Detonation inhibitor for ammonium nitrate

An explosion-proof agent, ammonium nitrate technology, applied in ammonium nitrate fertilizer, application, nitrogen fertilizer and other directions, can solve the problems of large amount of explosion-proof agent added, products are easy to agglomerate, and the scope of application is narrow, achieving low labor intensity for workers and low production costs. , the effect of easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] 1 implement according to the best formula (mass %) as follows:

[0024] 25 anti-hardening agent: octadecylamine formate;

[0025] 15 flame retardant: melamine;

[0026] 3 extinguishing agent: paraffin oil;

[0027] 57 explosion-proof agent: polyvinyl formal.

[0028] Manufacture of the present invention: Add four kinds of raw materials such as octadecylamine formate in proportion to a jacketed stainless steel or enamel reaction kettle with a stirring device and a temperature measuring system at the same time, and heat it to 90-90°C with steam. 100°C, melt the material into a uniform and transparent state under stirring, stir and keep warm at 90-100°C for 10-15 minutes, discharge, cool and solidify into a solid block; then use a drum tablet machine or a small BF-100 type The slicer is processed into slices to make a flake-like anti-explosive agent with a thickness of about 0.5-1.0mm.

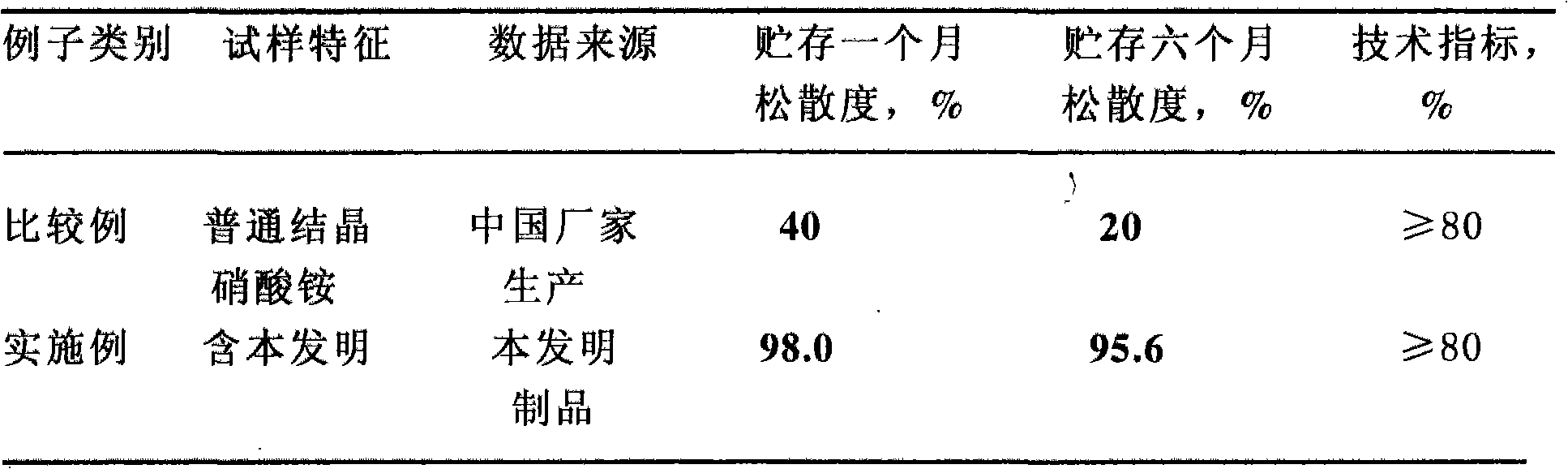

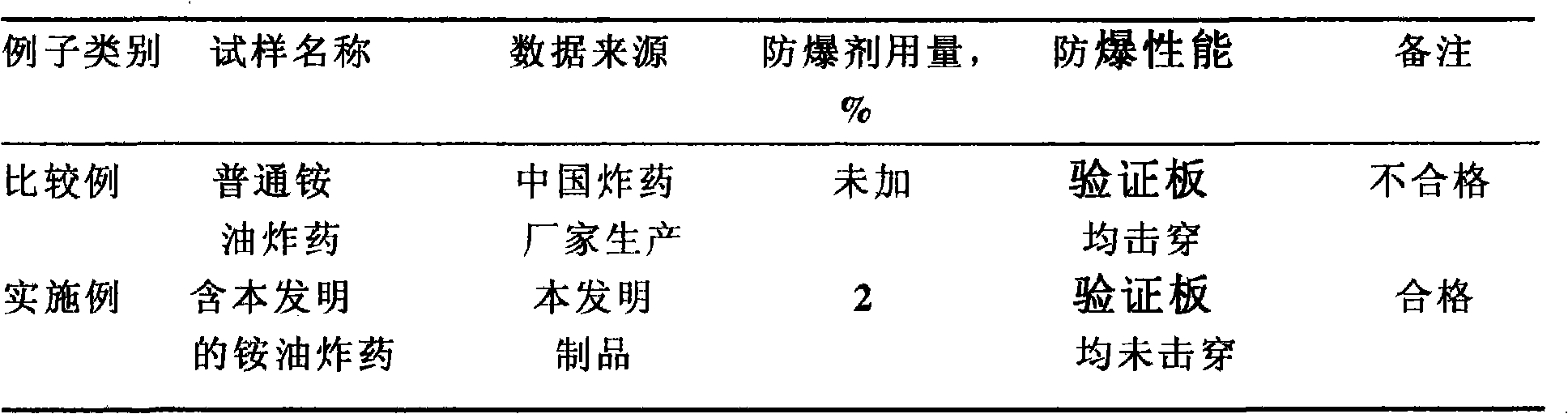

[0029] Utilize the present invention, apply to the manufacture of explosion-proof ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com