Combined exhaust passage independently installed in layered mode

A layered, independent and combined technology, applied in the direction of vertical pipes, building components, buildings, etc., can solve the problems of exhaust ducts hanging and falling, having no practical value, and occupying space, so as to facilitate maintenance or replacement, save raw materials, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

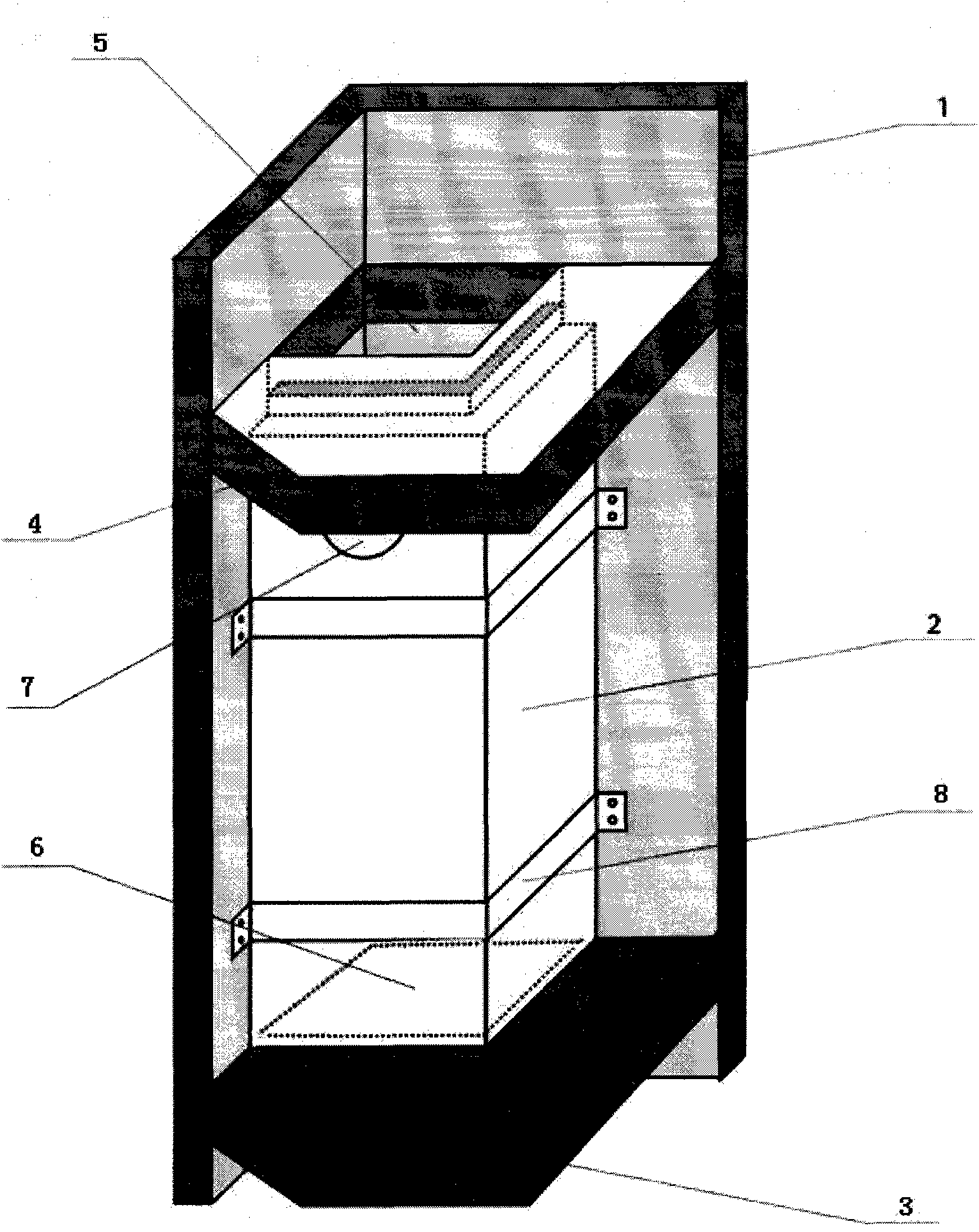

[0012] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

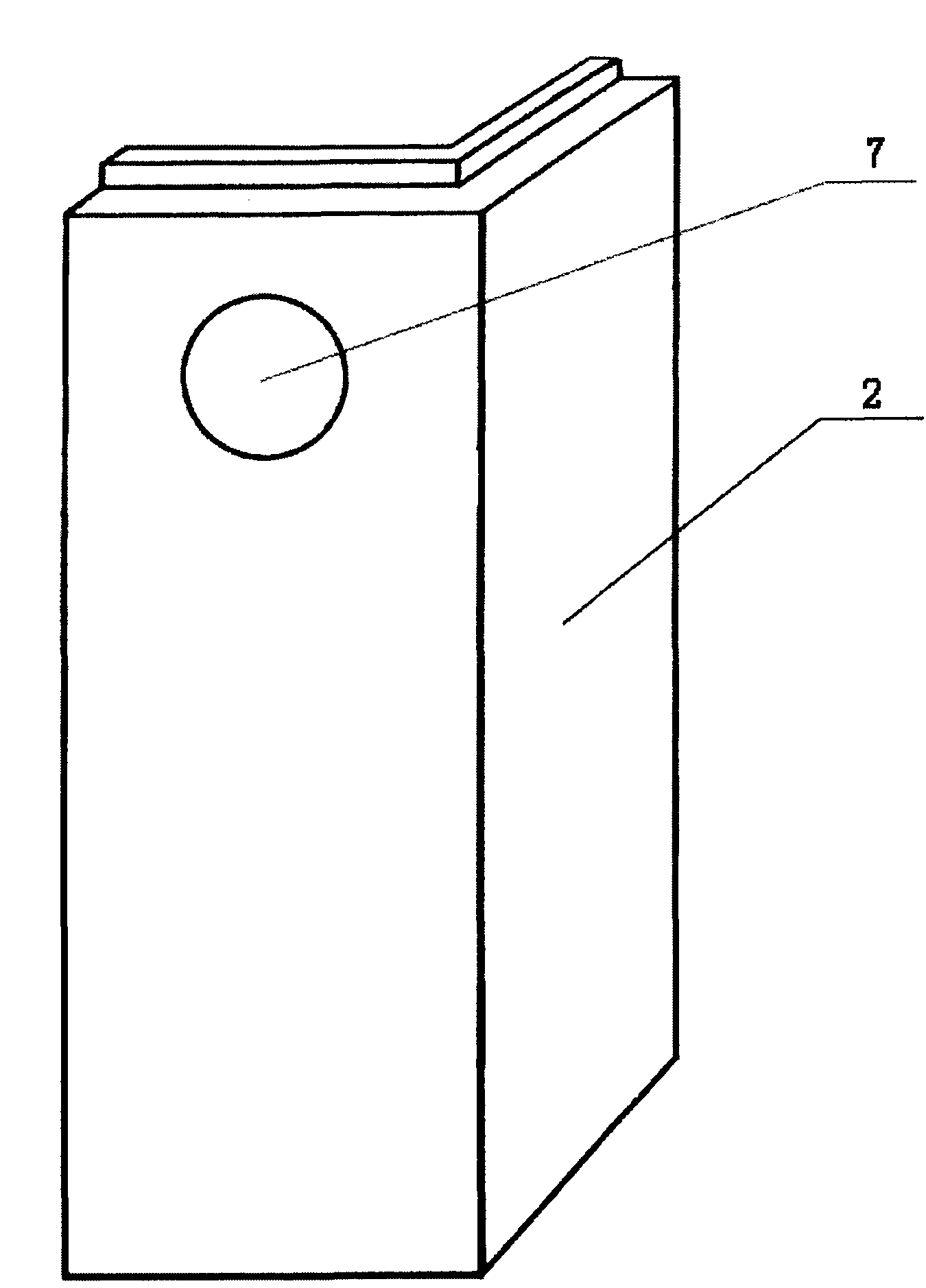

[0013] Refer to attached figure 1 , figure 2 , image 3 It can be seen that a combined exhaust duct installed independently in layers consists of a vertical wall 1, a right-angle strip plate 2, a lower floor 3, an upper floor 4, an upper reserved installation opening 5, a lower reserved installation opening 6, and a row Composed of air holes 7 and fixed metal hoops 8; it is characterized in that: the combined exhaust duct is formed by the vertical wall 1 on both sides of the vertical corner of the room and the right-angle strip plate 2, and the upper end of the right-angle strip plate 2 is The step interpolation structure, the step interpolation part is inserted into the reserved installation opening 5 on the upper floor 4, the width of the two vertical sides of the right-angle strip plate 2 is respectively larger than the corresponding aperture side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com