A biomass semi-gasification combustion equipment

A technology of combustion equipment and biomass, which is applied in the field of biomass semi-gasification combustion equipment to achieve the effect of relaxing the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

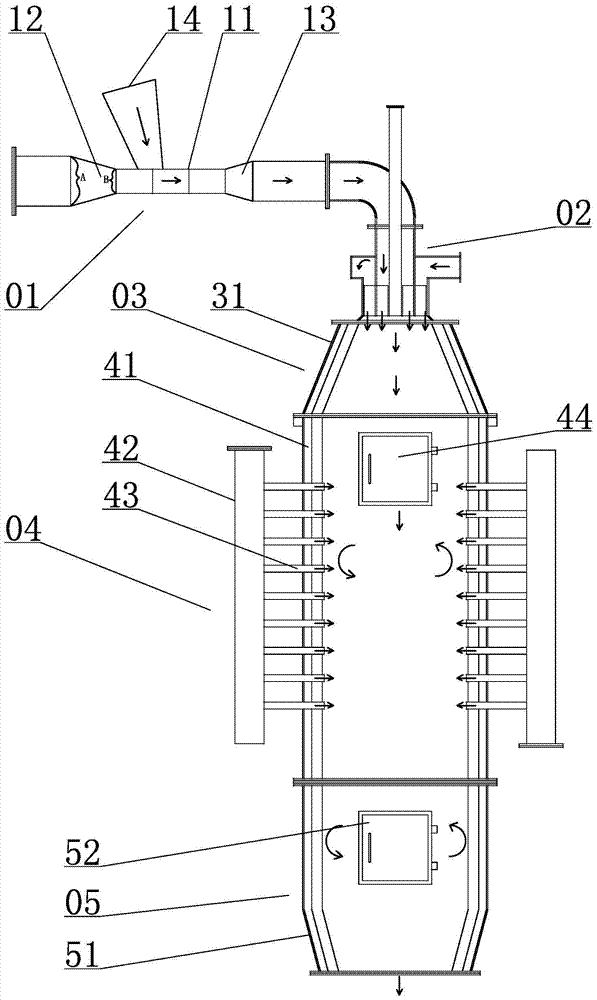

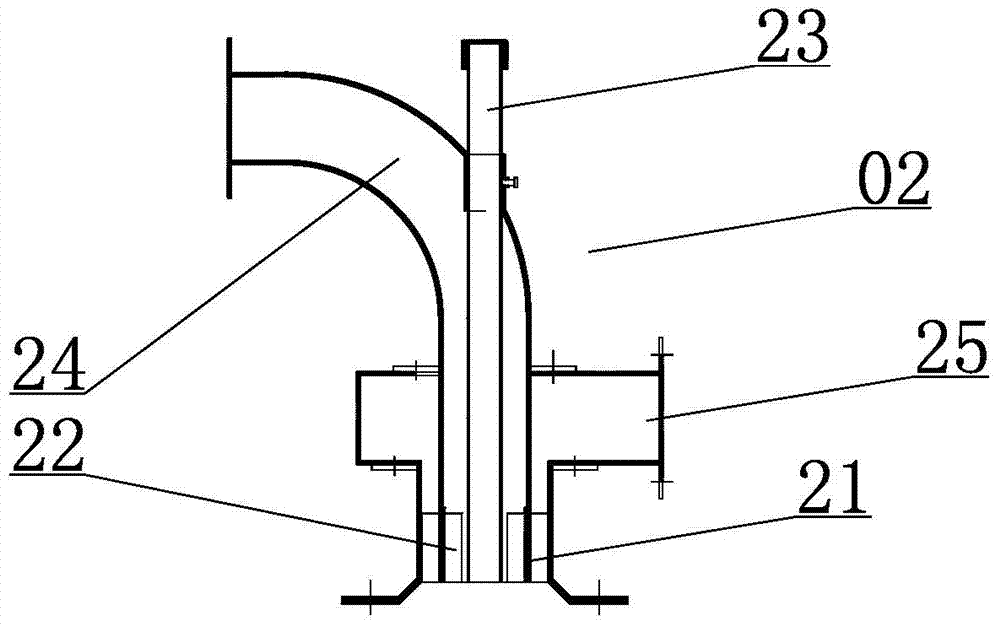

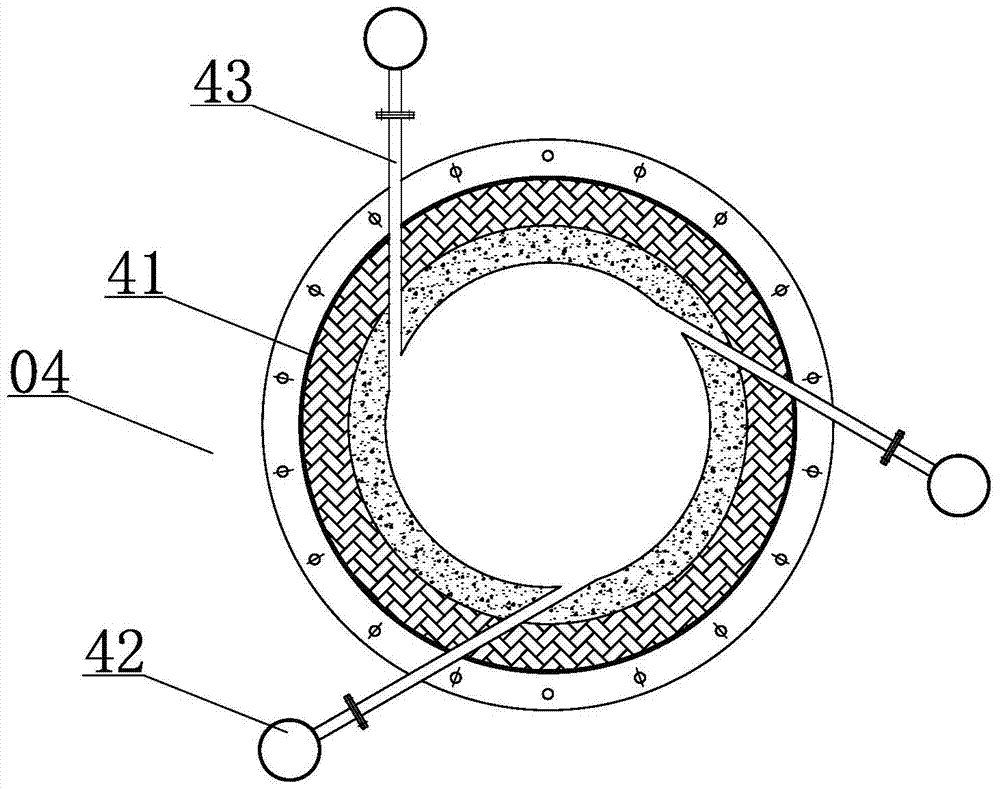

[0027] Below in conjunction with accompanying drawing, invention is described in further detail.

[0028] Such as Figure 1-3 As shown, a biomass semi-gasification combustion equipment includes a combustion chamber 04, a gasification chamber 03 communicated with the combustion chamber 04 is provided at the upper part of the combustion chamber 04, and a combustion chamber 03 communicated with the combustion chamber 04 is provided at the lower part of the combustion chamber 04. An ember chamber 05, and a burner 02 communicating with the gasification chamber 03 is provided on the gasification chamber 03. A mixer 01 is provided at the front end of the burner 02 . The main body of the entire combustion device is arranged in a horizontal or vertical arrangement. The mixer 01 includes a nozzle for feeding air and a feed pipe 14 for feeding biomass pulverized material or biomass molding pellets on the nozzle. The nozzle is designed with reference to the structure of the Lafal nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com