Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

403results about How to "Not sticky" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

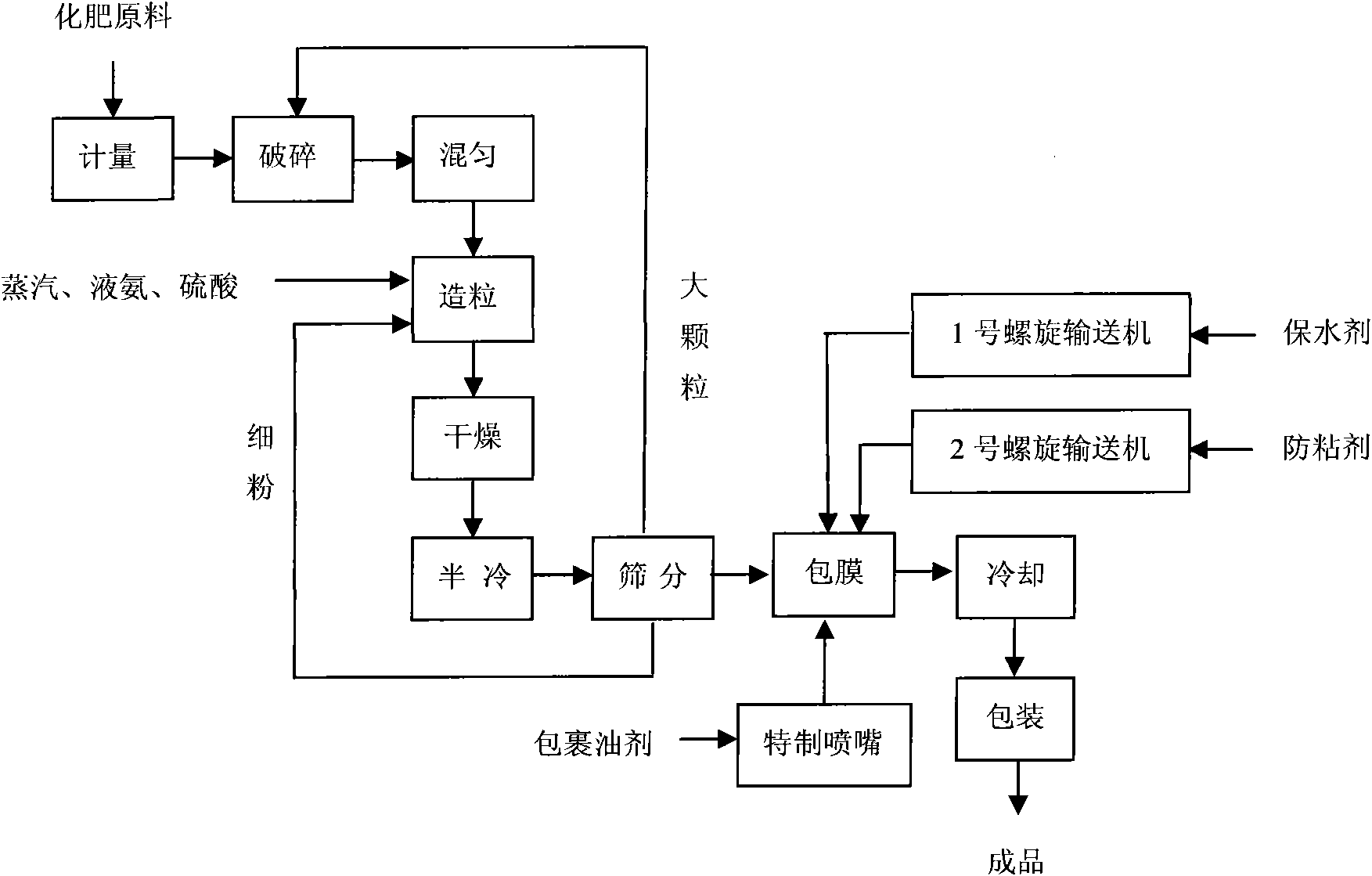

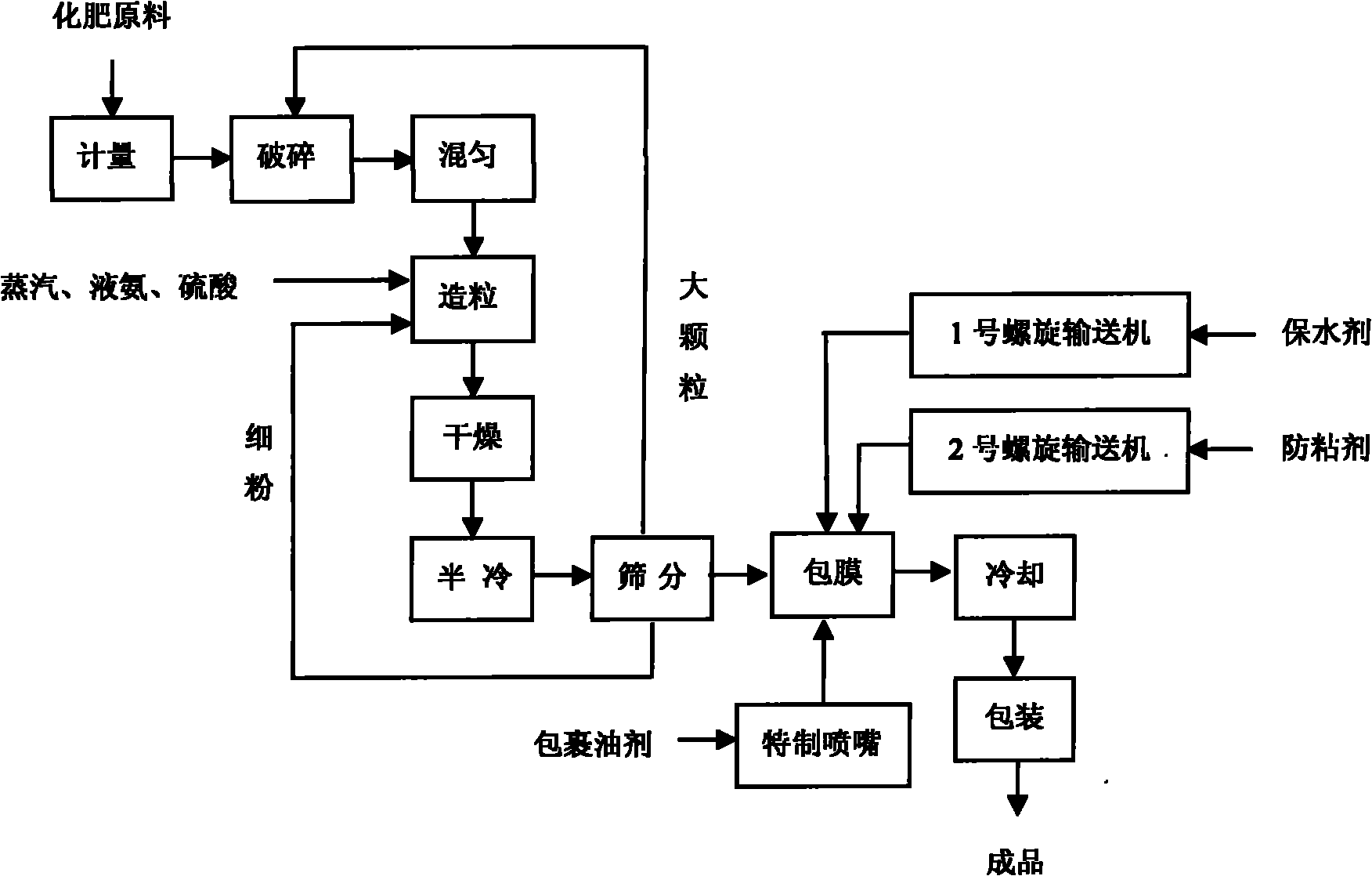

Color drought-resistance water-retention sustained-release compound fertilizer and method for producing same

ActiveCN101792354ASimple production methodHigh ball rateFertiliser formsFertilizer mixturesFilm coatingNutrient

The invention discloses a color drought-resistance water-retention sustained-release compound fertilizer and a method for producing the same, wherein the method comprises the followings steps of: measuring, crushing and uniformly mixing fertilizer raw materials, granulating by adopting an ammonia-acid method rotary drum granulating process, performing one-stage drying, semi-cooling and screening of grains, and sending the mixture to a coating machine; adopting a continuous melting rotary drum film-coating method coating process to perform compressed air atomization and uniform coating of color coating oil sprayed by a special nozzle; and adding a water-retaining agent and an anti-adhesive agent by a screw conveyor, and performing full stirring, cooling and packaging to obtain the finishedproducts. The color drought-resistance water-retention sustained-release compound fertilizer has the effects of drought resistance, water retention, nutrient preservation, soil condition improvement and environmental protection, and the appearance of the fertilizer has color marks; and when the fertilizer is applied to crops, the fertilizer has the advantages of increasing yield and incoming, along with simple production method, convenient operation, low cost and high benefits.

Owner:CNSG ANHUI HONG SIFANG FERTILIZER IND CO LTD

Method for processing composite fiber material spiral stirrup

The invention discloses a method for processing composite fiber material spiral stirrup. The method comprises the following steps of: gumming, premolding, semi-solidifying and drying, molding spiral stirrup, sizing and drying, and cutting and packaging. In the multiturn continuous closed-type composite material spiral stirrup of the invention, the continuous spiral composite material stirrup replaces the single-ring composite material stirrup, so that the spiral stirrup can save materials and man-hours in the same member, resists corrosion, and can also improve the bearing capacity of a girder or a column under the condition of constant section and equal spacing; the tensile strength of the composite material stirrup is three times that of steel bar; the weight is only one-fourth that of the steel bar; and the composite material stirrup has the advantages of no magnetism, water resistance, freeze resistance, strong chemical corrosive resistance and the like; and due to the adoption of a process for molding the composite fiber material spiral stirrup, the disadvantage that a conventional composite material is difficult to bend into the stirrups with different shapes after solidification and sizing is overcome, and the shape of the composite material steel bar can be changed so as to manufacture the spiral stirrup according to the requirements of people.

Owner:沈锋

Environment-friendly thermoplastic polyurethane (TPU) film and preparation method thereof

The invention discloses an environment-friendly thermoplastic polyurethane (TPU) film. The environment-friendly TPU film comprises TPU particles, propene polymer (PP) particles, a compatilizer, a PP functional masterbatch and a TPU color masterbatch. The preparation method of the environment-friendly TPU film comprises the following steps: (1) weighing the components based on the formula and mixing uniformly; (2) drying the uniformly mixed components in step (1) in a dehumidification dryer for 3-5h at 80-90 DEG C, and feeding the components into a casting machine through a feeding system, and extruding; (3) and embossing the surface of the TPU film subjected to tape casting in step (2). The prepared TPU film is high in thermal stability and tearing strength, is unlikely to be sticky at high temperature, and is improved in processing performance and low in production cost. The strength (particularly tearing strength) of products produced by the TPU film is improved.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

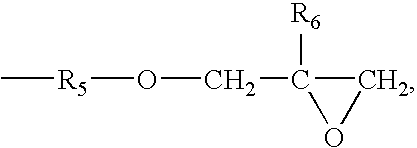

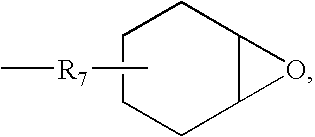

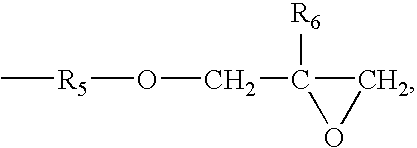

Acroleic acid modified polysiloxane resin and coating thereof

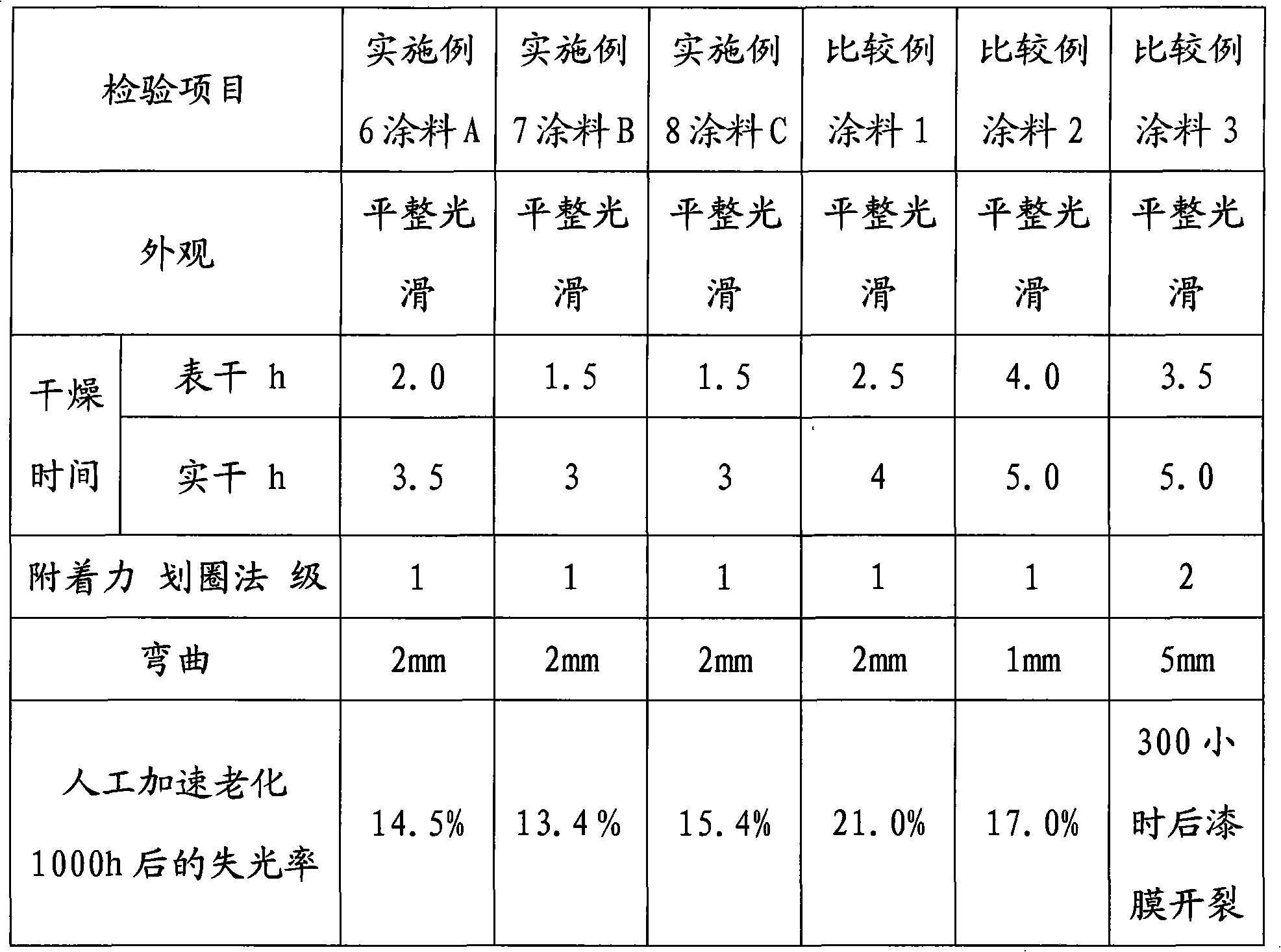

The invention relates to an acrylic modified polysiloxane resin and paint thereof. The acrylic modified polysiloxane resin is a compound resin of an acrylic resin with glycidyl and siloxane prepolymer with the number average molecular weight between 400 and 3,000. On the basis of counting solids, in the compound resin, the weight ratio of the acrylic resin with glycidyl and the siloxane prepolymer is between 10 and 40 to between 60 and 90. The paint containing the acrylic modified polysiloxane resin has a component A and a component B, wherein the weight ratio of the dosages of acrylic modified polysiloxane resin, pigment, filler, solvent and additives of the component A is 100:10-60:5-40:5-20:1-2; the component B is amino alkoxy silane as a curing agent; and when the coating is in use, the component A and the component B are well mixed in the weight ratio of 10 to between 0.8 and 1.5. Compared with the prior acrylic modified polysiloxane coating, the coating is fast in drying rate and excellent in weatherability.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Composite micropowder and method for manufacturing the same, ceramic paint, and protection coating

ActiveCN103849092ANot stickySimple stepsPaints with free metalsThin material handlingSilanesFluoropolymer

Disclosed is a method of forming a composite micropowder, including mixing 100 parts by weight of fluorine-containing polymer, 10 to 140 parts by weight of silane, catalyst, and water, such that the silane is in-situ polymerized in the fluorine-containing polymer to form a polysiloxane, and the fluorine-containing polymer and the polysiloxane form a composite. The composite is dried, and then physically crushed to form composite micropowder. The total weight of the fluorine-containing polymer and the silane and the weight of the catalyst have a ratio of 100:0.1 to 100:0.0001. The silane and the water have a molar ratio of 1:0.5 to 1:3. The composite micropowder has a diameter of 0.1 [mu]m to 15 [mu]m. The fluorine-containing polymer and the polysiloxane in the composite micropowder have a weight ratio of 95:5 to 60:40. The composite micropowder has excellent non-sticky property, manufactured in a simple way, safe, environmentally-friendly and low in cost.

Owner:GRAND TEK ADVANCE MATERIAL SCI

Novel interlayer fine dried noodles and processing method thereof

InactiveCN105380103AHas a clear fragranceNot stickyFood coatingFood ingredient as mouthfeel improving agentOff-flavourInsect pest

The invention discloses novel interlayer fine dried noodles, comprising upper flour slices and lower flour slices, as well as sweet potato or solanum tuberdsm flour slices pressed between the upper flour slices and the lower flour slices. The cooked interlayer sweet potato fine dried noodles are slightly white in surface color and internal red and external white in section, have unique fresh scent of the sweet potato, and are not pasty, not thick in soup, not sticky in taste, not gritty, are soft and tasty and refreshing, a cooking noodle break ratio is smaller than or equal to 5%, the irregularity is smaller than or equal to 15%, wherein, the natural noodle break ratio is smaller than or equal to 8%, physicochemical indexes of the fine dried noodles have a water content being smaller than or equal to 13.5%, acidity being smaller than or equal to 4.0, and a bending noodle break ratio being smaller than or equal to 15%; hygienic indexes achieve no impurity, no mildewing, no extraneous odor, no insect attack and no pollution, and raw materials and auxiliaries accord with national standards.

Owner:李少卫

Pumpkin and buckwheat vermicelli processing technology

InactiveCN103385419ABeautiful colorHas a clear fragranceDough treatmentFood preparationPolygonum fagopyrumPhysical health

The invention belongs to the food processing industry, and especially relates to a pumpkin and buckwheat vermicelli processing technology. Raw materials of pumpkin and buckwheat vermicelli comprise, by weight, 69 parts of wheat flour, 22 parts of mashed pumpkin, 8.3 parts of buckwheat flour, 0.5 parts of an egg and 0.2 parts of salt. The pumpkin and buckwheat vermicelli processing technology comprises the steps of raw and auxiliary material selection, raw and auxiliary material pretreatment, kneading, slaking, composite calendering, strip cutting, drying, cut-out and packaging. The pumpkin and buckwheat vermicelli has the characteristics of beautiful color, no sour or salty taste, no other peculiar smells, delicate fragrances of pumpkins and buckwheat, no stickiness after boiling, no turbid soup, non-sticky mouthfeel, no gritty feeling, soft and tasty mouthfeel, and convenient eating, and has certain efficacies to the health of human bodies after frequent eating.

Owner:辽宁振隆特产股份有限公司

Formulation and preparation method of polishing abrasive tools prepared by glass fiber leftover material

The present invention discloses one kind of polishing tool of glass fiber leftover and its material recipe and making process. The recipe consists of glass fiber 20-50 wt%, abrasive 20-50 wt%, and phenolic resin 10-30 wt%. The making process includes the following steps: screening glass fiber leftover to eliminate impurity, mixing abrasive and partial phenolic resin, mixing the mixed abrasive and partial phenolic resin with the rest phenolic resin mechanically to form agglomerate, weighing and pressing to form inside some mold, cooling and demolding, cutting and trimming. The polishing tool of waste glass fiber may be used in polishing field with oil stain and water stain and may result in unforeseen effect.

Owner:郭晓明

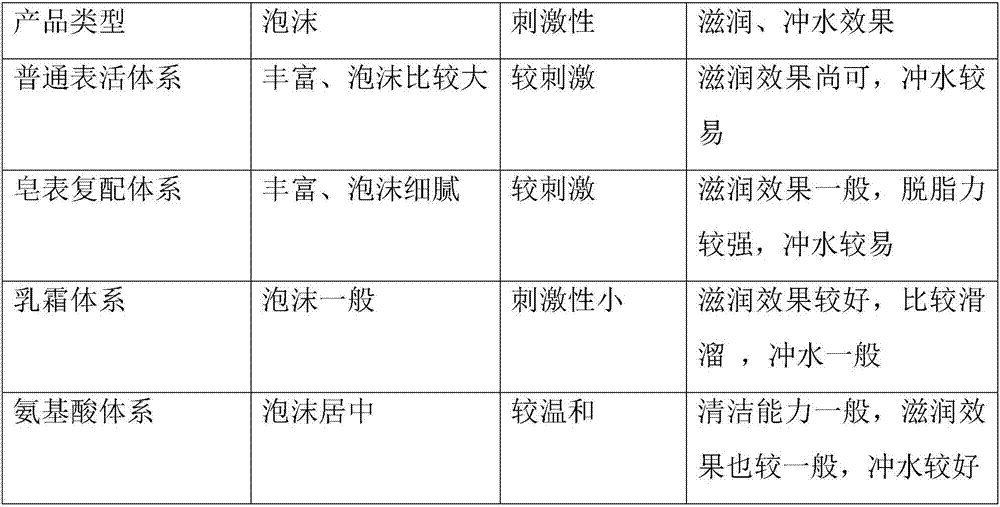

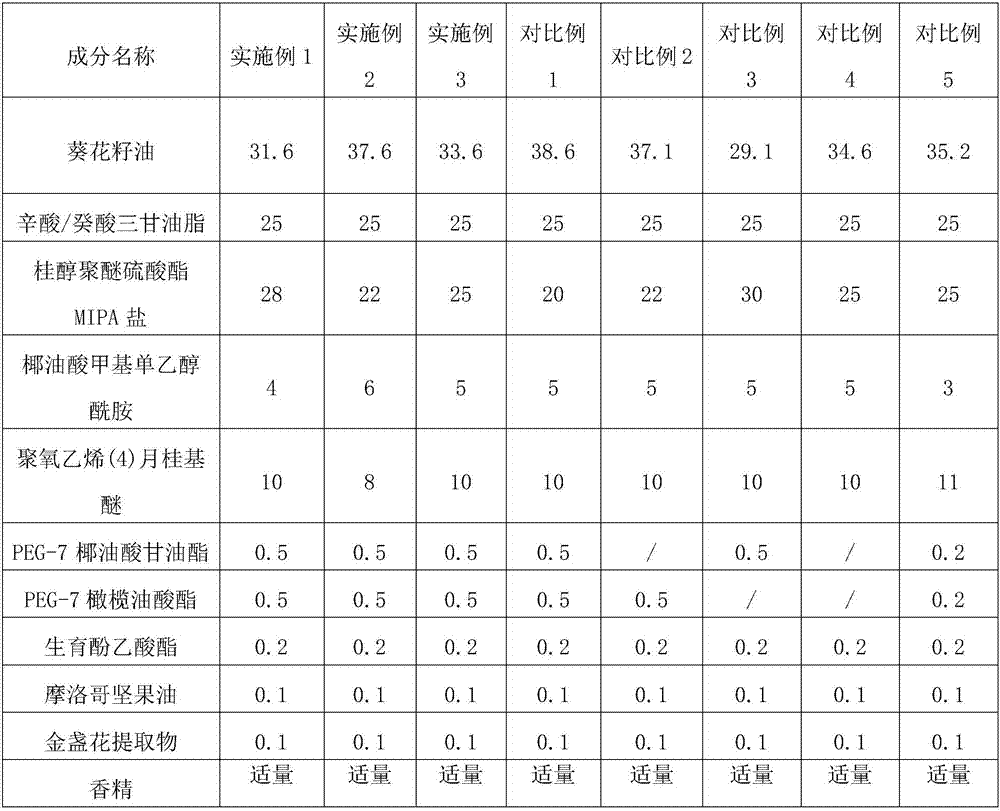

Two-in-one nourishing and moisturizing bath composition

InactiveCN107536748ANot stickyGood moisturizing effectCosmetic preparationsToilet preparationsCuticleAdditive ingredient

The invention discloses a two-in-one nourishing and moisturizing bath composition, which comprises the following ingredients (by weight): 40-70% of an oily component, 15-40% of a surfactant, 1-10% ofan emollient, 0.01-5% of a nutritional component and 0.01-5% of a stabilizer. The composition of the invention is mild, has low level of irritation, has good foam, is nourishing and moisturizing, is moisturizing and soft during bathing, and will not have sticky feeling. Through reasonable matching of selected natural oil, MIPA-laureth sulfate and lauryl polyoxyethylene (4), bathing sticky feelingof an oily bath product is improved. The selected sunflower seed oil and caprylic / capric triglyceride have nourishing and moisturizing, antioxidation and skin repairing and barrier functions. Througha reasonable proportion of the emollient, irritation caused by anionic and nonionic surfactants used in the product is greatly reduced. A hydrophilic film is formed on the epidermis, thus greatly raising skin barrier function. With the protective film while cleaning and through lots of oil, the skin is provided with a nourishing and soft feeling.

Owner:OPAL COSMETICS HUIZHOU

Extraction and separation method of anthocyanin

ActiveCN110643196AImprove drying methodOvercoming inefficiencyOrganic chemistryNatural dyesProcess engineeringFruit juice

The invention discloses an extraction and separation method of anthocyanin, and belongs to the technical field of natural pigment extraction and separation. According to the method, the drying mode isimproved, the anthocyanin in pomace is extracted with a deep-crystal eutectic solvent by combining microwave extraction and ultrasonic assistance, the effective and systematic anthocyanin extraction,separation and purification process is established, and the defects of low efficiency, residual organic solvent in product and low safety of the traditional natural anthocyanin extraction method areovercome; and the new way is provided for high-valued utilization of pomace waste, the pomace is turned into wealth, the by-product treatment burden of fruit juice processing enterprises is relieved,and great economic benefits, social benefits and ecological benefits are achieved.

Owner:JINAN UNIVERSITY

Mixture for improving quality of rice noodles, preparation method and application thereof

The invention discloses a mixture for improving the quality of rice noodles, a preparation method and an application thereof. Proportioning according to parts by weight, the mixture comprises a formula of the following raw materials: 1-10 parts of potato esterification crosslinked starch, 0.1-5 parts of soybean polysaccharide and 0.1-5 parts of other additives, wherein the potato esterification crosslinked starch, the soybean polysaccharide and other additives are all in an edible grade; other additives comprise one or more than one of carageenan, sodium alginate, single-glycerin ester, potatostarch and cassava starch. The preparation method comprises the following steps: weighing the potato esterification crosslinked starch, the soybean polysaccharide and other additives according to theformula of the raw materials, directly mixing the potato esterification crosslinked starch, the soybean polysaccharide and other additives evenly and preparing the mixture for improving the quality of the rice noodles. The rice noodles produced by adding the mixture have high transparence, are not easy to stick strips and have better toughness, and the rehydration performance, the mouth feel, thetoughness, the chawing strength, the soup turbidness, the strip breakage and the like of the rice noodles are all improved more obviously.

Owner:SOUTH CHINA UNIV OF TECH +1

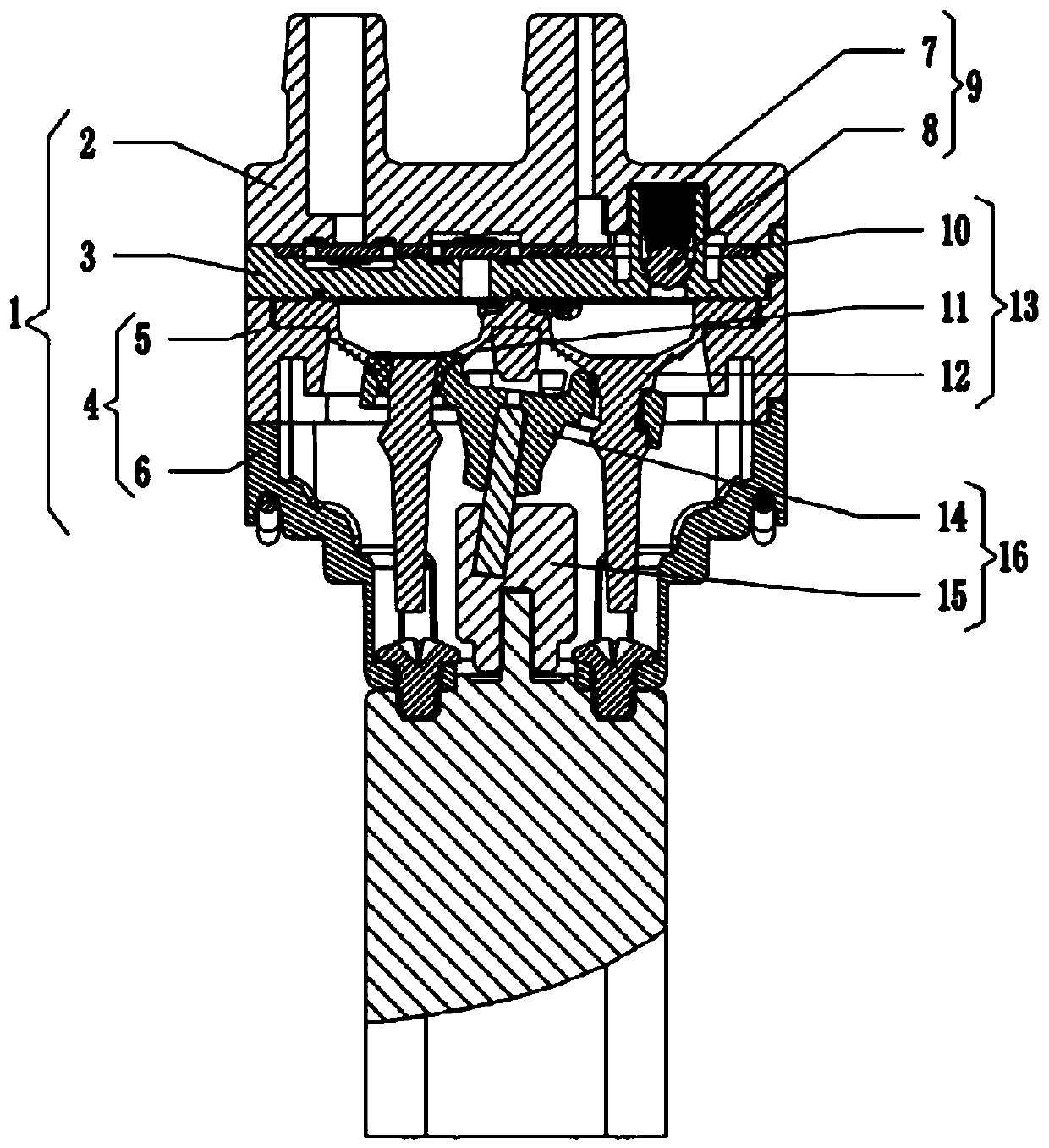

Series diaphragm pump with non-return and anti-seepage functions

ActiveCN110821798AStable jobFailure will not occurPositive displacement pump componentsFlexible member pumpsDiaphragm pumpMechanical engineering

The invention discloses a series diaphragm pump with non-return and anti-leakage functions, and relates to the technical field of diaphragm pumps. The diaphragm pump comprises a shell mechanism, a diaphragm mechanism, a driving mechanism and a non-return mechanism; specifically, the shell mechanism comprises a supporting component, a diaphragm seat and an upper cover, wherein a first accommodatingcavity, a second accommodating cavity and a third accommodating cavity are clamped between the upper cover and the diaphragm seat, and the diaphragm seat is provided with a first channel, a second channel and a third channel; the diaphragm mechanism comprises a diaphragm, and a first movable bag and a second movable bag which are connected in series, wherein the diaphragm is provided with a firstdiaphragm body and a second diaphragm body, the first movable bag comprises a first bag cavity, the second movable bag is provided with a second bag cavity, the first channel and the second channel communicate with the first bog cavity, and the third channel and the third cavity communicate with the second bag cavity; the driving mechanism is used for driving the first movable bag and the secondmovable bag to move up and down in a staggered mode; and the non-return mechanism is used for preventing external solution from flowing back to the second bag cavity.

Owner:XIAMEN CONJOIN ELECTRONICS TECH

Artificial stone production system

ActiveCN104385436AWell mixedNot stickyCeramic shaping plantsFeeding arrangmentsAutomatic controlEngineering

The embodiment of the invention discloses an artificial stone production system, comprising a stirring device, a material distributing machine, a vibrating device and a pressurizing device, wherein the stirring device is used for evenly mixing raw materials; the material distributing machine is used for distributing the materials according to artificial stone textures; the vibrating device is used for vibrating the distributed materials; the pressurizing device is used for pressing the vibrated materials to form a green body; the stirring device, the material distributing machine, the vibrating machine and the pressurizing device are sequentially connected with one another through a conveyer. The artificial stone production system is applied to the field of artificial stone production; the productive task can be finished according to presetting; particularly, high-quality and high-fidelity simulation artificial stone can be prepared; automatic control can be achieved; the artificial stone production system has the characteristics of being high in production efficiency and high in product percent of pass.

Owner:贺州市鸿源岗石有限公司

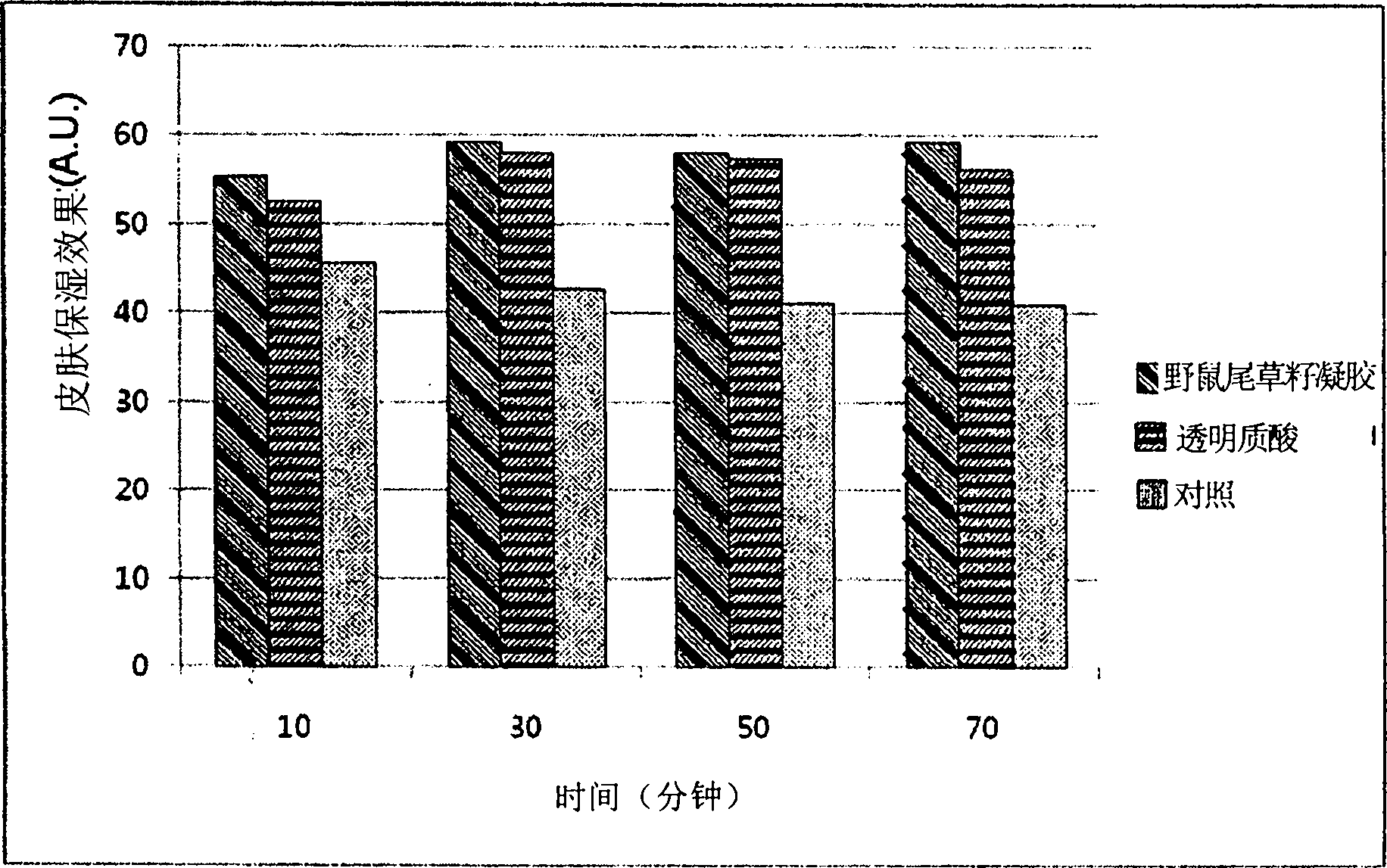

Cosmetic composition for skin moisturizing

InactiveCN102316848AGood moisturizing effectNot stickyCosmetic preparationsToilet preparationsMedicineAdditive ingredient

Owner:AMOREPACIFIC CORP

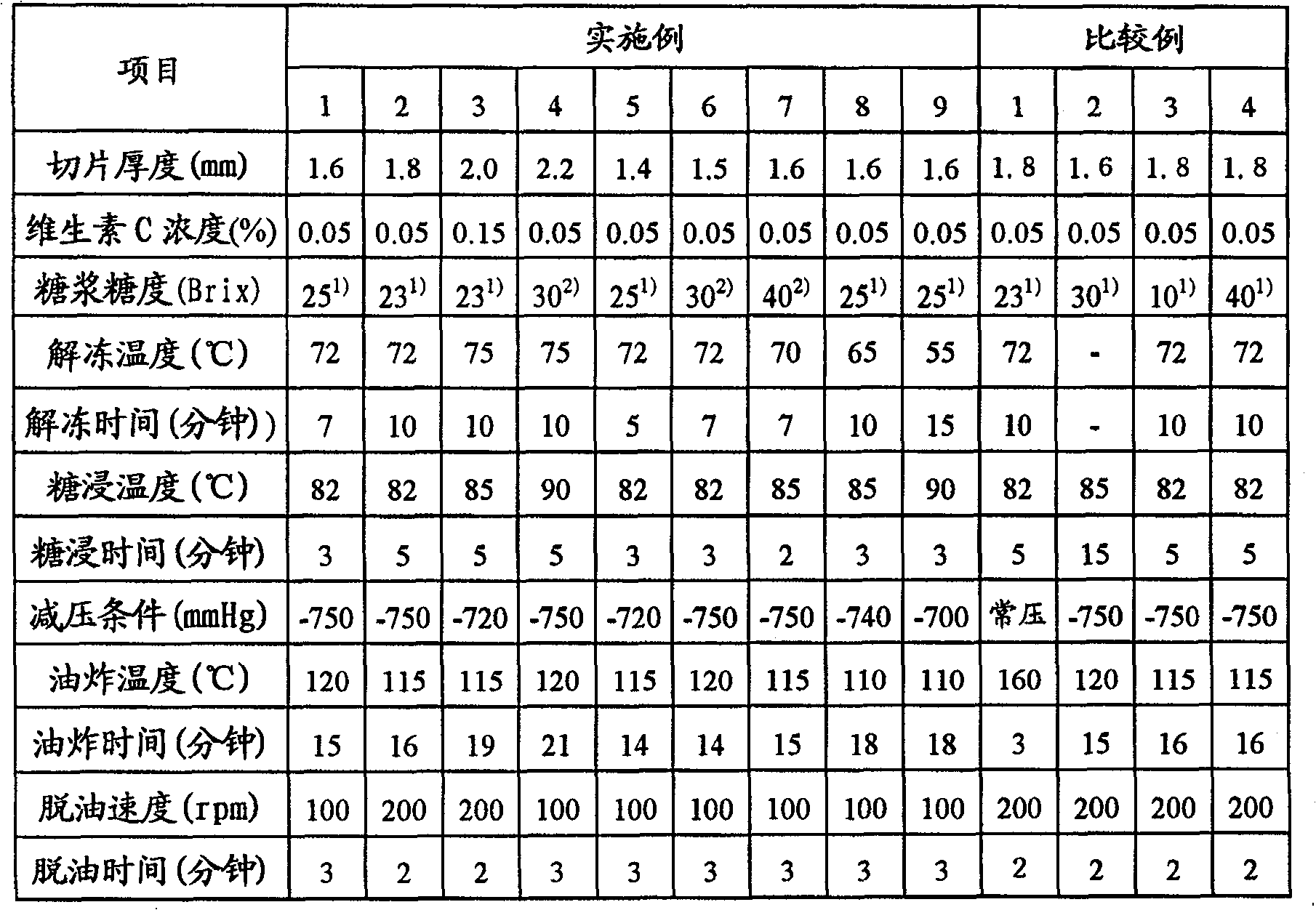

Method of producing fresh sweet potato

PROBLEM TO BE SOLVED: To provide a method for producing improved raw sweet potato chips by a series of continuous steps comprising the quick freezing of sliced raw sweet potato, the immersion in a sugar syrup and the frying in an oil under reduced pressure. SOLUTION: The invention relates to a method for the production of raw sweet potato chips, more particularly, to a method for the production of improved raw sweet potato chips keeping, different from conventional sweet potato snack foods, the original state of sweet potato such as the surface appearance and color to give natural feeling even after frying the raw sweet potato, free from the staining of the hand with sugar syrup impregnated in the sweet potato for improving the taste and flavor of the potato, having uniform texture and taste of the product as a whole, having soft and crisp feeling and eatable without additional seasoning and processing. The method comprises the slicing of sweet potato to thin slices, the quick freezing of the slices, the immersion in a sugar syrup to impregnate the sugar not only to the surface layer but also to the inner part of the slice, and the frying under a reduced pressure in a state having high sugar content and water content.

Owner:LOTTE CONFECTIONERY

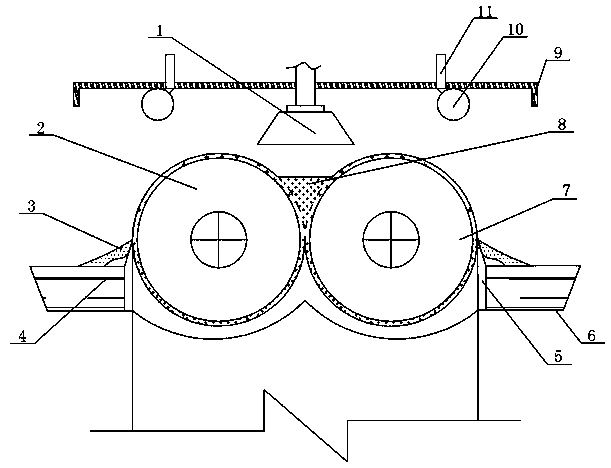

Double-roller dryer

InactiveCN104315829AImprove cooling effectKeep dryDrying solid materialsDrying machinesClassical mechanicsEngineering

The invention relates to the technical field of dryers, in particular to a double-roller dryer. The double-roller dryer comprises a first roller and a second roller, wherein the first roller and the second roller are arranged in parallel and are opposite in rotation direction, a material spraying device is arranged above the first roller and the second roller, a gap smaller than 5 cm is reserved between the first roller and the second roller, and the material spraying device is aligned to the gap. A material bin is arranged on the side opposite to the gap between the first roller and the second roller, a scraping plate is arranged on the material bin, the other end of the scraping plate is in circular contact with the periphery of the first roller and the periphery of the second roller, guide grooves are formed in the positions in contact with the first roller and the second roller, of the scraping plate, and the other end of each guide groove is connected with the inside of the material bin. By means of the technical scheme, the double-roller dryer enables materials to be dried easily and facilitates material discharge.

Owner:CHONGQING TENGHAN IND & TRADE

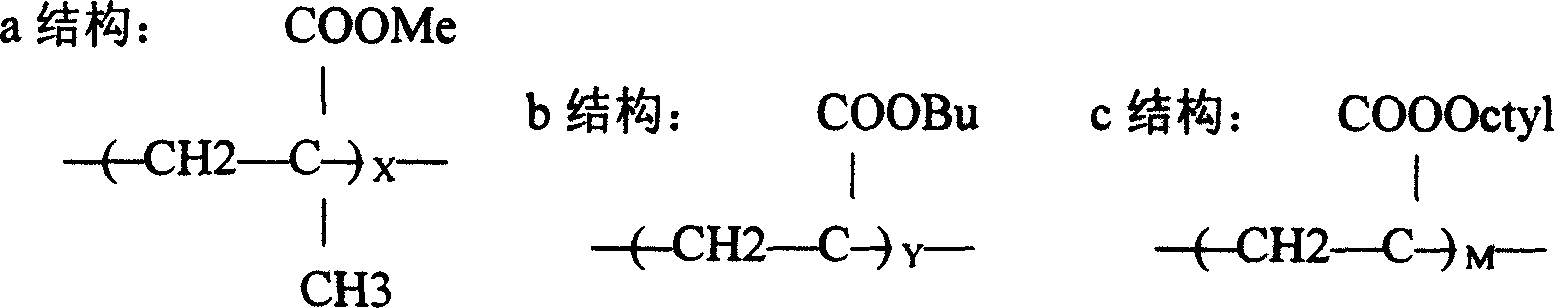

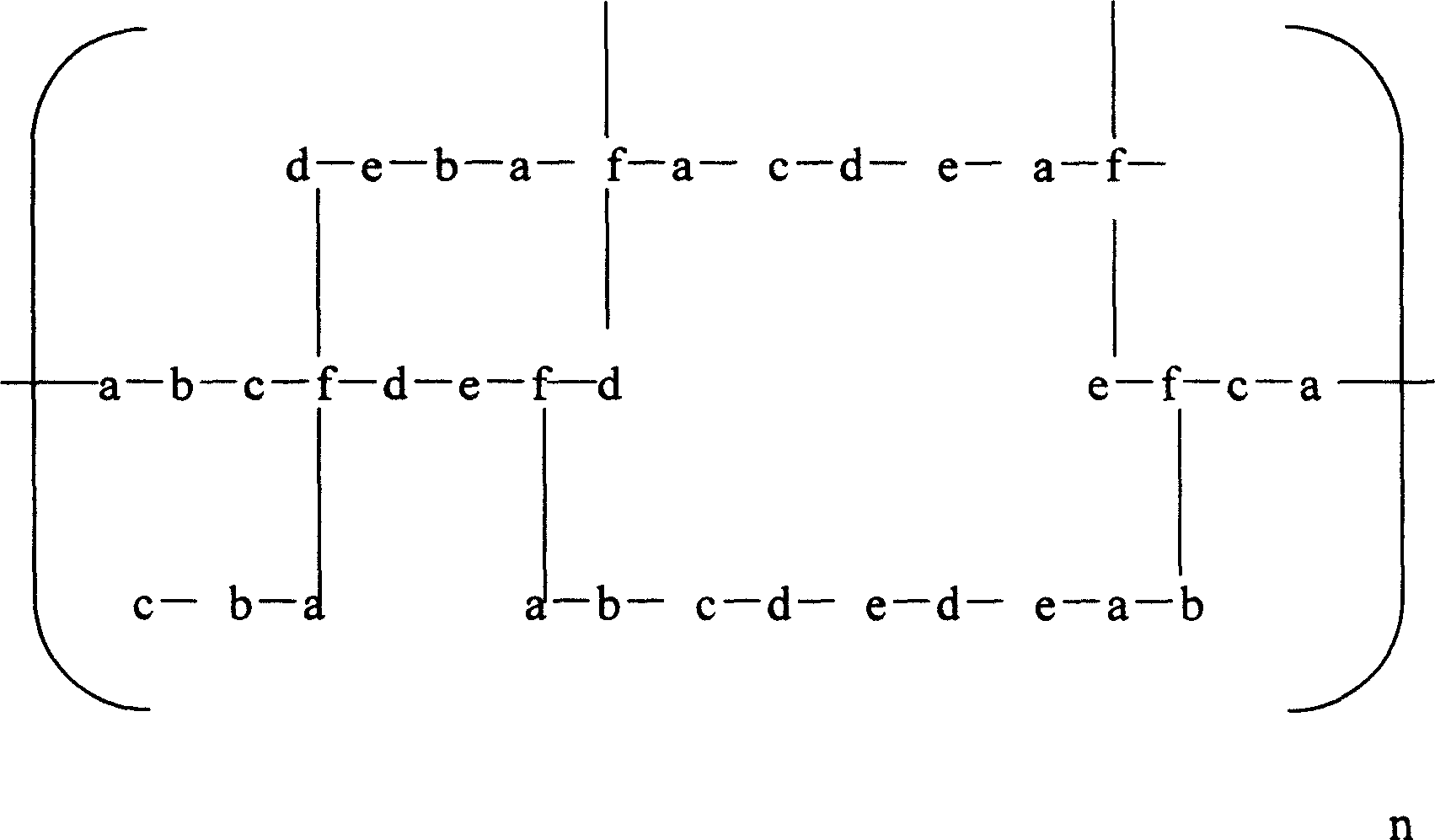

Baking-free no-methanal coating dyeing nano adhesive water-based latex

This invention includes a kind of face baking-free formaldehyde coating dying nanometer adhesive water latex, the adhesive borns from the following steps. The pre-crosslinking monomer, soft monomer, hydrophilic monomer, anion and the non-ion types emulsify complex emulsifying agent and initiator. It is to get together the precrosslinking monomer, soft monomer, hard monomer, water hydrophile monomer , and get close to water get the hybrid body and initiator aqueous solution to join to emulsify to respond, moderate in the distilled waters, filter to make. This latex not only make in simple method, but also print to dye to process the application in the textile product, needing below 100 deg.C to dry but did not need to be baked, the hand feeling is soft, the degree of the wet or dry friction meets the request.

Owner:DONGHUA UNIV

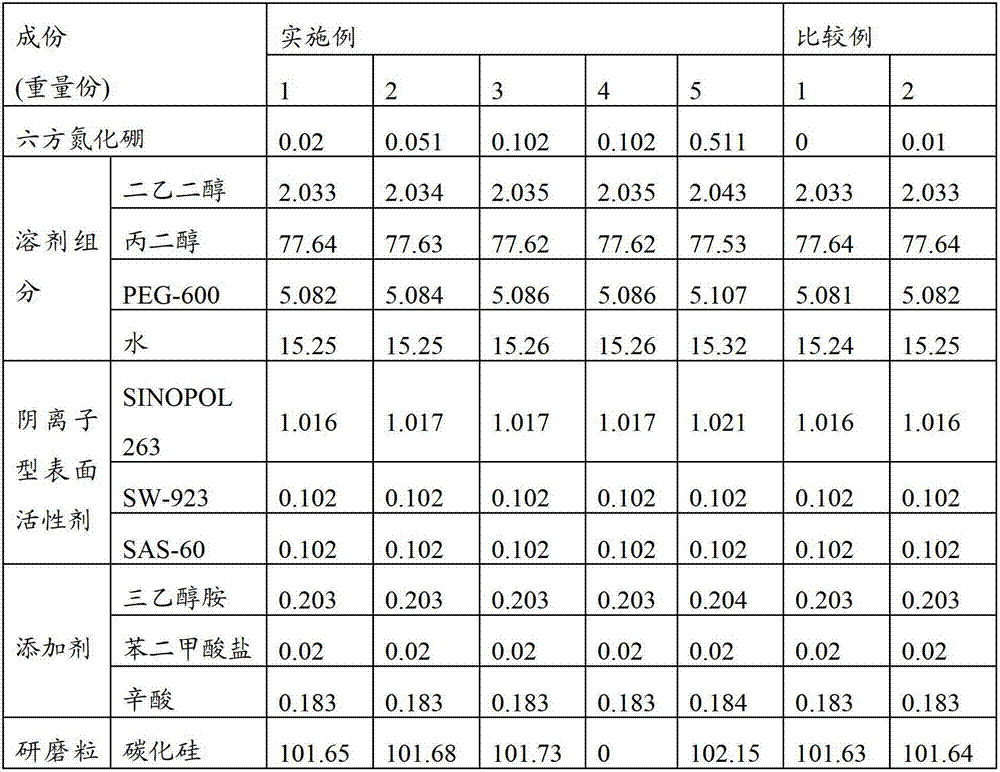

Processing component for cutting hard and brittle materials and cutting component

InactiveCN102787005AEasy to peelNot stickyFine working devicesStone-like material working toolsHexagonal boron nitrideBoron nitride

The invention provides a processing component for cutting hard and brittle materials, comprising hexagonal boron nitrides, solution constituents and surface active agents. The total weight of the solution constituents is 100 part by weight, the content of the hexagonal boron nitrides is 0.01-10 part by weight, but not equal to 0.01 part by weight. When being used for cutting hard and brittle materials, the processing component has the characteristics of high-temperature resistance, good lubricating property, good polishing effect and good cutting capability. When the processing component is cut into a plurality of hard and brittle sheets, the hard and brittle sheets are easy to be separated and uneasy to be bonded. No surface damage of the sheet will occur due to the friction generated by the separation of the hard and brittle sheets, and no breaking of the sheet due to the absorption force generated during cutting will occur. Yield is effectively improved.

Owner:DAXIN MATERIALS

Ultra-thin layered wax film antirust composition for firearm

The fire-arm ultrafine waxed-film anti-rust compound as weapon protective material comprises the wax film-forming material, the PTFE lubricating agent, the oil-soluble inhibitor and organic solvent, can form 2-5mu waxed film rapidly with well lubrication, has no greasiness, drain, and resistance to scratch and wet-heat, fit to shoot with oil and thereby meet the protective requests in exacting terms in desert, jungle and underwater, simplifies maintenance practices for weapon equipment to advance army response speed to burst accident, and can also fit to domestic use.

Owner:ORDNANCE TECH RES INST OF THE GENERAL ARMAMENT DEPT PLA

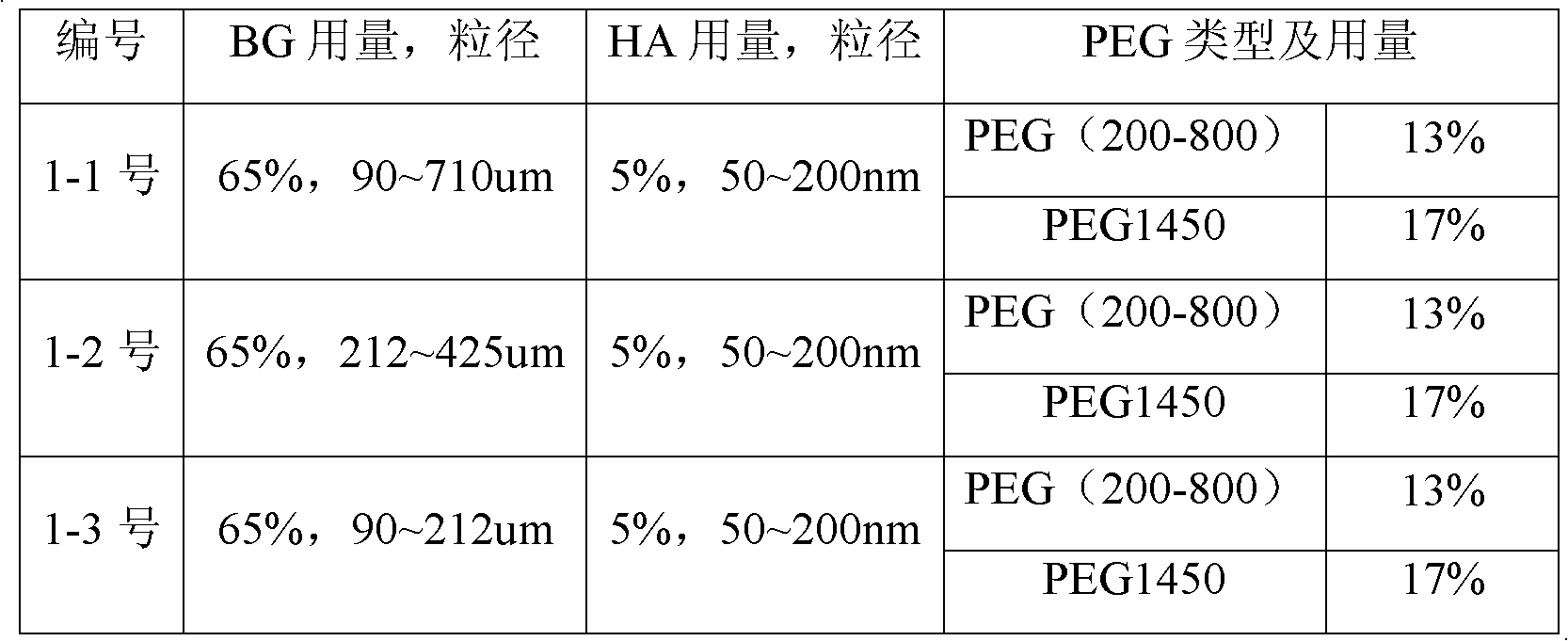

Bone repairing material and preparation method thereof

ActiveCN102488927ATransport without refrigerationReduce the risk of growthProsthesisPolyethylene glycolBiocompatibility Testing

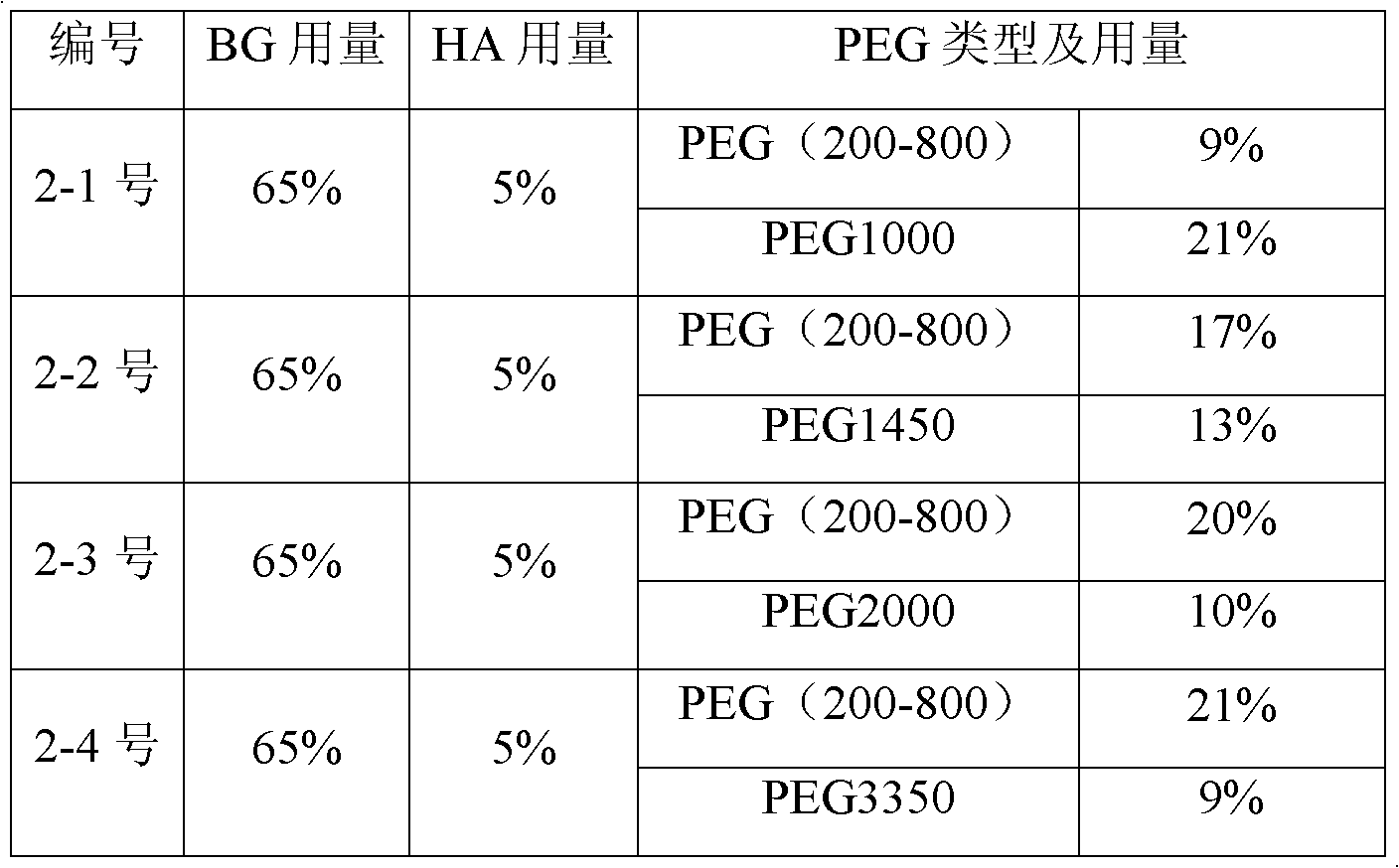

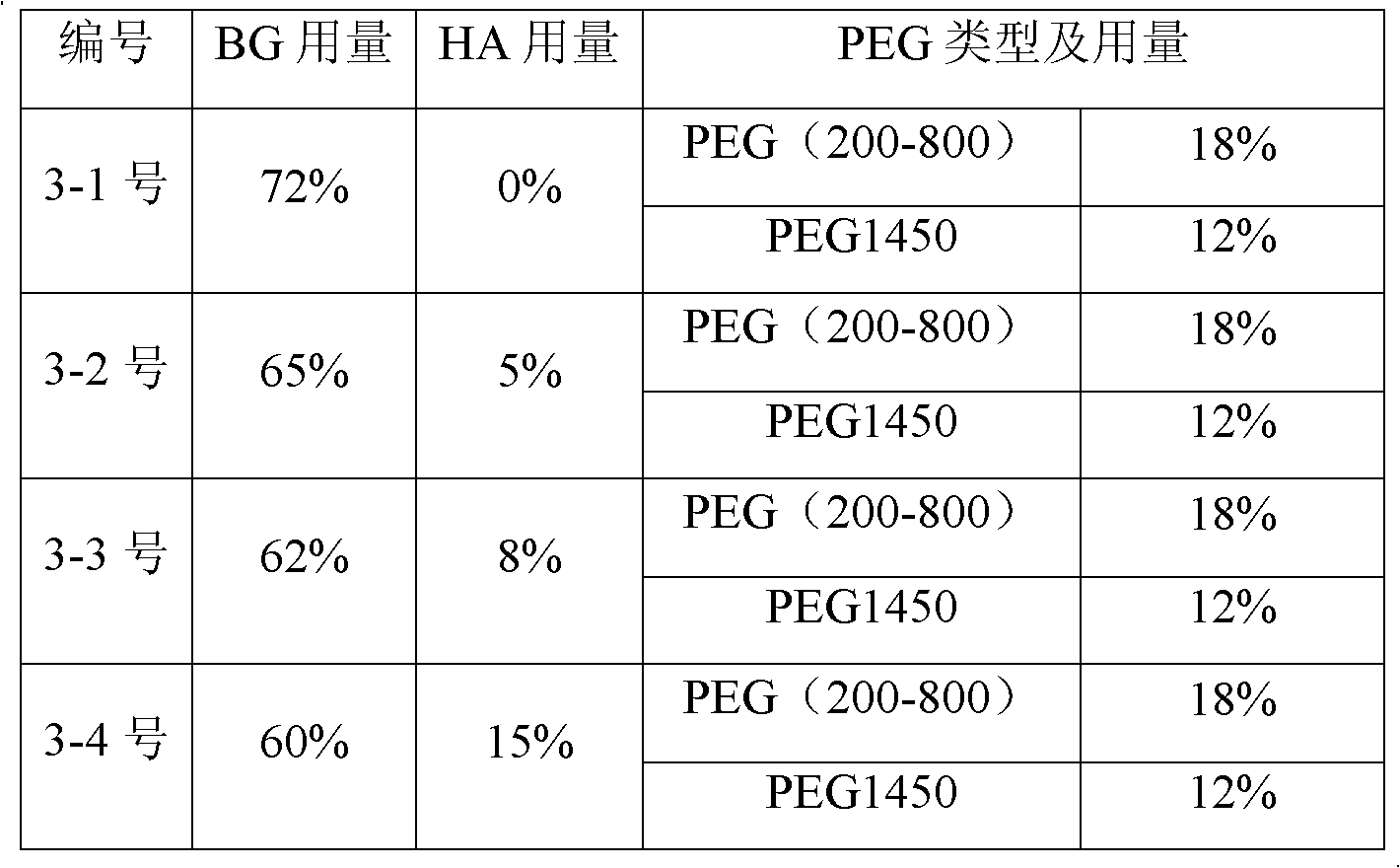

The invention relates to a bone repairing material and a preparation method thereof, belongs to the field of medical materials, and aims at providing a bone repairing material which is less influenced by the changes of ambient temperature and humidity and is more stable. The bone repairing material is prepared from the following components in percentage by weight: 60-75% of bioactive glass with particle size of 212-425 mu m, 25-40% of PEG (polyethylene glycol) and 0-15% of hydroxyapatite with particle size of 50-200 nm. According to the bone repairing material provided by the invention, high-molecular-weight PEG is used as a plasticizing agent, and low-molecular-weight PEG is used as a softening agent or lubricant, thus the ointment product can be in any shapes, and the product has the characteristics of being more stable and better biocompatibility and safety. The bone repairing material has the advantages of being convenient for storage and transport, needing no cold storage measure, being difficult in moisture absorption, threshing, sand falling and hand sticking, and being obvious in postoperative X-ray development and postoperative recovery observation.

Owner:成都迪康中科生物医学材料有限公司

Composite substrate structure

InactiveCN102729566AImprove hydrophobicityImprove wear resistanceLayered productsComposite substrateHardness

A composite substrate structure comprises a transparent base material, a first diamond-like carbon layer and a second diamond-like carbon layer, wherein the first diamond-like carbon layer is arranged between the transparent base material and the second diamond-like carbon layer. Sp3 bonding proportion of the first diamond-like carbon layer is greater that that of the second diamond-like carbon layer, thus providing enough hardness for the composite substrate structure. Simultaneously, the second diamond-like carbon layer contains an adulterant to raise hydrophobicity and / or lipophobicity of the composite substrate structure surface and make the composite substrate structure maintain good maneuverability and durability after it has been used for a long time.

Owner:KINIK

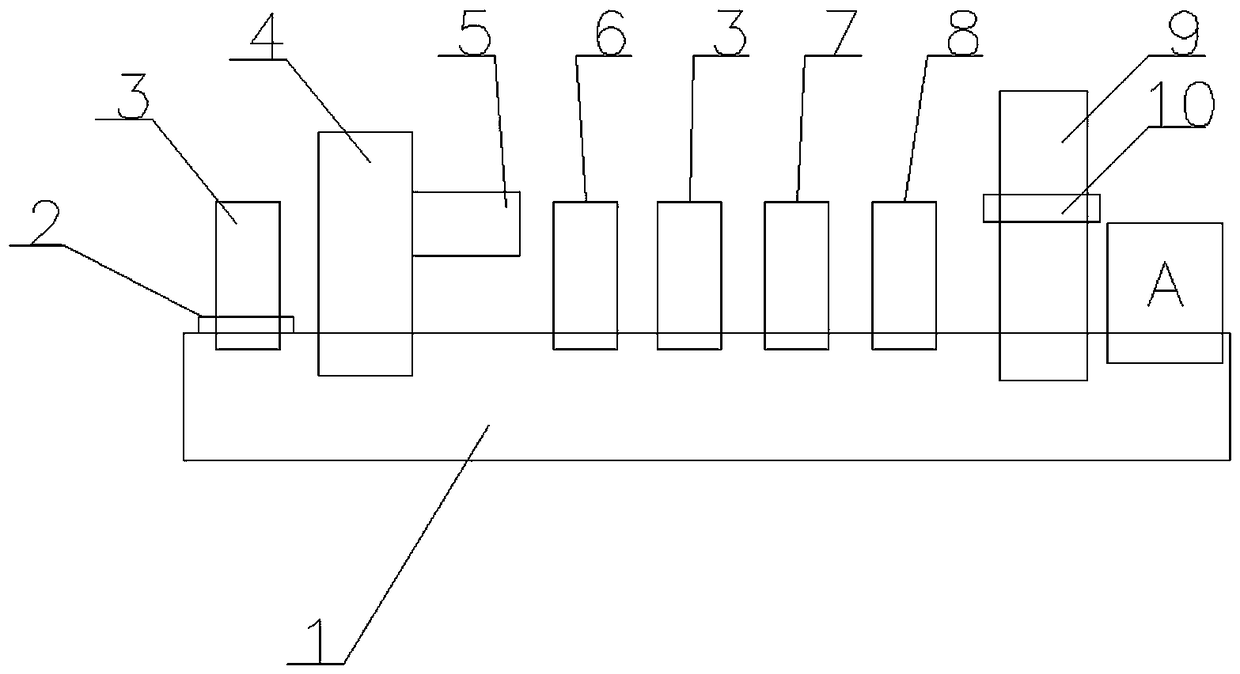

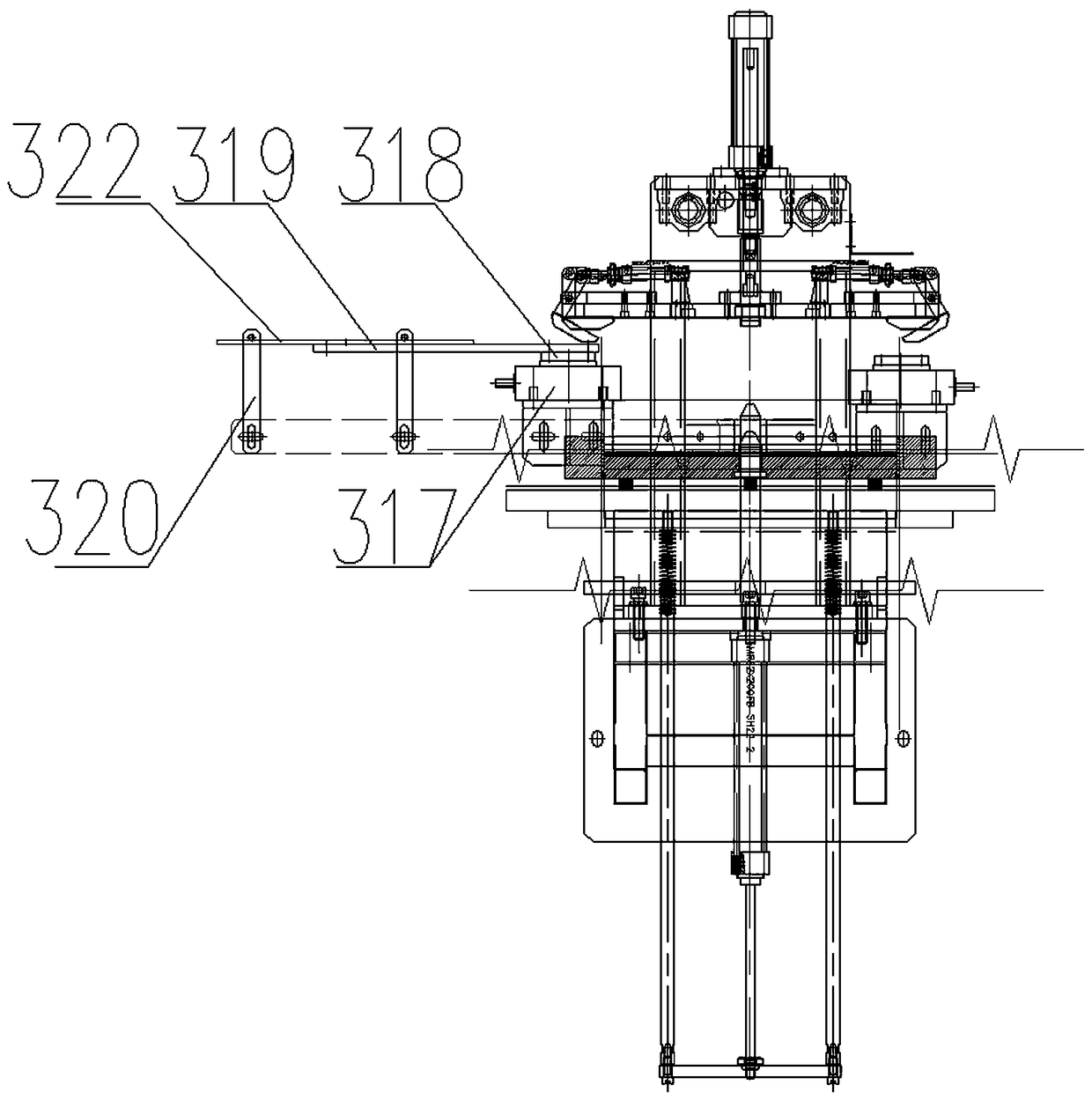

Automatic production line for high-precision grinding wheel

InactiveCN109048701AWell mixedAvoid overfeeding all the timeGrinding devicesProduction lineEngineering

The invention relates to an automatic production line for a high-precision grinding wheel. The automatic production line comprises a grinding wheel forming die and further comprises a lower mesh containing system, a feeding system, a charging system, a material scraping system, an upper mesh containing system, a mesh pressing system, a core ring containing system, a die pressing machine and a demoulding device, all of which are arranged on a production track. The grinding wheel forming die is arranged on the production track and conveyed, and lower mesh containing, feeding, charging, flat material scraping, upper mesh containing, mesh pressing flattening, core ring containing, die pressing forming and demoulding are sequentially finished. The automatic production line is high in automationdegree, feeding is convenient, charging is stable and uniform, meshes are flatly placed, raw materials in the die are uniform, and the grinding wheel die pressing forming quality can be better improved.

Owner:张和庆

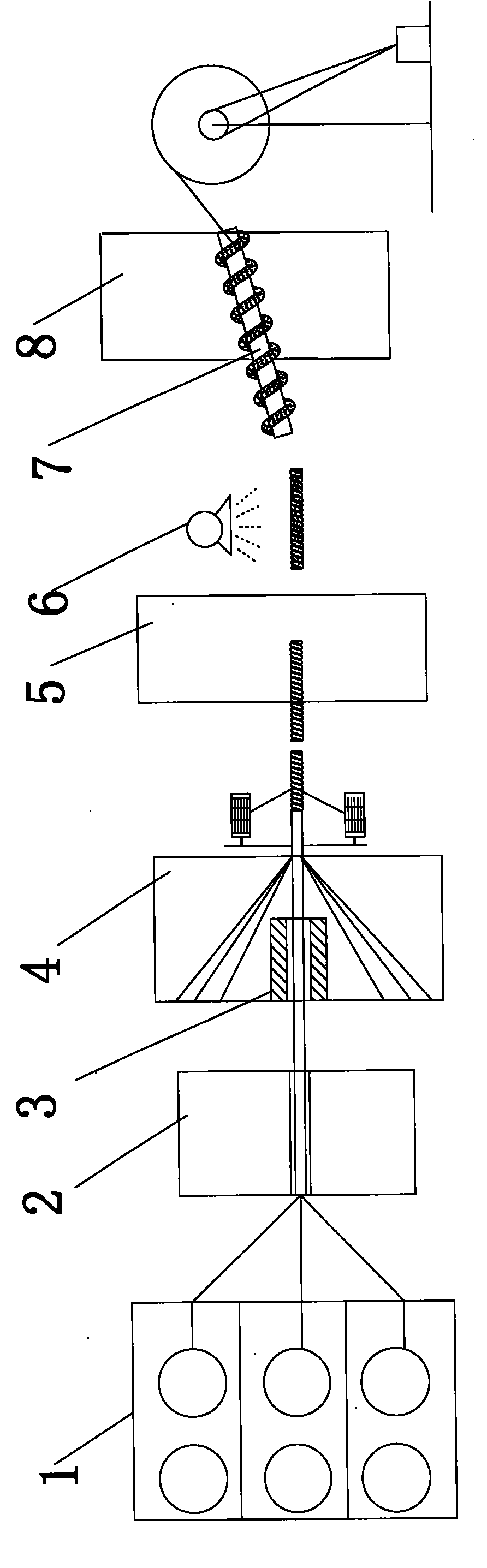

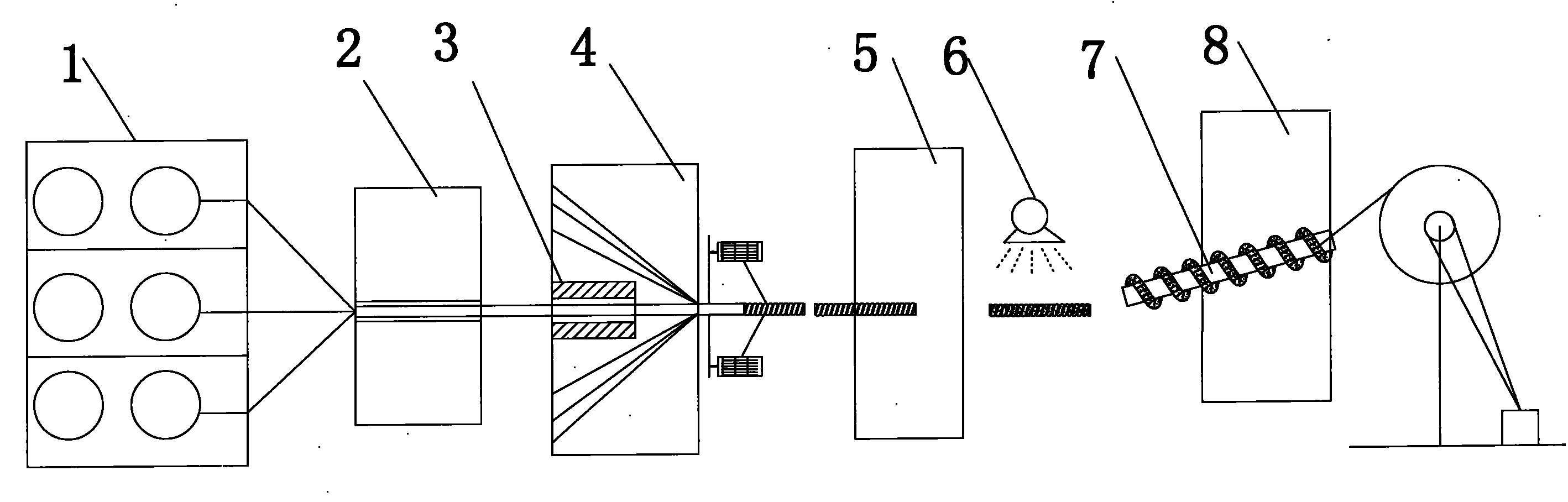

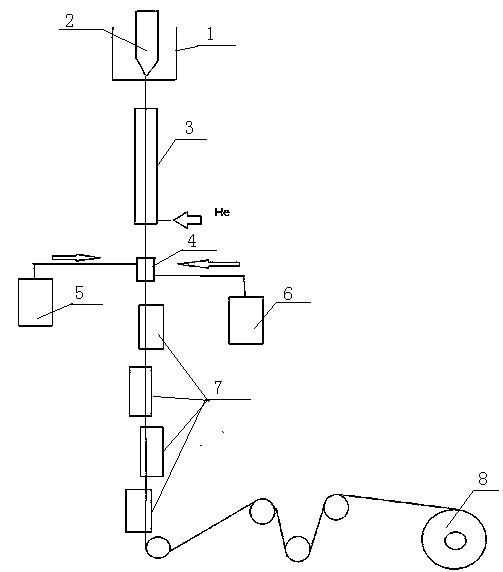

Colored optical fiber and manufacturing method thereof

InactiveCN103472526ANot stickyEasy to removeOptical fibre with multilayer core/claddingFibre mechanical structuresOptical communicationMaterials science

The invention provides a colored optical fiber and a manufacturing method of the colored optical fiber and relates to the field of optical communication. The colored optical fiber is composed of a bare optical fiber, a first coating layer, a second coating layer and a coloring layer from the inner side to the outer side in sequence. The release force of each coating layer of the colored optical fiber is 1.5N-1.8N. The manufacturing method of the colored optical fiber comprises the steps that the bare optical fiber is coated with the first coating layer and the second coating layer in sequence in the same eye model and solidifying disposing and coloring disposing are conducted in sequence. After optical fibers are combined and an optical fiber belt is obtained, the first coating layer, the second coating layer, the coloring layer and a belt combining layer are easy to strip in an integrated mode, and therefore following belt combination and optical cable production are facilitated. Meanwhile, in the process of production of the optical fiber, the optical fiber is not sticky and can not block the eye model. The manufacturing method of the colored optical fiber is simple and easy to control.

Owner:NANJING WASIN FUJIKURA OPTICAL COMM LTD

Silver clay and method for producing silver products using the silver clay

The invention discloses a sliver clay which is composed of sliver powder, bismuth powder, an adhesive, grease and water, wherein, the content of each component calculated based on weight is as follows: 70-80% of the sliver powder, 0.3-1.2% of the bismuth powder, 5-8% of the adhesive, 1-2% of the grease, and the rest of water; the sliver powder is composed of 30-40% of micro sliver powder with the average grain diameter less than or equal to 0.5Mum and the rest of micro sliver powder with the average grain diameter of 1-3Mum by weight. The sliver clay of the invention has a lower sintering temperature, and can be fully sintered at the temperature of 450-500 DEG C. The invention further discloses a method for preparing silverware with the sliver clay.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

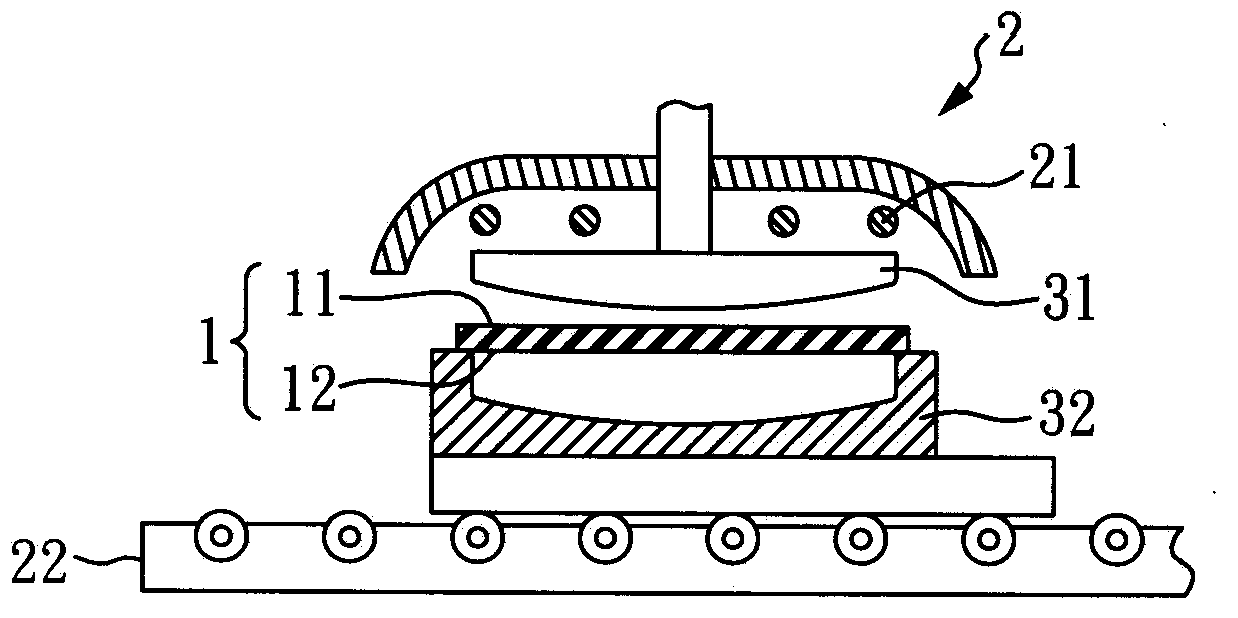

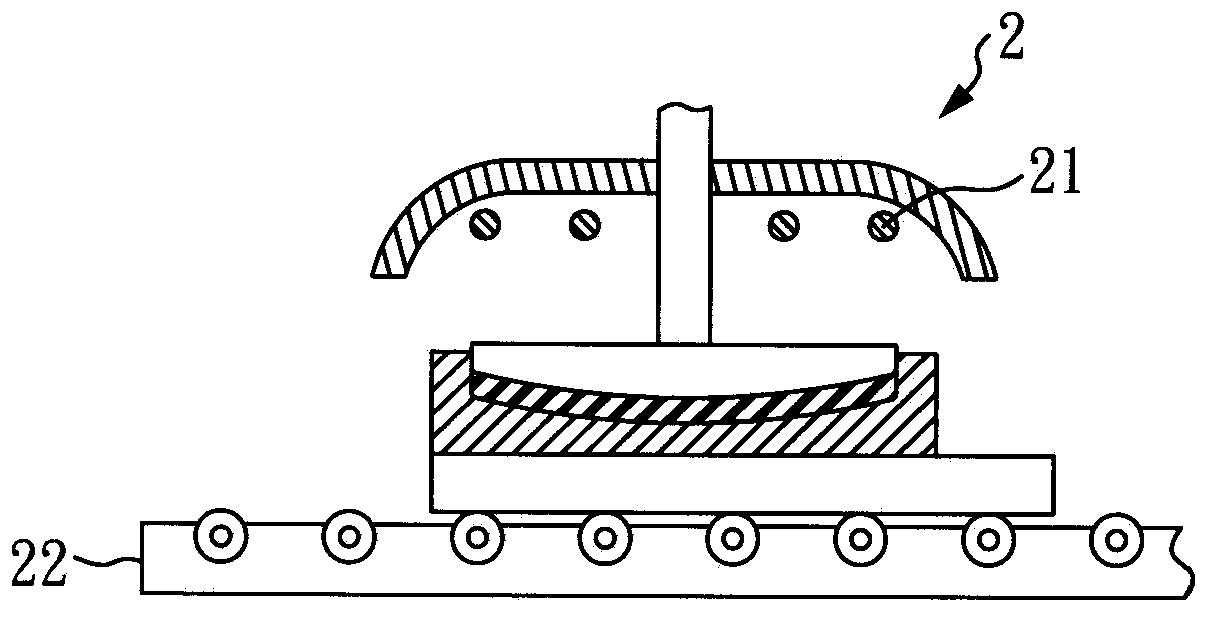

Three-dimensional glass and method for manufacturing the same

InactiveCN103420566AQuality improvementImprove flatnessGlass reforming apparatusThermal expansionHeating furnace

The invention provides three-dimensional glass and a method for manufacturing the same. The method for manufacturing the three-dimensional glass comprises: (a) providing a first insert, a second insert and a glass substrate in a cavity of a heating furnace; (b) heating until the temperature of the heating furnace exceeds the softening temperature of the glass substrate, and applying weight of the first insert onto the glass substrate, so as that the glass substrate is relatively abutted against the second insert to form the three-dimensional glass, wherein the coefficient of thermal expansion of the glass substrate is between that of the first insert and that of the second insert; and (c) quenching and annealing the glass substrate. Therefore, the method solves the problem of adhesion between the glass substrate and the insert in a demolding stage, and effectively raises quality and flatness of the glass substrate moulding.

Owner:RITEDIA CORPORATION

High performance metallic composite material and its preparation method and application

InactiveCN1830656AEnsuring Metallurgical BondingGuaranteed composite strengthCooking vesselsRoll mill control devicesMetallic materialsAlloy

A high-performance composite metallic material used for manufacturing cooking pan or cooker is composed of the 1st stainless steel layer, the 2nd aluminum layer, the 3rd Al-alloy layer, the 4th aluminum layer and the 5th stainless steel (or iron) layer. Its preparing process includes such steps as laminating three aluminum layers, rolling, heat treating, attaching two stainless steel layers, hot rolling and heat treating.

Owner:SHANGHAI XINGYUYING COMPOSITION METAL MATERIAL

Underclothes made from flax and its producing technique

An underclothes (or underpants) is made up of flax yarns, cotton or viscose or natural fibres, and optional polyurethane fibres through blending, softening and smoothing, knitting, washing and fixating shape. Its advantages are suppressing bacteria, romoving odor, good hydroscopicity, no deformation, and not sticking onto human body.

Owner:姜元麒 +1

Light color clay and production method thereof

The invention relates to light color clay and a production method thereof. The production method is characterized by comprising the following steps: adding water in proportion into a reactor for stirring, slowly adding polyvinyl alcohol in proportion into the reactor for stirring, and gradually raising the temperature to fully dissolve the polyvinyl alcohol; continuing stirring, and adding a wetting agent, a defoamer, a mildewproof agent, pigment or dye for stirring; and slowly adding a light filler, and adding gel solution dropwise with stirring until the end. The light color clay comprises the following compositions: 4 to 15 portions of polyvinyl alcohol, 0.1 to 2 portions of gel, 40 to 60 portions of water, 10 to 30 portions of filler, and auxiliary materials of 1 to 2 portions of defoamer, 0 to 20 portions of wetting agent, 0.15 to 0.75 portion of mildewproof agent and proper portions of pigment or dye. The light color clay has no pulverizing, crack or hand sticking, and flexibility, can be dried in air, and can stick small articles such as paper, and dust on clothes before the drying.

Owner:宁海随喜文具有限公司

Silicone-based coating composition with middle and high refractive index, method of preparing the same, and optical lens prepared therefrom

InactiveUS20070128454A1Keep for a long timeNot stickySynthetic resin layered productsCoatingsRefractive indexSolvent

The present invention relates to a silicone-based coating composition with middle and high refractive index, a method of preparing the same, and an optical lens prepared therefrom, and more specifically to a silicone-based coating composition including organosilanes, inorganic oxides having a refractive index of from 1.7 to 3.0, an aluminum acetyl acetone, a C1-C5 alkyl cellosolve, and a solvent, a method of preparing the same, and an optical lens prepared therefrom. The siloxane-based coating composition is transparent, not sticky, and stable for long time storage. Therefore, the coating composition can be applied to a coating layer on a surface of a plastic lens such as an optical lens, an industrial safety lens, or goggles for leisure.

Owner:LG CHEM LTD

Application of pectin polysaccharide in preparation of antiallergic food, medicine or cosmetic

InactiveCN101623101ANot stickyImprove solubilityCosmetic preparationsOrganic active ingredientsPectic polysaccharideSide effect

The invention relates to the application of pectin polysaccharide in the preparation of antiallergic food, medicine or cosmetic. The adopted technical scheme comprises: the antiallergic food, medicine or cosmetic contains the active ingredient of pectin polysaccharide which is prepared according to the method: pectin water solution with the mass percentage concentration of 1-2% is taken, the pH value of the pectin water solution is adjusted to be 2-4, the decomposition reaction is carried out for 15-24min at 95-120 DEG C, and pectin decomposition substance can be obtained; the obtained pectin decomposition substance is separated by a hollow fiber membrane or ceramic filtering membrane, and compound with the molecular weight of 6000 daltons is recovered, so that the pectin polysaccharide can be obtained. The invention has the advantages of safe use, no toxic side effect, good antiallergic effect and easy practical operation.

Owner:LIAONING UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com