Coal blending method for blast furnace injection coal and blast furnace injection coal

A blast furnace coal injection and coal blending technology, which is applied to the coal blending and blast furnace coal injection fields, can solve the problem of low coal blending ratio, and achieve the effects of increasing the coal blending ratio, expanding the dosage and reducing the explosiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0019] A coal blending method for blast furnace injection coal, comprising:

[0020] Grinding the low-rank coal to obtain low-rank coal powder, wherein the weight percentage of the low-rank coal powder in the low-rank coal powder is 38.05% to 93.74%;

[0021] The pulverized coal of the blast furnace is obtained by mixing the pulverized low-rank coal with other pulverized coal.

[0022] In the existing coal blending method of blast furnace injection coal, due to the high volatile content and strong explosiveness of low-rank coal, in the existing coal blending method of blast furnace injection coal blending, low-rank coal is used as blast furnace injection coal blending method. The weight ratio is up to about 30%.

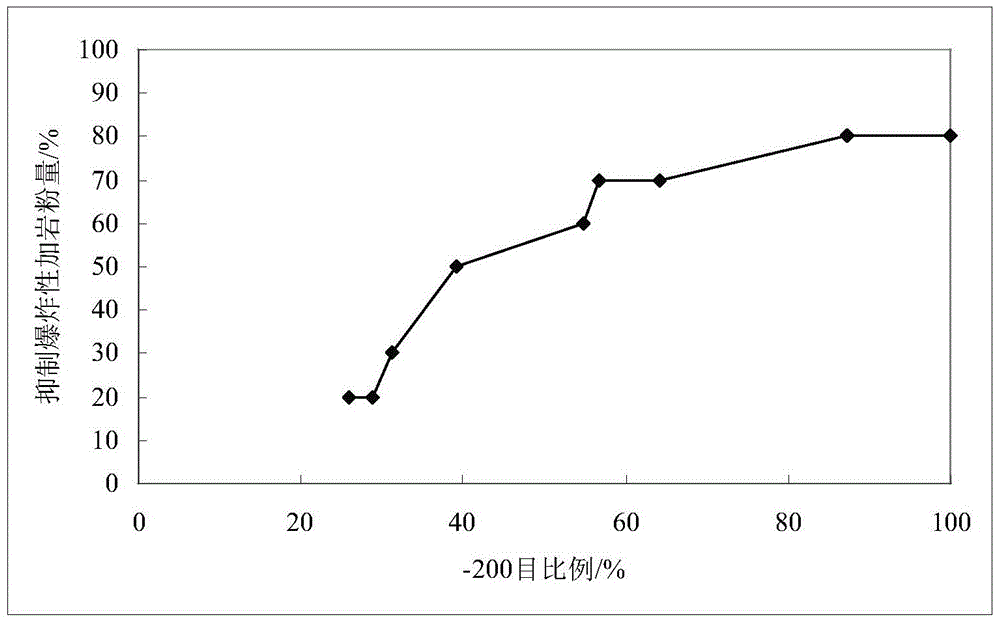

[0023] The present invention relaxes the particle size of low-rank coal in the pulverizing process, increases the conten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com