Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Obvious practicality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

USY molecular sieve modification method

InactiveCN104096586AHigh ratio of silicon to aluminumHigh crystallinityMolecular sieve catalystsMolecular sieveReaction temperature

The invention relates to a USY molecular sieve modification method. The USY molecular sieve modification method comprises the following steps of adding a citric acid solution having a concentration of 0.10-0.35mol / L into a USY molecular sieve according to a solid-liquid quality ratio of 1: 5 for modification with stirring at a reaction temperature of 500-1200 DEG C, after a temperature is increased to a preset temperature of 600-900 DEG C, adding an ammonium fluosilicate solution having a concentration of 0.05-0.20mol / L into the reaction product at a rate of 0.1-3.5ml / min according to a volume ratio of citric acid to the ammonium fluosilicate solution of 0.5-3.0, after material addition, carrying out a reaction process at a temperature of 50-120 DEG C for 1-6h, carrying out washing by deionized water until a pH value is 7, and carrying out constant-temperature drying at a temperature of 110 DEG C. The USY molecular sieve obtained by the USY molecular sieve modification method has substantially improved specific surface, secondary pore volume and moderate strong acid level and can be used for a hydrocracking catalyst for maximizing middle distillates as desired products.

Owner:PETROCHINA CO LTD

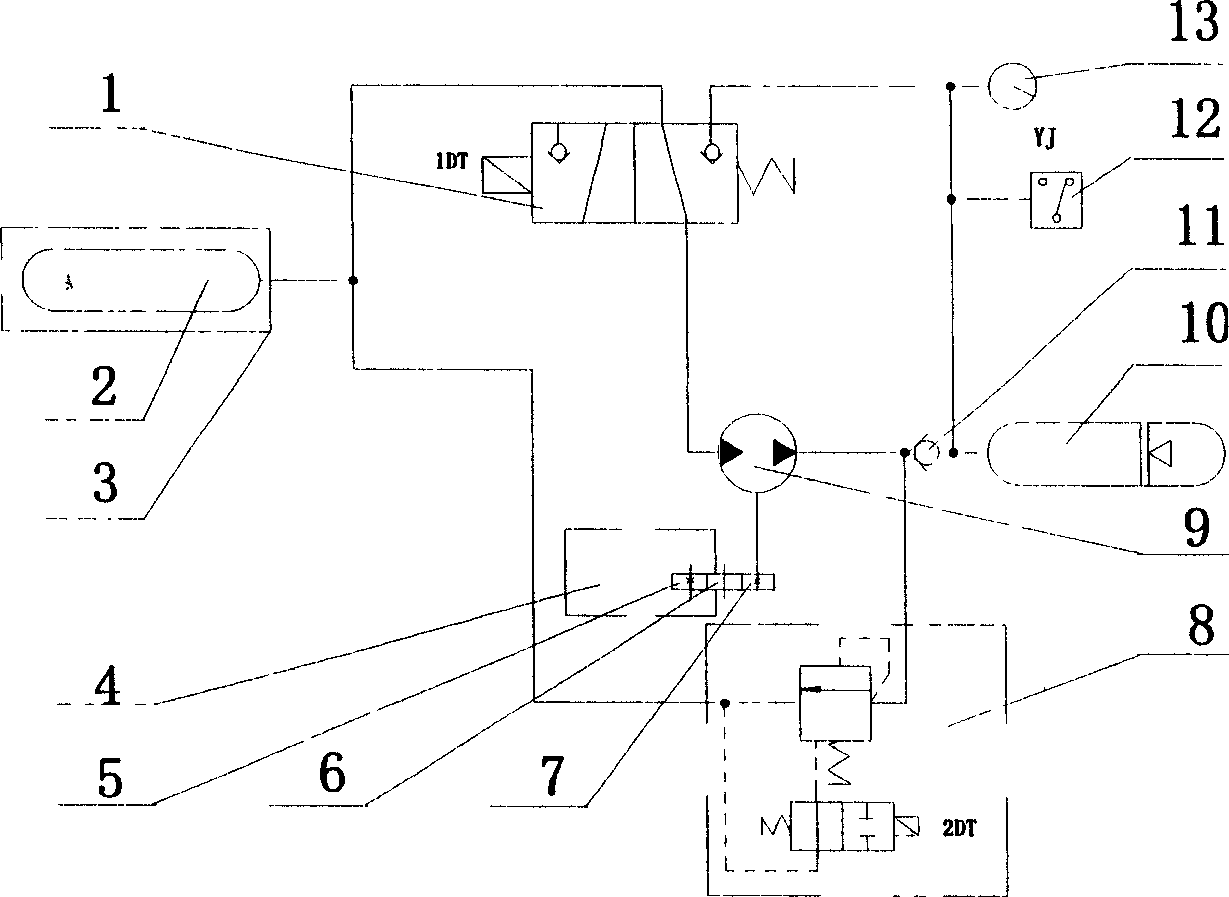

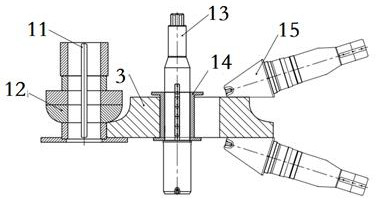

Automotive braking force reclaiming economizing and accelerating unit

InactiveCN1833901AImprove economyExtend your lifeGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingFuel tankAutomotive transmission

An oil-saving boosting unit able to recover the braked kinetic energy for car features that the additional mechanical structure and simple hydraulic system are additionally installed to the output axle of speed variator or drive axle. When the car is braking, its inertia can drive oil pump to become the pressure energy of fluid and store it in energy accumulator. When the car is driven or accelerated, the energy is released via the same mechanism. An enclosed leather bag type oil tank and a simple hydraulic system are used.

Owner:SHANGHAI SHENZHOU VEHICLE RES & DEV

Electroslag remelting premelted slag for improving purity of GH4169 alloy return scraps and preparing method

The invention belongs to the technical field of high-temperature alloy purifying smelting and relates to an electroslag remelting premelted slag for improving the purity of GH4169 alloy return scrapsand a preparing method. According to the ranges of composition proportions of the premelted slag, CaF2 accounts for 40-55%, CaO accounts for 20-25%, Al2O3 accounts for 18-22%, MgO accounts for 3-6%, TiO2 accounts for 2-3%, and MgF2 accounts for 1-2%; and in the premelted slag at 600 DEG C or lower, moisture is smaller than or equal to 0.06%, SiO2 is smaller than or equal to 0.5%, C is smaller thanor equal to 0.03%, P is smaller than or equal to 0.01%, and S is smaller than or equal to 0.005%. Prepared ceramic materials are subjected to ball milling mixing, smelting through an electric arc furnace, quick cooling and crushing screening, then dried for 2-3 h at the high temperature of 950 DEG C + / -20 DEG C and finally sealed and packaged under the protection of the inert gas (Ar). The premelted slag can ensure the internal metallurgical quality and the surface quality of GH4169 alloy return scrap ingots for aircraft engines, the alloy purity is high, and the premelted slag has the advantages of energy conservation and environmental friendliness, and has wide market prospects and application value.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

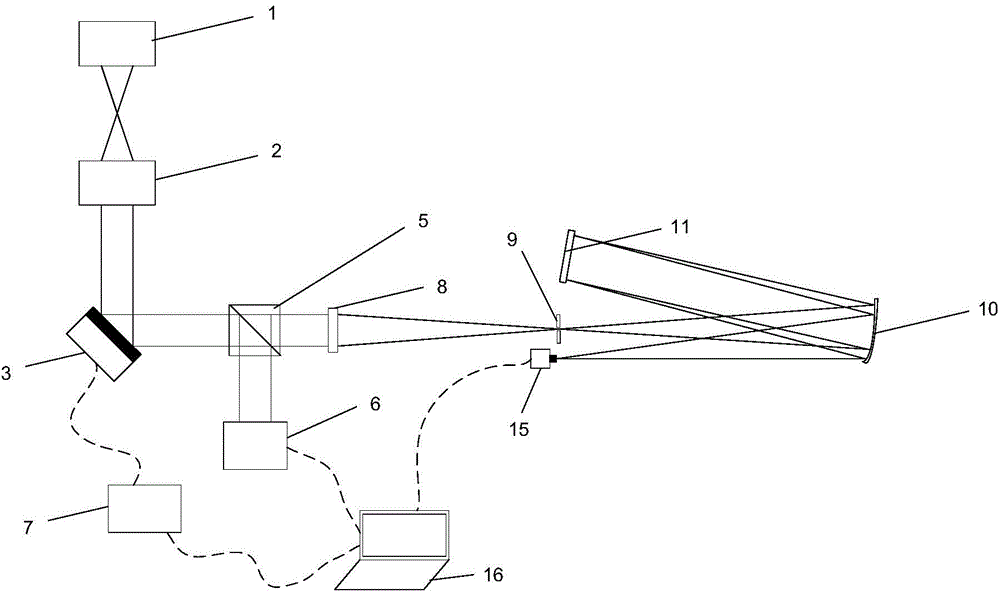

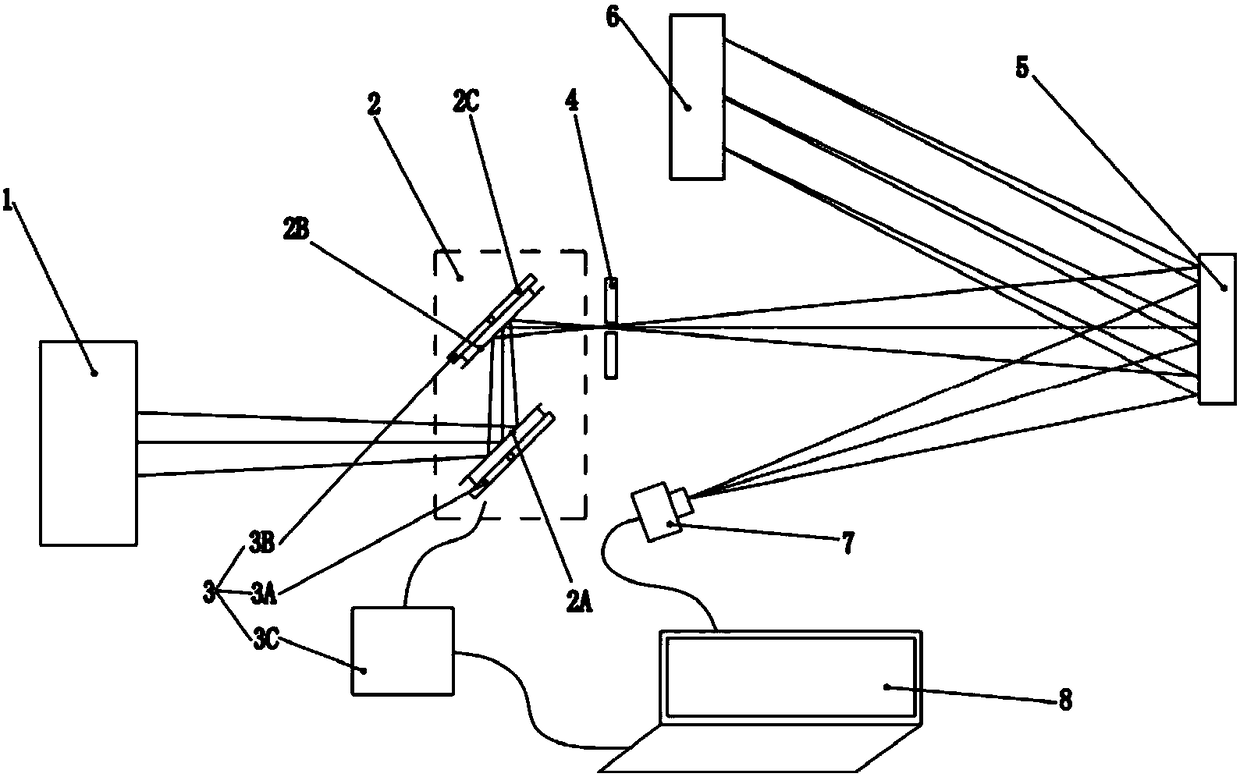

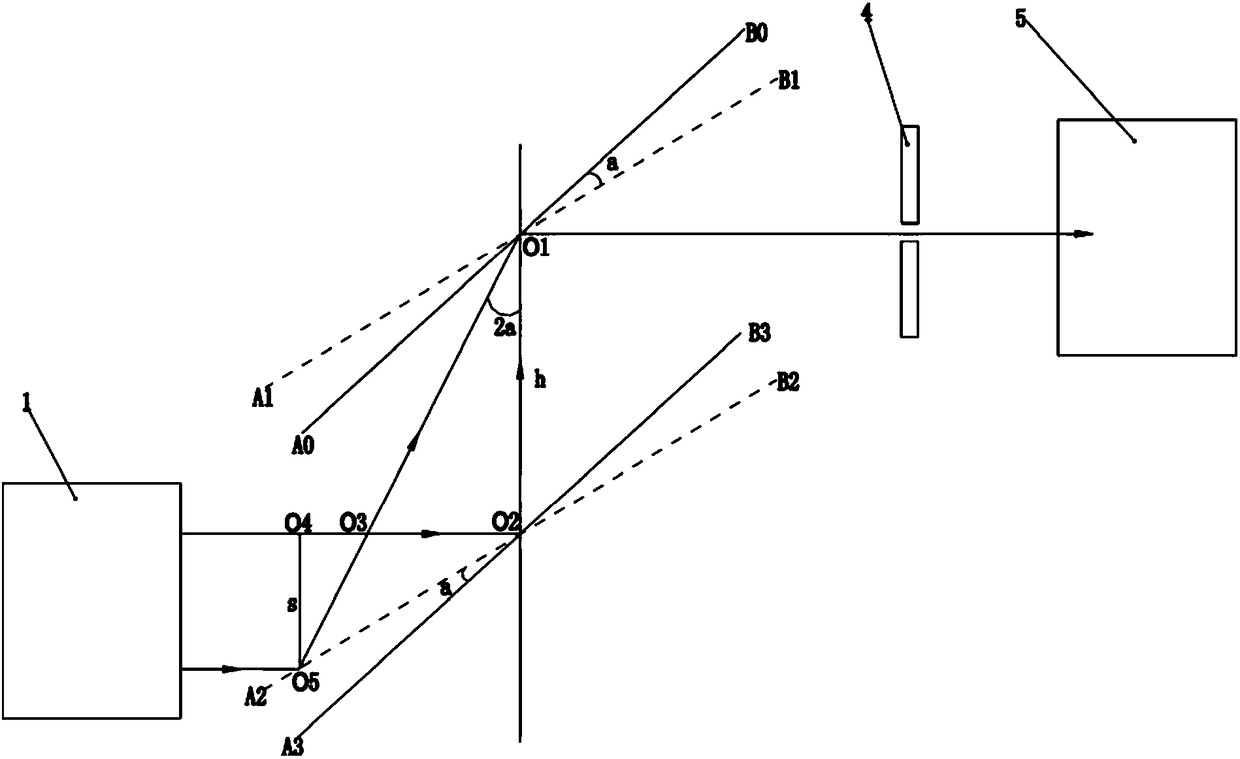

Solar grating spectrum imaging device capable of correcting system aberration

ActiveCN104568149AReduce the difficulty of assembly and adjustmentLower requirementRadiation pyrometrySpectrum investigationGratingOptic system

The invention provides a solar grating spectrum imaging device capable of correcting system aberration. On the premise that cost and system complexity are not increased evidently, an adaptive optical system with double wavefront detectors is formed by an adaptive optical system integrated in a telescope system and a wavefront detector arranged at a conjugation position of a focal surface of a spectrograph system. Therefore, the solar grating spectrum imaging device is not only capable of correcting dynamic wavefront aberration but also capable of correcting static aberration of the whole optical system to give great significance to improvement of spectral imaging quality of the spectrum imaging device.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

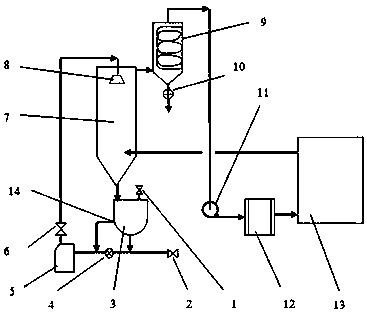

Method and device for producing biological diesel oil

InactiveCN1821348AReduce work intensitySimple processBiofuelsLiquid hydrocarbon mixture productionEthylenediamineBiodiesel

The biological diesel oil is produced with fatty acid, oleic acid, acidified oil and / or sewage oil as main material, and through adding methanol in 5-10 wt%, n-butanol in 5-10 wt%, ethylene-vinyl acetate copolymer in 0.1 wt%, octyl nitrate in 0.1 wt%, alkyl naphthalene in 0.05 wt%, and ethylenediamine and high base number calcium naphthenate successively white stirring in a reactor. The production apparatus consists of reacting tank, high speed stirrer, operating platform, rack and PLC control system. The present invention provides environment friendly biological diesel oil.

Owner:杨慈闵 +1

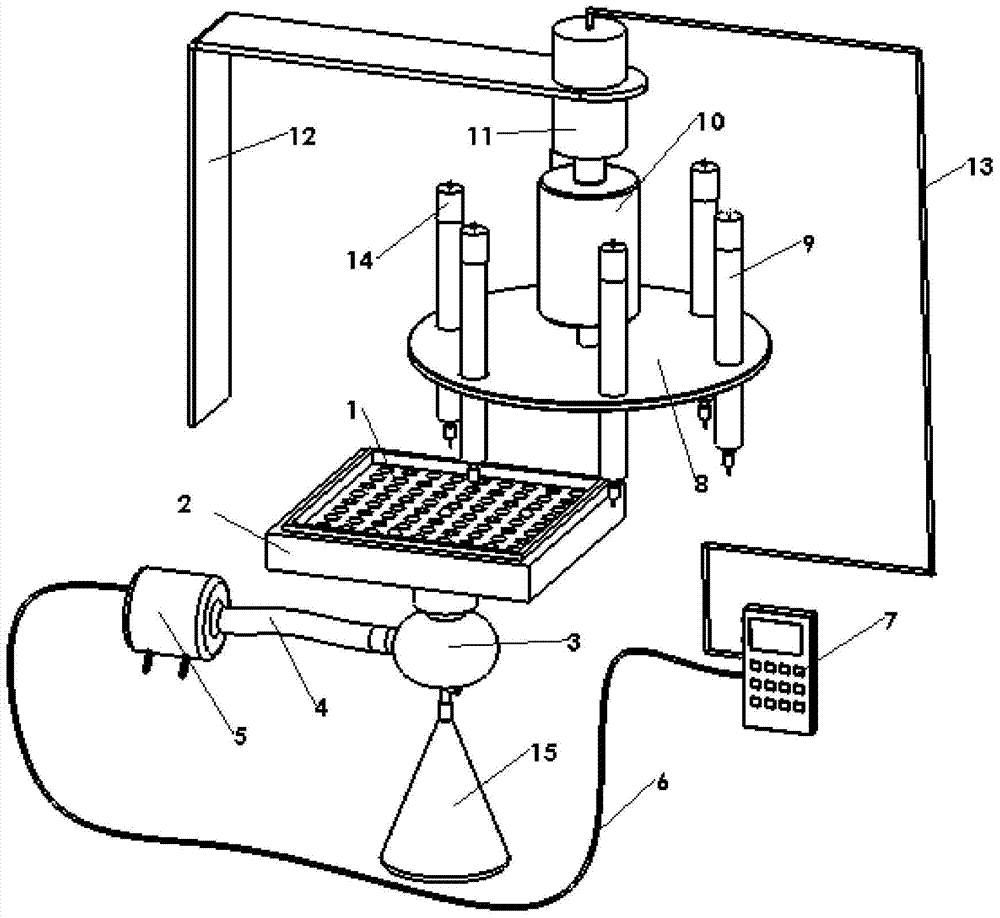

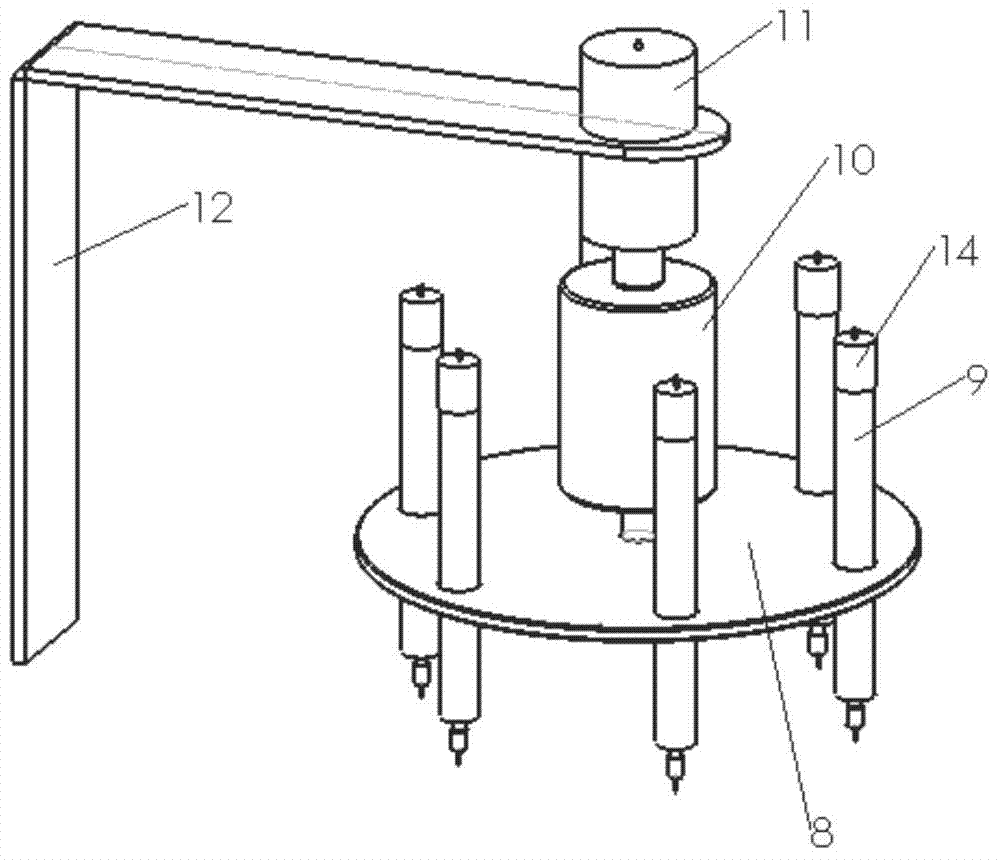

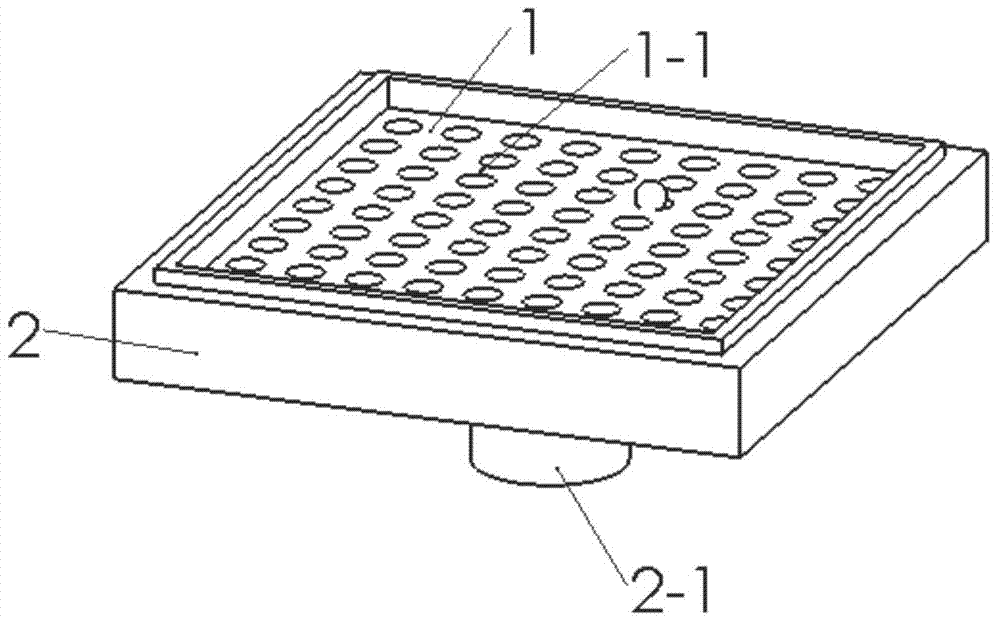

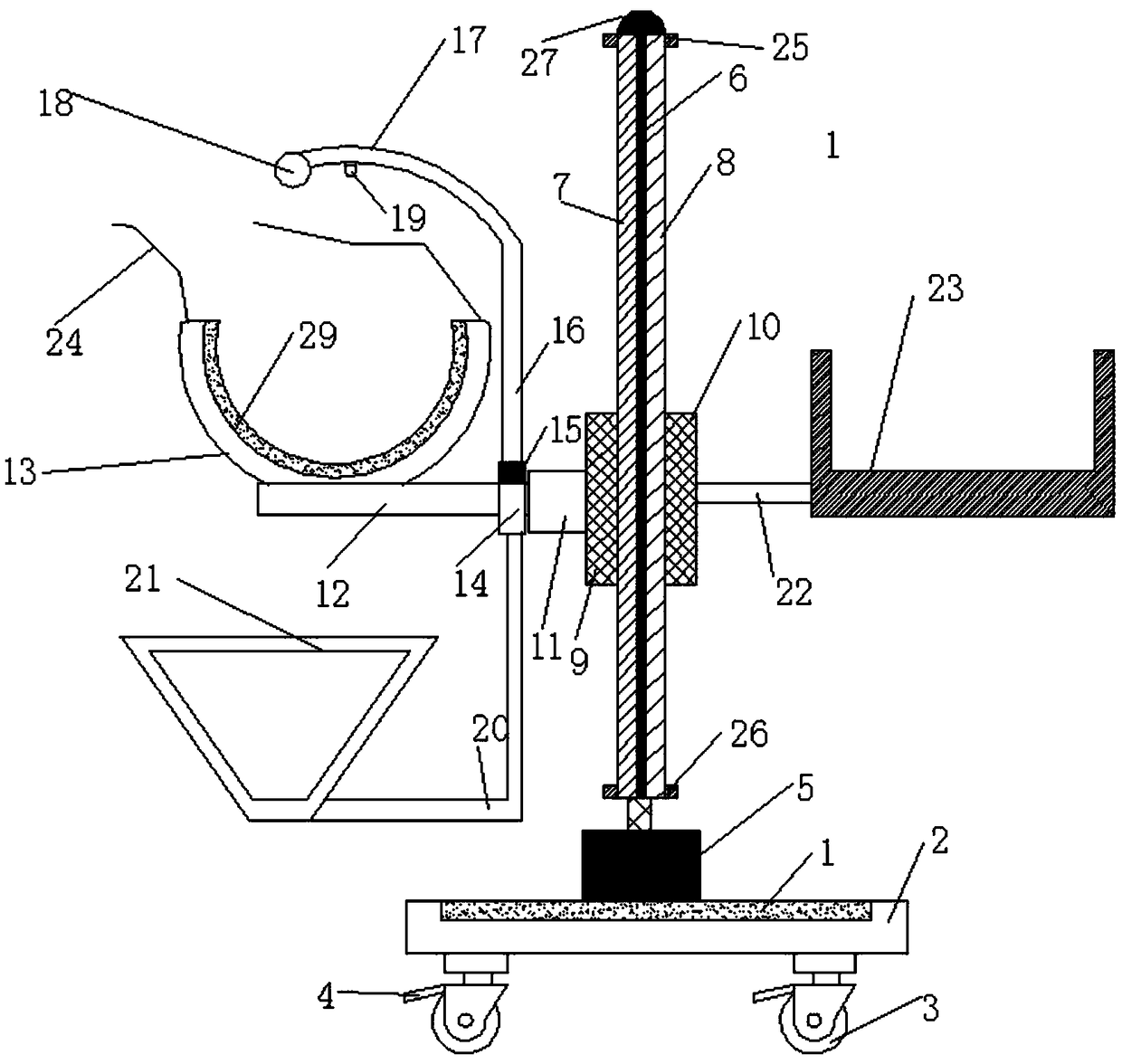

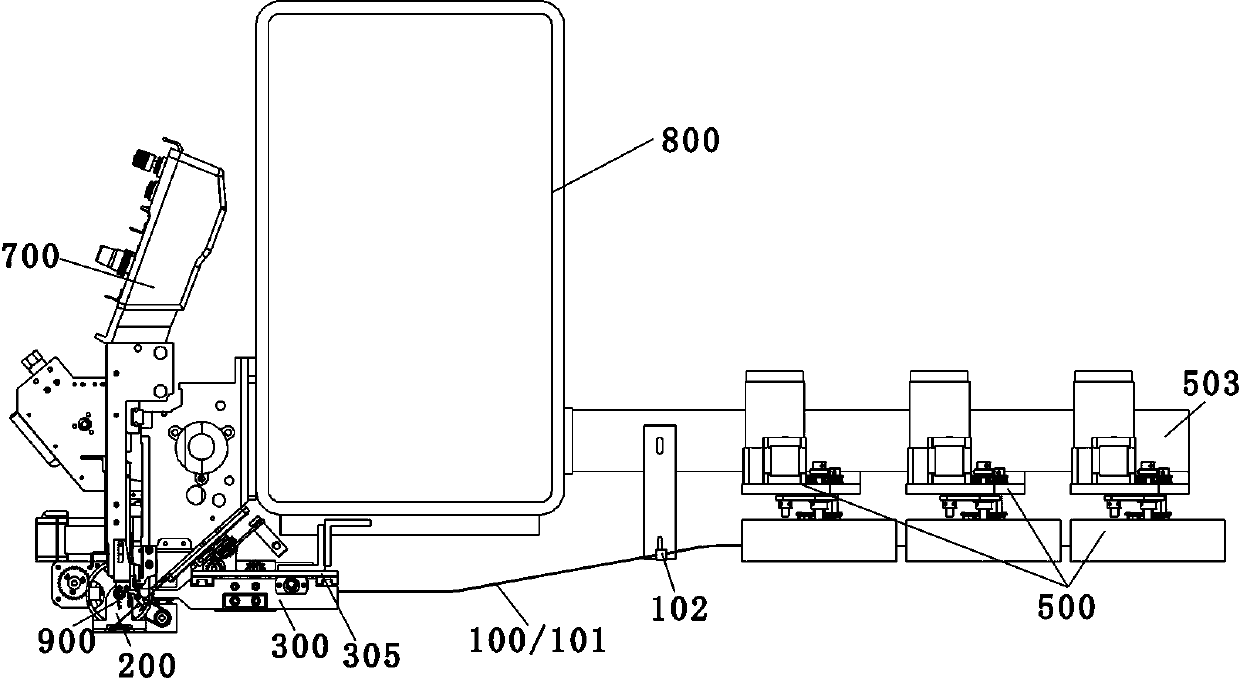

Automatic egg cell capturing and culturing device

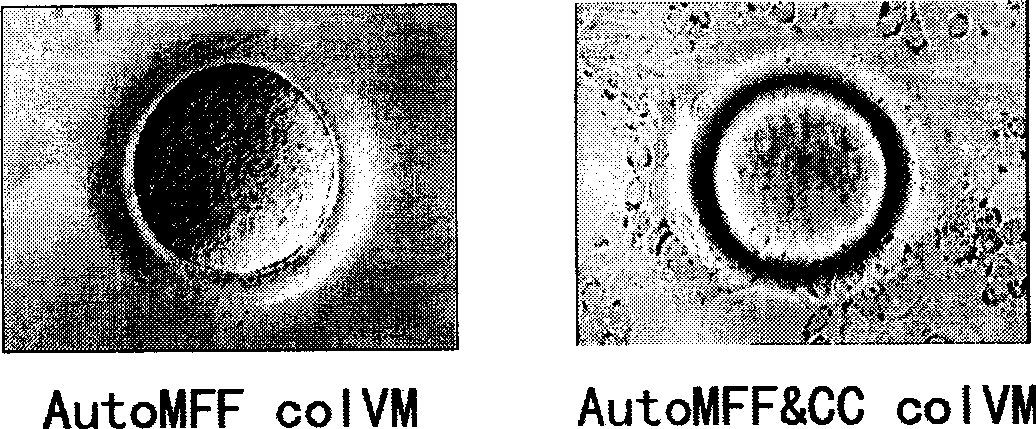

ActiveCN103695313AObvious noveltyObvious practicalityTissue/virus culture apparatusBiological material testing proceduresEgg cellComputer science

The invention discloses an automatic egg cell capturing and culturing device. The automatic egg cell capturing and culturing device comprises a culture solution supply mechanism which is arranged on a bracket and is linked by an electric motor, wherein the culture solution supply mechanism is connected with the motor through the bracket; the electric motor is connected with a rotary wheel disc connected by a bearing; injectors which penetrate through the disc surface are annularly and uniformly distributed on the rotary wheel disc; a cell capturing mechanism is arranged below the culture solution supply mechanism and comprises a base formed by a rectangular frame; a double-layer hole film embedded on the base is arranged on an enclosure of the rectangular frame; a waste liquid removal mechanism is arranged below the cell capturing mechanism and comprises a flask connected to the lower side of a three-neck container; a control mechanism comprises a control board which is respectively connected with a micro pump, the electric motor and a motor through wires. According to the device, batch capture of egg cells and liquid transfer culture automation are realized, and a technical scheme which is low in cost and easy to operate is provided for realizing in-vitro culture of egg cells, fertilization and early culture of embryos.

Owner:XIDIAN UNIV

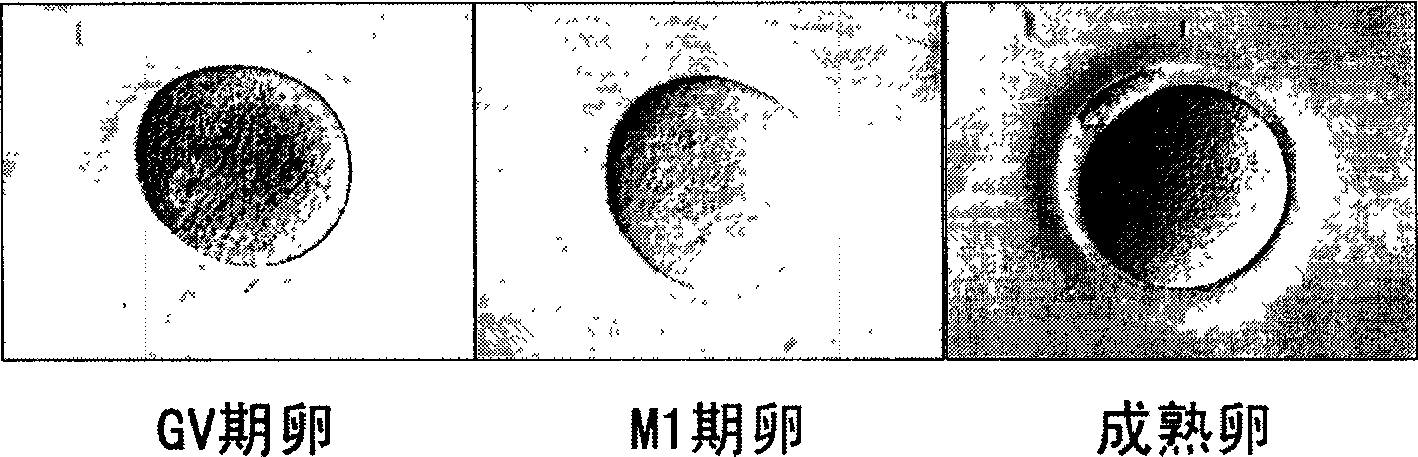

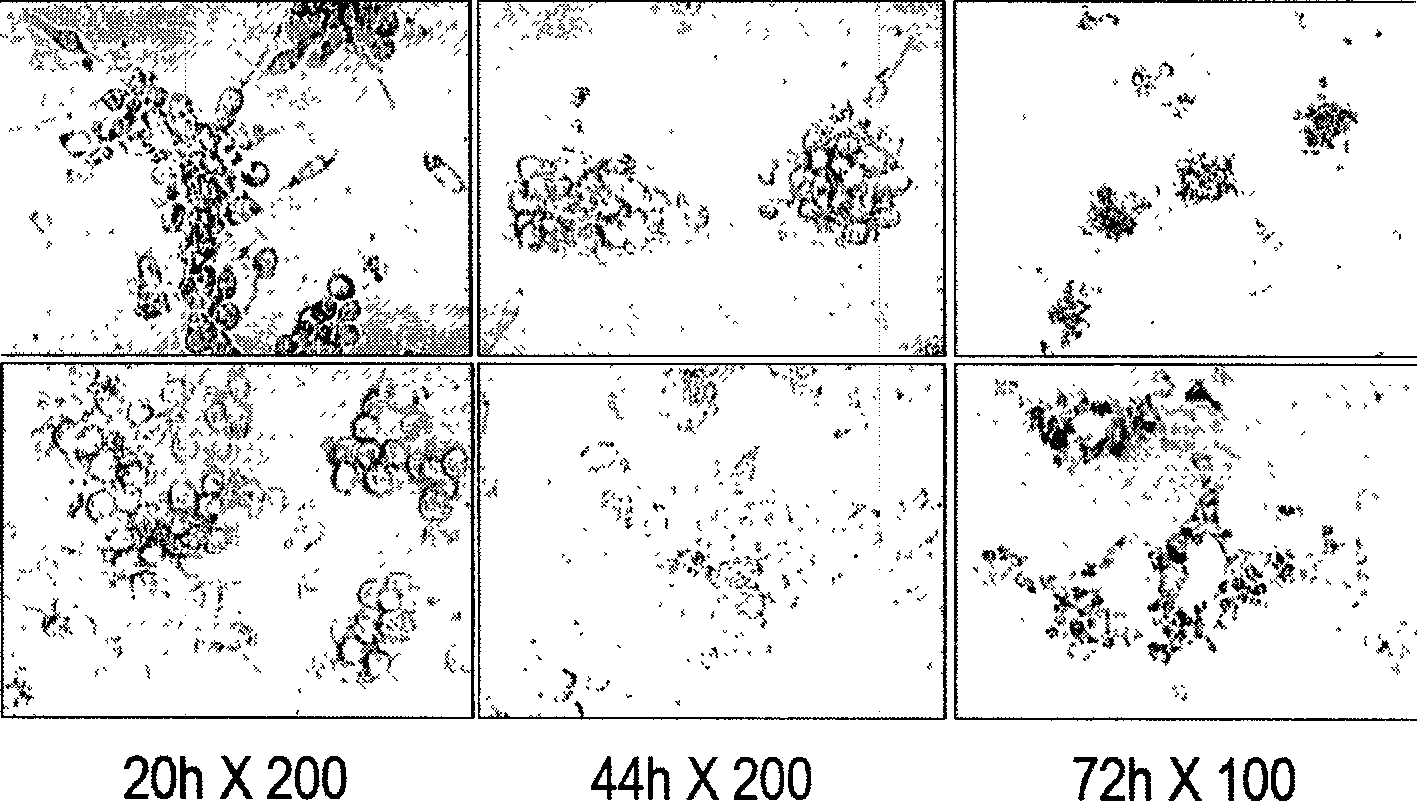

In vitro maturing culture method for human immature ovum

InactiveCN1800371AClearly deal with individuationMedical Security GuaranteeGerm cellsCulture fluidMeiosis

The invention discloses a human immaturity ovum external mature culture method, which comprises: preparing for human external mature culture liquid, adding self-body mature follicle liquid to prepare for the culture liquid A, positioning the immaturity ovum of the first inter middle phase in the micro drop of the culture liquid A, adding separated and purified self-body ovum particle cell deposition in the culture liquid A to float into the culture liquid B with self-body ovum particle cell density 1-5*105 / ml, adding the immaturity ovum of the first inter front phase in the micro drop of the culture liquid B.

Owner:ZHEJIANG UNIV

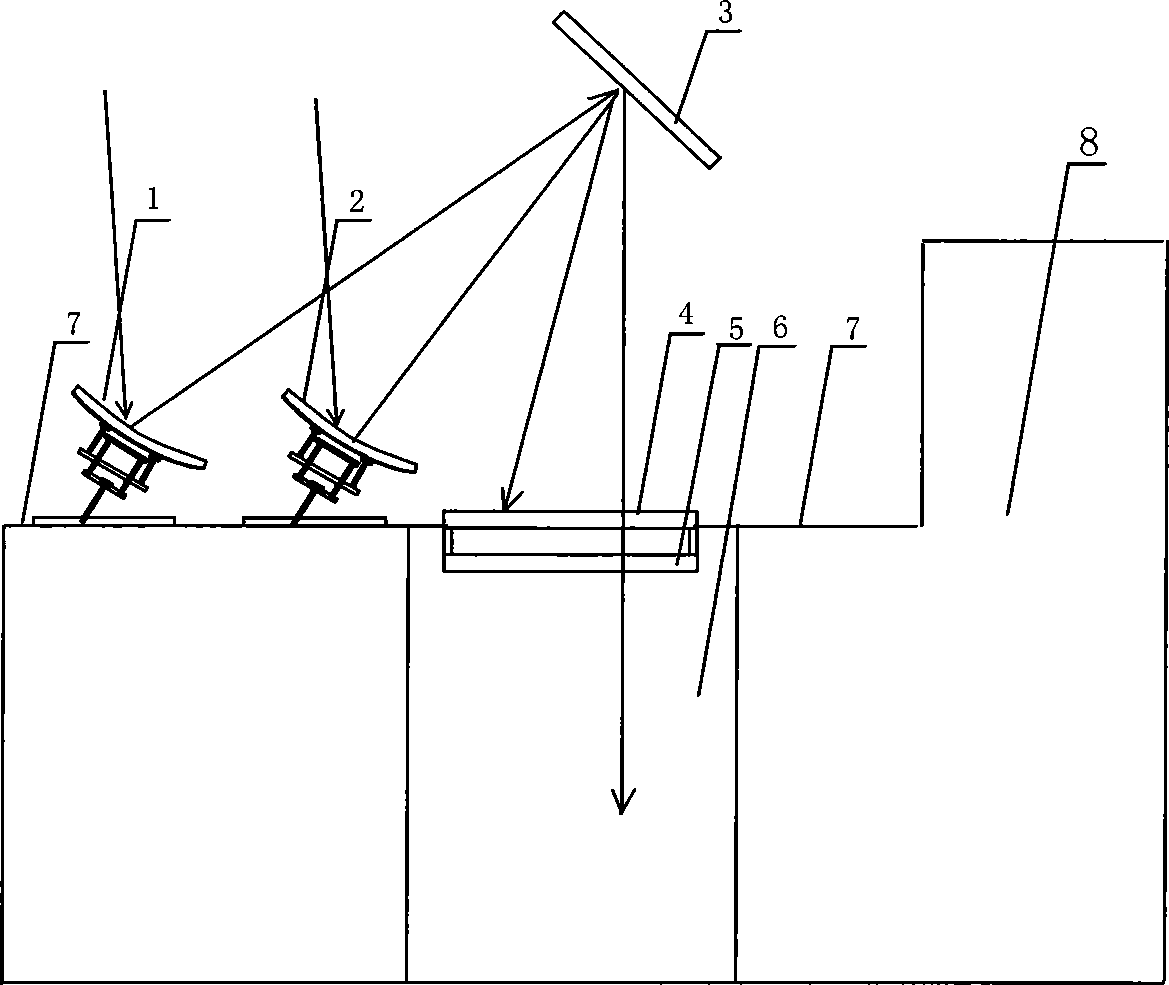

Active type natural light guide method and device

InactiveCN101794008AUniform incident lightPrevent glareSky-lights/domesMountingsIlluminanceHeliostat

The invention belongs to a construction technology, in particular to an active type natural light guide method and a device. The traditional building adopts a passive type natural lighting method, and the lighting quality is restricted by the position, the area, the size, the orientation and the like of a daylight opening. The active type natural light guide method guides sunlight into a building by the modes of collection, reflection, transmission and scattering. Two heliostats (1) and (2) which are arranged at the front and the back of a roof (7) of a building and can track the illumination angle of the sun collect the sunlight actively, and the sunlight is focused and irradiated to a reflecting mirror (3); and light rays are irradiated to a skylight (4) by the reflecting mirror (3), pass through a diffusing panel (5), are scattered and enter an atrium (6) of the building. The invention has the advantages of prolonging the sunshine time in the building, enhancing the lighting illumination in the building, enhancing the comfort level of a luminous environment in the building and providing conditions for the growth of green plants in the areas of the atrium and a patio in the building.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

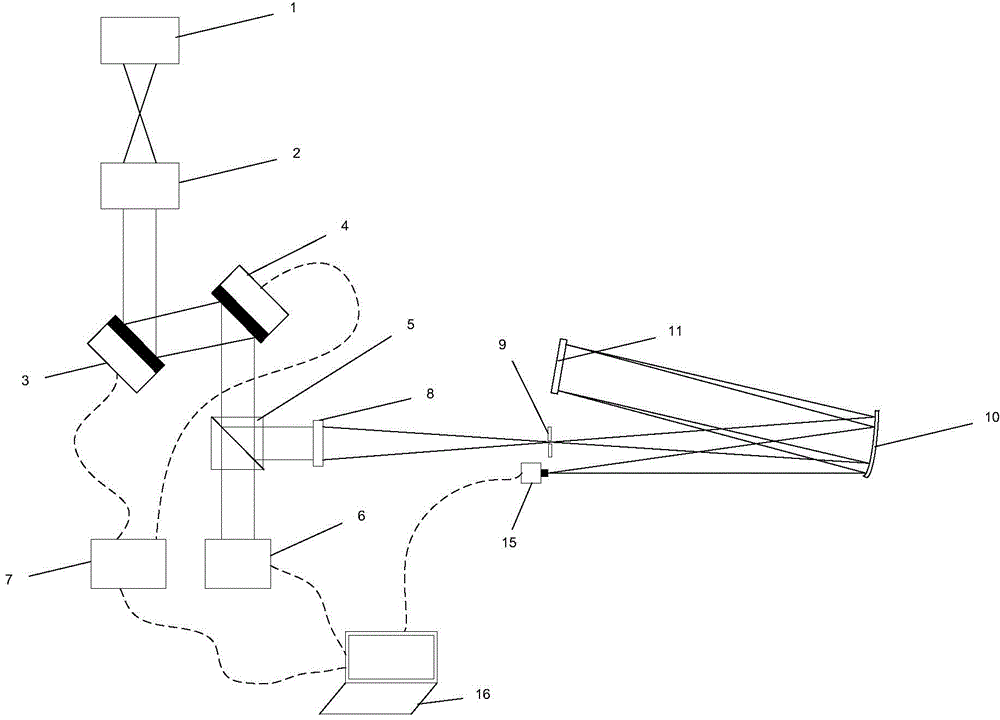

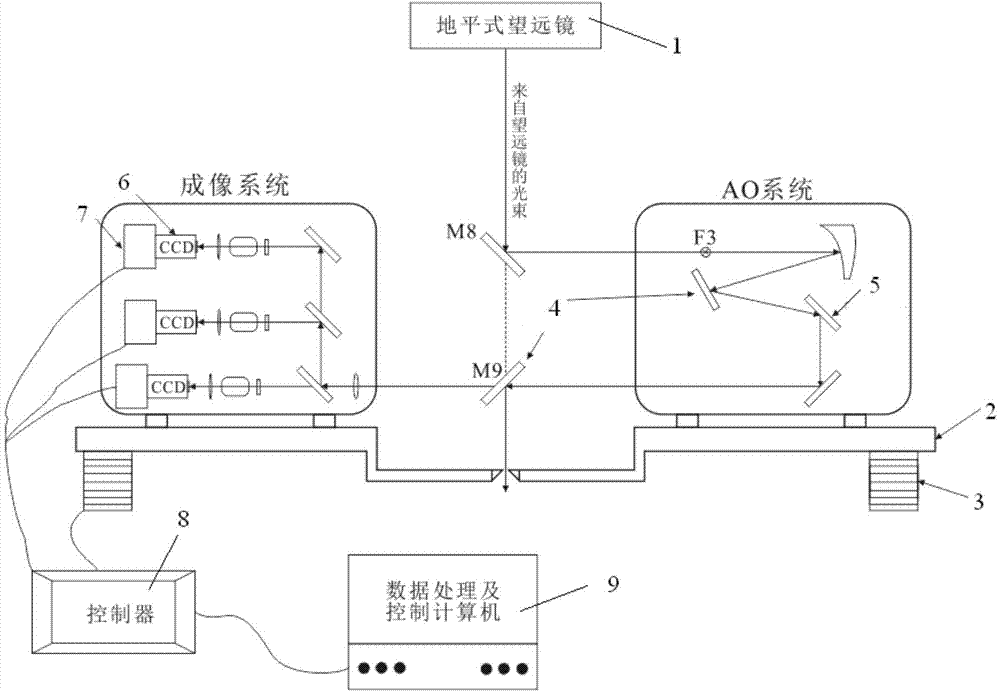

Azimuthal telescope pupil plane and image plane mechanical racemic integration device

The invention discloses an azimuthal telescope pupil plane and image plane mechanical racemic integration device comprising an azimuthal telescope, a rotating table, an electrical control drive, a relay optical path, a deformable mirror DM, a camera, a camera rotating table, a controller and a data processing and controlling computer. Owing to the mechanical advantages of an azimuthal frame, a majority of large-diameter telescopes adopt the structures currently in the worldwide. However, in the target tracking process, the pupil plane and image plane rotate accordingly, the atmospheric wavefront aberration cannot be measured and corrected accurately through adaptive optics due to pupil plane rotation, and continuous and stable observation results cannot be acquired by the telescope due to image plane rotation. According to the device, the pupil plane rotation is eliminated through the rotation table, the image plane rotation is eliminated through the rotating camera, additional instrument polarization is omitted, optical path integrated reflectivity reducing is avoided, and the practicality and creativity are high.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Molten iron thermal insulating agent taking fly ash deducted from dry quenching as raw material and manufacturing and using method of molten iron thermal insulating agent

The invention provides a molten iron thermal insulating agent taking fly ash deducted from dry quenching as a raw material and a manufacturing and using method of the molten iron thermal insulating agent. The molten iron thermal insulating agent comprises the following components in percentage by weight: 50%-100% of fly ash deducted from dry quenching, 0-50% of water-granulated blast furnace slag,and 0-10% of expanded perlite. Compared with the prior art, the molten iron thermal insulating agent and the manufacturing and using method have the beneficial effects that 1) 90%-100% of the raw material of the molten iron thermal insulating agent comprises metallurgical waste in a metallurgical enterprise, machining or grinding is not required, the cost is remarkably lower to that of the similar molten iron thermal insulating agent, the cost is continuously reduced according to a formula, and the cost reducing requirements of enterprises at different levels are met; 2) the molten iron thermal insulating agent can be tightly combined with high blast slag on the surface of molten iron, slagging is easy, the heat conductivity coefficient is small, the thermal insulating effect is stable and reliable, resulfurization is not needed, and the steelmaking cost is not increased; 3) the slag gathering effect is good, the crusting phenomenon of an opening of a molten iron jar is reduced, and the workload and the working difficulty of manual slag removal are reduced; and 4) the economic benefits and the environmental benefits are remarkable, and the molten iron thermal insulating agent hasremarkable economic benefits and popularization and application values within the industry.

Owner:ANGANG STEEL CO LTD

Cultivating method of new breeding strain of pinctada martensii with high carotenoid content

ActiveCN105900874AIncrease carotenoid contentEasy to operateClimate change adaptationAnimal feeding stuffPinctada martensiiZoology

The invention discloses a cultivating method of a new breeding strain of pinctada martensii with high carotenoid content. The cultivating method comprises the basic steps of parent selection, population construction, larval cultivation, sea area breeding and multi-generation population selection, and the new breeding strain of pinctada martensii with the high carotenoid content can be cultivated; for the obtained new strain, prismjatic layers of 96% of individuals are golden yellow, pallia, adductor muscles and gill filaments of 96% of the individuals are golden yellow, and the carotenoid content in pinctada martensii is 2-5 times that of control population. The new strain of pinctada martensii with the high carotenoid content is cultivated through a population selection breeding technology, obvious golden yellow is achieved, and the carotenoid content in pinctada martensii is high; the method is easy to popularize in production units and has a significant practical value and economic value.

Owner:GUANGDONG OCEAN UNIVERSITY

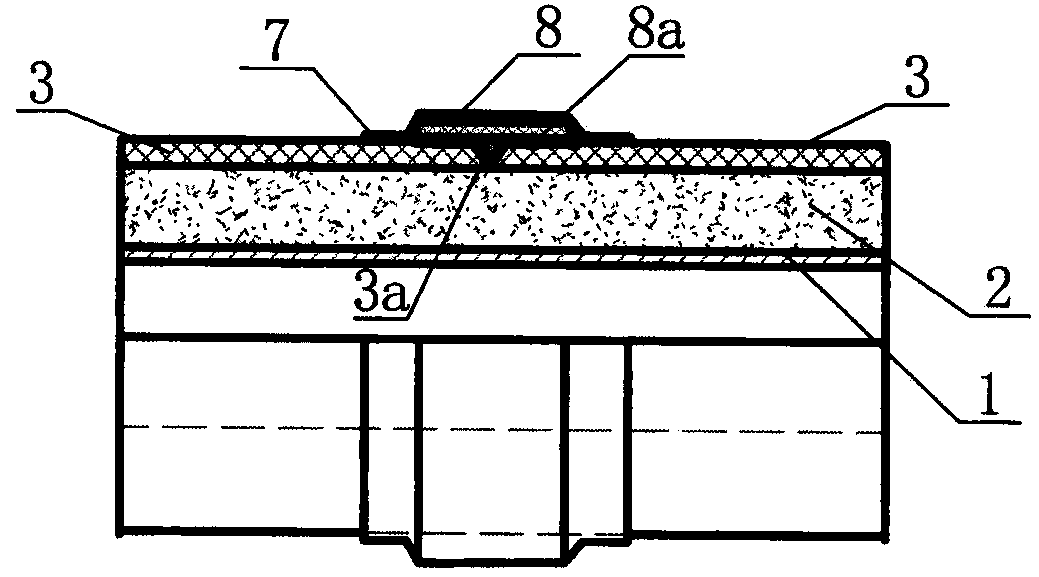

Combined exhaust passage independently installed in layered mode

InactiveCN103967258AEasy to operateReduce construction costsVertical ductsSupporting systemEngineering

The invention discloses a combined exhaust passage independently installed in a layered mode. The combined exhaust passage independently installed in the layered mode is formed by indoor vertical walls and a right-angled strip-type board in an enclosing mode, wherein the vertical walls are arranged on the two sides of a vertical wall corner. The upper end of the right-angled strip-type board is of a stepped internal insertion structure, wherein the widths of the two perpendicular side faces of the right-angled strip-type board are larger than the corresponding opening side lengths of a lower preformed mounting opening in a lower floor respectively; the stepped internal insertion structure is inserted into an upper preformed mounting opening in an upper floor; the bottom end of the right-angled strip-type board is located on the lower floor on the edges of the lower preformed mounting opening. The combined exhaust passage can be installed independently in the layered mode and supported by the floors, and as a result, the defects of inconvenient maintenance and replacement caused by a supporting system of an existing exhaust passage that the existing exhaust passage is installed from bottom to top in an overlapped mode are overcome; meanwhile, through combination of section bars and the wall, raw materials are saved, the production efficiency is improved, and the combined exhaust passage is easy and convenient to operate in the installation process; a variable pressure plate assembly is particularly suitable for being arranged on the combined exhaust passage, then the exhaust passage with a variable pressure function is manufactured, and the combined exhaust passage is convenient to maintain after being used and has obvious practical value.

Owner:张家口市宝通建筑配套制品厂

Processing method for soft prickly pear cans

InactiveCN103584212ASolve the soft problemHigh hardnessFruits/vegetable preservation by heatingMulti-step food processesPEARAdditive ingredient

The invention discloses a processing method for soft prickly pear cans. Firstly, thorns of prickly pear are removed; the prickly pears are peeled to obtain pulps; the pulps are put in citric acid solution for color protecting; canned sugar water containing saccharose, calcium lactate and citric acid is prepared, boiled for disinfecting, and cooled to be at the normal temperature; the pulps are put in high-pressure-resistant compound bags; the rest parts are added to the canned sugar water, and sealed to obtain pre-packaged soft cans; the pre-packaged soft cans are put in a superhigh-pressure disinfector, are pressurized to be under 10-20 MPa; the state is kept for 5-9 minutes; the pre-packaged soft cans are pressurized to be under 200-500 MPa at 65-85 DEG C for the second time for superhigh-pressure disinfection; after the pressure is relieved, the soft cans are taken out for cooling to obtain the soft prickly pear cans. The processing method solves the problem of the pulp tissue is soft and pulpy duo to the thermal disinfection technique, and provides the high-quality wild fruit can product with a good taste, a unique flavor, various nutrients and a health-care effect; the achievement of large-scale production for the technique process is easy; obvious practicability and economy are achieved.

Owner:KUNMING UNIV OF SCI & TECH

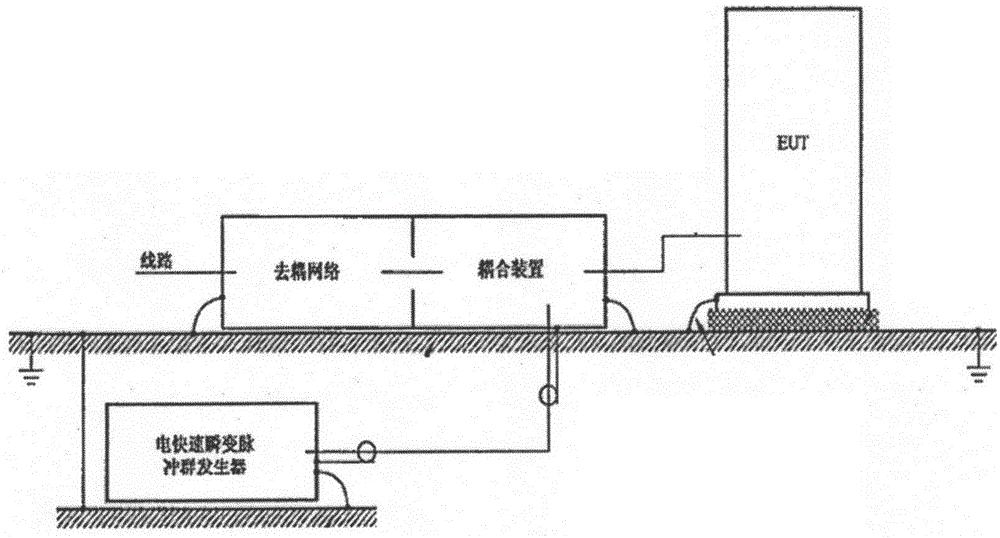

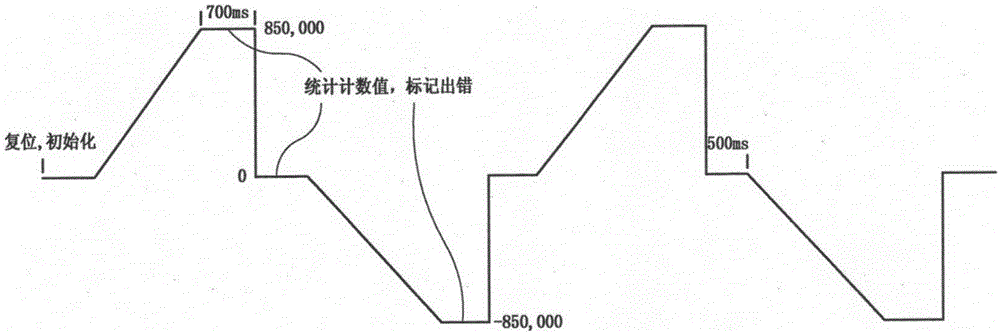

Immunity test quantitative evaluation method for programmable logic controller (PLC)

ActiveCN107436584ASimple structureEasy to operateComputer controlSimulator controlCapacitanceTest sample

The invention provides an immunity test quantitative evaluation method for a programmable logic controller (PLC). The method is characterized by comprising the following steps: 1, an immunity test quantitative evaluation device is built; 2, high-speed counting pulses with a frequency of XHz and counting direction signals are generated by an accompany test sample, a high-speed counting pulse end of a tested sample is connected through a capacitive coupling clamp for counting, and during the process, interference signals generated by an interference pulse generator are injected to a power output line of a tested device, or, through the capacitive coupling clamp, the interference signals generated by the interference pulse generator are coupled to a high-speed counting pulse signal line; and 3, the ratio of the number of incorrect pulses to the total counted number of pulses during the operation time for one standard test is calculated. Through the method of the invention, judgment on the test results of the anti-interference ability of the PLC interference signals are guaranteed to be more effective, quantifiable and high accurate.

Owner:SHANGHAI ELECTRICAL APP RES INST +1

Orthopedic dressing change combined support

InactiveCN109044692ASimple structureImprove discomfortAmbulance serviceNursing accommodationElectric machineDressing change

The invention belongs to the field of medical instruments and discloses an orthopedic dressing change combined support, which comprises a base, wherein a first rotating motor is arranged on the base;a first upright post is connected with the first rotating motor; one end of the first upright post is provided with a first sliding rail; the other end of the first sliding rail, opposite to the firstupright post, is provided with a second sliding rail; a first linear motor is arranged on the first sliding rail; the second sliding rail is provided with a second linear motor, the first linear motor is connected with a second rotating motor which is horizontally arranged, the rotor of the second rotating motor is connected with a first connecting rod, the upper end of one side of the first connecting rod, away from the second rotating motor, is connected with a supporting bracket, a third sliding rail is connected with the upper end of one side of the first connecting rod, close to the second rotating motor, and a third linear motor is arranged on the third sliding rail. The orthopedic dressing change combined support is simple in structure, convenient to operate and convenient to use,can effectively improve the comfort of a patient, reduce the labor intensity of a doctor, and has obvious progress significance and practical value.

Owner:王星

Dry-type mortar material special for decoration

The invention relates to a dry type mortar material for dwelling house architectural decoration and a method for preparing the same, in particular to a technical method in which river sand and clean sand are taken as aggregate, cement is taken as a main material, white limestone powder, an anti-mildew agent, an eliminating smell agent and the like are taken as auxiliary materials, and the mixing materials with different types are formed by adopting different mix proportions according to specific requirements on different decorative construction contents of dwelling house buildings; and by utilizing general technical equipment and adopting processes of drying, screening, mix-stirring, weighing, bagging, seaming and the like, the mortar material integrates various architectural ornamentation raw and auxiliary materials into a whole, facilitates the selection of users as well as storage and transportation; and in the construction field, the mortar material can be directly used only by mixing water, and no waste treatment is needed, so that the mortar material is suitable for needs of different decorative construction contents of the dwelling house buildings in large or medium-sized cities, such as division wall rebuilding and masonry, wall surface flattening and plastering, ground flattening, wall surface or ground pasting.

Owner:四平市立山机械制造有限责任公司

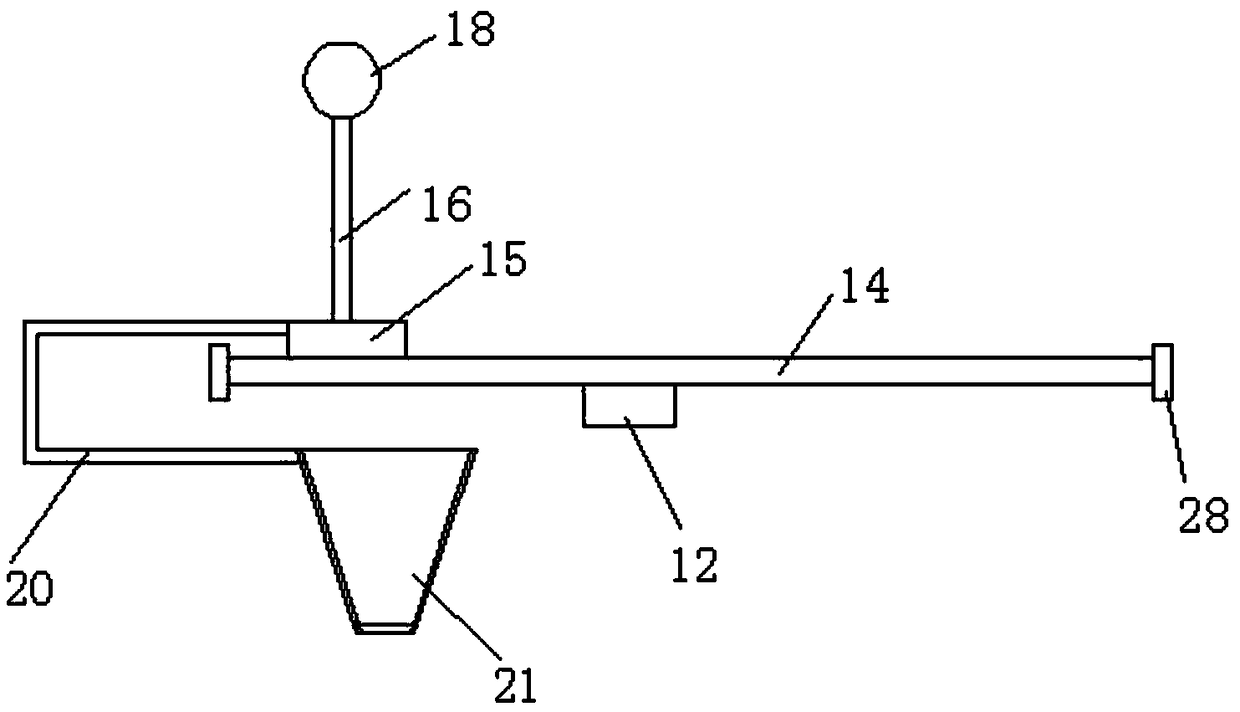

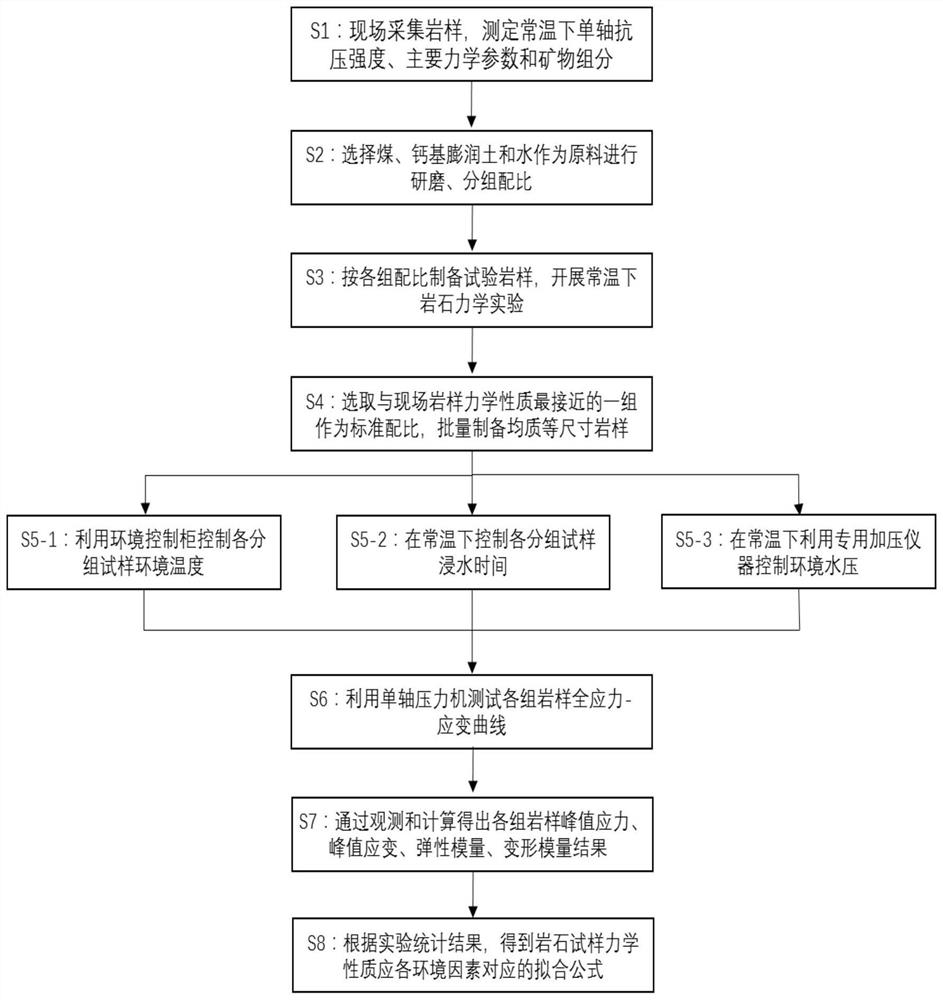

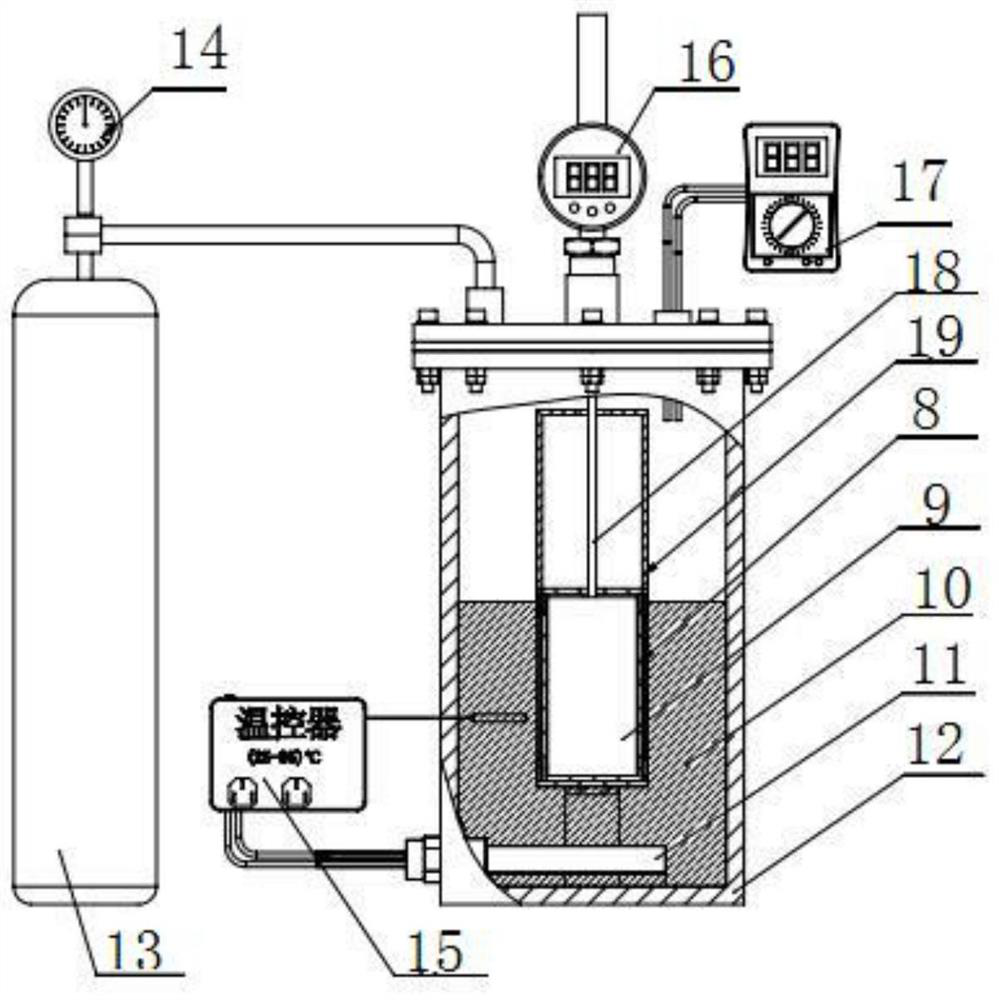

Method for quantitatively analyzing influence of environmental factors on mechanical properties of coal-series mudstone

InactiveCN111693351AAids in quantitative analysis of deformationAids in Quantitative AnalysisPreparing sample for investigationMaterial strength using tensile/compressive forcesCoal measuresRock sample

The invention belongs to the field of rock mechanics experiments. The invention relates to a method for quantitatively analyzing influence of environmental factors on mechanical properties of coal-series mudstone. Coal, calcium bentonite, quartz sand, cement and water are selected as raw materials to prepare coal-series mudstone samples, remolded rock samples highly consistent with natural coal-series mudstone in expansibility, water absorbability and basic mechanical properties are prepared in batches at a low cost, and rock mechanics experiments can be conveniently carried out. By controlling single environmental variables (including environmental temperature, environmental water pressure and soaking time), a large batch of homogeneous test pieces with similar field mechanical propertiesare used for carrying out grouped cross tests, the influence degree of a single factor on the deformation and mechanical properties of the coal-series mudstone is quantitatively analyzed, and a curveand a parameter equation with clear reference values are obtained.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD +1

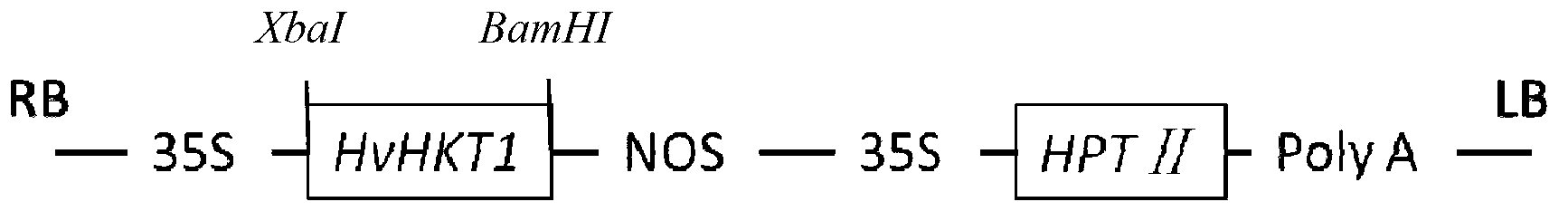

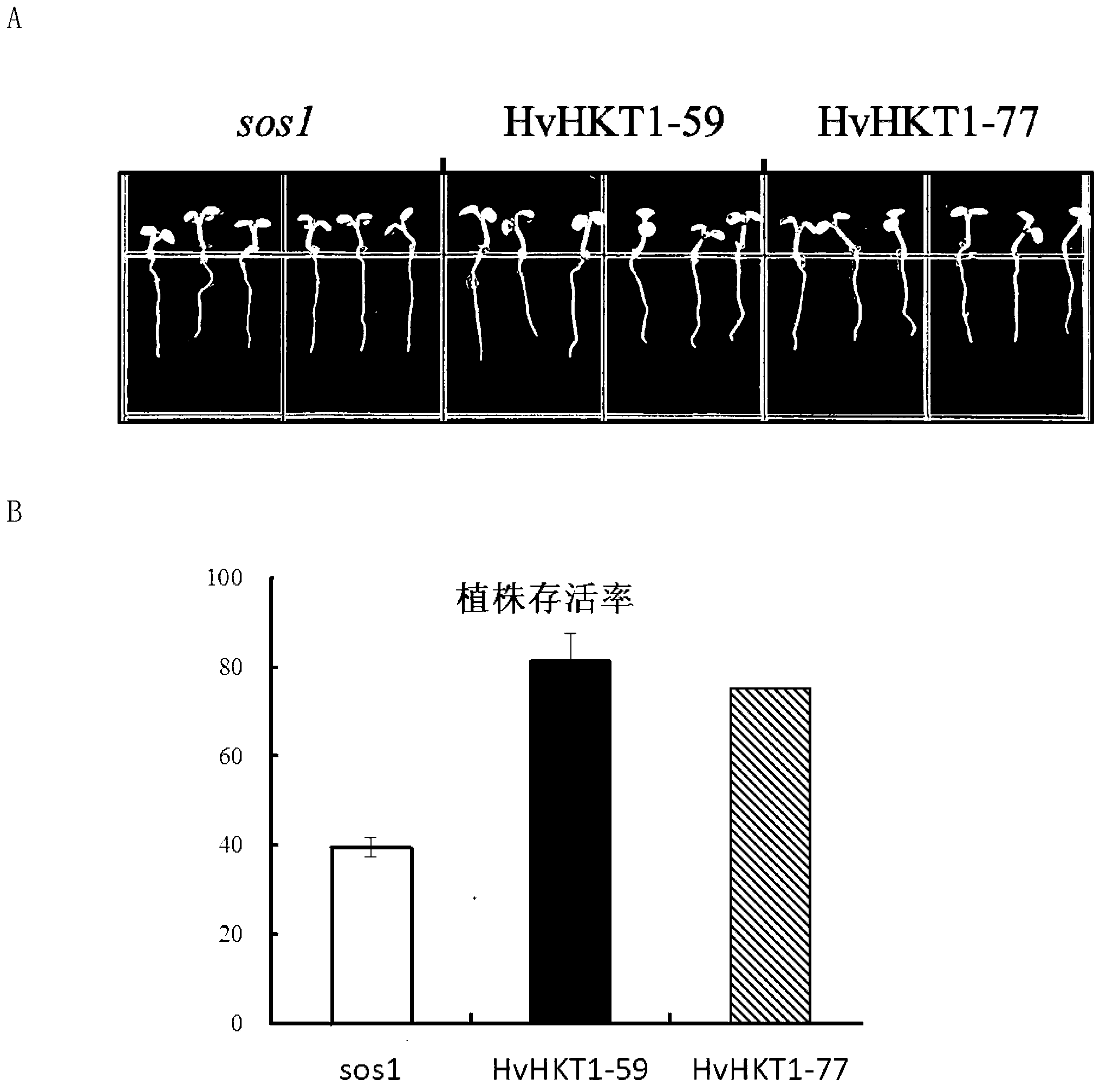

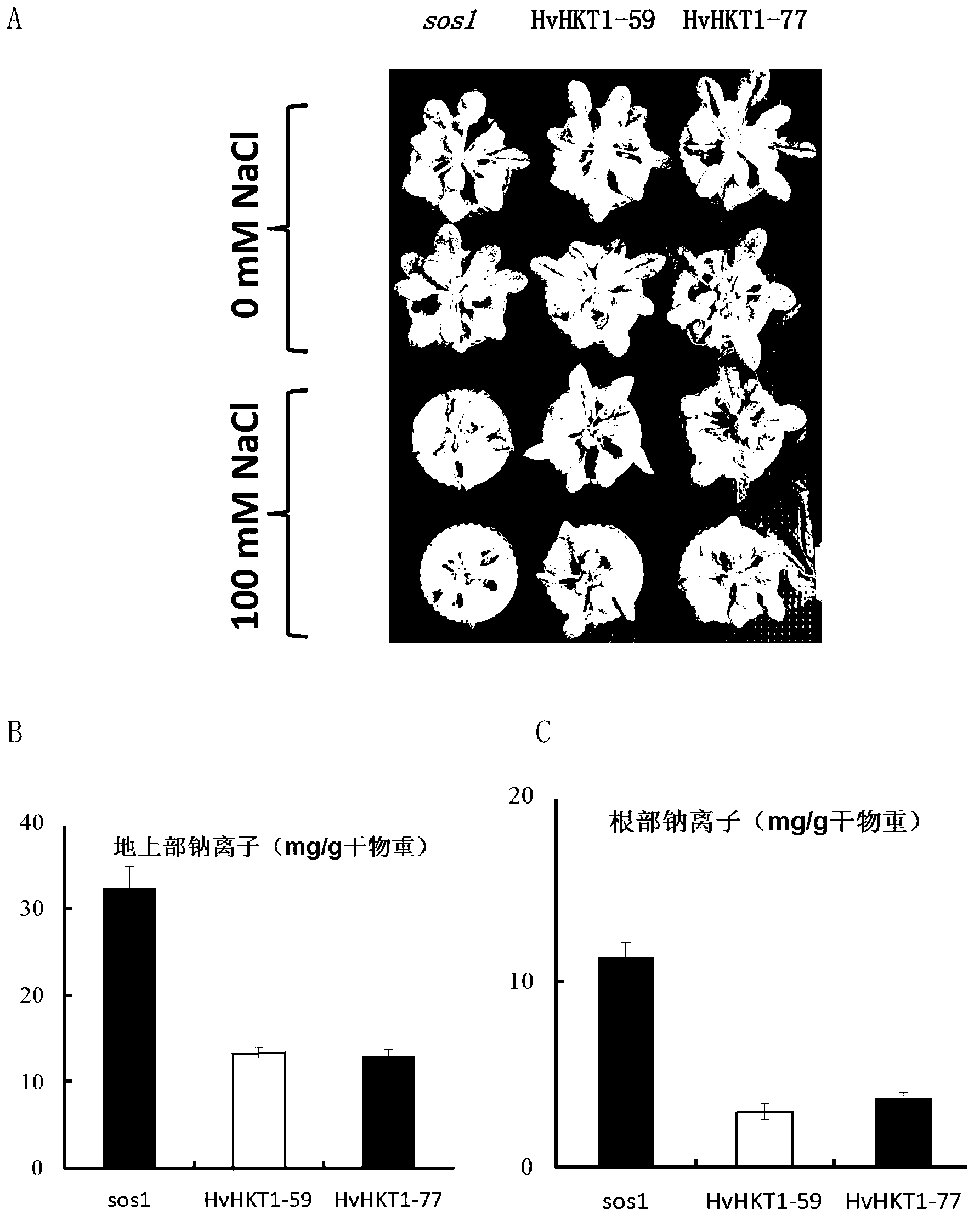

Application of barley HvHKT1gene

InactiveCN103275977AImprove utilizationGuaranteed normal growthVector-based foreign material introductionAngiosperms/flowering plantsGenomicsHalotolerance

The invention relates to plant function genomics, in particular to the application of a barley HvHKTI gene in building transgenic plants, wherein after the separation and cloning of a HvHKT1gene coding sequence (coding sequence), the coding sequence is connected with a promotor of a mosaic virus of a cauliflower, and then arabidopsis is converted; and finally evaluation is conducted for salt endurance of the transgenic arabidopsis and the wild type Arabidopsis. According to the invention, the salt endurance of the transgenic plants is improved, and the barley HvHKT1 gene has a nucleotide sequence shown by SEQ ID NO:1.

Owner:ZHEJIANG UNIV

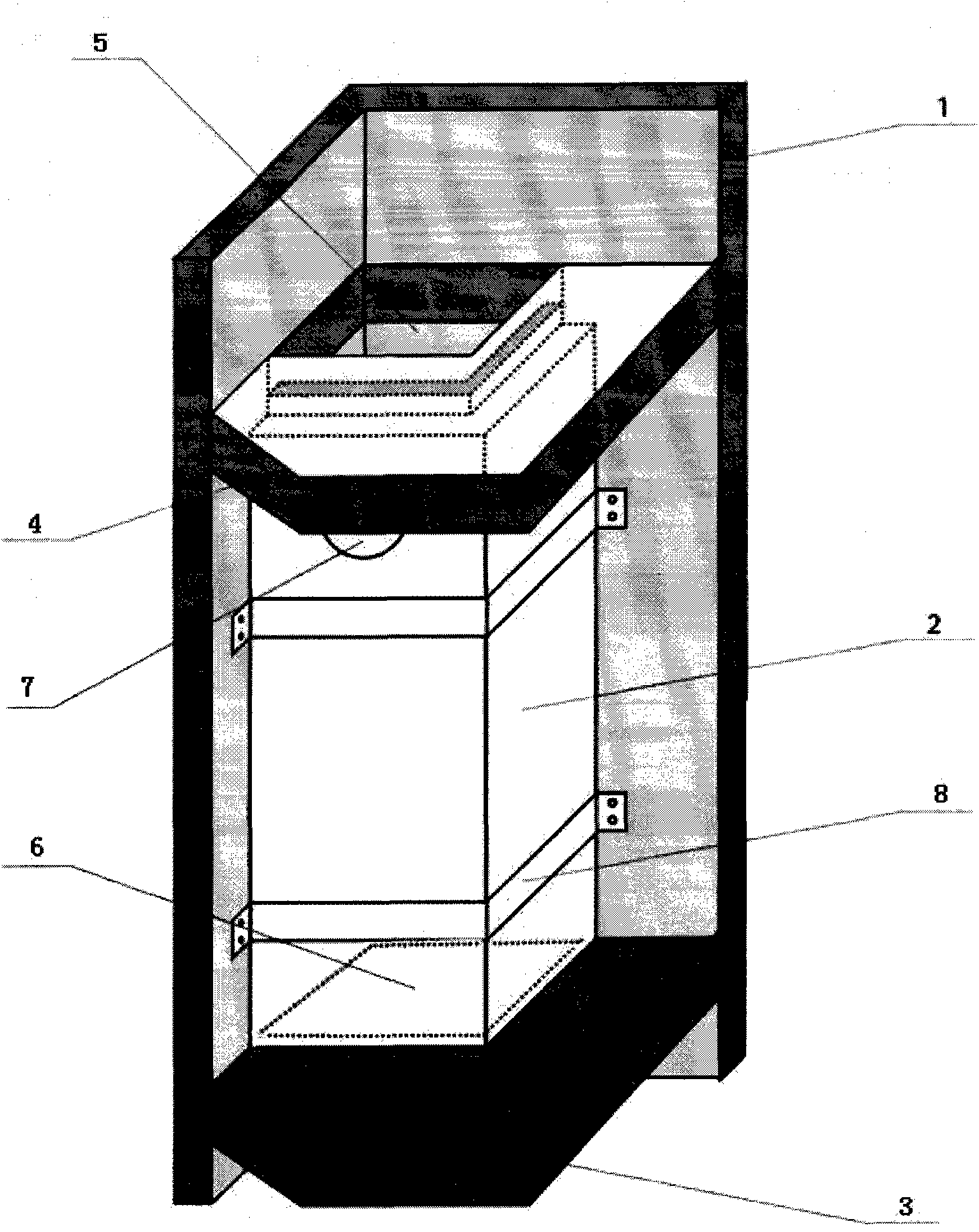

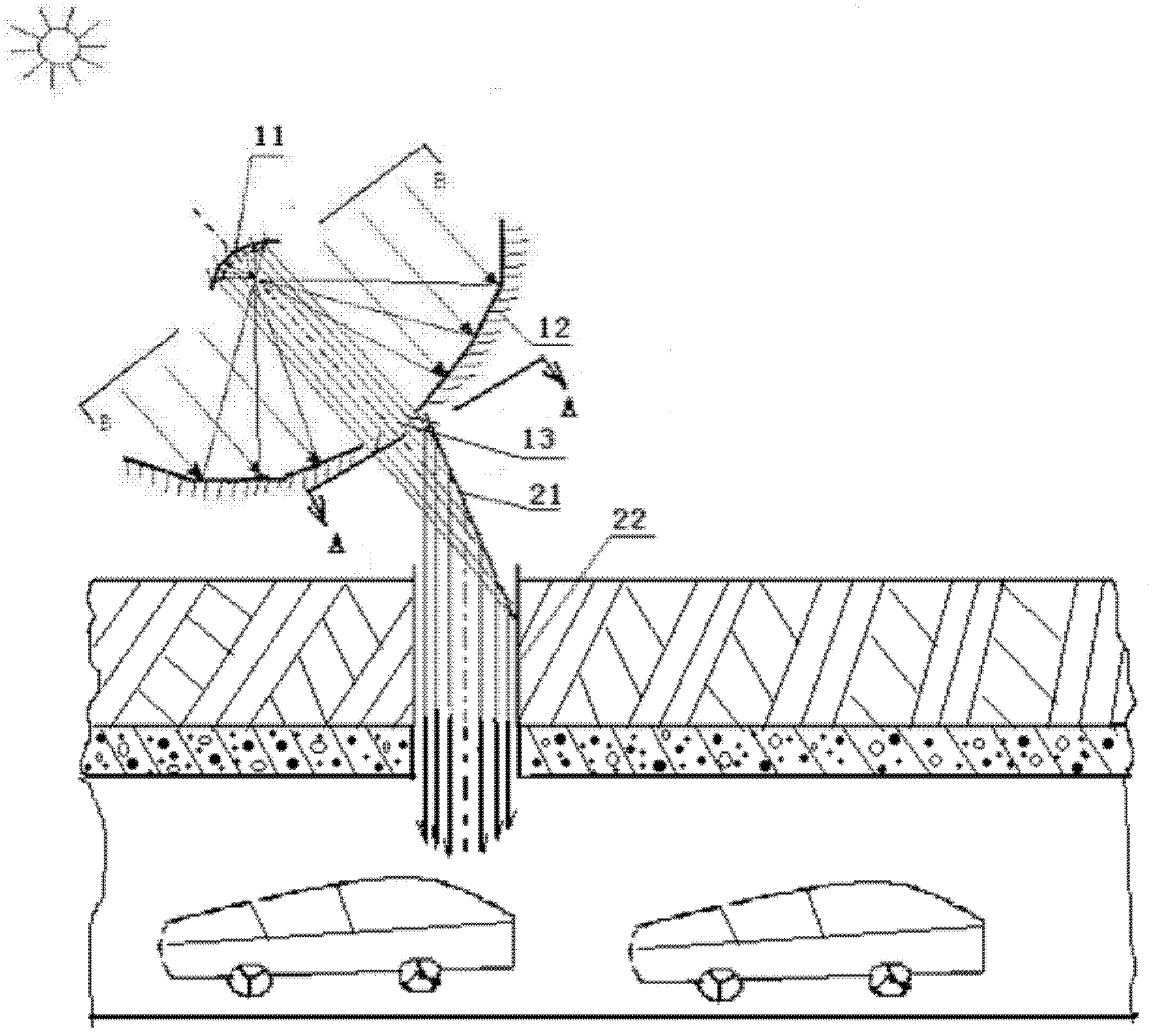

Sunlight transmission device for illuminating underground building

InactiveCN102635832AHigh Efficiency Direct LightingHigh strengthLight fasteningsReflectorsFiberTransmission illumination

The invention discloses a sunlight transmission device for illuminating an underground building, and the sunlight transmission device comprises a folding surface type collecting mirror and a parabolic cylinder curved surface dimming mirror which are fixedly connected with an optical axis, wherein the folding surface type collecting mirror and the parabolic cylinder curved surface dimming mirror are provided with the same focal point and are respectively located at two sides of the focal point; the folding surface type collecting mirror faces to the sun; and parallel sunlights reflected by the parabolic cylinder curved surface dimming mirror are reflected to a light transmitting barrel at the top of the underground building through a curved surface light-guiding mirror. Compared with the condition that the existing illumination of an underground garage is directly carried out by a light collecting barrel, the brightness of the sunlight collected by a light collecting system is obviously enhanced; and the sunlight transmission device directly realizes the transmission illumination by a reflection manner so that the cost is greatly reduced compared with the optical fiber transmission illumination.

Owner:NANJING FUGAN LIGHTING TECH

Organic material quantitatively recommending fertilization method for preventing and treating non-point source pollution of vegetable fields

ActiveCN108353599AObvious applicabilityObvious practicalityFertilising methodsLivestock manurePotassium

The invention discloses an organic material quantitatively recommending fertilization method for preventing and treating non-point source pollution of vegetable fields; based on the standard that theamount of nitrogen or phosphorus brought in by organic fertilizers is 40%-70% of the recommended amount of total nitrogen or total phosphorus, the recommended total amount of nitrogen, phosphorus andpotassium of organic and inorganic nutrients minuses the amount of nitrogen, phosphorus and potassium brought in by the organic materials is the recommended fertilization amount of nitrogen, phosphorus and potassium of inorganic fertilizers is obtained. The amount of nitrogen or phosphorus brought in by the organic materials such as livestock manure fermented organic fertilizers, commercial organic fertilizers or composted fertilizers used in production of protected-cultivation vegetables is taken as the index of the quantitatively recommended fertilization amount of the organic materials; with a method of 'control of the total amount of organic and inorganic nutrients, balanced distributed application of organic and inorganic nutrients and precise quantitative control of chemical fertilizers', the technology of reduction of organic materials of the protected-cultivation vegetables and chemical fertilizer precise application is formed, the total amount of recommended fertilization is determined according to the crop target yield, nutrient absorbing capacity, soil fertility status and irrigation mode, and the amount of topdressing nitrogen, phosphorus and potassium, the topdressingperiod and the distribution ratio of nitrogen, phosphorus and potassium nutrients are determined according to the maximum absorption period of nitrogen, phosphorus and potassium nutrient of crops.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT HEBEI ACADEMY OF AGRI & FORESTRY SCI

Different bead changeable conveying device

PendingCN110117879AEasy to match for color changeObvious practicalityAutomatic machinesAuxillary devicesEngineeringColor changes

Owner:ZHUJI GUANXIANG MACHINERY TECH CO LTD

Antibacterial collagen-based medical material and preparation method thereof

InactiveCN113274541AImprove mechanical propertiesImprove resistance to degradationSurgical adhesivesPharmaceutical delivery mechanismCyclodextrinBiocompatibility

The invention relates to an antibacterial collagen-based medical material and a preparation method thereof, and belongs to the field of biomedical materials. According to the antibacterial collagen-based medical material, beta-cyclodextrin is used as a raw material, and an aldehyde group derivative of beta-cyclodextrin and a plant essential oil antibacterial agent are simultaneously applied to crosslinking modification of a collagen-based material. The preparation method can improve the structural stability of materials; and on the other hand, the loaded plant essential oil antibacterial agent can endow the material with a good and lasting antibacterial function, and the preparation method is a novel preparation method of the antibacterial collagen-based medical material. The collagen-based medical material has good degradability, mechanical property and biocompatibility, further has a lasting antibacterial function, and has important clinical application value.

Owner:SICHUAN UNIV

Method and system for analyzing fluid potential of fractured-vuggy reservoir

PendingCN114429085AVarious storage spacesStrong reservoir heterogeneityDesign optimisation/simulationCAD numerical modellingAnalytic modelWell drilling

The invention discloses a method for analyzing the fluid potential of a fractured-vuggy reservoir, which comprises the following steps of: carving a target fractured-vuggy unit, determining a geometrical shape model of the target fractured-vuggy unit, and obtaining a geological model of the target fractured-vuggy unit on the basis of the geometrical shape model in combination with drilling and logging data for the fractured-vuggy unit; based on the geologic model, according to the current carving result and historical yield data of the target fracture-cavity unit, a numerical simulation technology is used for fitting the development and production history of the target fracture-cavity unit, and an initial distribution model, including an oil reservoir pressure field, an oil saturation field and a fluid velocity field, of the target fracture-cavity unit is established; according to the initial distribution model, fluid potential energy at all positions in the model is counted, and a fluid potential energy distribution model of the target fracture-cavity unit is obtained. The invention provides a fluid potential analysis model and characterization for fracture-vug type oil reservoir development, and provides a theoretical basis for a regulation and control technology for balanced exploitation of fracture-vug type oil reservoirs.

Owner:CHINA PETROLEUM & CHEM CORP +1

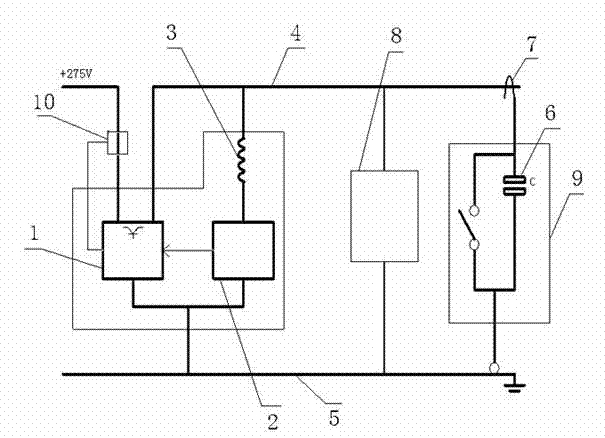

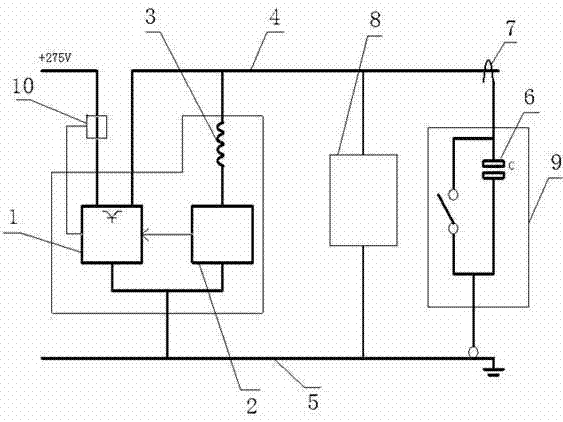

Subsection intelligent controller for underground electric locomotive string

InactiveCN102385325AReasonable layout designImprove the level of intrinsic safetyProgramme control in sequence/logic controllersCapacitanceEngineering

The invention relates to a subsection intelligent controller for an underground electric locomotive string, which belongs to the technical field of controller structures and comprises a control switch. The input end of the control switch is connected with a power supply, a Hall current transformer is arranged between the power supply and the control switch, the control switch comprises a digital logic circuit and a transistor IGBT, the output end of the IGBT is connected with the string, a gate pole of the IGBT is connected with the output end of an oscillator and a rail connected with the ground, the output end of the oscillator is connected with an inductor which is connected with the string, a capacitor is installed in a locomotive on the rail, and the capacitor is connected with the string through an electric arc. The subsection intelligent controller is reasonable in circuit design and capable of shrinking string electrification range as much as possible, shortens string electrification time and greatly reduces accident incidence.

Owner:NUCLEAR IND YANTAI TONCIN IND GRP CO LTD

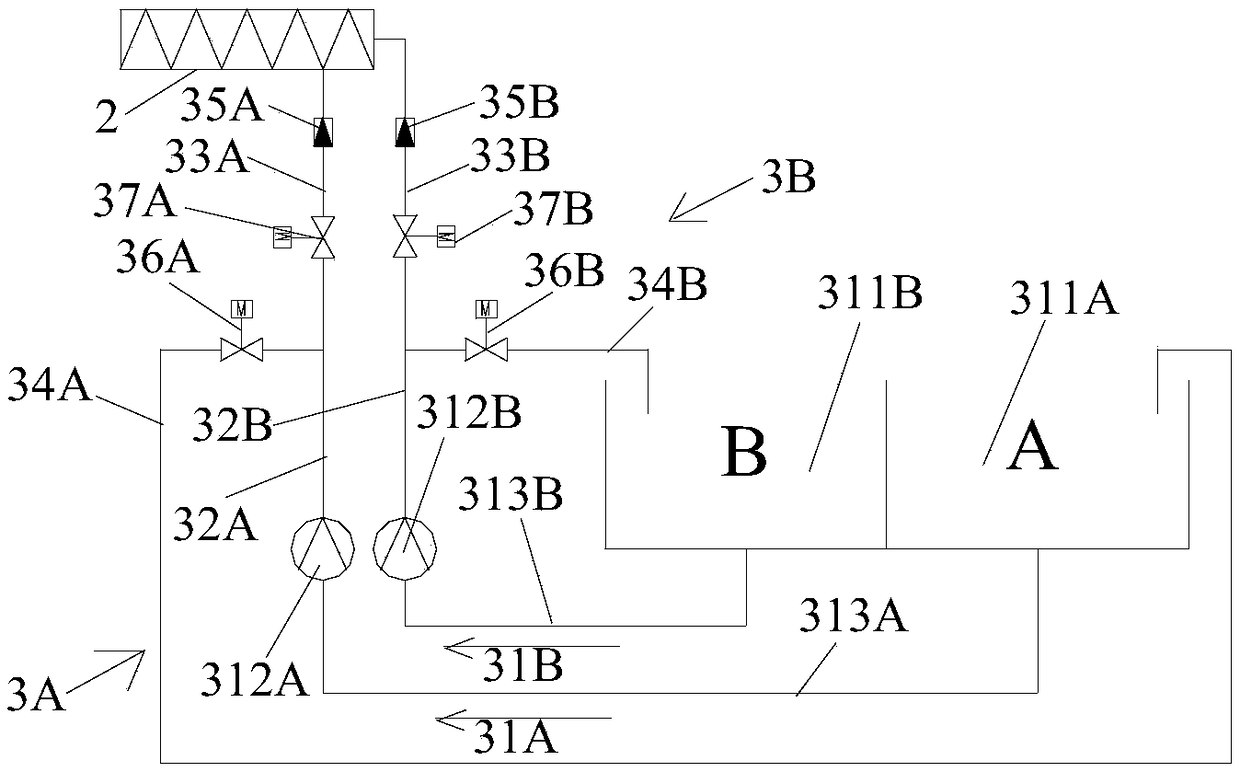

Method for high-precision on-line proportional mixing of plurality of liquids

ActiveCN108201798AStable outputMeet online high-precision mixing requirementsControlling ratio of multiple fluid flowsTransportation and packagingRefluxFlow ratio

The invention discloses a method for high-precision on-line proportional mixing of a plurality of liquids. With the method provided by the invention, a reflux bypass is additionally arranged at the tail end of a conveying main pipeline in each liquid output unit; a reflux proportion adjusting valve is arranged on each reflux bypss; a liquid flowmeter is arranged at the tail end of each output pipeline; an output proportion adjusting valve is arranged at the front end of each liquid flowmeter; when conveying of to-be-mixed liquids is started, the reflux proportion adjusting valves in liquid output units are adjusted to maximum opening, and the output proportion adjusting valves are adjusted to preset opening; real-time flow values of liquids are acquired and adjusted by comparing with a preset flow value; when the real-time flow values of the liquids are adjusted to a preset flow range, the real-time flow ratio of the to-be-mixed liquids is calculated according to a predetermined mixingtarget and adjusted again by comparing with a predetermined mixing proportion value; thus, on-line high-precision mixing of a plurality of liquids is realized, and extensive application range is achieved.

Owner:SHANGHAI GRAMAN INT FIRE EQUIP

Reinforced prefabricated direct-buried insulation pipe

InactiveCN108386625AExtended service lifeGuaranteed uptimeThermal insulationPipeline systemsPipe fittingElectric heating

The invention discloses a reinforced prefabricated direct-buried insulation pipe. The reinforced prefabricated direct-buried insulation pipe is characterized in that all injecting holes, exhaust holes, detecting holes and the like on a PE outer protecting pipe and an electric heating melting sleeve are provided with reinforced sealing modules; all welding lines of the PE outer protecting pipe areprovided with welding line reinforcing belts; a steel pipe fitting of an insulation pipe fitting and the PE outer protecting pipe are thicker than a steel pipe of a corresponding insulation straight pipe and the PE outer protecting pipe; the foam density of the insulation pipe fitting is larger than the foam density of the insulation straight pipe; an insulation joint adopts multiple reinforced sealing measures; a rigid waterproof end seal is added at a well chamber pipe end; and a sealing branch pipe is arranged in an alarm wire leadout point. According to an equal-life optimal design principle, the pipe network maintenance frequency is reduced, and the service life is prolonged; and the direct-buried insulation pipe with a conveying medium exceeding 120 DEG C or provided with a leakage detecting alarm system is particularly adapted to.

Owner:齐慧

Near-net forming manufacturing process for hundred-ton special-shaped section ring forge piece

PendingCN113182470ASave raw materialsIncrease productivityForging/hammering/pressing machinesMetal rollingTemperingManufacturing technology

The invention discloses a near-net forming manufacturing process for a hundred-ton special-shaped section ring forge piece. The near-net forming manufacturing process comprises the following steps that (1) free forging cogging is conducted, specifically, after a raw material steel ingot is put into a furnace to be heated and subjected to heat preservation, the steel ingot is placed on a workbench of an oil press to be machined through a forging process, and then a cylindrical blank is manufactured; oil press mold forming; after cogging, carrying out fire heat treatment; rolling and forming by a ring rolling mill; performing positive and tempering heat treatment after the rolling; performing rough turning; performing nondestructive testing; quenching and tempering heat treatment, specifically, carrying out performance heat treatment on the forge piece; sampling detection, specifically, performing body sampling and mechanical property detection on the forge piece subjected to the performance heat treatment; conducting finish turning; and packaging and warehousing finished products. According to the near-net forming manufacturing process, the material utilization rate can be increased by about 15%, and the production cost is greatly reduced.

Owner:SHANDONG IRAETA HEAVY IND

Large field of view scanning system

InactiveCN108303179ASimple structureReduce assembly requirementsSpectrum investigationSolar atmospherePlane mirror

The invention relates to a large field of view scanning system which comprises a solar optical telescope, a field of view scanning device, a rotary drive mechanism, a grating spectrometer, a CCD camera and a computer. The grating spectrometer is provided with a slit part, a collimating mirror and a grating part. The field of view scanning device comprises two parallel plane mirrors. The rotary drive mechanism is used for driving two plane mirrors to rotate synchronously. The solar optical telescope is used for collecting light beams emitted by a solar atmospheric moving target, and the collected light beams are sequentially reflected by two plane mirrors and then enter the slit part. The light beams come into the collimating mirror through the slit part, and the collimated light beam comeinto the grating part. The CCD camera is used to collect the light beams re-come into the collimating mirror and convert the light beams into an electrical signal. The computer is used to form corresponding spectral information according to the electrical signal. According to the large field of view scanning system provided by the invention, the field of view scanning device adopts the field of view scanning mode of double plane mirrors; the structure of the optical system is simplified; and the installation requirements of the optical system are reduced.

Owner:SANMING UNIV

Device and process for cyclically absorbing and producing balm

ActiveCN108130187AEfficient Contact Absorption ProcessIncrease productivityEssential-oils/perfumesEngineeringHigh pressure

The invention discloses a device and a process for cyclically absorbing and producing balm, and belongs to the fields of essence, perfume and cosmetic industry. The device particularly comprises a charge valve, a discharge valve, a constant-temperature storage tank, a ball valve, a high-pressure pump, a pressure regulating valve, an absorption tower, a high-pressure spray head, a coiled pipe cooler, an automatic drain valve, a circulating fan, an air heater and a drying chamber. The device is provided with grease circulating and air current circulating systems; the contact absorption area, toa fragrance, of grease is greatly increased; the efficient contact absorption of the balm is realized; the effect is good; the efficiency is high; the problems and defects that a conventional static fragrance releasing method has a long time period and low in efficiency and a fragrant flower is possibly rotten, and the like, are solved and overcome; a dried flower releasing the fragrance still hasa purpose and a commodity attribute; the comprehensive benefit is good; the device provided by the invention is easy to manufacture; the procedure of the production process is easily controlled; thelarge-scale production is easily realized, and the device has obvious practicability and economical efficiency.

Owner:KUNMING UNIV OF SCI & TECH

Carnosine-enriched animal protein powder and preparation method thereof

InactiveCN110419618AImprove nutritional efficacyEfficient use ofAnimal proteins working-upProtein composition from waste materialsFiltrationHydrolysis

The invention discloses carnosine-enriched animal protein powder and a preparation method thereof. The carnosine-enriched animal protein powder is animal protein powder of which the carnosine contentis 5-7wt% and which is from leftover materials produced after processing of animal meat products. The preparation method comprises the steps of performing grinding, performing first-class film filtration, performing hydrolysis, performing second-class film filtration, performing bioconversion, performing biosynthesis and performing drying. The leftover materials produced after processing of animalmeat products are used as raw materials, so that the carnosine-enriched animal protein powder of which the carnosine content is as high as 5-7wt% is directly prepared, effective utilization of wasteresources is realized, the nutrient efficacy of the animal protein powder can be improved, the carnosine-enriched animal protein powder is low in cost, and large-scale production is easy to realize.

Owner:李猷

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com