx powder (0.5 < x < 1.5) used in a negative electrode of a lithium secondary battery. On a powder particle cross section in a visual field of 1 [mu]m in four directions containing a particle surface and having a definition of 50 pixels * 50 pixels or greater, EELS measurements are performed, and in so doing, the spectral intensities in the Li-K edge domain and the Si-L edge domain are determined. Among the integrated intensities over one row of a particle outermost surface in the visual field, the integrated intensity for the Li-K edge domainis ILi(s), the integrated intensity for the Si-L edge domain is ISi(s), and ILi(s) / (ILi(s) + ISi(s)) is the outermost surface Li intensity ratio R(s). Among the integrated intensities over one row ofa near-surface 500 nm away inward from the particle outermost surface in the visual field, the integrated intensity for the Li-K edge domain is ILi(i), the integrated intensity for the Si-L edge domain is ISi(i), and ILi(i) / (ILi(i) + ISi(i)) is the near-surface Li intensity ratio R(i). Then, the Li-containing silicon oxide powder satisfies R(s) / R(i) < 1.

Owner:OSAKA TITANIUM TECHNOLOGIES

Method for matching mixed coal with relatively high heating value

PendingCN114214473AIncrease the actual coal char replacement ratioGood for furnace conditionBlast furnace detailsProcess engineeringAnthracite

The invention discloses a matching method of mixed coal with a relatively high heating value. The method comprises the following steps: 1) selecting bituminous coal and anthracite as components of the mixed coal; 2) designing a 6-17 coal blending scheme according to all-anthracite injection and all-series coal blending thoughts of all-anthracite injection, designing a coal injection framework according to anthracite proportion decreasing by m% and bituminous coal increasing by m%, and determining the matching ratio of mixed coal, m being 6.25-20; and 3) selecting the scheme with the highest intersection degree of the combustion rate and the exothermic value index as the scheme of the invention. The anthracite and the bituminous coal are mixed and injected according to a certain proportion, and meanwhile, the dry basis volatile component and the ash content of the mixed coal are well controlled, so that combustion can be mutually promoted, the actual coke replacement ratio of a blast furnace is increased, the explosiveness of the mixed coal powder is greatly reduced, the combustion performance is relatively improved, the generation amount of unburned coal powder is reduced, and the production cost is reduced. And smooth operation of the blast furnace is facilitated.

Owner:武汉钢铁有限公司

Perfuming or flavouring microcapsules comprising an explosion suppressant

ActiveUS7846481B2Reduce violenceLow hygroscopicityPowder deliveryCosmetic preparationsFlavorAdditive ingredient

Perfuming or flavoring microcapsules that include, further to a perfuming or flavoring ingredient and a carrier material, an explosion suppressant, proved to undergo, when suspended in hot air during their preparation, an explosion of a reduced violence. The explosion suppressant is selected from C1 to C12 carboxylic acids, their salts and mixtures of these.

Owner:FIRMENICH SA

Gasoline blending agent

InactiveCN109022065APromotion labelLabel increaseLiquid carbonaceous fuelsFuel additivesDimethylcarbinolN-Butanol

The invention relates to a gasoline blending agent. The gasoline blending agent comprises 5-10 g of barium petroleum sulfonate, 10-15 g of n-butanol, 10-15 g of methyl tert-butyl ether, 10-20 g of dimethylcarbinol, 0.1-0.2 g of ferrocene, 10-15 g of t-butyl acetate, 15-20 g of fatty alcohol and 24-28 g of anhydrous alcohol. The gasoline blending agent can reduce sediments, increase the combustionpower of gasoline, increase the label number of the gasoline, reduce the pollution of combustion of the gasoline to air and reduce the explosiveness of the gasoline, and also has the advantages of lowprice, simplicity, and easiness in operation.

Owner:齐广浩

Formula of luminous polyvinylidene fluoride

InactiveCN102634149AImprove toughnessPlay a bright rolePhosphoric Acid EstersPolyvinylidene difluoride

The invention discloses a formula of luminous polyvinylidene fluoride. The formula comprises modified polyvinylidene fluoride, a tough material, an auxiliary and a special material, wherein the tough material is SBS, the auxiliary is silicon oil, and the special material is phosphite ester; and the modified polyvinylidene fluoride accounts for 10-60% by weight, the SBS accounts for 10-40% by weight, the silicon oil accounts for 15-25% by weight, and the phosphite ester accounts for 15-25% by weight. Through the invention, the luminous polyvinylidene fluoride has high toughness, realizes a lighting effect and reduces the explosion occurrence.

Owner:SUZHOU NEW DISTRICT TEFLON PLASTIC PRODS FACTORY

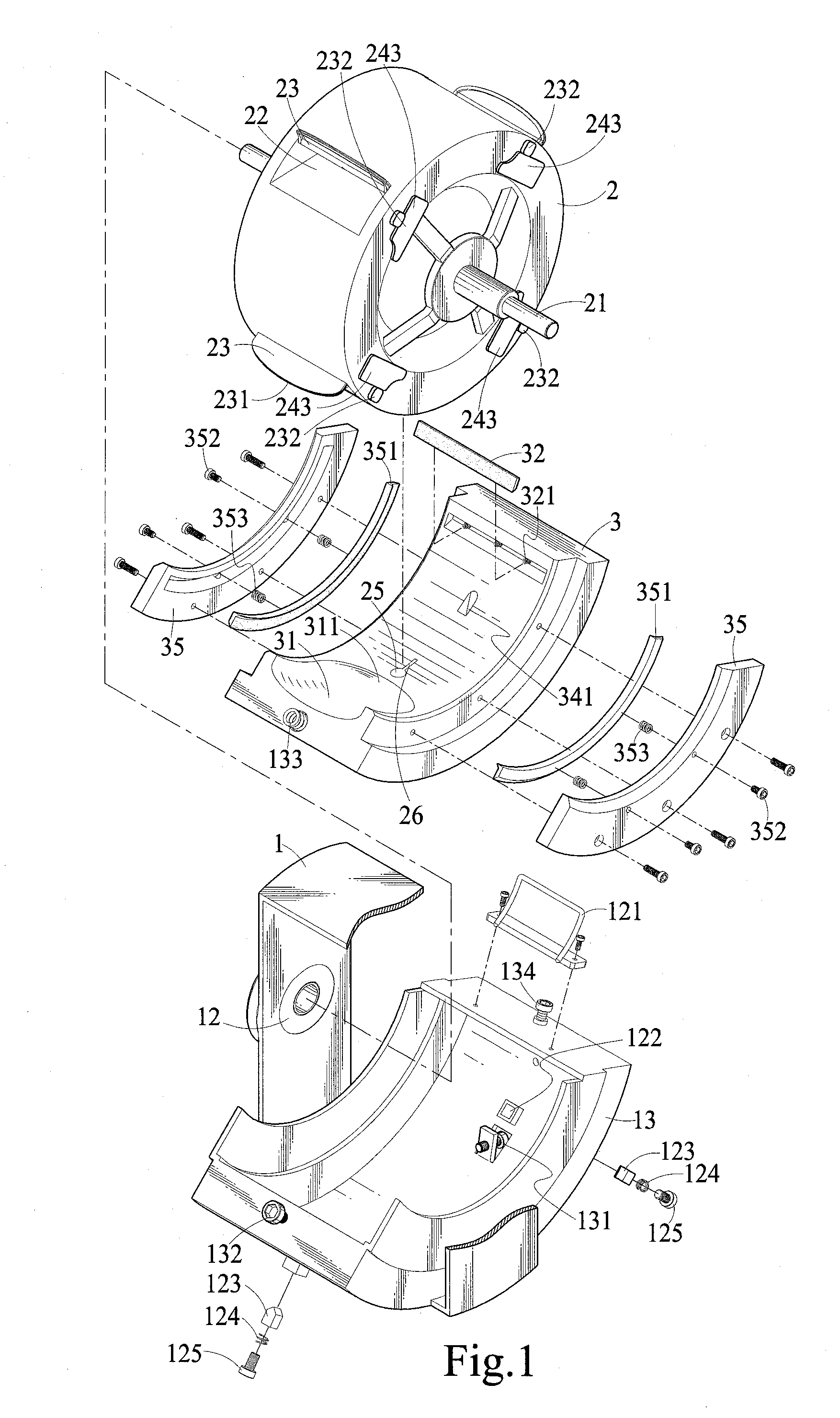

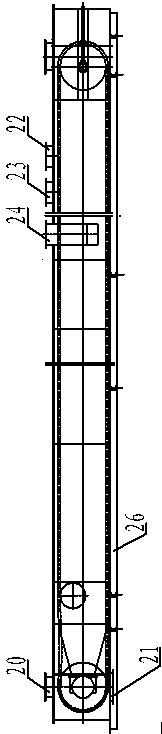

Main driving gear shaft of underground ten-meter anti-explosion conveying box

The invention discloses a main driving gear shaft of an underground ten-meter anti-explosion conveying box. The main driving gear shaft of the underground ten-meter anti-explosion conveying box comprises a driving shaft, a driving gear, shaft bases, a shaft base connecting rack and a shaft end sealing piece, wherein the driving gear located in a long strip-shaped airtight box is installed on the driving shaft, the two ends of the driving shaft penetrate out of the long strip-shaped airtight box, the shaft end sealing piece is arranged at the position where the driving shaft is combined with the long strip-shaped airtight box, the shaft bases are arranged at the two ends of the driving shaft and are located on the two sides of the long strip-shaped airtight box, and the shaft bases are fixed to the long strip-shaped airtight box through the shaft base connecting rack. In this way, the main driving gear shaft of the underground ten-meter anti-explosion conveying box has the advantages that dust pollution can be effectively prevented during material conveyance, and thus the explosibility of materials is effectively reduced; in addition, due to the fact that multiple feeding ports and multiple viewing ports are arranged, feeding of materials and checking of residual materials can be achieved conveniently.

Owner:吴中区横泾博尔机械厂

Long-strip-shaped sealed box of buried ten-meter anti-explosion conveying box

The invention discloses a long-strip-shaped sealed box of a buried ten-meter anti-explosion conveying box. The long-strip-shaped sealed box of the buried ten-meter anti-explosion conveying box is a rectangular long-strip-shaped hollow box body. The left end and the right end of the rectangular long-strip-shaped hollow box body are respectively provided with a detachable end plate. Detection windows are formed in the top face of the left end and the top face of the right end of the rectangular long-strip-shaped hollow box body. A discharging port is formed in the bottom of the left end of the long-strip-shaped sealed box. A top feeding port, a unilateral feeding port and a bilateral feeding port are formed in the right end of the long-strip-shaped sealed box in sequence from right to left. In this way, flowing dust pollution caused during material conveyance can be effectively avoided, and therefore the explosibility of materials can be lowered. Due to the fact that the long-strip-shaped sealed box of the buried ten-meter anti-explosion conveying box is provided with the multiple feeding ports and observation openings, feeding is convenient, and detection of material residuals is convenient.

Owner:吴中区横泾博尔机械厂

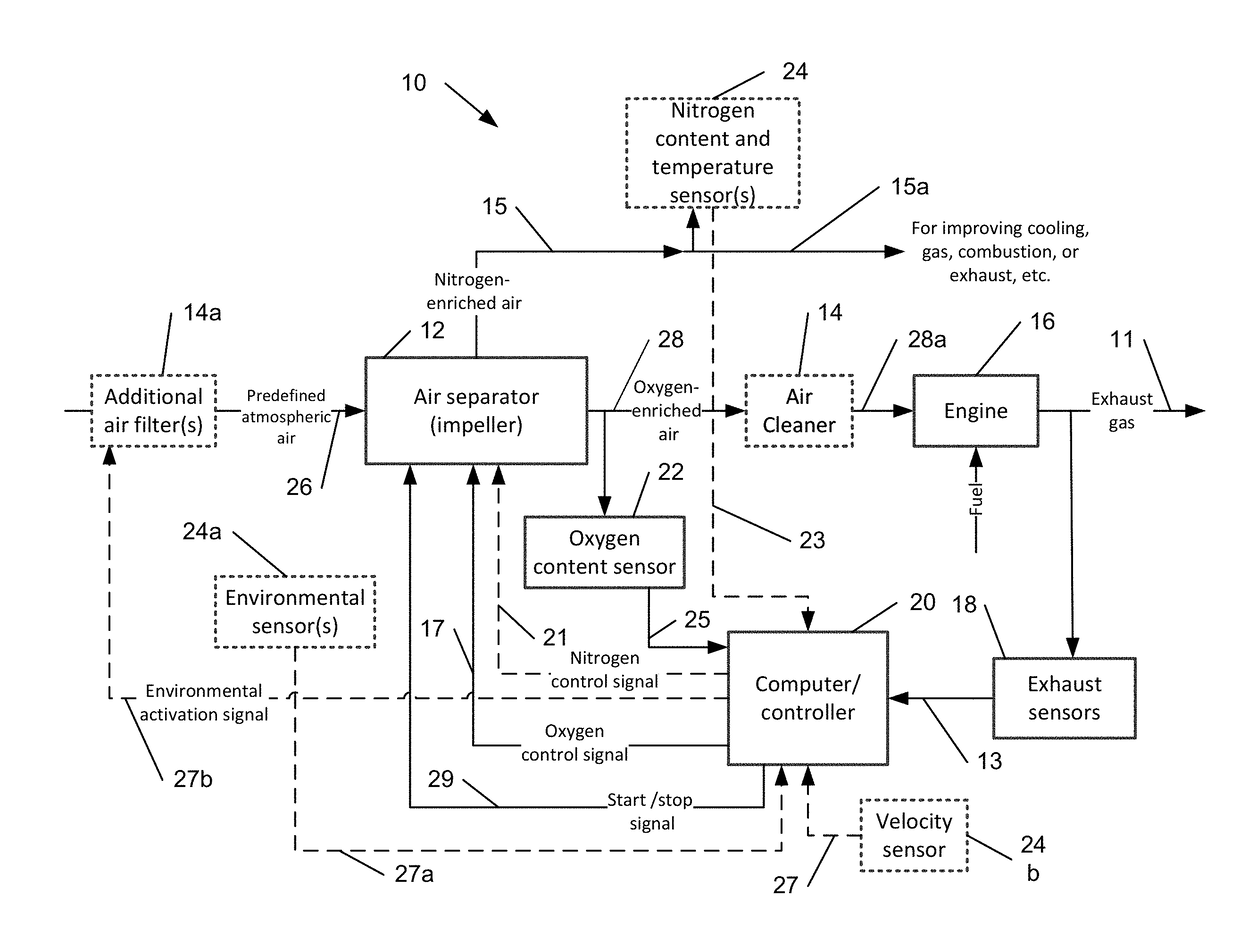

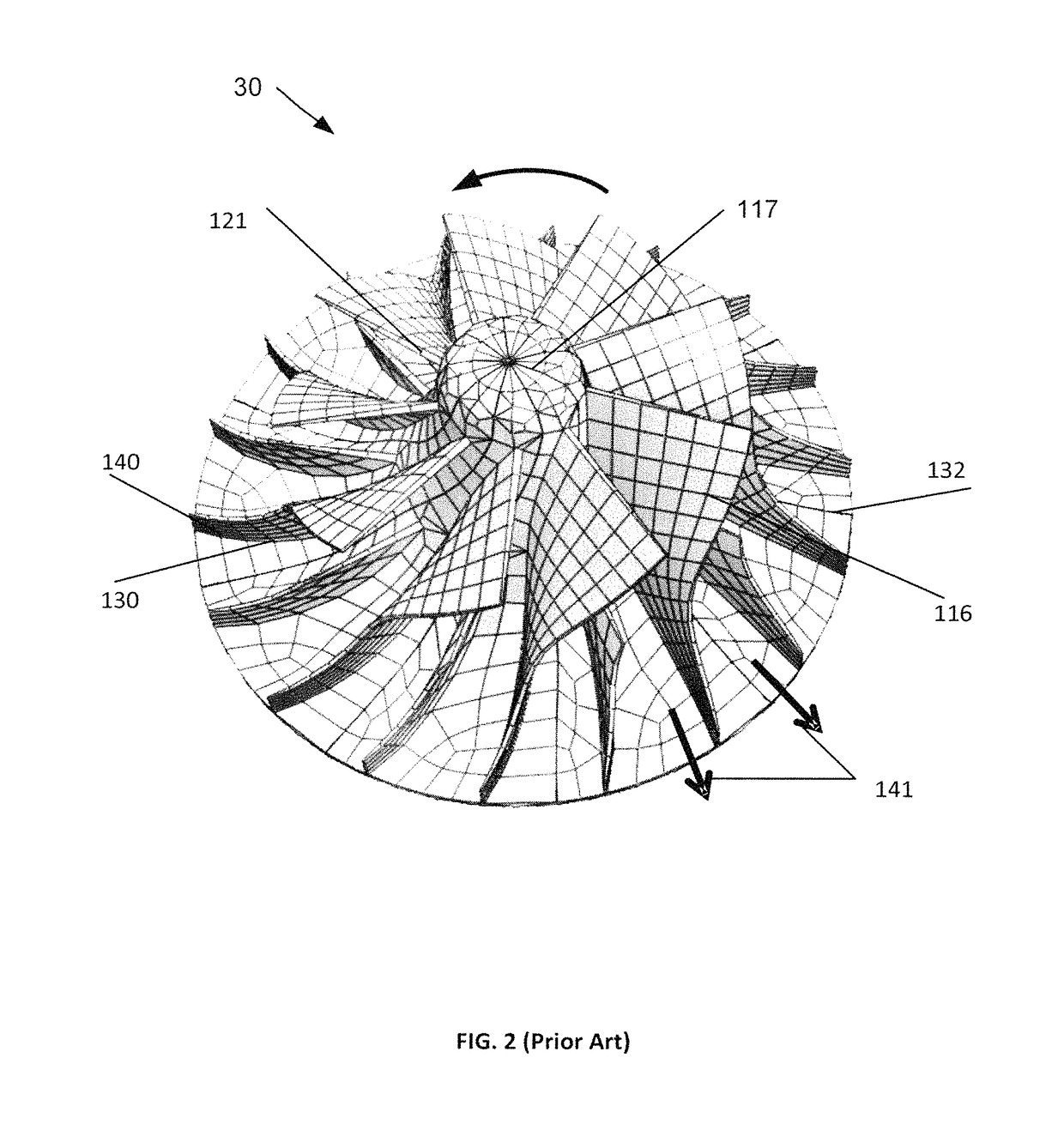

Oxygen and nitrogen enrichment of atmospheric air using an impeller-based apparatus

ActiveUS9863633B2Improve collection efficiencyPortion is increasedCombination devicesElectrical controlImpellerCombustion

The specification and drawings present a new apparatus and method for continuously providing oxygen-enriched gas / air produced from a predefined atmospheric air (normally comprising 78% of nitrogen N2 and 21% of oxygen O2) to a combustion area / chamber, using an impeller-based apparatus having a duct system. The impeller system can comprise at least one plurality of gates for capturing the oxygen-enriched gas / air to automatically improve processes of combustion, exhaust and / or related properties of the apparatus. The impeller can comprise a plurality of blades which, when rotating / spinning, may create the desired gas density / mass separation of oxygen and nitrogen. Furthermore, a nitrogen-enriched gas / air can be further provided from a predefined atmospheric air using the impeller-based apparatus with at least one plurality of further gates system / duct, gates rotating in sync with impeller blades, for collecting the nitrogen-enriched gas / air to further improve one or more apparatus parameters.

Owner:DONAHUE LEONARD LAWRENCE

Method and installation for destroying waste detonator

InactiveCN100485259CNo distractionReduce explosivenessIncinerator apparatusDetonatorExplosive Agents

Owner:SICHUAN YIBIN WEILI CHEM CO LED

Detonation inhibitor for ammonium nitrate

ActiveCN101333120BReduce explosivenessReduce dosageOther chemical processesAmmonium nitrate fertilisersDetonationOxidation-Reduction Agent

The invention provides a modified explosion-proof agent which is used to prepare totally explosion-free crystal ammonium nitrate. The invention is characterized in that the explosion-proof agent is composed of anti-hardening agent, flame retardant, misfiring agent and flameproof agent. The invention aims to solve the problems that the existing explosion-proof agent for ammonium nitrate has large dosage and poor explosion-proof effect in the actual use, and the modification technology of the existing explosion-proof agent follows the mechanical mixing method and the products can easily get hardened in the storage period. As the invention adds long-chain fatty amine cationic surfactant as anti-hardening agent, the products can be stored for six months and the loose degree reaches more than 95%; the selection of high-heat-capacity flame retardant effectively prevents the generation of explosion hot points; the introduction of misfiring agent enables the explosion to be instantly extinguished; the flameproof agent which generates the protective film with the ammonium nitrate radically prevents the source of explosion caused by redox reaction and prevents producing weapons of terror with ammonium nitrate. The invention can also be used as the effective explosion-proof agent for preparing granular ammonium nitrate through tower granulation process. The adding concentration of the invention is 1% to 2%.

Owner:SHANXI TOND CHEMICAL CO LTD

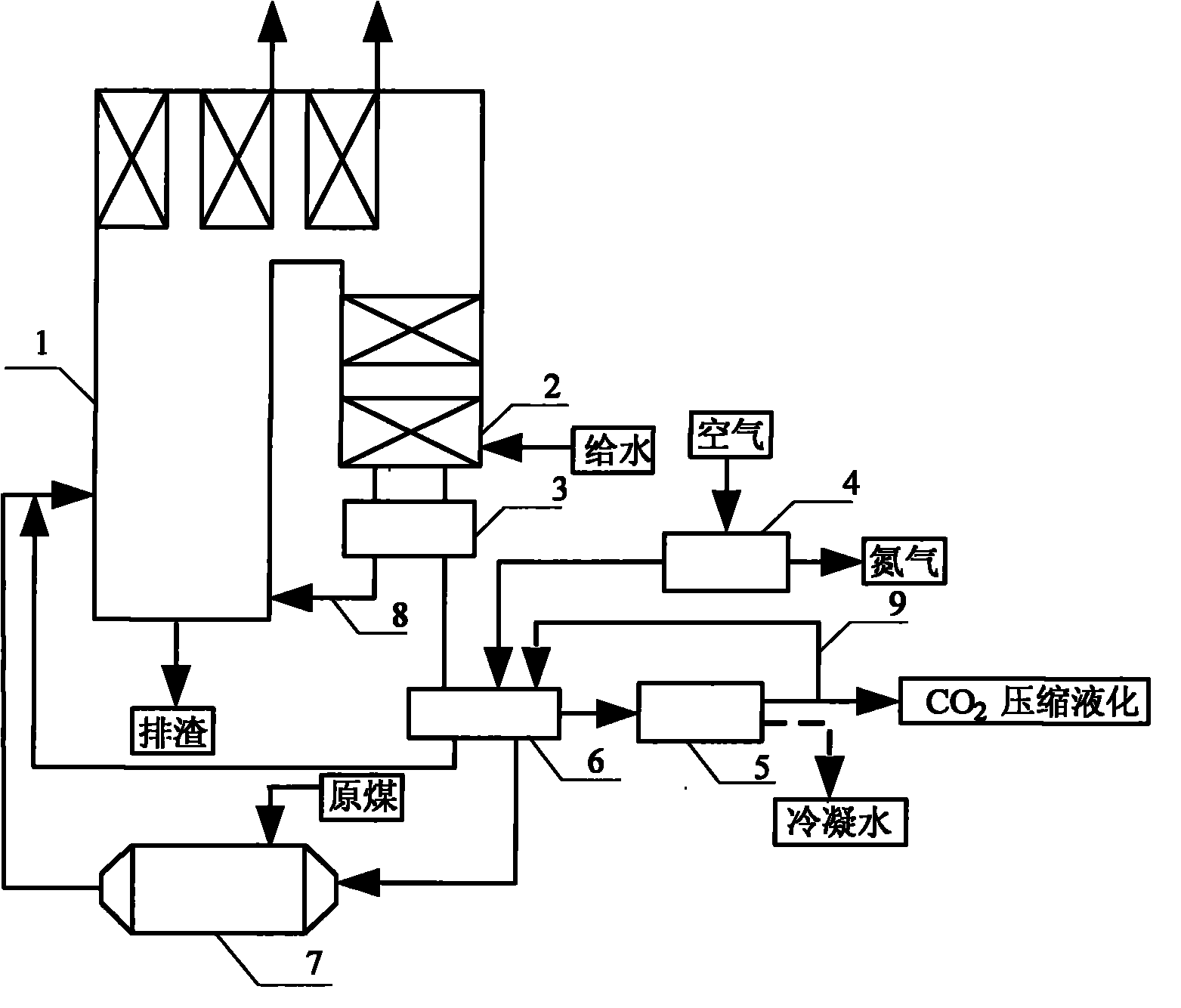

System adopting high concentration CO2 flue gas as coal dust drying medium in boiler

InactiveCN101893370BImprove securityOvercoming Explosive ProblemsDrying gas arrangementsHigh concentrationCoal dust

The invention relates to a system adopting a high concentration CO2 flue gas as a coal dust drying medium in a boiler and belongs to the technical field of energy technology application and CO2 capture. The flue gas which is dehydrated and heated to a certain temperature and contains over 95 percent of CO2 is used as the drying medium for coal dust pulverizing. The drying medium is an inert gas with low oxygen content so as to solve the problem of easy explosion of a coal pulverizing system when hot air is used as the drying medium and improve the operational safety of the coal pulverizing system. Meanwhile, compared with the temperature of the hot air, the initial temperature of the drying medium can be greatly improved so as to reduce the power consumption of a coal mill, improve the fineness of coal dust, improve combustion efficiency, reduce the exhaust gas temperature and improve the heat efficiency of the boiler.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Coal blending method for blast furnace injection coal and blast furnace injection coal

ActiveCN104745753BRelax granularityIncrease the proportion of coal blendingBlast furnace detailsGranularityEconomic benefits

The invention discloses a coal blending method of blast-furnace-injected pulverized coal and the blast-furnace-injected pulverized coal. The coal blending method comprises the following steps: grinding low-rank coal into the coal powder of the low-rank coal, wherein the coal powder of which the particle size is smaller or equal to 100-mesh bore diameter accounts for 38.05-93.74% of the total weight of the coal powder of the low-rank coal; then mixing the coal powder of the low-rank coal with coal powder of the other coals to obtain the blast-furnace-injected pulverized coal. According to the coal blending method of the blast-furnace-injected pulverized coal, the particle size of the low-rank coal is broadened in the powdering process so as to increase the content of the coal powder whose particle size is smaller or equal to 100-mesh bore diameter in the low-rank coal, so that the explosiveness of the coal powder is reduced and the safety requirements of the blast furnace coal injection are met; thus, the ratio of the low-rank coal in coal blending is increased. Moreover, the dosage of the low-rank coal in the blast-furnace-injected pulverized coal is enlarged, so that the production costs of the iron and steel enterprises are greatly decreased and the economic benefits of the enterprises are increased.

Owner:CHINA SHENHUA ENERGY CO LTD +2

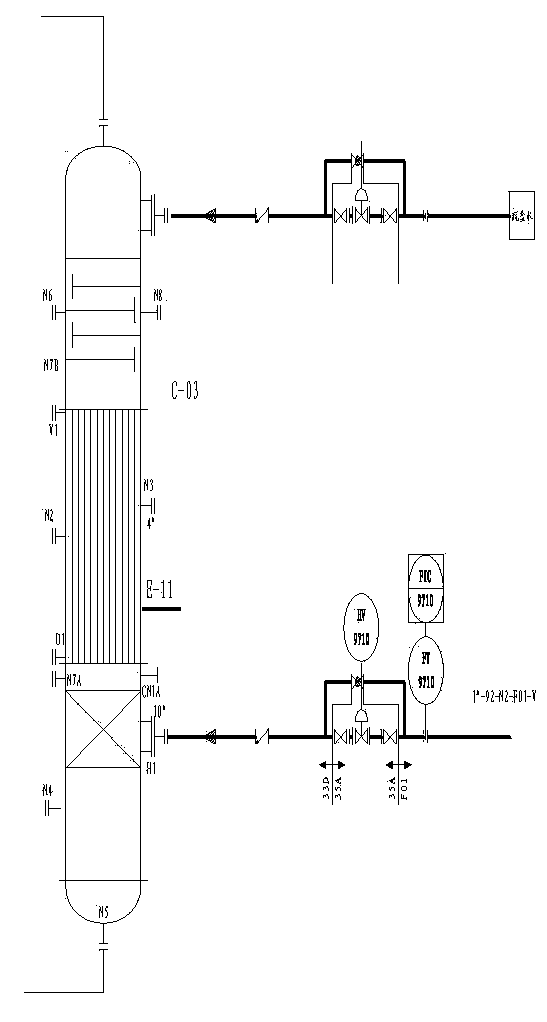

Method for reducing ammonia content and blasting property of medium-pressure emptying gas

ActiveCN103804237AReduce ammonia contentReduce partial pressureUrea derivatives preparationProductsNitrogen gasAbsorption layer

The invention discloses a method for reducing ammonia content and blasting property of a medium-pressure emptying gas in urea production. The method comprises the following steps: increasing a packing absorption layer on the lower part of a medium-pressure ammonia absorber, reducing the ammonia content of the medium-pressure emptying gas, and continuously adding 2.2MPa nitrogen into the medium-pressure ammonia absorber equipment for preventing the medium-pressure emptying gas from entering an explosion limit. According to the process method, the ammonia content in the medium-pressure emptying gas is greatly reduced, the ammonia recovery efficiency is high, the operation is simple and reliable, and a liquid level in a medium-pressure inert gas scrubbing tower is easily stabilized. According to the introduced nitrogen, partial pressure of combustible gases such as hydrogen and methane in the emptying gas can be greatly reduced, so that the blasting property of the emptying gas is reduced, and the safety performance of the device is improved.

Owner:GNSG ANHUI HONG SIFANG

Ethanol gasoline for motor vehicle and preparation method thereof

InactiveCN101358151BAchieve the effect of processingOctane reductionLiquid carbonaceous fuelsAutomotive engineIndustrial alcohol

The invention relates to clean fuel, in particular to ethanol gasoline for motor vehicles and a preparation method thereof. Ethanol gasoline for motor vehicles is composed of the following raw materials by weight percentage: industrial alcohol 15.0-25.0%, isopropanol 0.60-5.0%, gasoline 30.0-50.0%, methylal 29.0-45.0%, tert-butanol 4.0-15.0%, diisopropyl ether, 2.0-10.0%, naphtha 1-5%; after mixing the above raw materials, add 1-6% activated clay by weight, stir the physical and chemical reaction and filter to obtain the The above-mentioned ethanol gasoline for motor vehicles. The invention has the characteristics of high octane number and strong explosive power, reduces production cost, has no smoke and odor in tail gas emission, reduces automobile tail gas pollution, has no adverse effect on automobile engines, and can partially replace existing gasoline.

Owner:郭国星

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com