Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Fewer returns" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Humic acid composite material and preparation method thereof

InactiveCN101041600APromote absorptionGood water solubilityAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphorNitrogen

The invention discloses a particle-typed composite fertilizer of humic acid and manufacturing method, which consists of dressing and karyosome, wherein the dressing contains nitrogen, phosphor and potassium. The manufacturing method comprises the following steps: graining humic acid; cladding; graining; solidifying fused fertilizer on the particle of humic acid; making the composite fertilizer dissolved into water without falling; fitting for large scale of agricultural product.

Owner:阴高鹏

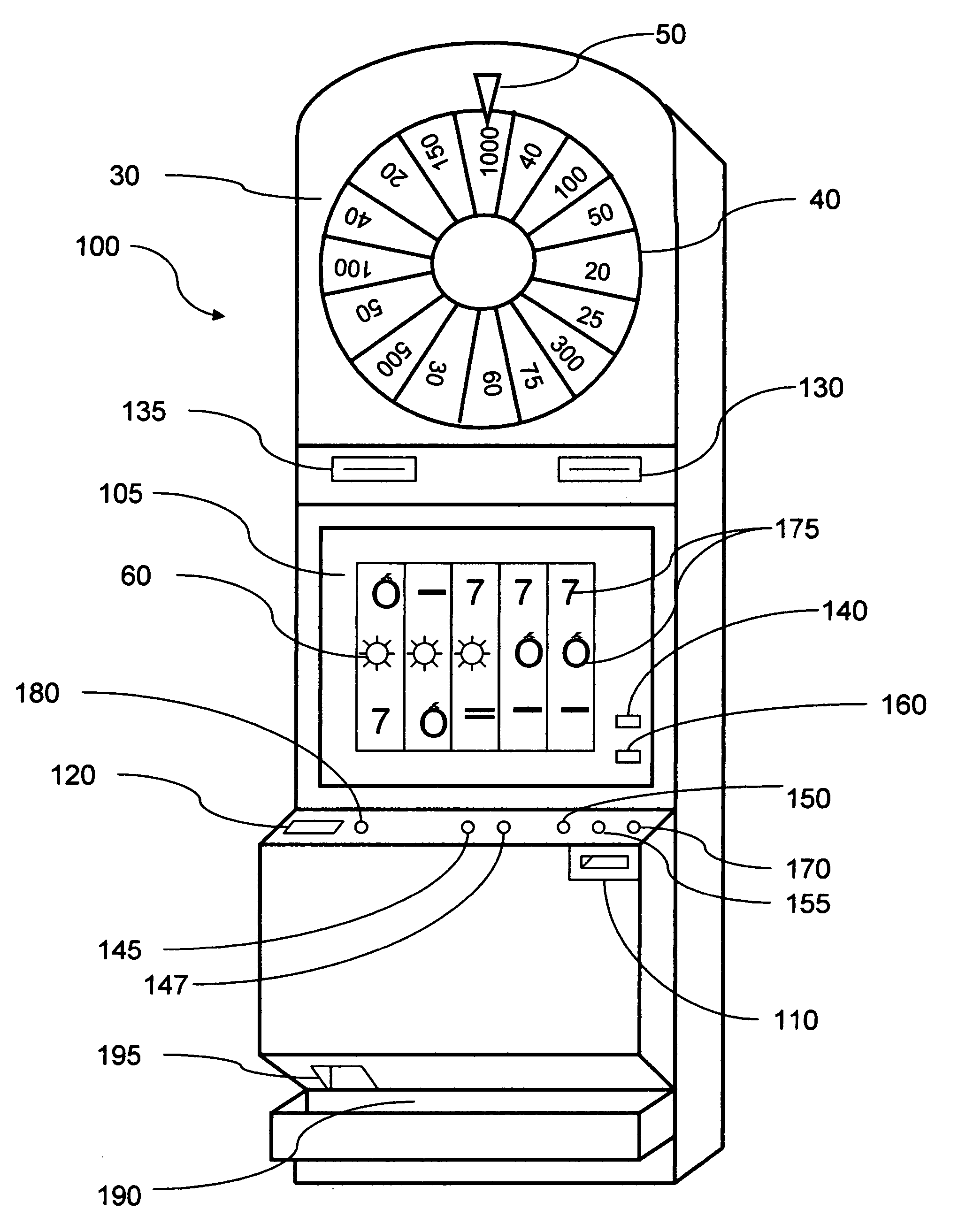

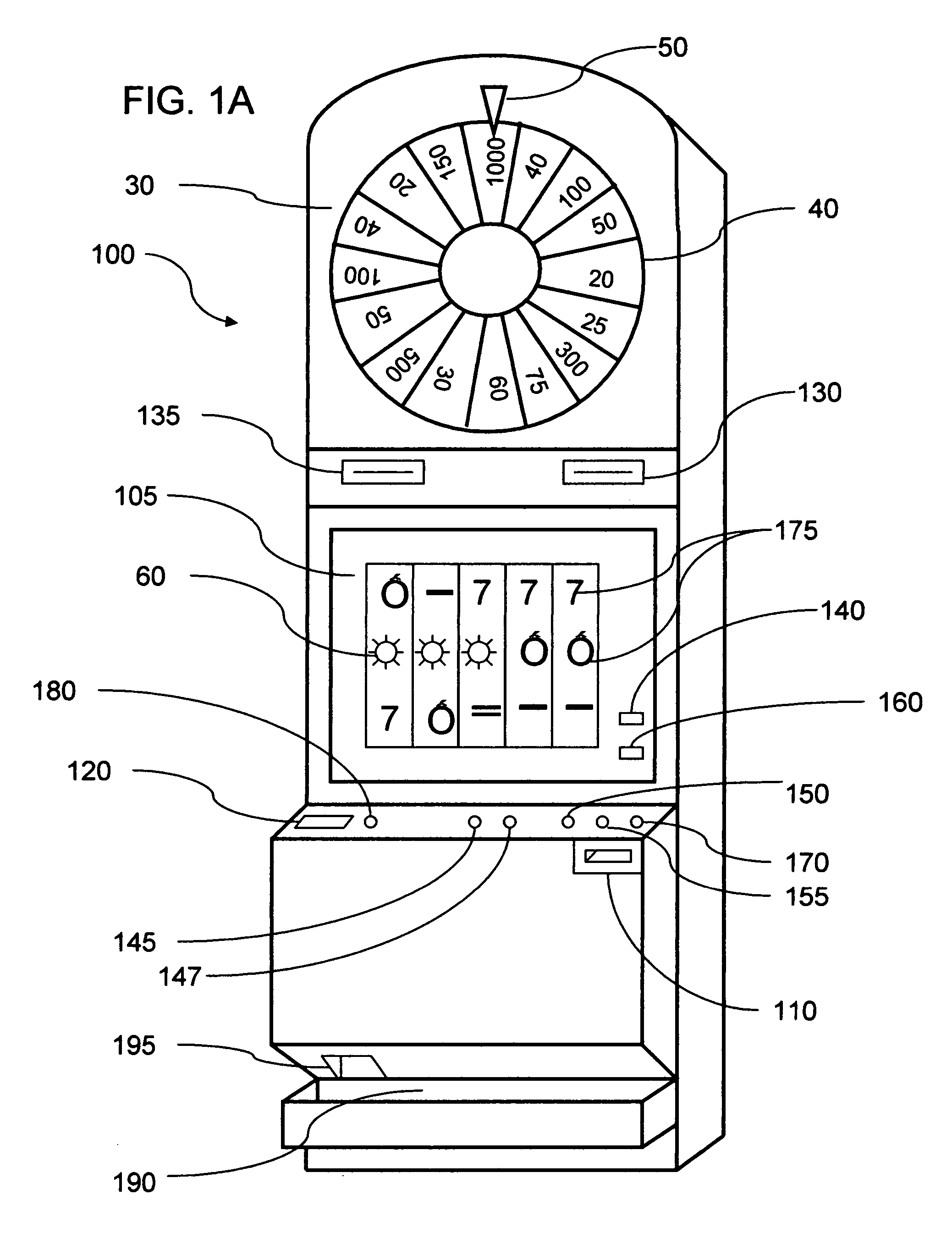

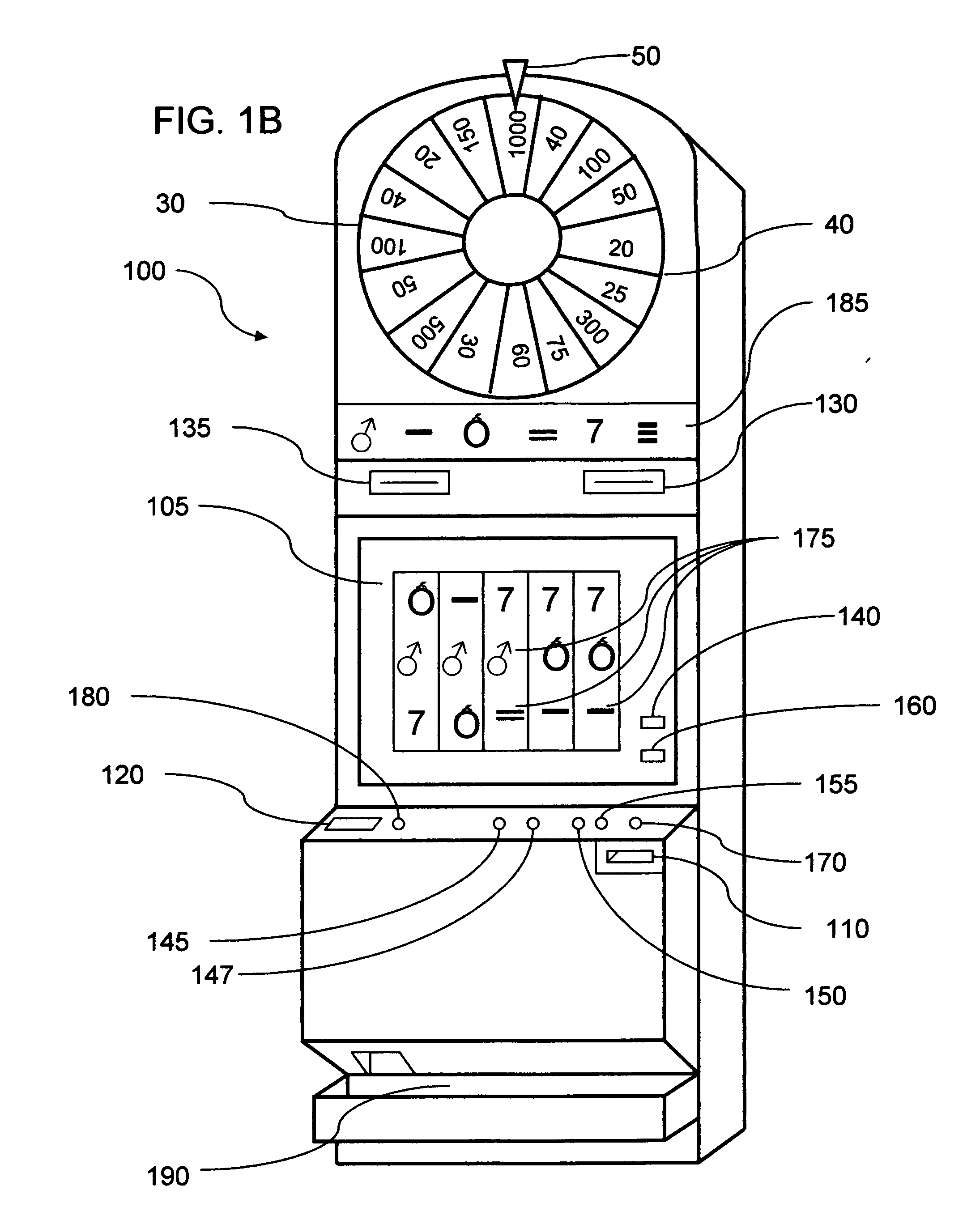

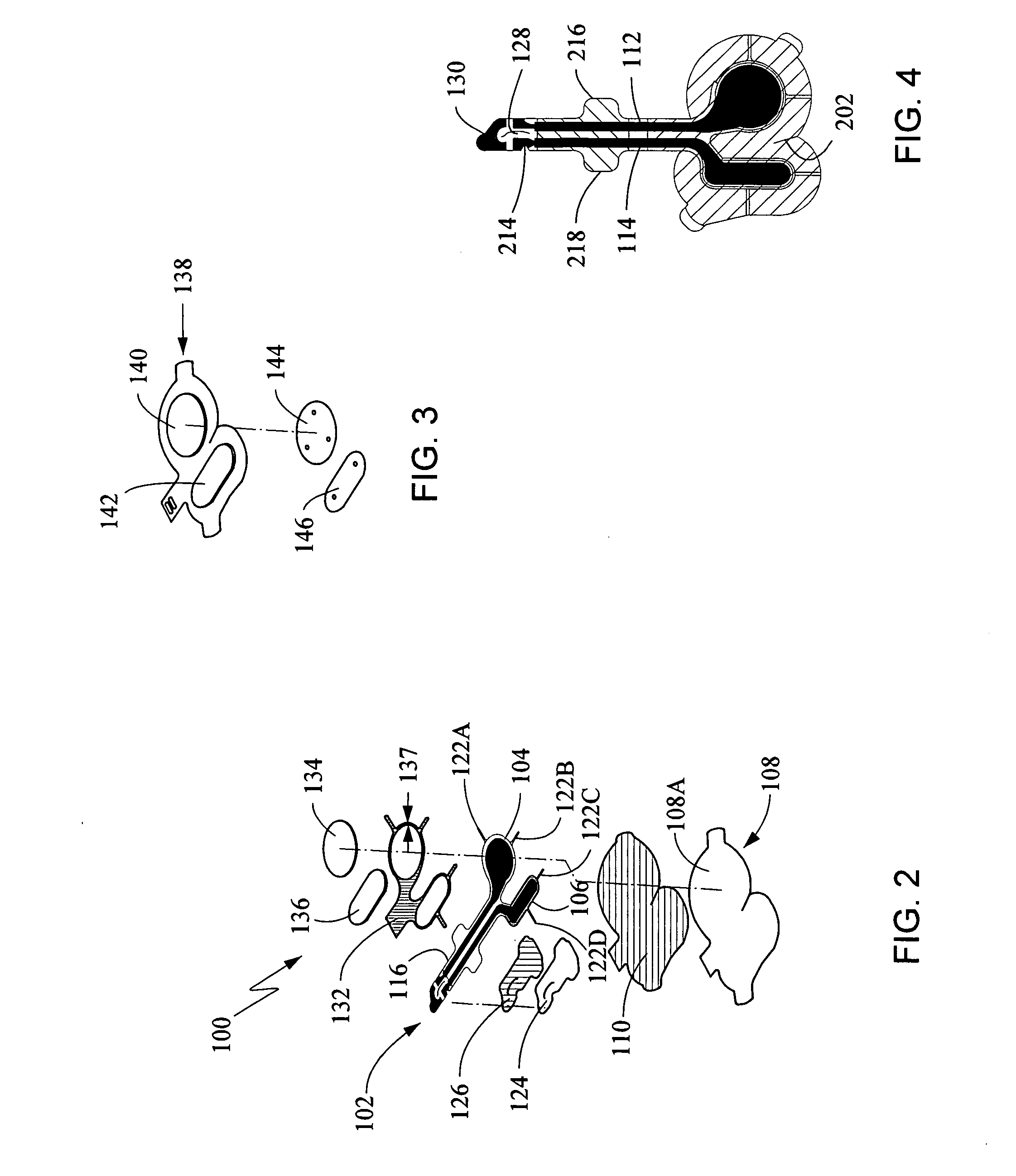

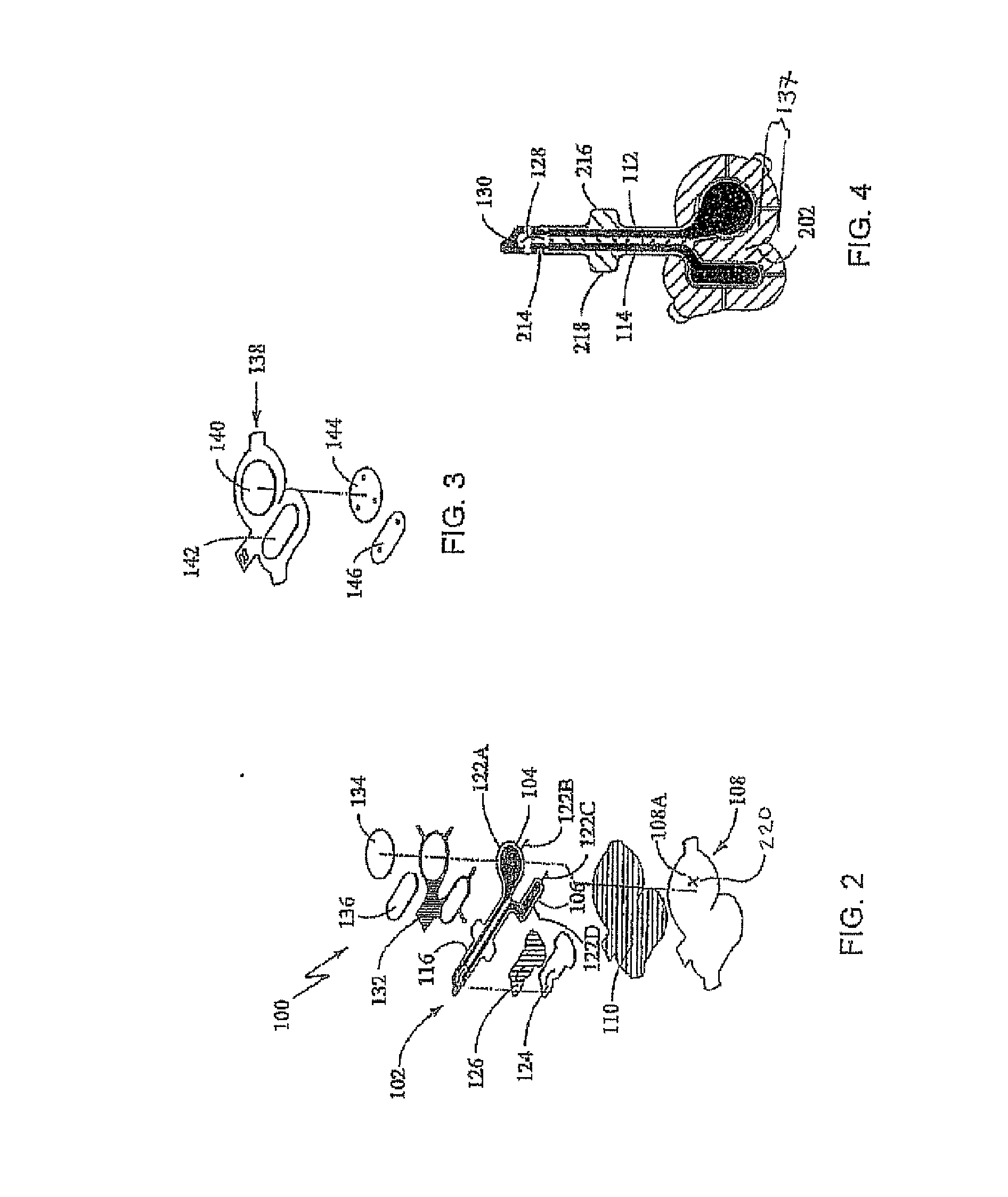

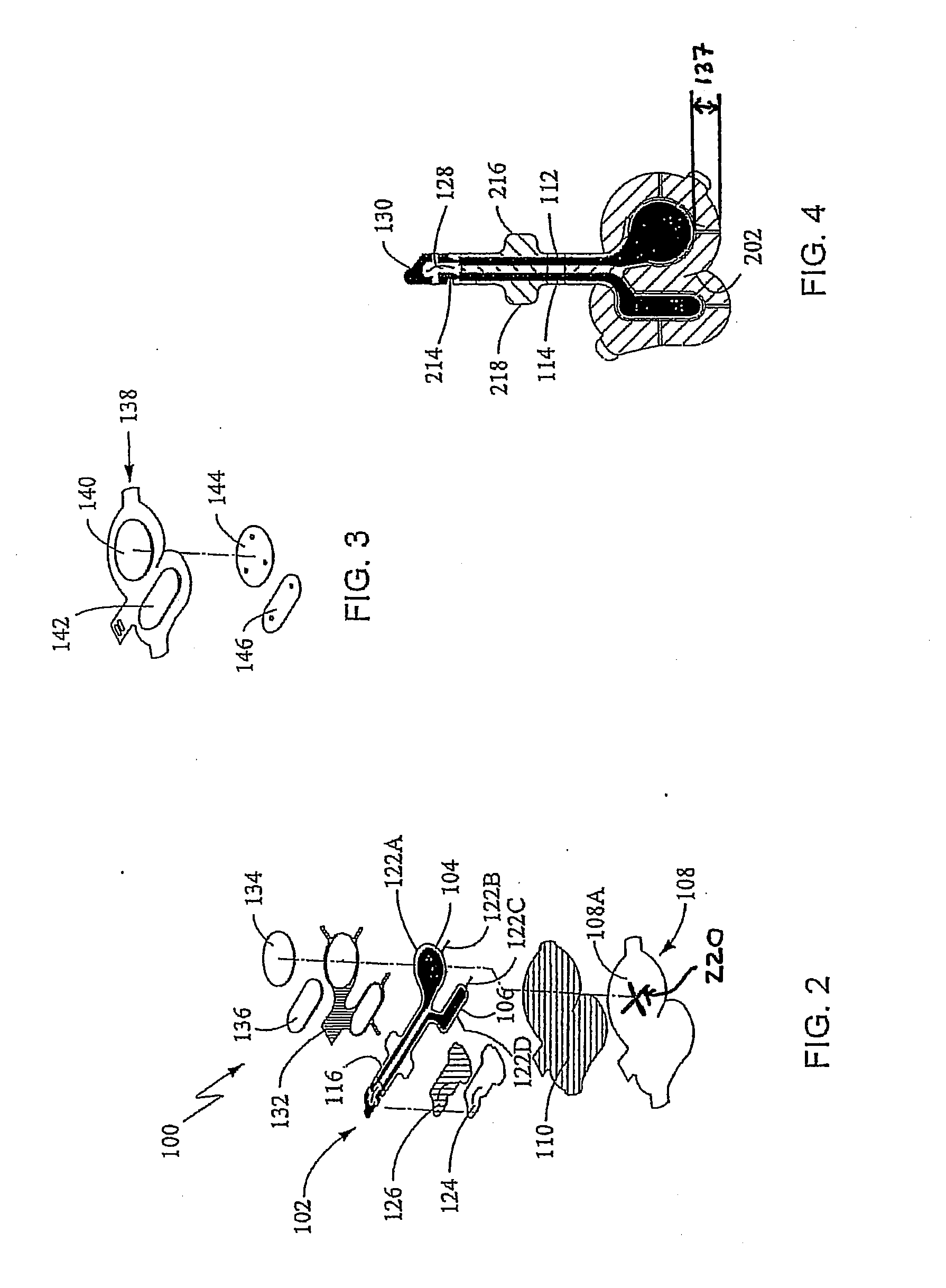

Slot machine

InactiveUS20060025201A1Fewer returnsApparatus for meter-controlled dispensingVideo gamesEngineeringBiological activation

Owner:VAN ASDALE SHAWN MICHAEL

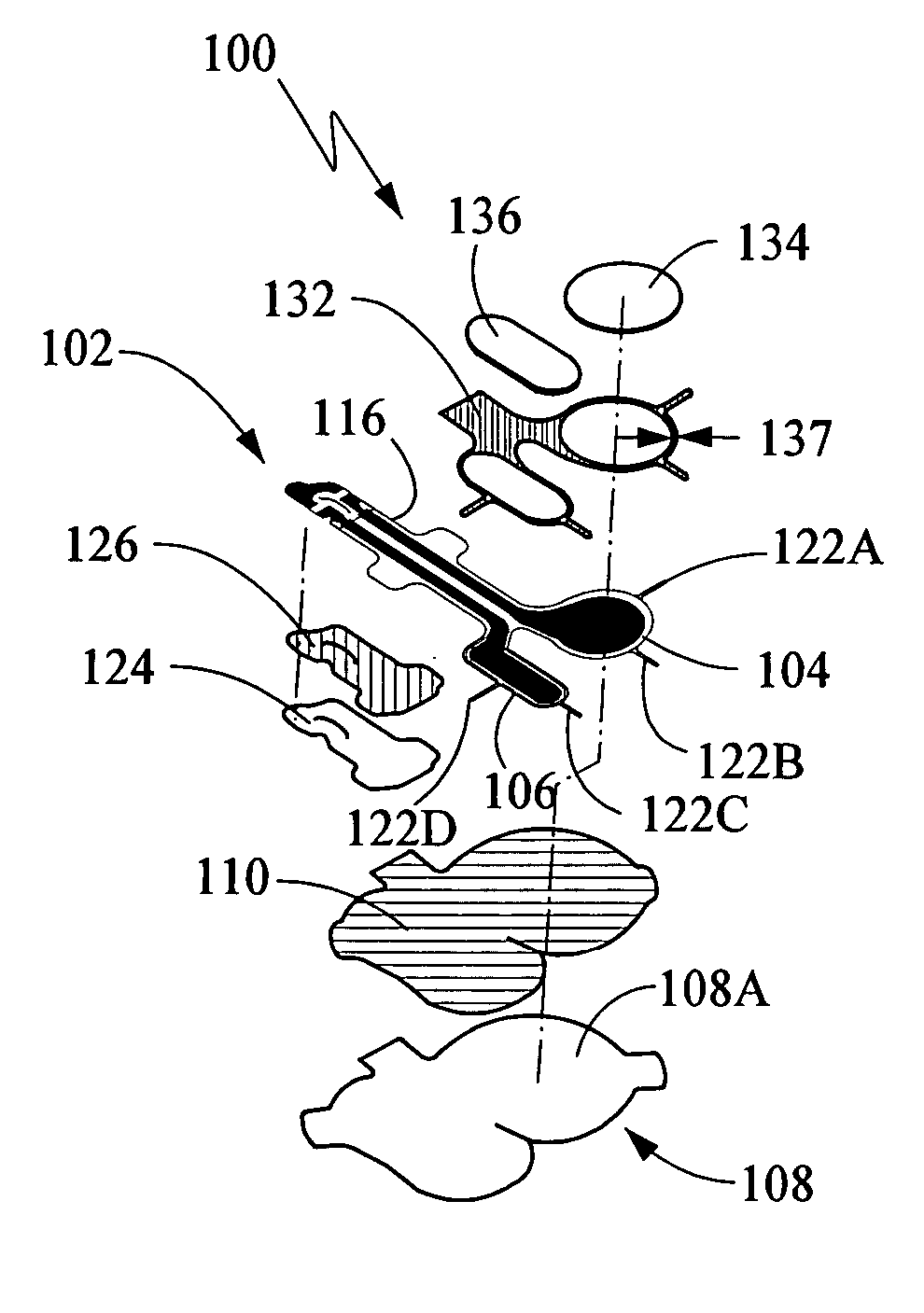

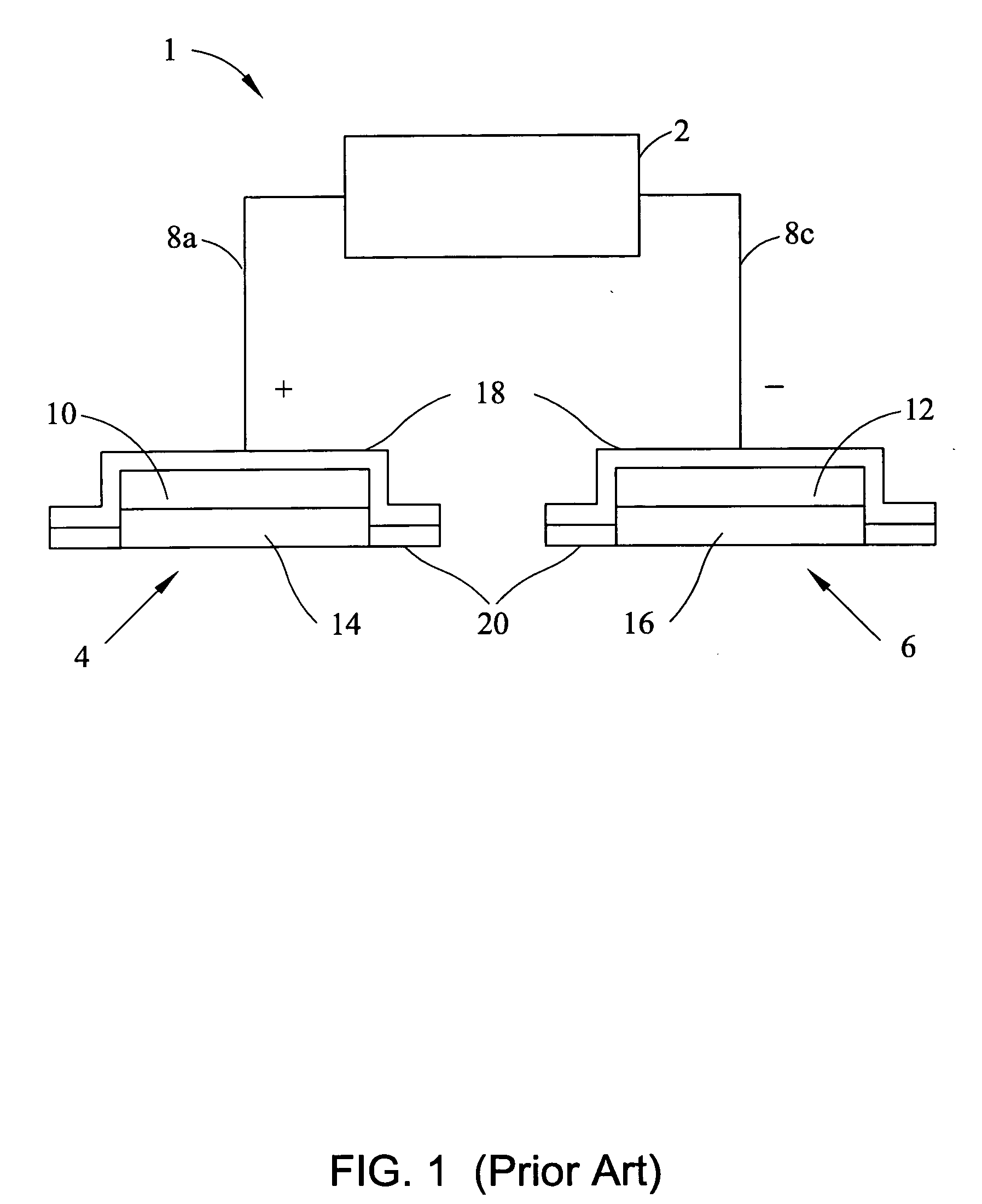

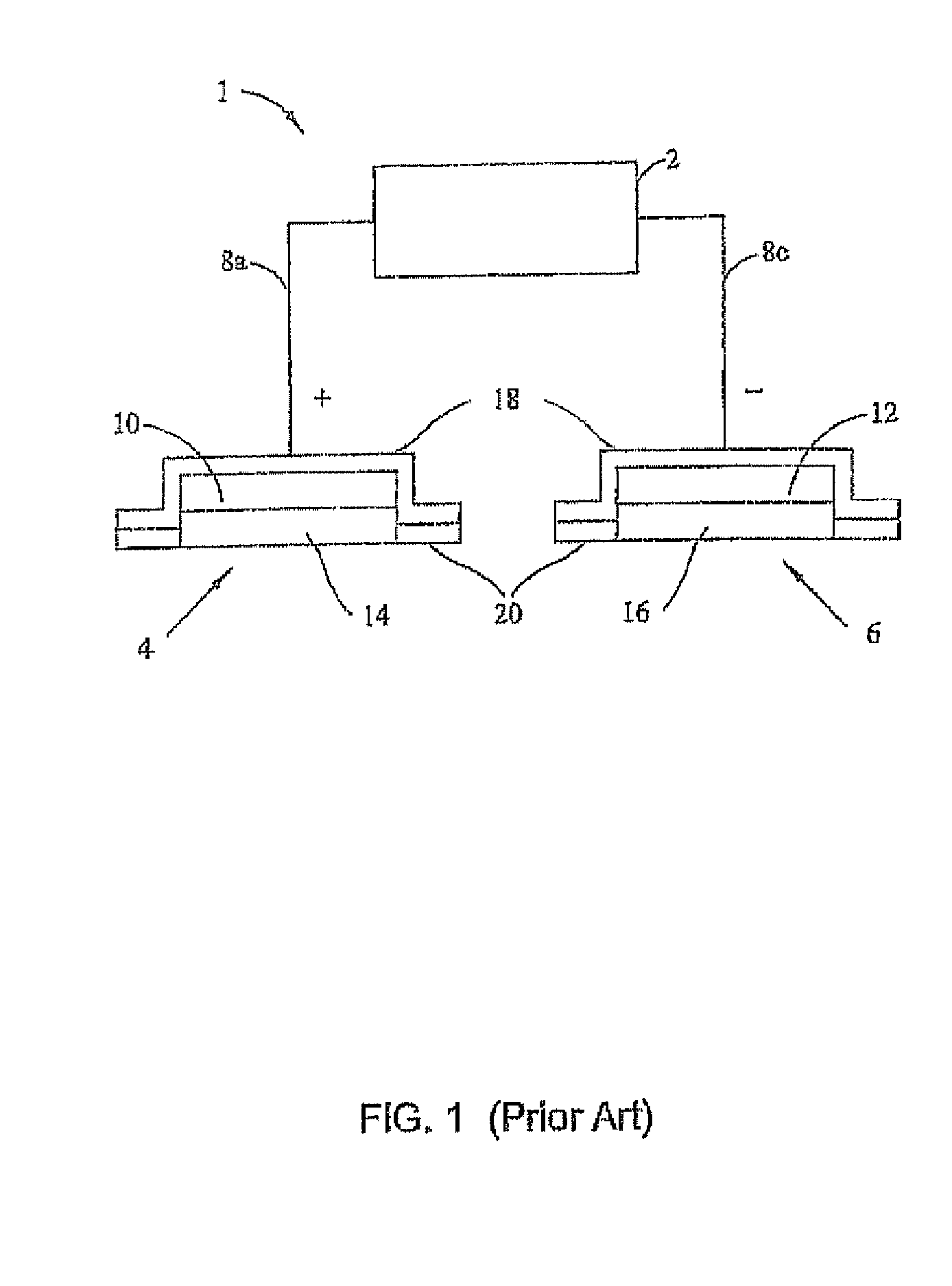

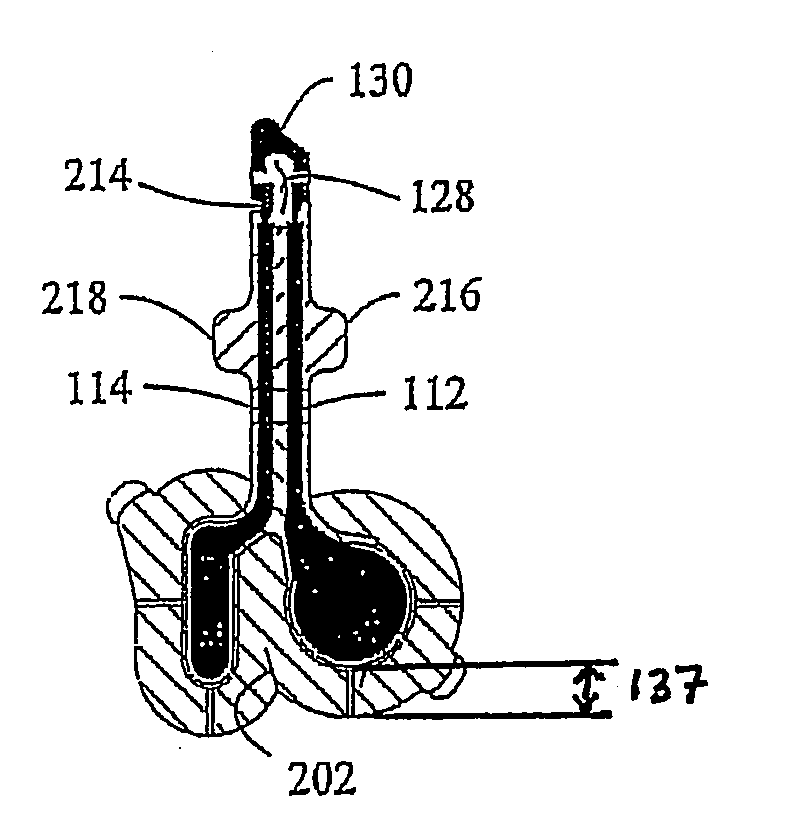

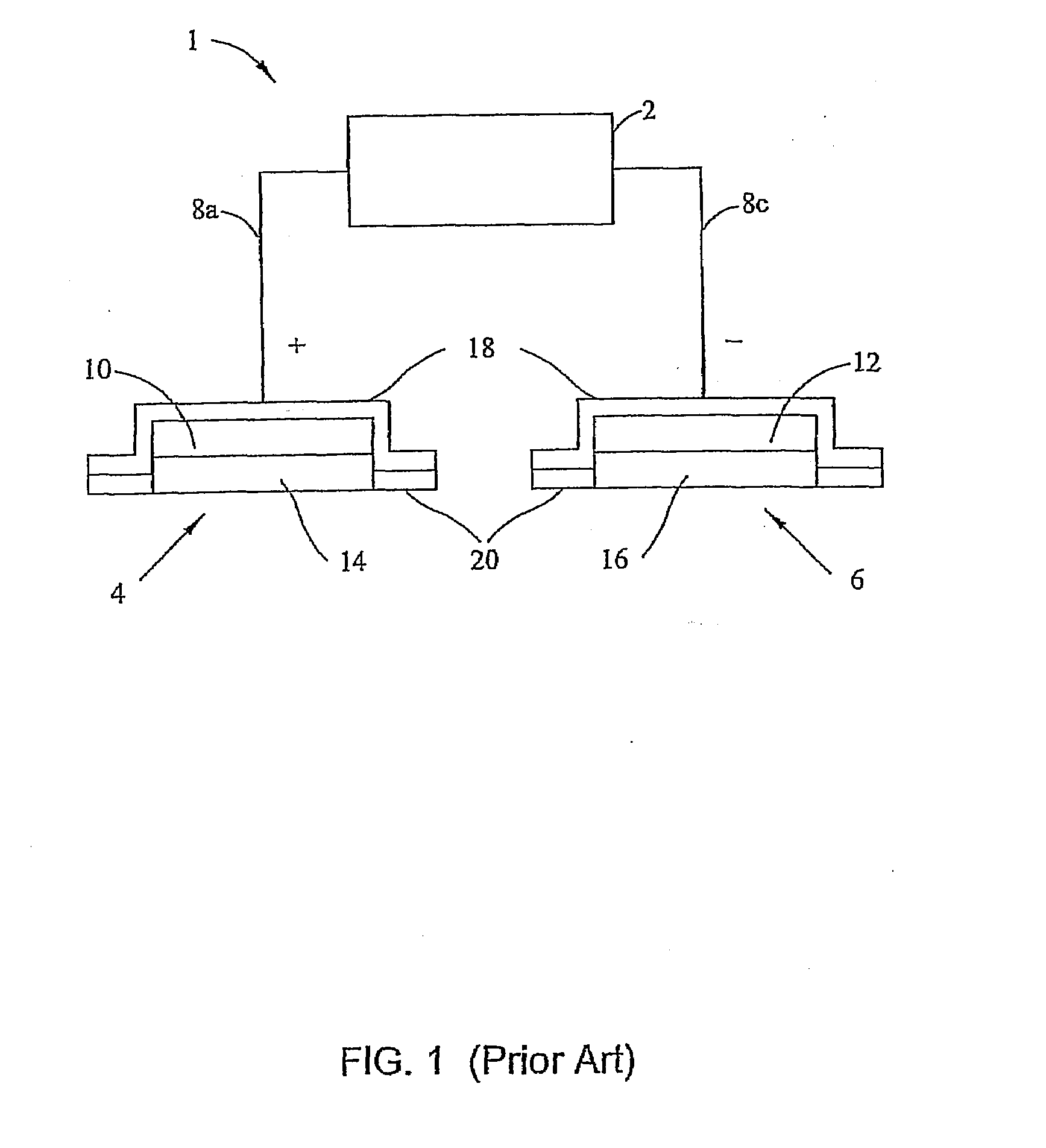

Electrically assisted lidocaine and epinephrine delivery device having extended shelf-stability

InactiveUS20050228336A1Great confidenceFewer returnsOrganic active ingredientsElectrotherapyLidocaineAnesthetic

Highly shelf-stable electrically assisted transdermal drug delivery systems for delivering epinephrine, typically with an anesthetic such as lidocaine, are provided along with methods for making the highly shelf-stable epinephrine-containing transdermal delivery device. Highly shelf-stable packaged electrode assemblies for transdermal delivery of epinephrine also are provided.

Owner:VYTERIS

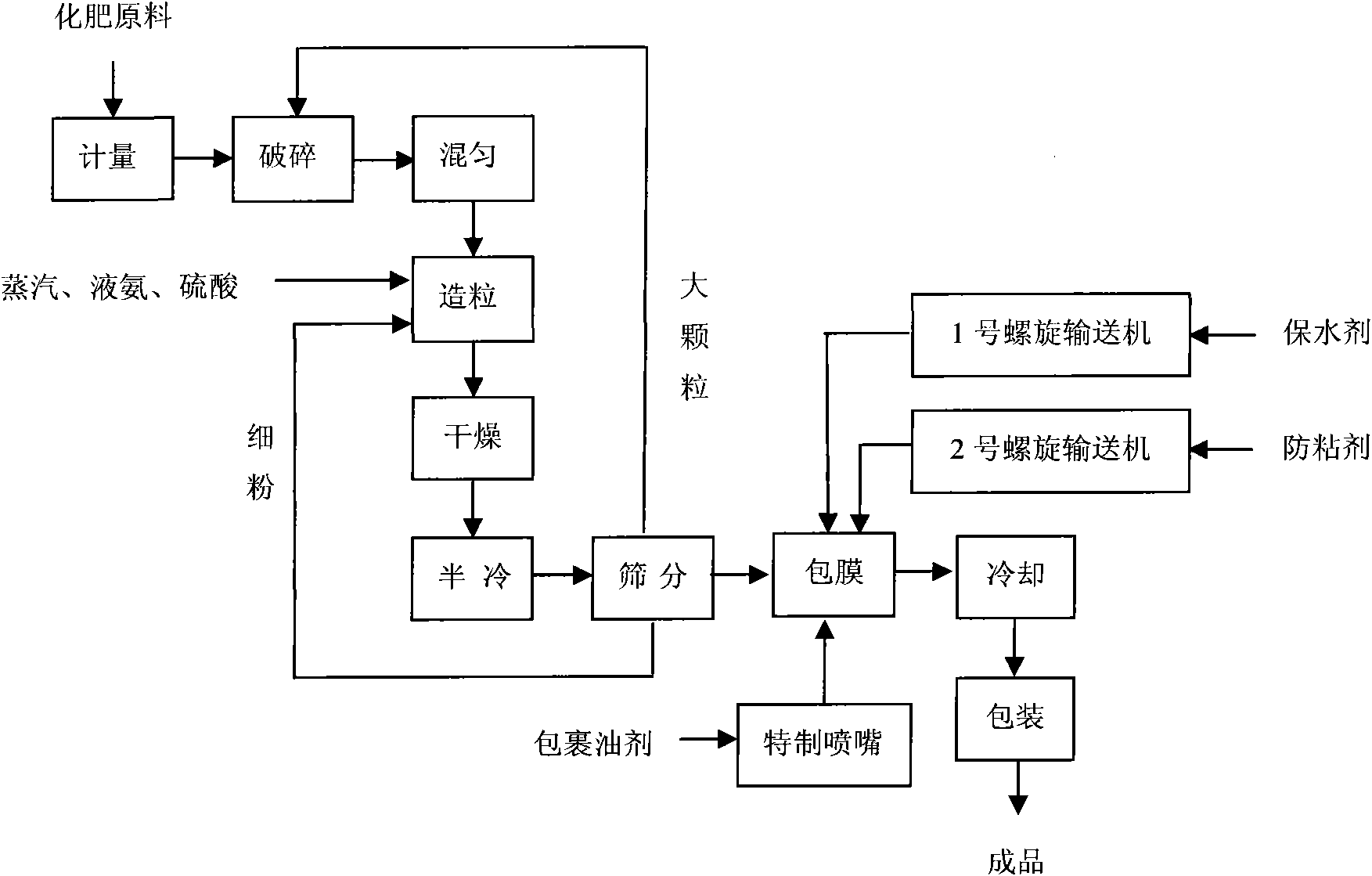

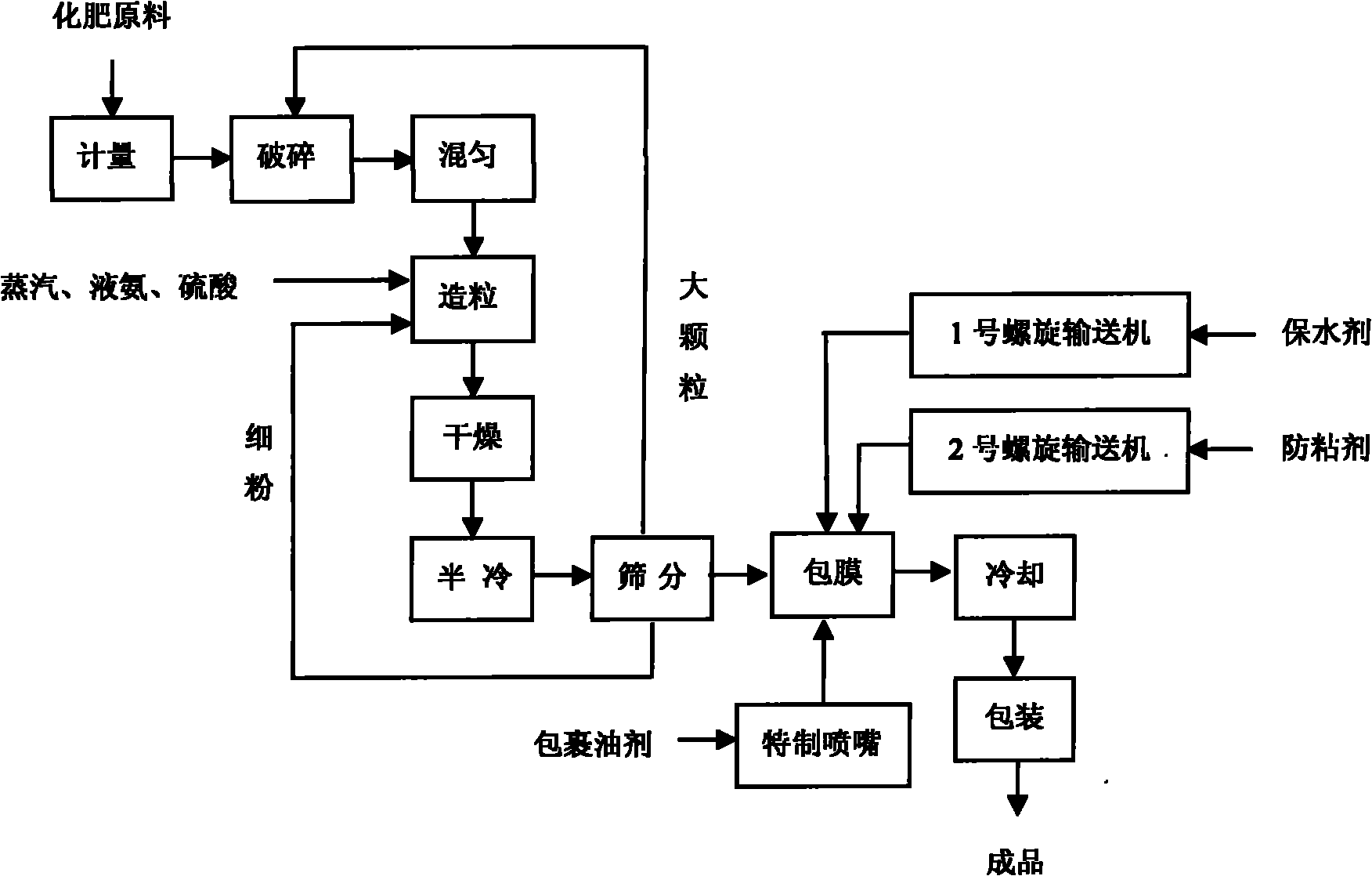

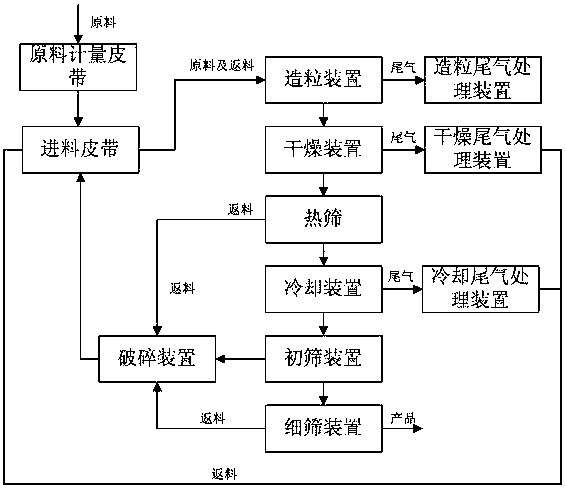

Color drought-resistance water-retention sustained-release compound fertilizer and method for producing same

ActiveCN101792354ASimple production methodHigh ball rateFertiliser formsFertilizer mixturesFilm coatingNutrient

The invention discloses a color drought-resistance water-retention sustained-release compound fertilizer and a method for producing the same, wherein the method comprises the followings steps of: measuring, crushing and uniformly mixing fertilizer raw materials, granulating by adopting an ammonia-acid method rotary drum granulating process, performing one-stage drying, semi-cooling and screening of grains, and sending the mixture to a coating machine; adopting a continuous melting rotary drum film-coating method coating process to perform compressed air atomization and uniform coating of color coating oil sprayed by a special nozzle; and adding a water-retaining agent and an anti-adhesive agent by a screw conveyor, and performing full stirring, cooling and packaging to obtain the finishedproducts. The color drought-resistance water-retention sustained-release compound fertilizer has the effects of drought resistance, water retention, nutrient preservation, soil condition improvement and environmental protection, and the appearance of the fertilizer has color marks; and when the fertilizer is applied to crops, the fertilizer has the advantages of increasing yield and incoming, along with simple production method, convenient operation, low cost and high benefits.

Owner:CNSG ANHUI HONG SIFANG FERTILIZER IND CO LTD

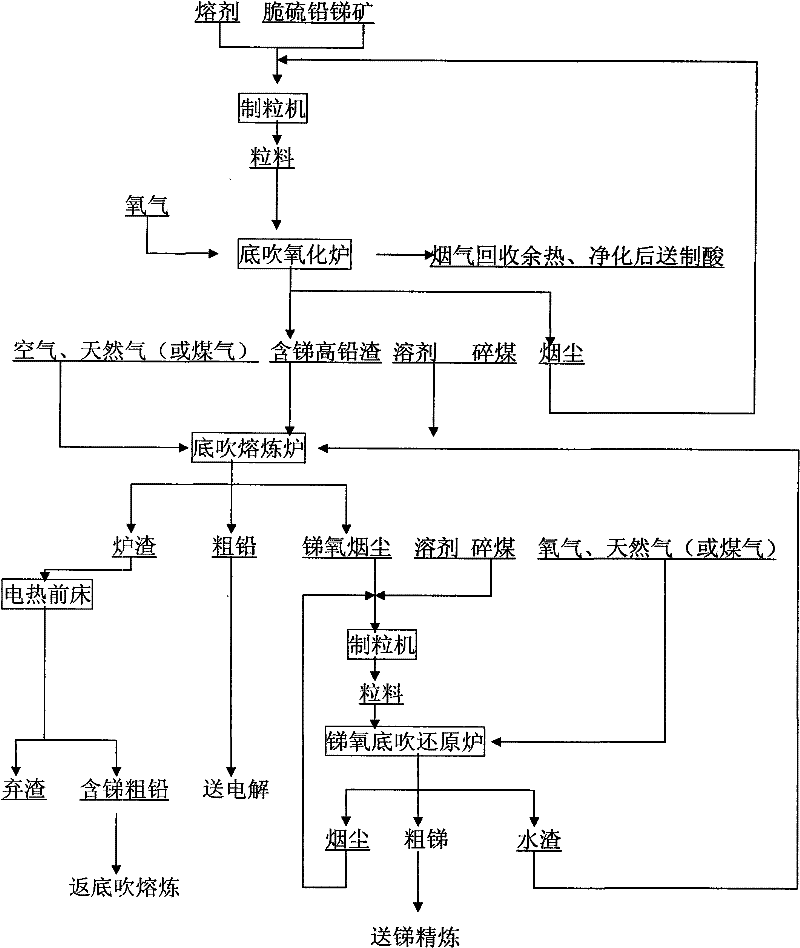

Method and device for smelting jamesonite by bottom-blowing pool

The invention relates to a method and a device for smelting jamesonite by a bottom-blowing pool. The method comprises the following steps of: performing pool smelting, oxidation and desulfurization on the jamesonite by using a bottom-blowing oxidation furnace to produce antimony-containing high-lead slag, a lead-antimony alloy and flue gases suitable for acid preparation; reducing the antimony-containing high-lead slag and blowing the lead-antimony alloy by using a bottom-blowing smelting furnace to produce antimony oxides and lead bullion capable of being used for electrolysis; and reducing the antimony oxides by using a bottom-blowing reduction furnace to produce needle antimony. In the smelting method of the invention, the three bottom-blowing furnaces and an electrically-heated settler are adopted to treat the jamesonite to produce the lead bullion, the needle antimony and the slag; therefore, compared with the prior art, the method has the advantages of short flow, good lead-antimony separation effect, fewer intermediate products, less revert, high resource utilization rate and production continuity; and the bottom-blowing oxidation furnace can realize spontaneous heating balance by sulfide combustion with low energy consumption and high recovery rate and can greatly reduce the cost.

Owner:JIYUAN YUGUANG NONFERROUS METALLURGY DESIGN & RES INST CO LTD

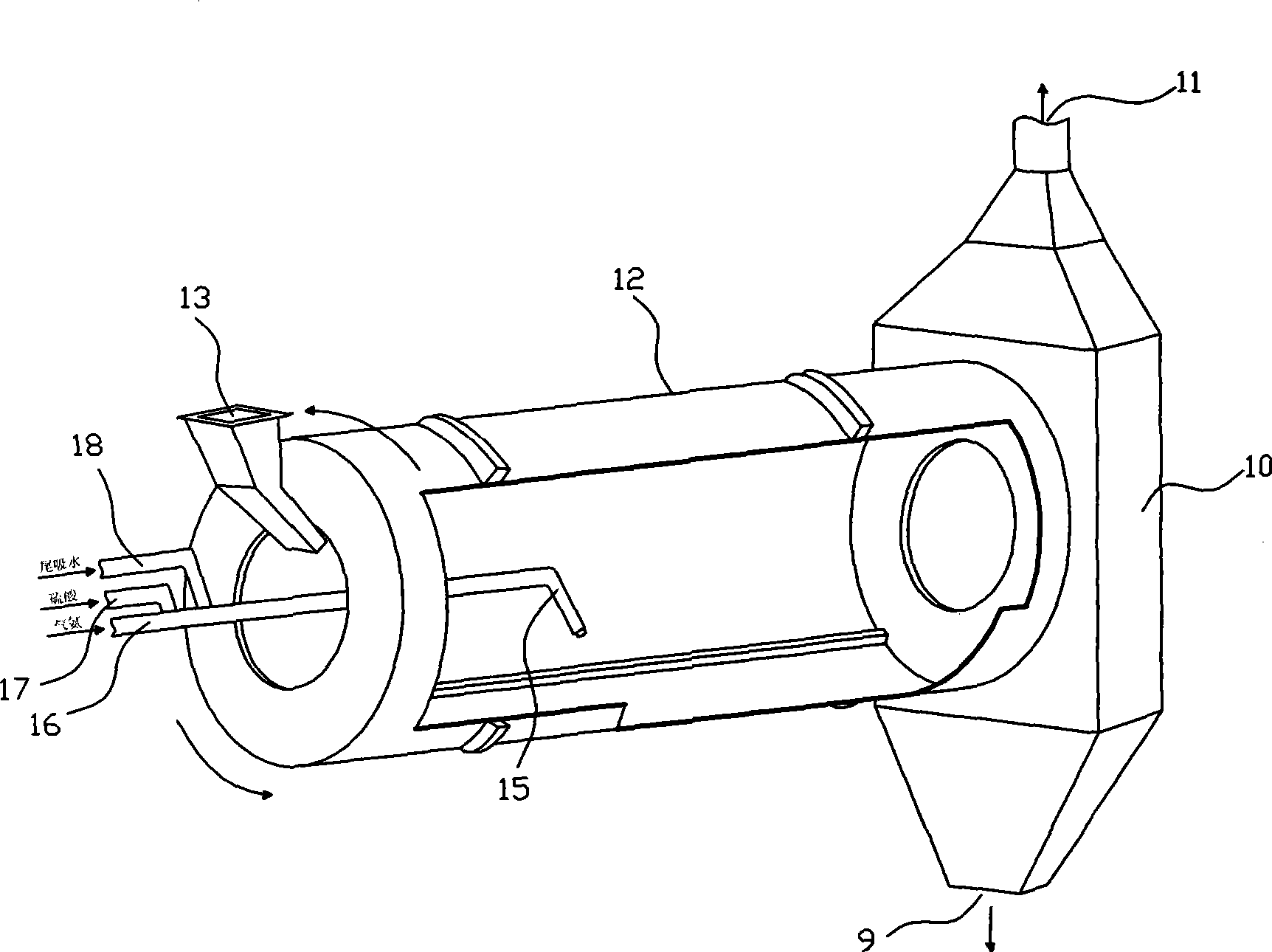

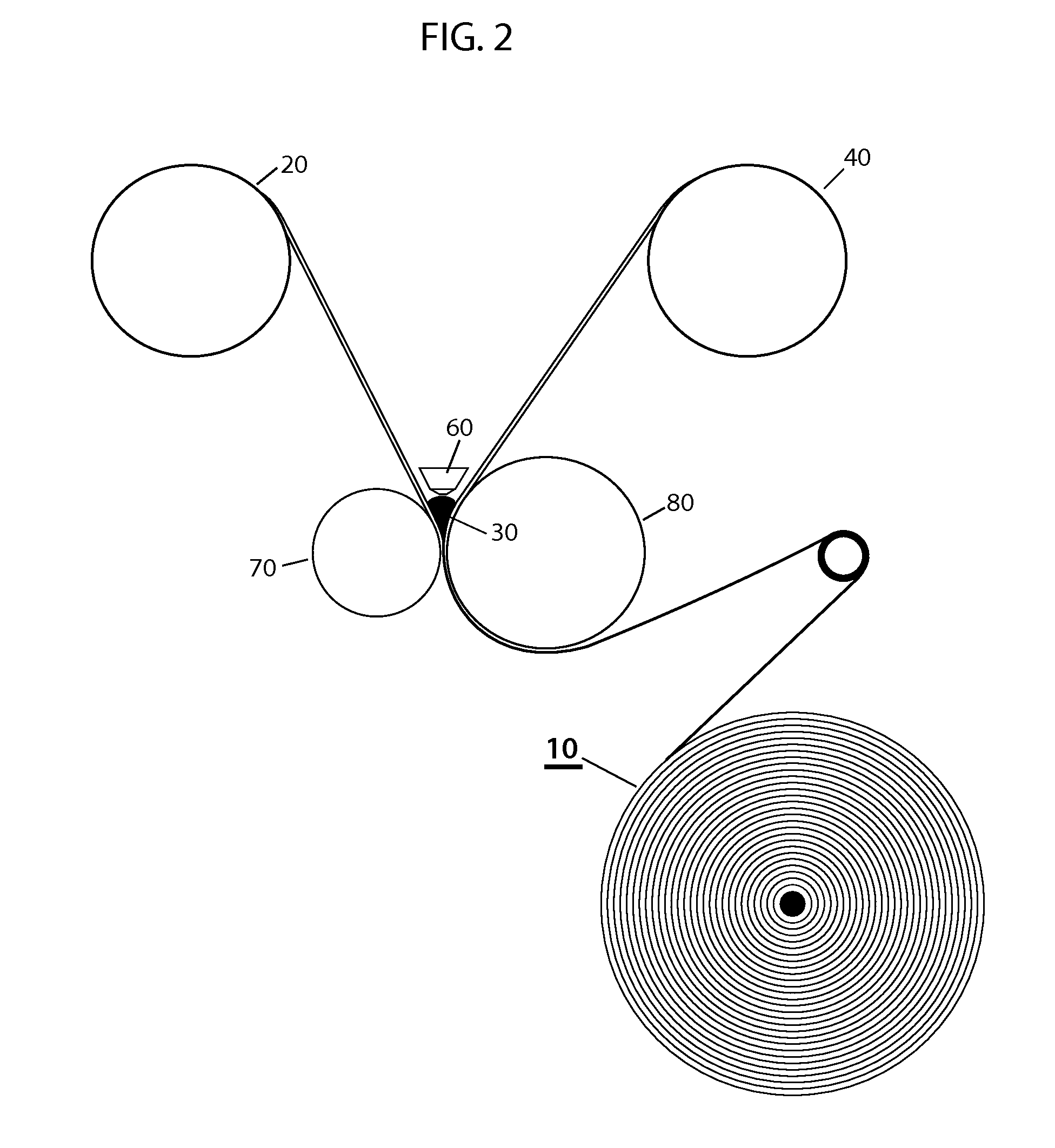

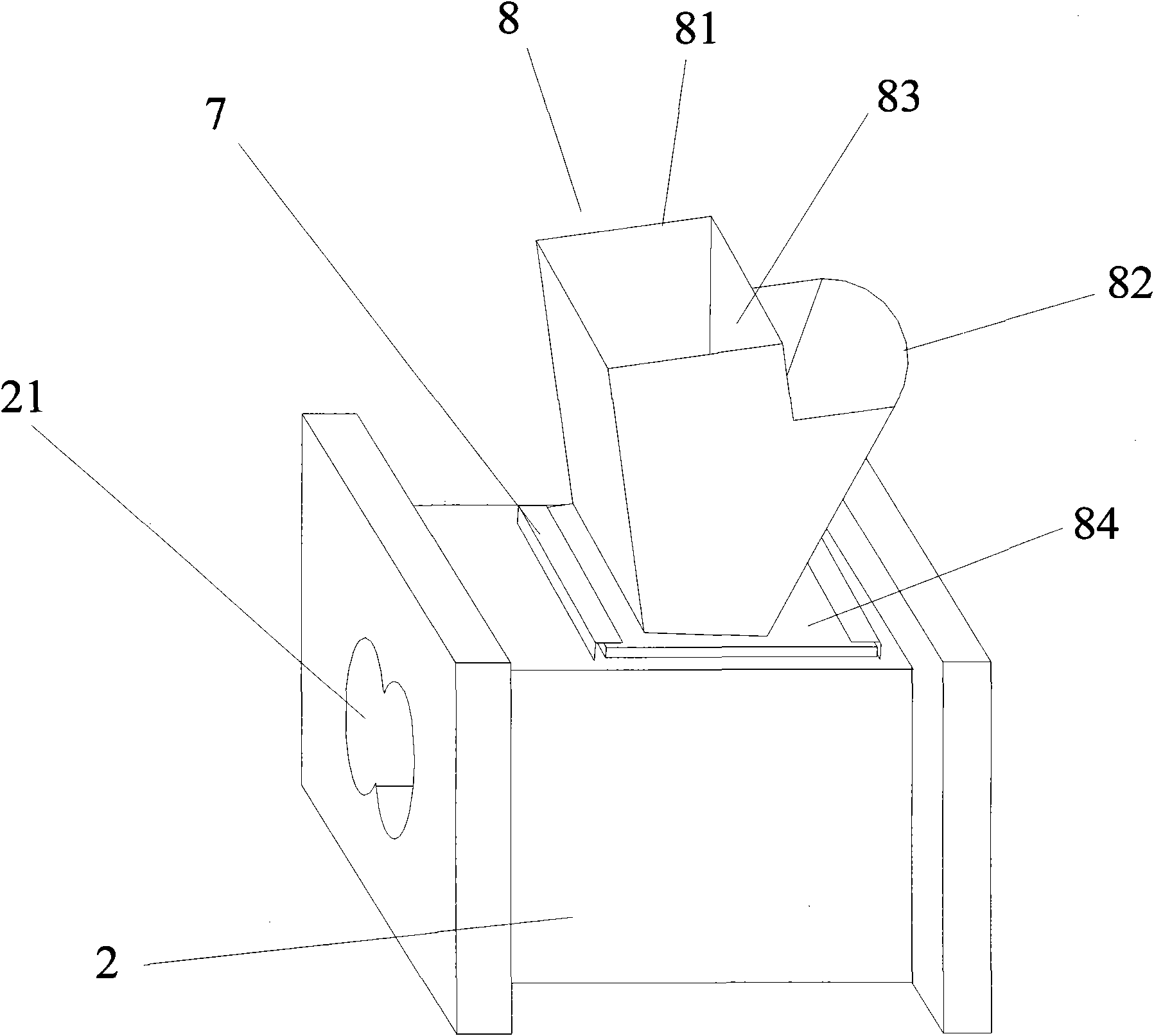

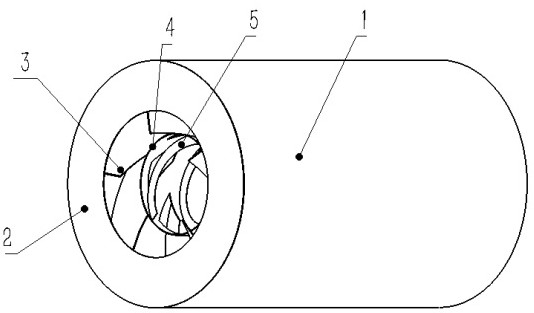

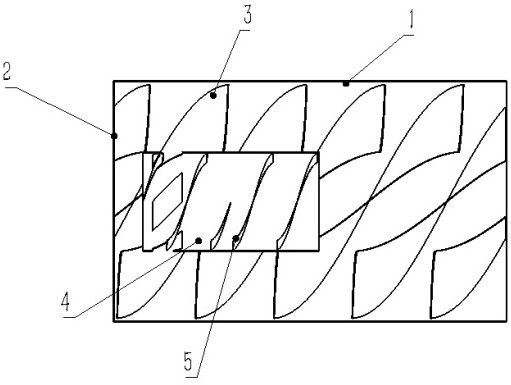

Ammoniation granulator and composite fertilizer production novel technique

InactiveCN101391934AEasy to adjustIncrease elasticityFertiliser formsFertilizer mixturesSolid particleWater resistant

The invention relates to an ammoniation granulator and a compound fertilizer production technology by an amino acid method, aiming at solving the technical problems in the compound fertilizer production process that: biuret is easy to generate, the granulating effect is not good, the production efficiency is low and the energy consumption is high. An amino acid distributor of the ammoniation granulator is respectively and independently arranged, an amino spraying branch pipe provided with an inclined plane spout has an angle of 30 to 60 degrees with a vertical line on the cross section of a cylinder, the rotating directions of the inclined plane spout and the cylinder are consistent; the spout of an acid spraying branch pipe is correspondingly arranged in the opening direction of the inclined spout of the amino spraying branch pipe; and when ammoniation granulating, the granulator sprays liquid ammonia in a material layer with the pressure of 0.5 to 1.0MPa through the amino distributor, an acid distributor sprays sulphuric acid of 50 to 70 percent in the material layer with the pressure of 0.2 to 0.5Mpa, and each ton of solid material is injected with 15 to 25kg of liquid ammonia and 16.8 to 39.2kg of dilute sulphuric acid. The invention is applied in various raw materials and suitable for the scale production of various compound fertilizers; and the finished products have perfectly round and solid particles, are water resistant and movement resistant and not easy to be crushed and agglomerated.

Owner:JIANGSU ABOLUO COMPOUND FERTILIZER

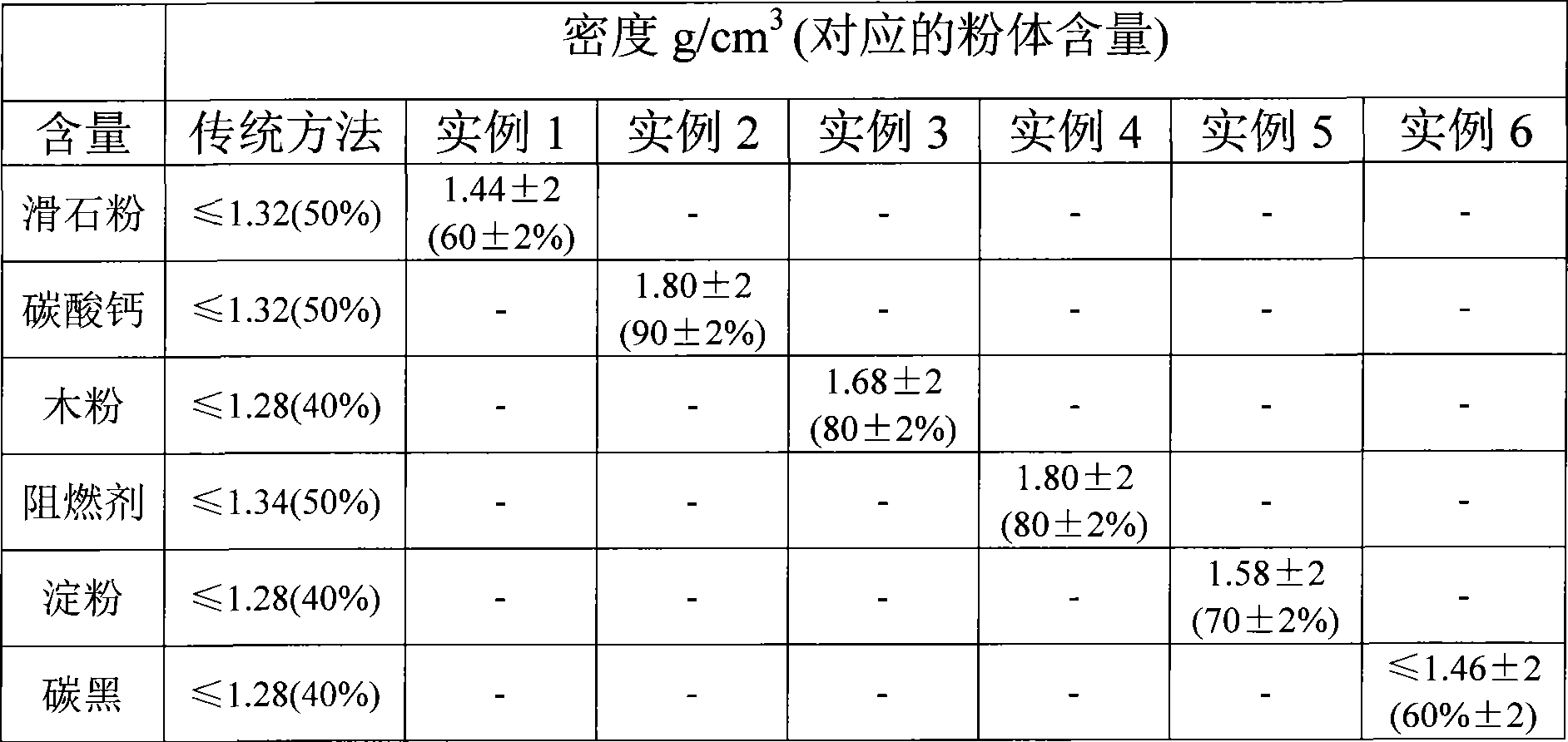

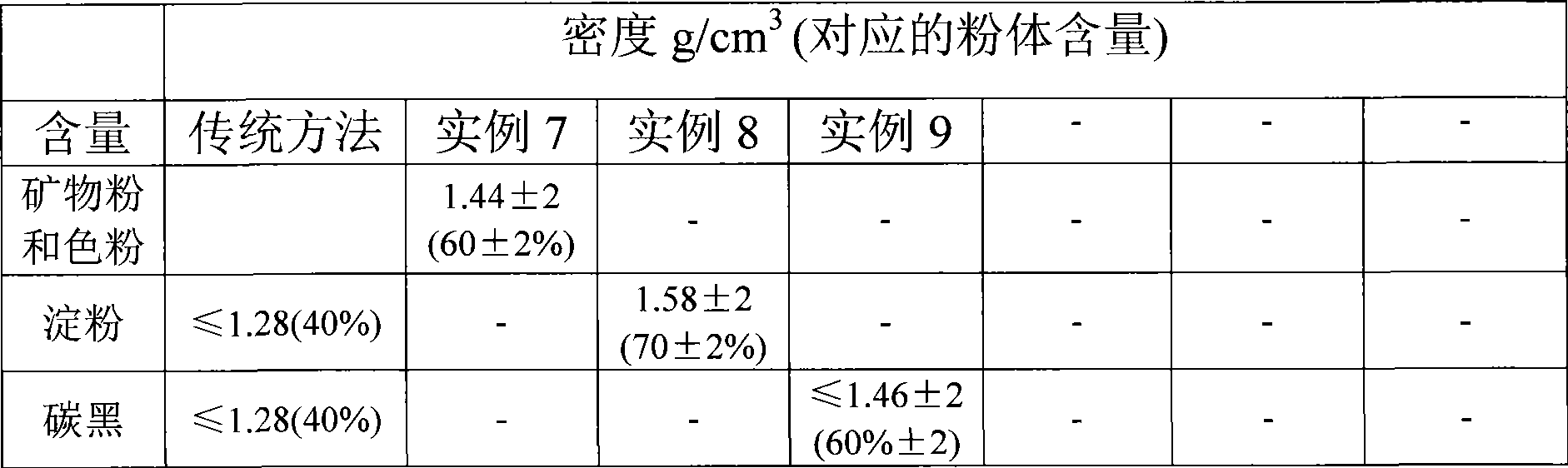

Method for preparing master batch with high-powder content

The invention provides a method for preparing masterbatch with high powder content. The method comprises the following steps: various raw materials are prepared, a Banbury mixer is kept at constant temperature, all the carriers and 50-80 percent of or all powder components, lubricant, dispersing agent and coupling agent are placed in the Banbury mixer for kneading; after the remained functional components are placed in the Banbury mixer for kneading, the Banbury mixer barn is turned over; the materials are decanted into the feeding hopper of a single screw extruder through a transporting receptacle; by the forced feeding of the feeding hopper, the single screw extruder is used to obtain functional masterbatch with high powder content. The method is capable of solving the problem that feeding is difficult during direct production of high powder when blending modified plastics system is filled, and the problem of difficult processing in the modified plastics industry; the masterbatch with high powder content can also meet the requirements of downstream products, and used to produce injection-moulded or extruded products.

Owner:GUANGDONG KINGFA TECH CO LTD

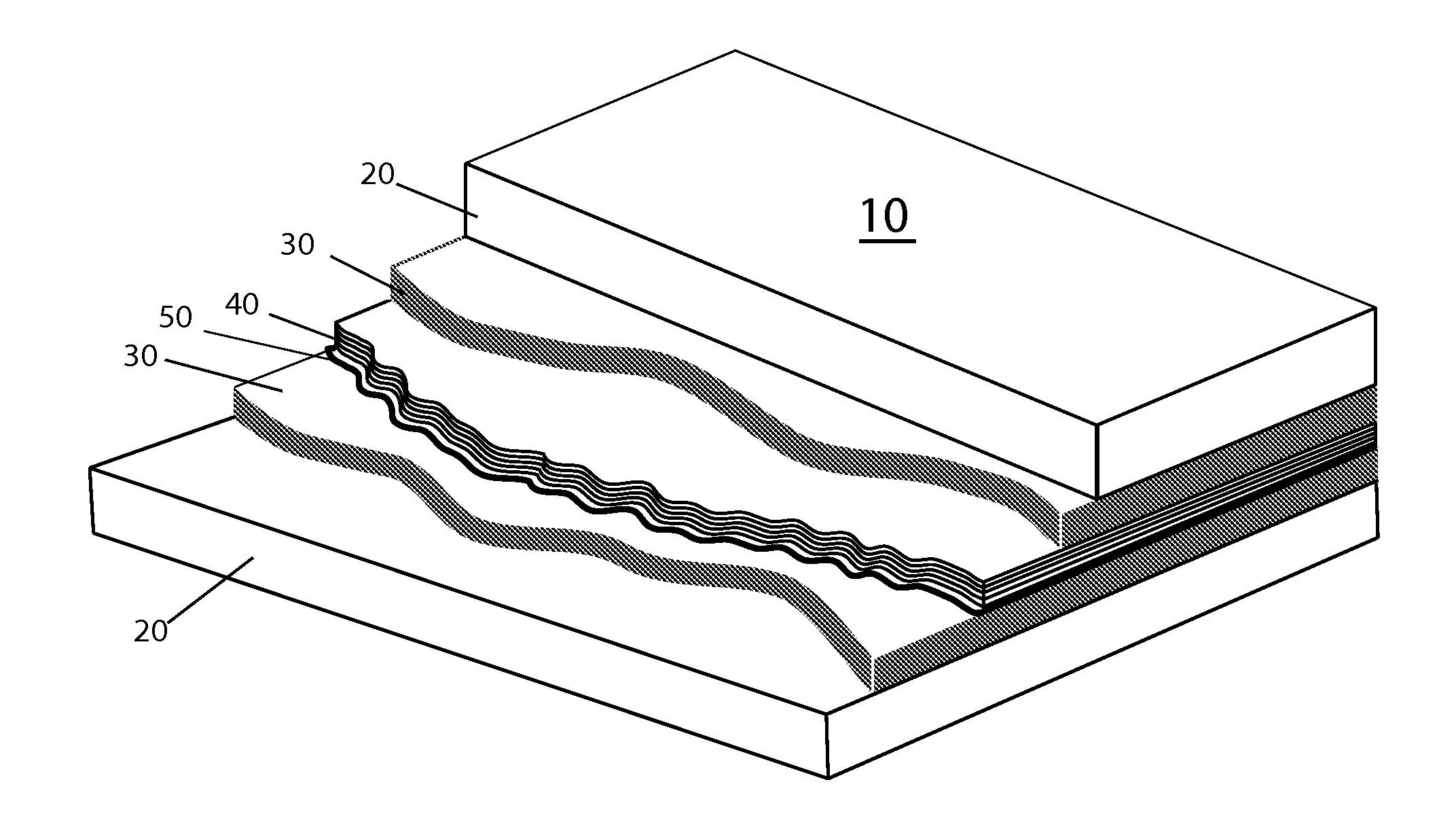

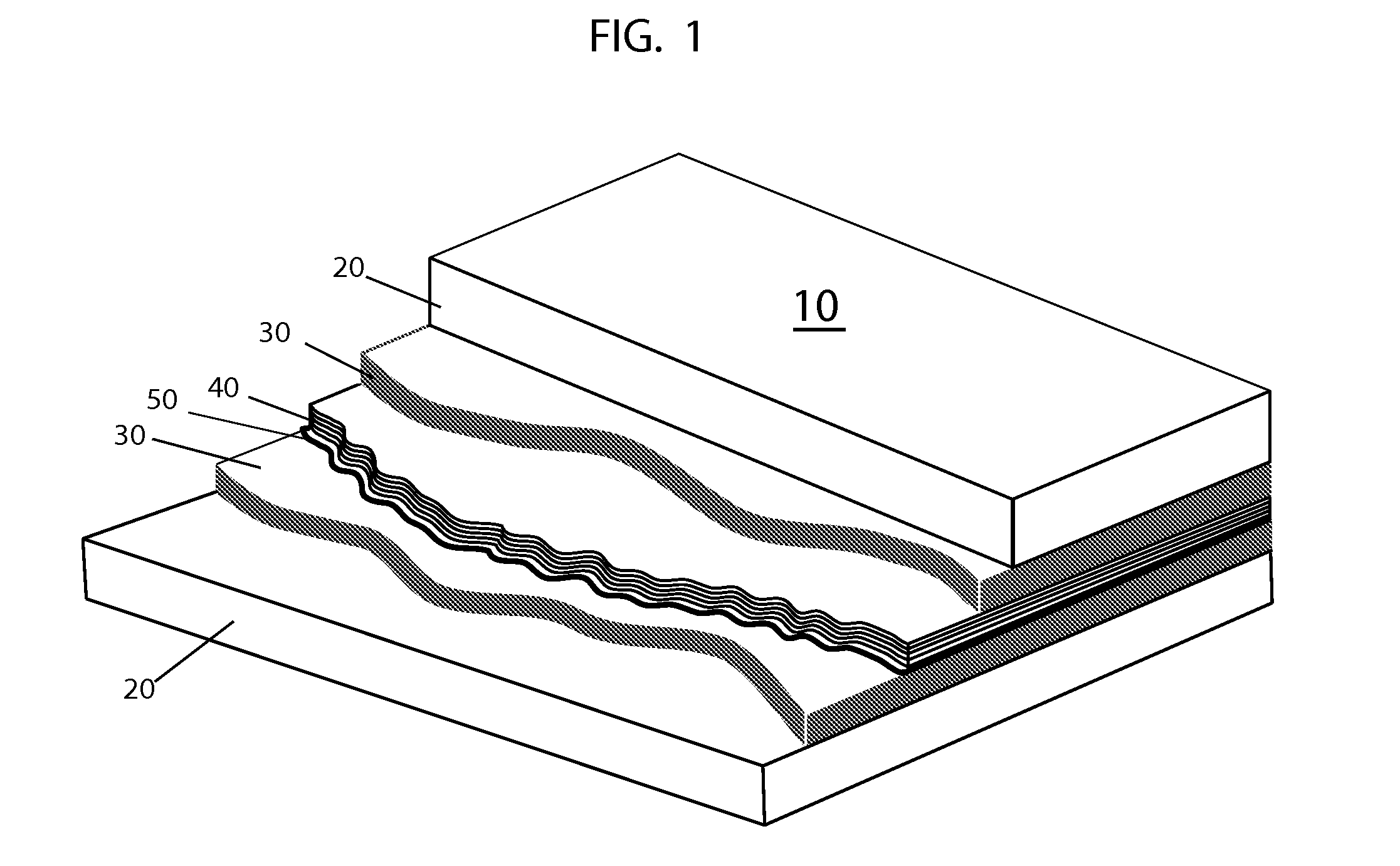

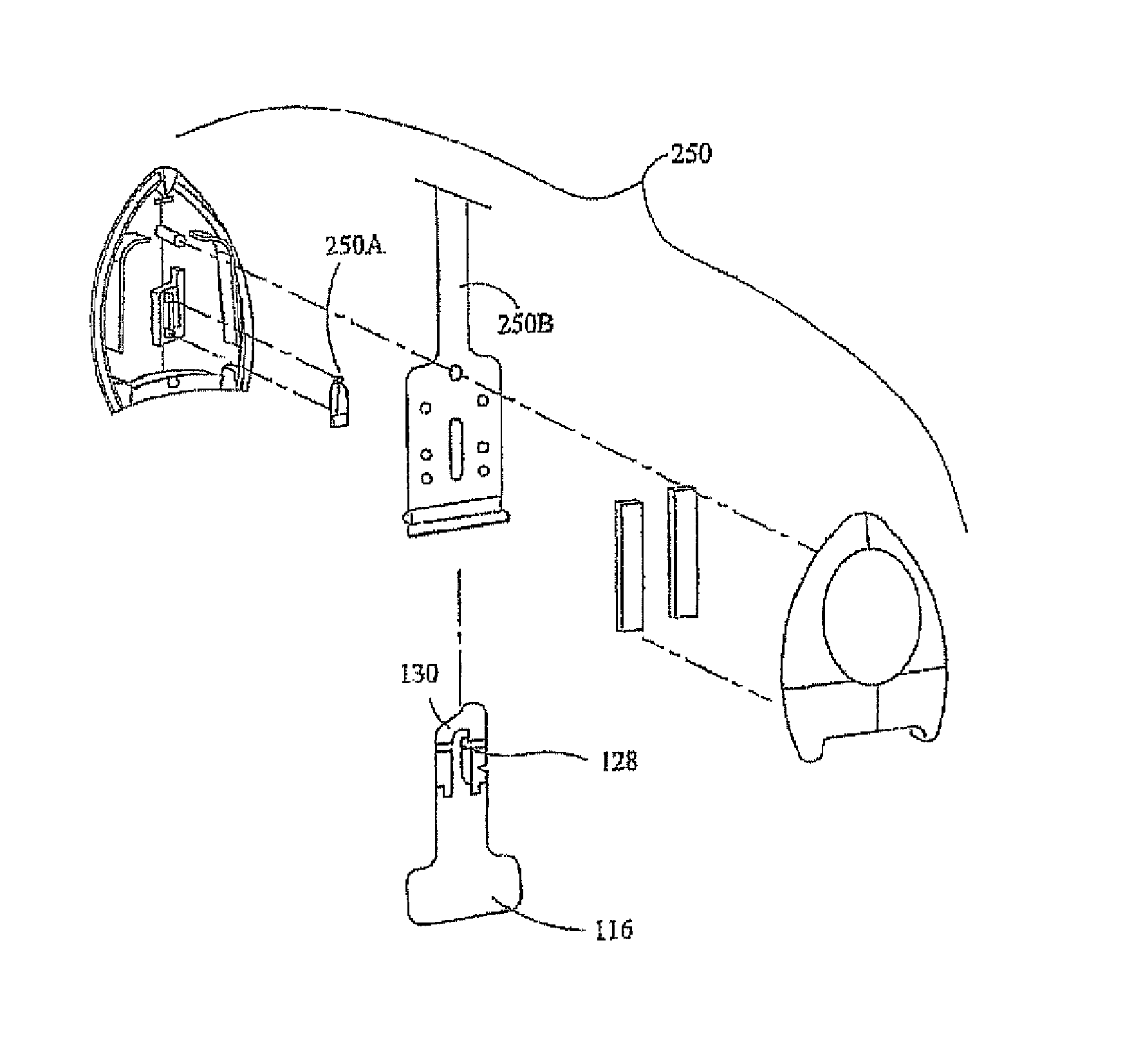

Compostable Composite Multipanel Smartphone, Tablet & Mobile Electronic Device Cover Kits for Consumer Print Personalization and Structural Customization

ActiveUS20150151515A1Minimized environmental impactGreat range of tonal valueStampsWrappersFiberPersonalization

Disclosed is DIY consumer kit for making print personalized, structurally customized covers and cases used to protect mobile electronic devices. In all embodiments, covers and cases use an encapsulated bio-based compostable resin composite fused with external layers of organic carbon neutral reclaimed industrial fiber, this composite provides an inkjet receptive sheet that may be fed through any printer for consumer customization. These composites in sheet or roll form may be scored, laser cut and mirco-cut for all flat electronic devices to facilitate folding into a 3D form. Once printed, consumers may fold the 2D composite sheet, attach pre-cut layered adhesives, nano suction attachment pads and attachment clear plates for device placement on the interchangeable covers or cases. Nano rubber polymer suction pads provide locking cover attachment, attachment of the electronic device to other surfaces and enable angled viewing when the covers are folded in a stand configuration.

Owner:FOUTCH ALLAN

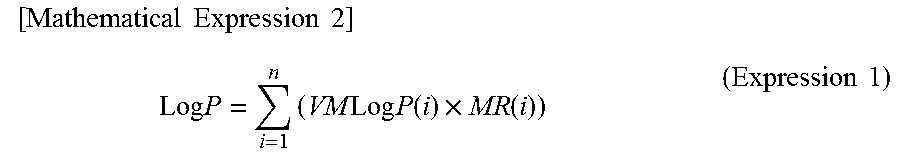

Water absorbent resin material, and method for producing same

ActiveUS20150360204A1Increase capacityImprove liquid permeabilityOther chemical processesAbsorbent padsWater dispersibleWater soluble

An object of the present invention is to provide a water absorbent resin which attains high liquid permeability and water absorbing speed, and which does not have problems of coloring and odor. The water absorbent resin includes: (A) a water absorbent resin particle having a carboxyl group; (B) a covalent surface crosslinking agent in which the number of carbons is not more than 10; (C) 0.001 mass % to 0.2 mass % of a water-soluble or water-dispersible polymer whose Log P is not less than 1.0; and (D) 0.001 mass % to 1 mass % of a water-soluble polyvalent cation. The water absorbent resin has not less than 20 g / g of a fixed height absorption (FHA) at a height of 20 cm.

Owner:NIPPON SHOKUBAI CO LTD

Iontophoresis Drug Delivery Device Providing Acceptable Depth and Duration of Dermal Anesthesia

An electrically assisted transdermal drug delivery system for highly effective electrotransport of an anesthetic and a vasoconstrictor producing clinically acceptable depth and duration of dermal anesthesia at a treatment site. In certain embodiments, the anesthetic comprises lidocaine and the vasoconstrictor comprises epinephrine.

Owner:VYTERIS

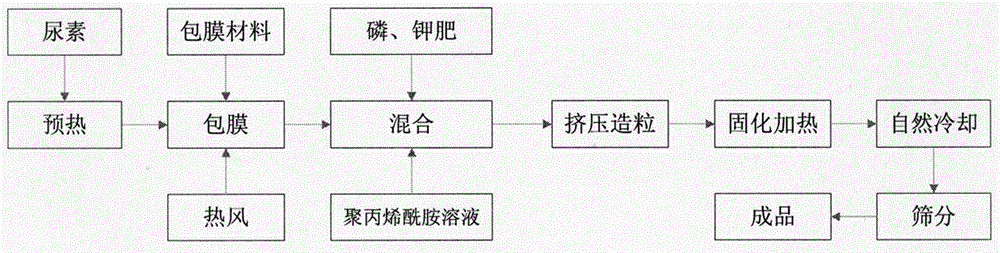

Production method of large-granule slow-release fertilizer

InactiveCN102976859AAdapt to the needs of the nutrient slow release periodShort processFertiliser formsFertilizer mixturesEpoxyPhosphate

The invention relates to a production method of a large-granule slow-release fertilizer, belonging to the technical field of manufacturing of fertilizers. The production method comprises the following steps: adding granular urea which is preheated to 50-100 DEG C into a rotating drum coating machine, and coating by using a mixed solution of polyisocyanate, polyalcohol, epoxy resin, dimethylbenzene and inorganic powdery filler as a coating material; after finishing the coating, adding monoammonium phosphate, potassium chloride (or potassium sulfate) and polyacrylamide solution, evenly mixing, and adding the mixture into an extrusion granulator to carry out extrusion granulation; and standing the granulated semi-finished product at 60-100 DEG C for 1-10 hours for curing, naturally cooling, and screening to obtain the finished product. The large-granule slow-release fertilizer with the diameter of 10-100 millimeters and the weight of 10-500g can be produced according to the size of the mold of the extrusion granulator. Compared with the common small-granule slow-release fertilizer, the large-granule slow-release fertilizer has the advantages of lower cost, stable nutrient release, uniform nutrition in every granule, and fixed weight, can implement precise fertilizer application, and reduces the fertilizer application frequency and labor investment.

Owner:ZHENGZHOU UNIV

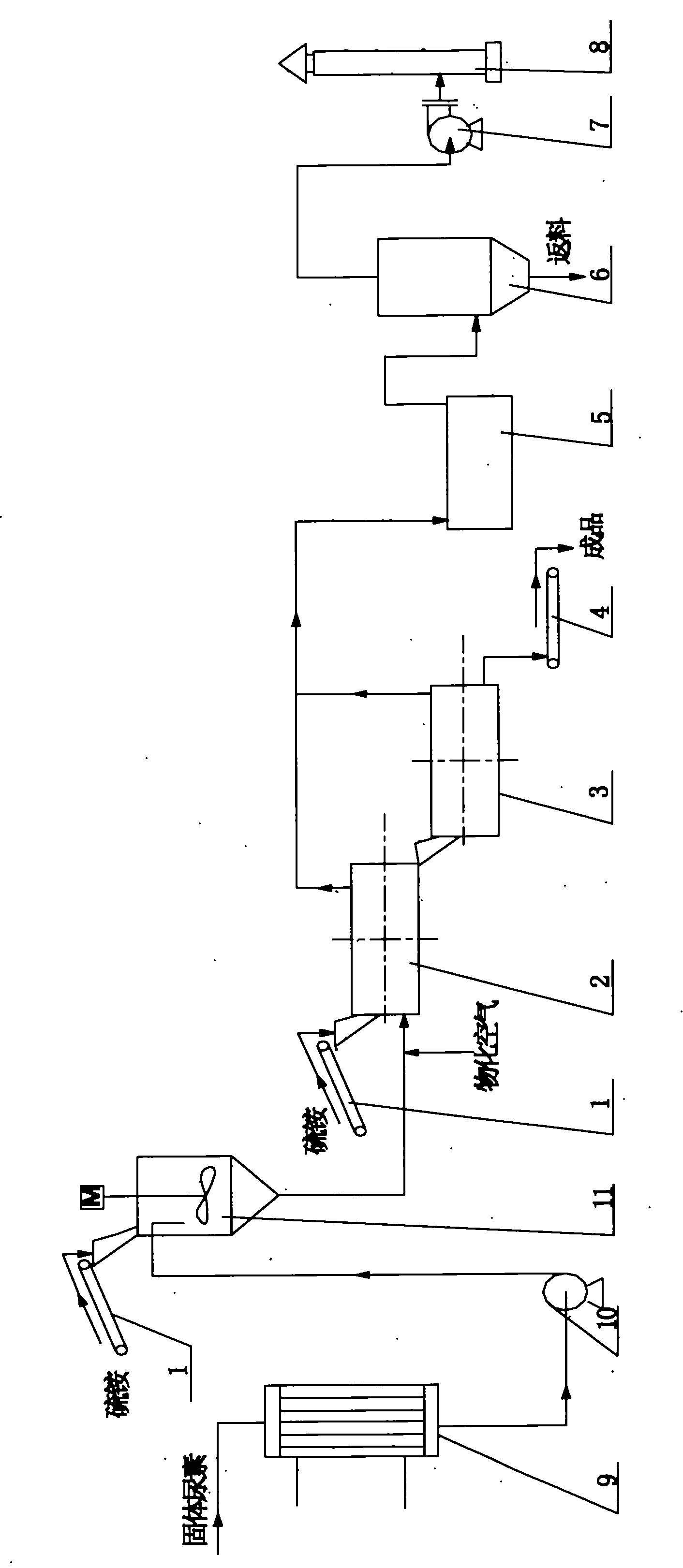

Process for producing urea ammonium sulfate by using by-product of ammonium sulfate from flue gas desulfurization with ammonia process

InactiveCN101863696AImprove stabilityPrevent compactionAmmonium salt fertilisersUrea compound fertilisersSeed crystalNuclear chemistry

The invention discloses a process for directly producing long-acting large-particle urea ammonium sulfate by using the by-product of ammonium sulfate from the flue gas desulfurization. Solid urea is measured and added to a urea quick melting device, and then liquid urea is added to a urea and ammonium sulfate mixer; one part of ammonium sulfate crystal from the flue gas desulfurization and drying is added to the urea and ammonium sulfate mixer to be pulped, and the other part is delivered to a rotary drum coating granulator so as to be used as seed crystal; the mixed pulp from the urea and ammonium sulfate mixer is sprayed on small ammonium sulfate particles through an air atomizing spray nozzle; the small ammonium sulfate particles are cooled by a rotary drum cooler; the cooled small ammonium sulfate particles are added into a vibrating screen so as to be screened; and the qualified small ammonium sulfate particles are added into a packaging belt. The large-particle urea granulating technology is adopted by the process, thus the external material return is reduced in the production process, and the consumption is lowered. The urea and the ammonium sulfate are combined, thus the defect of signal product is overcome. The proportion of nitrogen to sulfur can be adjusted according to the crop or market demand. The urea ammonium sulfate can prevent the soil hardening and increase the crop yield and can take effect quickly for a long term.

Owner:北京九州美电环保工程有限公司 +1

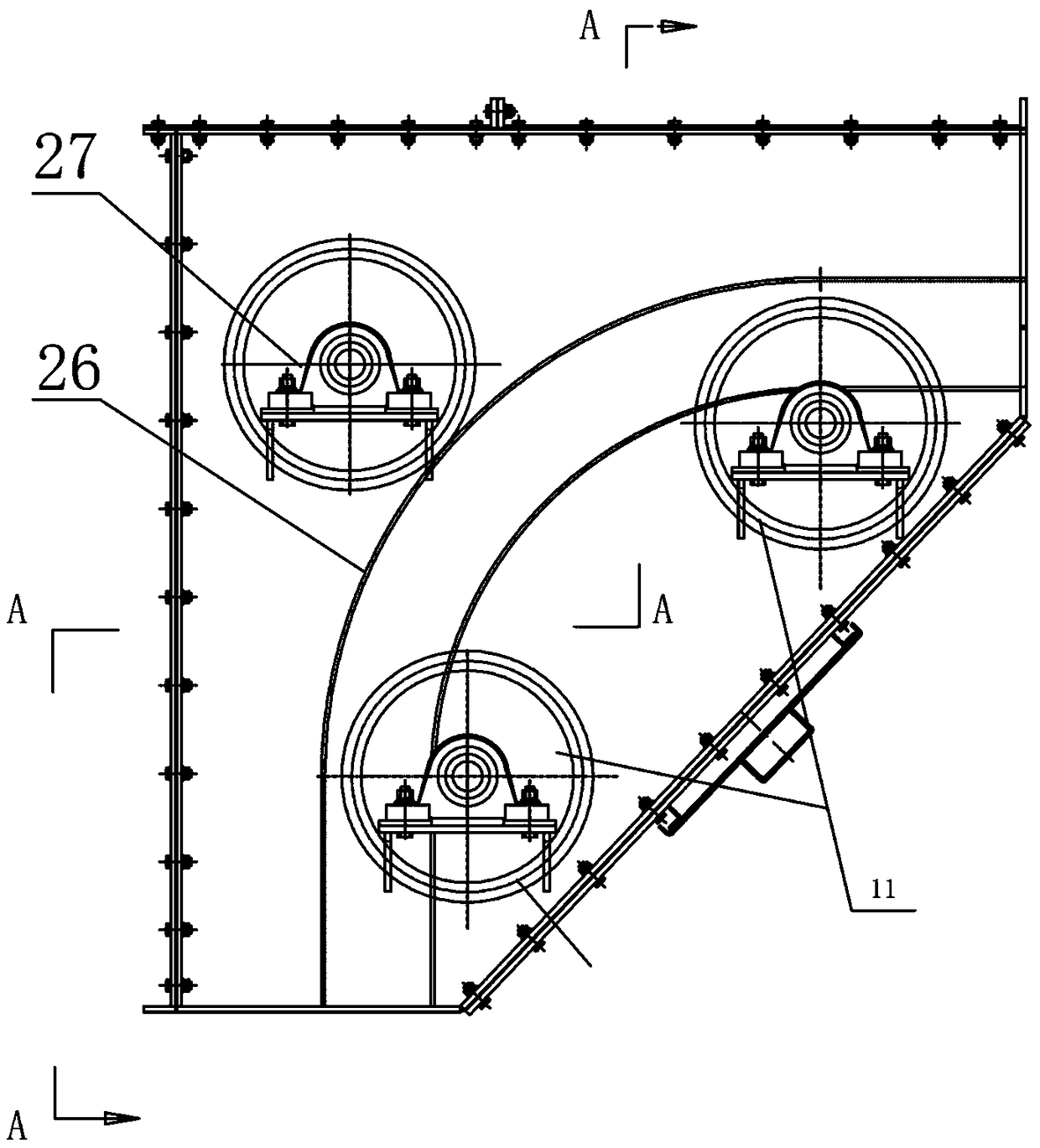

Method and device for smelting jamesonite by bottom-blowing pool

The invention relates to a method and a device for smelting jamesonite by a bottom-blowing pool. The method comprises the following steps of: performing pool smelting, oxidation and desulfurization on the jamesonite by using a bottom-blowing oxidation furnace to produce antimony-containing high-lead slag, a lead-antimony alloy and flue gases suitable for acid preparation; reducing the antimony-containing high-lead slag and blowing the lead-antimony alloy by using a bottom-blowing smelting furnace to produce antimony oxides and lead bullion capable of being used for electrolysis; and reducing the antimony oxides by using a bottom-blowing reduction furnace to produce needle antimony. In the smelting method of the invention, the three bottom-blowing furnaces and an electrically-heated settler are adopted to treat the jamesonite to produce the lead bullion, the needle antimony and the slag; therefore, compared with the prior art, the method has the advantages of short flow, good lead-antimony separation effect, fewer intermediate products, less revert, high resource utilization rate and production continuity; and the bottom-blowing oxidation furnace can realize spontaneous heating balance by sulfide combustion with low energy consumption and high recovery rate and can greatly reduce the cost.

Owner:JIYUAN YUGUANG NONFERROUS METALLURGY DESIGN & RES INST CO LTD

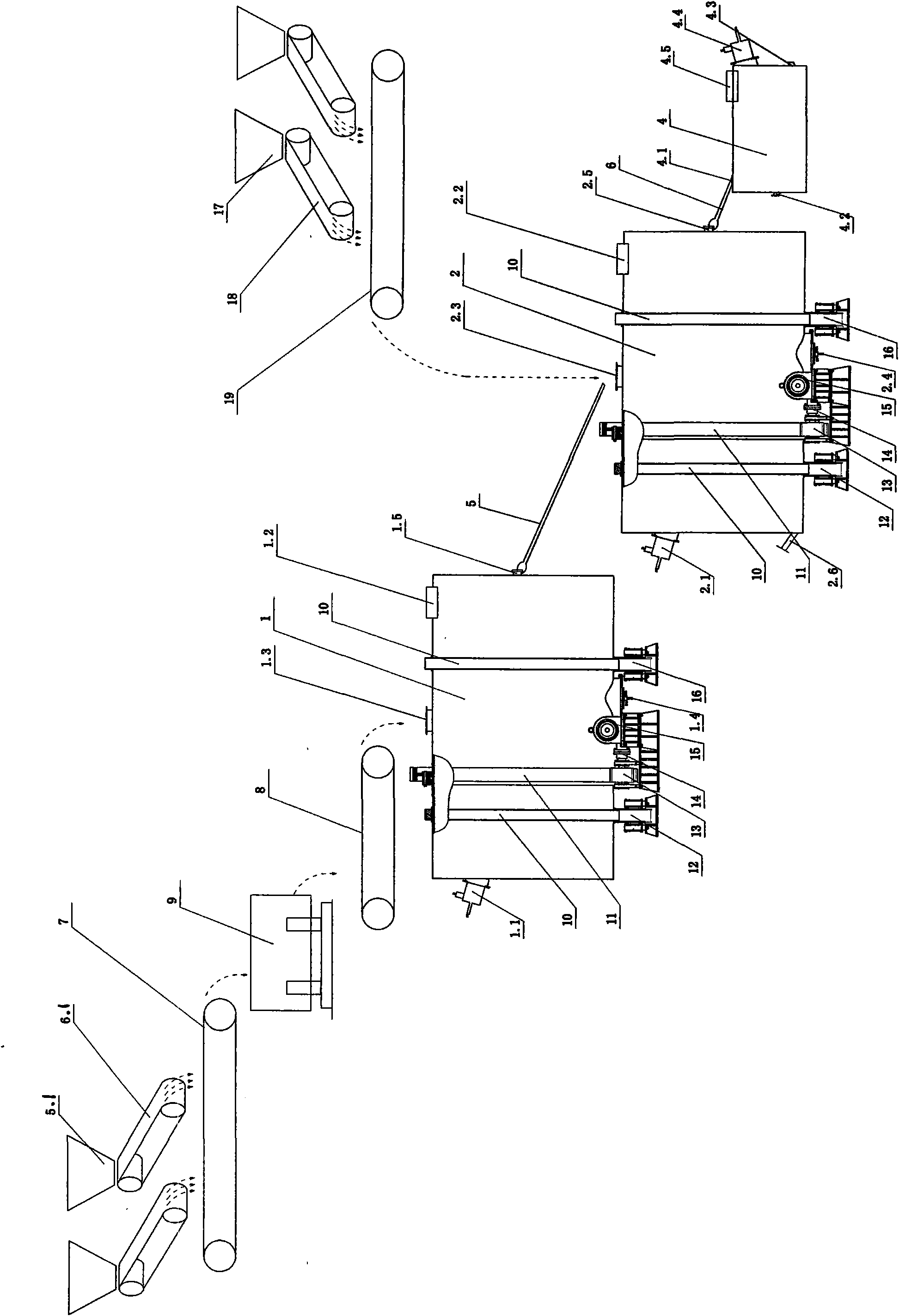

Environment-friendly high-quality sand making building station system

PendingCN109127086APrecise screeningCompact structureGrain treatmentsProduction rateEnvironmental resistance

The invention discloses an environment-friendly high-quality sand making building station system. A discharging port of a feeding and collecting bin is connected with a feeding port of a spill waterfall type vertical shaft through a pipeline, a discharging port of the spill waterfall type vertical shaft is connected with a feeding port of a primary powder concentrator, and a plate conveyor is placed below a discharging port of the primary powder concentrator. The system has the benefits as follows: 1, the gradation and fineness can be controlled according to demands of clients, so that different selling prices of products in different specifications can be obtained, and better economic effects can be obtained; 2, the capacity is high, finished products have superior granule shapes and thesand production rate is high; 3, the stone powder content and moisture content of sand can be controlled as required.

Owner:NANTONG UNION MACHINERY ELECTRONTCS TECH CO LTD

Iontophoresis drug delivery formulation providing acceptable sensation and dermal anesthesia

InactiveUS20090312688A1Great confidenceFewer returnsElectrotherapyAnaesthesiaVasoconstrictor AgentsBlood vessel

A shelf-stable electrically assisted transdermal drug delivery system for highly effective electrotransport of an anesthetic and a vasoconstrictor producing clinically acceptable dermal anesthesia and sensation is provided. In certain embodiments the anesthetic includes lidocaine and the vasoconstrictor includes epinephrine. Medicament delivery is affected to provide dermal anesthesia with little or no sensation during delivery, as measured by a variety of indicator tests. Methods of producing dermal anesthesia in patients are also provided.

Owner:VYTERIS

Special fertilizer for preparing granular rice from sandy raw materials and preparation method and application of special fertilizer

InactiveCN109942338AIncrease costPromote photosynthesisRice cultivationFertilizer mixturesPhosphate fertilizerCalcium magnesium phosphate

The invention relates to a special fertilizer for preparing granular rice from sandy raw materials and a preparation method and application of the special fertilizer. A calcium-magnesium-phosphate fertilizer, ammonium chloride and a granulating agent are mixed in the weight ratio of (30-70):(30-70):(1-10); the mixture is added into a granulator for granulation, then the granulated particle material is transferred into a drying machine for drying, the dried particle material is transferred into a cooling screening machine for cooling and screening, and the special fertilizer is obtained. Compared with the prior art, the calcium-magnesium-phosphate fertilizer and the ammonium chloride are put together, and a small quantity of granulating agent is added, so that granulation is easy, nutritional requirements of paddy rice are met, and the use quantity of other chemical fertilizers can be replaced and reduced.

Owner:SHANGHAI RES INST OF CHEM IND

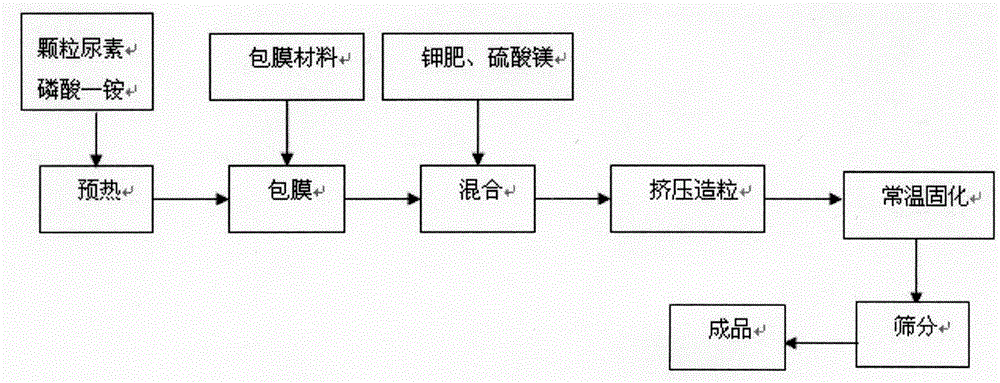

Production method of special network controlled-release fertilizer for eucalyptus

The invention relates to a production method of a special network controlled-release fertilizer for eucalyptus, belonging to the technical field of preparation of fertilizers. The production method comprises the following steps: adding granular urea and monoammonium phosphate which are preheated to 50-100 DEG C into a rotating drum coating machine, and coating with a coating material; after finishing the coating, adding a potassium fertilizer and magnesium sulfate, evenly mixing, and adding the mixture into an extrusion granulator to carry out extrusion granulation; and curing and cooling the granulated semi-finished product by standing at natural temperature for 1-30 hours, and screening to obtain the finished product. The special network controlled-release fertilizer for eucalyptus with the diameter of 10-100 millimeters and the weight of 10-500g can be produced according to the size of the mold of the extrusion granulator. Compared with the common coated controlled-release fertilizer, the special network controlled-release fertilizer for eucalyptus has the advantages of lower cost, stable nutrient release, uniform nutrition in every granule, and fixed weight, can implement precise fertilizer application, and reduces the fertilizer application frequency and labor investment.

Owner:ZHENGZHOU UNIV

Quick-acting and long-acting controllable compound fertilizer and preparation method thereof

InactiveCN109134120AQuick resultsSustained fertilizer effectAlkali orthophosphate fertiliserExcrement fertilisersSeedlingFilm-coated tablet

The invention discloses a quick-acting and long-acting controllable compound fertilizer and a preparation method thereof. The compound fertilizer comprises a granular fertilizer core and a slow-release compound fertilizer film coating the surface of the fertilizer core, wherein the slow-release compound fertilizer film comprises the following raw materials: polylactic acid, perlite powder, acrylicacid and volcanic ash. The compound fertilizer provided by the invention takes effect fast, has sustained, long-lasting and stable fertilizer efficiency, and can continuously supply plant nutrients;after application of a large amount of the compound fertilizer at a time, seedlings are not burned, and the fertilization amount and the fertilization times are reduced.

Owner:ANHUI HUIPU BIOTECH

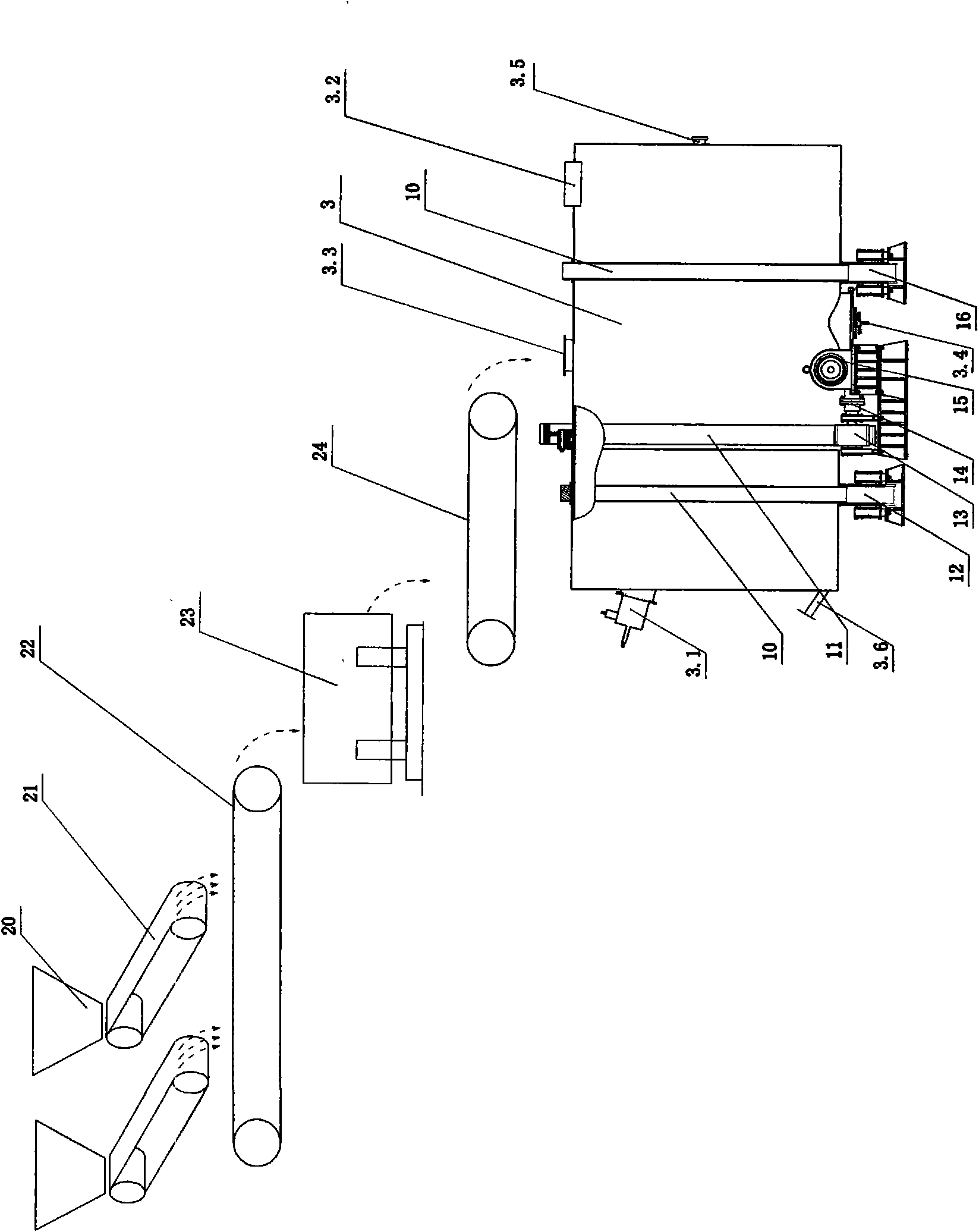

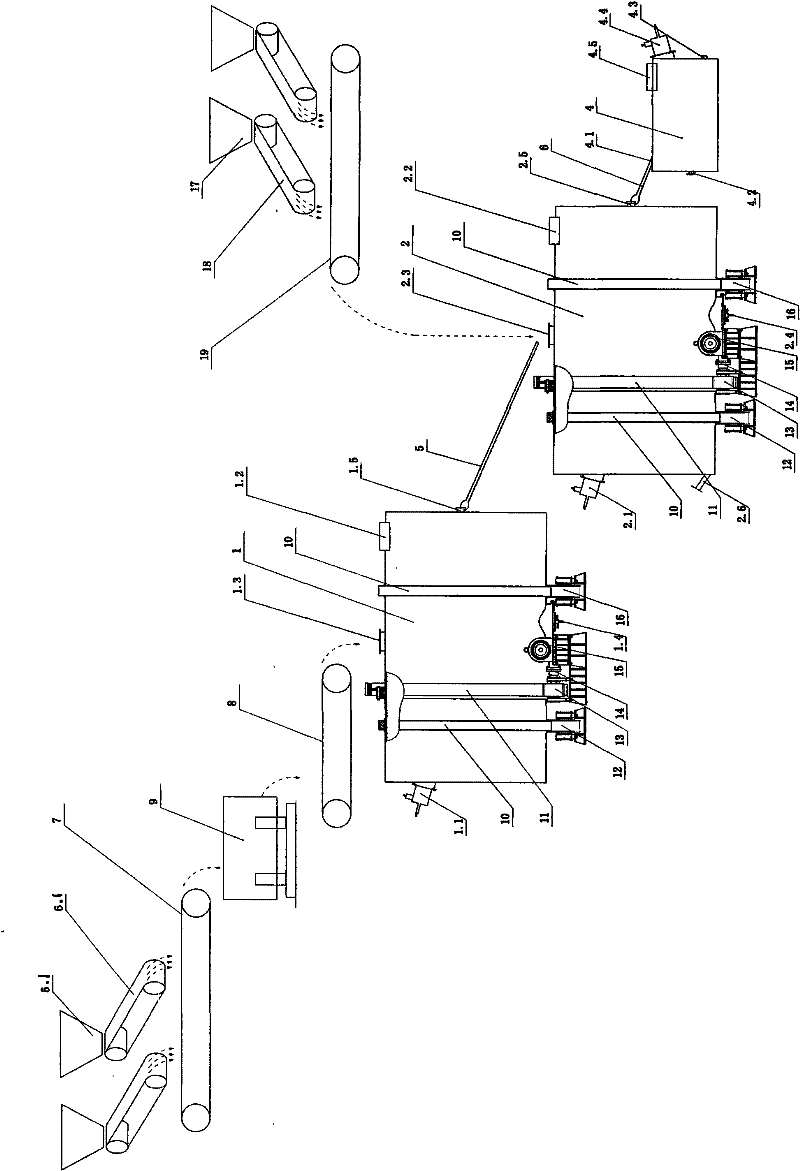

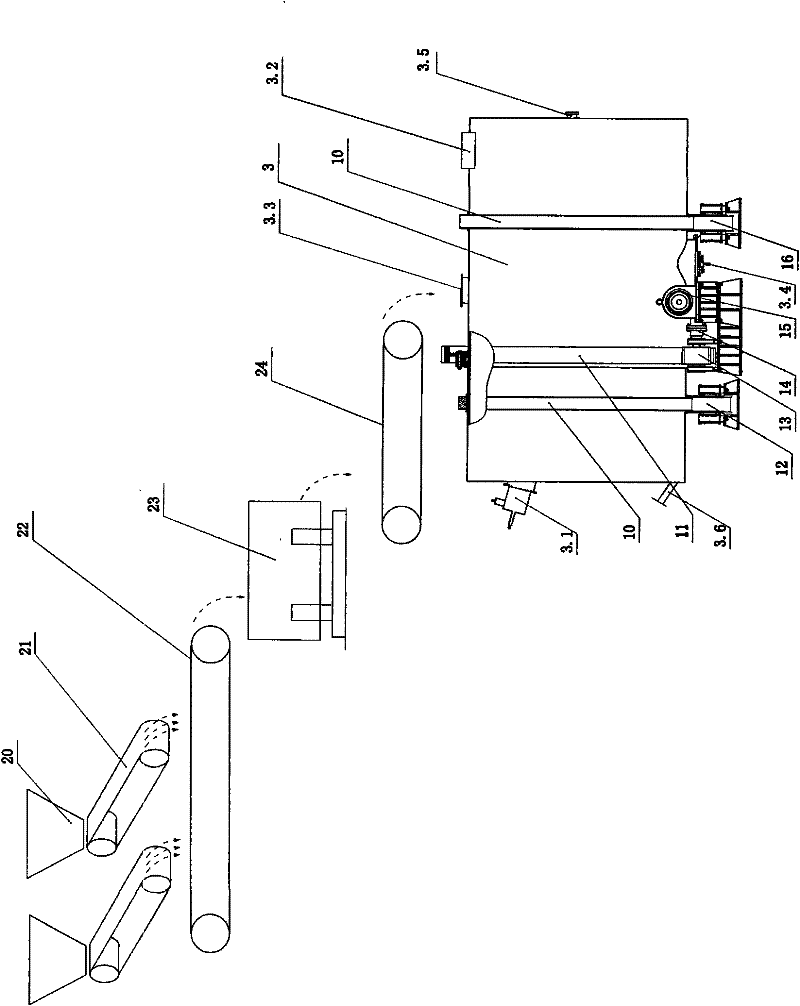

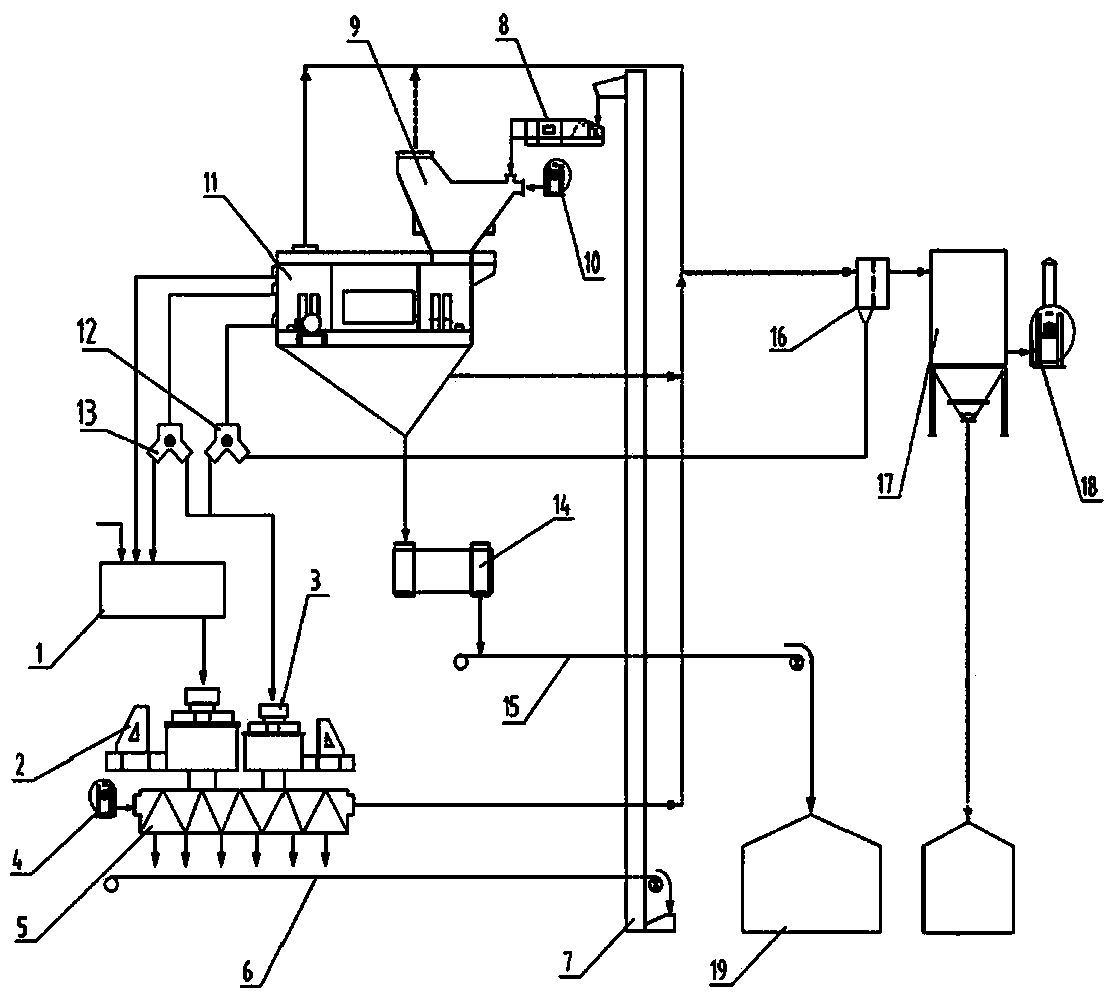

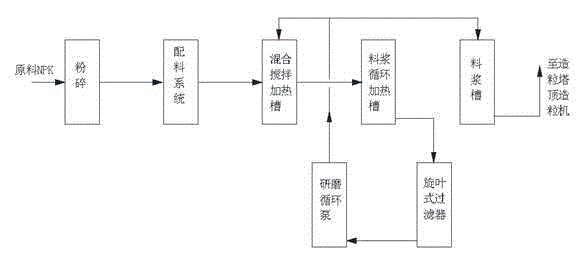

Tower pulping production system and process for tower production compound fertilizers

ActiveCN104860737AReduce pollutionReduce health impactFertilizer mixturesSocial benefitsEconomic benefits

The invention discloses a tower pulping production system and process for tower production compound fertilizers. The production system comprises a grinder and a batching system, wherein the grinder is connected with the batching system; a mixing and stirring heating tank, a slurry circulation heating tank, a filter, a grinding circulating pump, a slurry delivery pump and a rotary granulator are sequentially connected in series behind the batching system; the mixing and stirring heating tank is connected with the slurry circulation heating tank; and the slurry delivery pump is connected with the granulator. The invention discloses a tower pulping production process for tower production compound fertilizers. The process is formed by integrating key technologies such as batching, pulping, circulation heating, filtering and grinding and equipment technologies. Therefore, the yield of the product is over 90 percent, the productions safety is improved, the environmental pollution and influence on health of personnel are reduced, the equipment and civil engineering investment is greatly reduced, and the equipment is convenient to maintain. Therefore, the technology has considerable economic benefits and social benefits.

Owner:SICHUAN GOLDEN ELEPHANT SINCERITY CHEM CO LTD

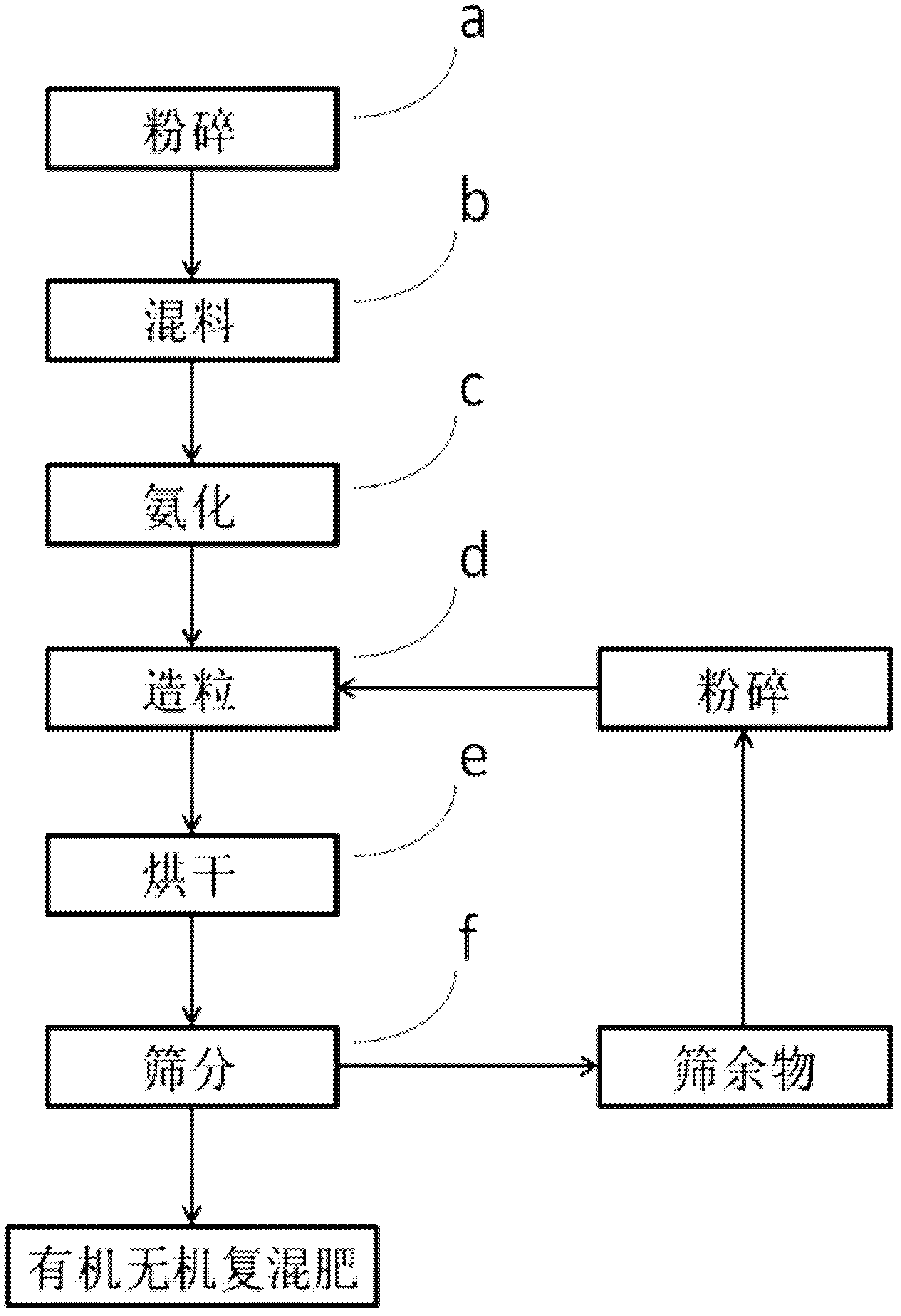

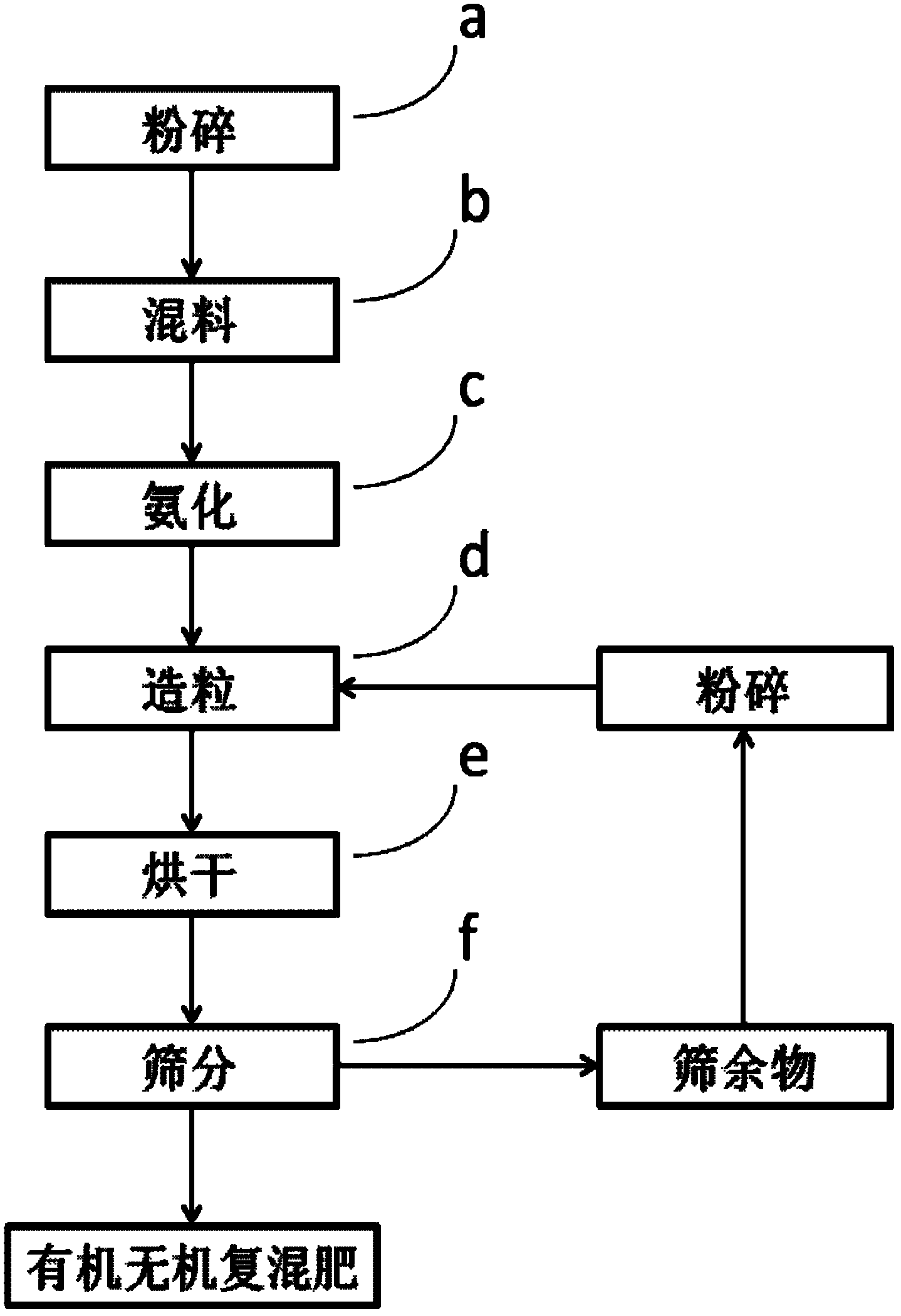

Method for making organic-inorganic compound fertilizer by composting municipal sludge

ActiveCN102285829AEfficient use ofNutrient balanceFertilizer mixturesSludge compostInorganic compound

The invention discloses a method for preparing an organic and inorganic compound fertilizer by using urban sludge compost, which prepares the organic and inorganic compound fertilizer by using urban sludge compost as a main raw material and weathered coal, ammonium bicarbonate, urea, ammonium hydrogen phosphate, potassium sulfate and modified corn flour binding agent as auxiliary materials and byan ammoniation granulation process. The method has the advantages that: the nutrient utilization rate is high; the fertilizer effect is lasting; less material is returned; the granulation rate is high; and the product has high storage performance. The method is suitable for large-scale treatment of sludge compost. The prepared organic and inorganic compound fertilizer can be applied conveniently and keep nutrient balance and has lasting fertilizer effect.

Owner:SOUND ENVIRONMENTAL RESOURCES

Double-ammoniation pelletizing process

PendingCN107935666AHigh reaction efficiency of production processHigh granulation rateAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPrillSlurry

The invention discloses a double-ammoniation pelletizing process which is characterized by comprising the following steps: I, preparing slurry; II, performing reactions in a tubular reactor; III, performing a double-ammoniation reaction. The production process disclosed by the invention is high in reaction efficiency, simple to wash and short in process procedure, washing water can be completely recycled, the obtained product is high in strength, granule surfaces are smooth, relatively round and glossy, a high pelletizing rate is achieved, a small amount of materials are turned back, the effective device utilization rate is high, and no clay is needed for pelletizing.

Owner:盘锦冠桥复合肥科技服务有限公司

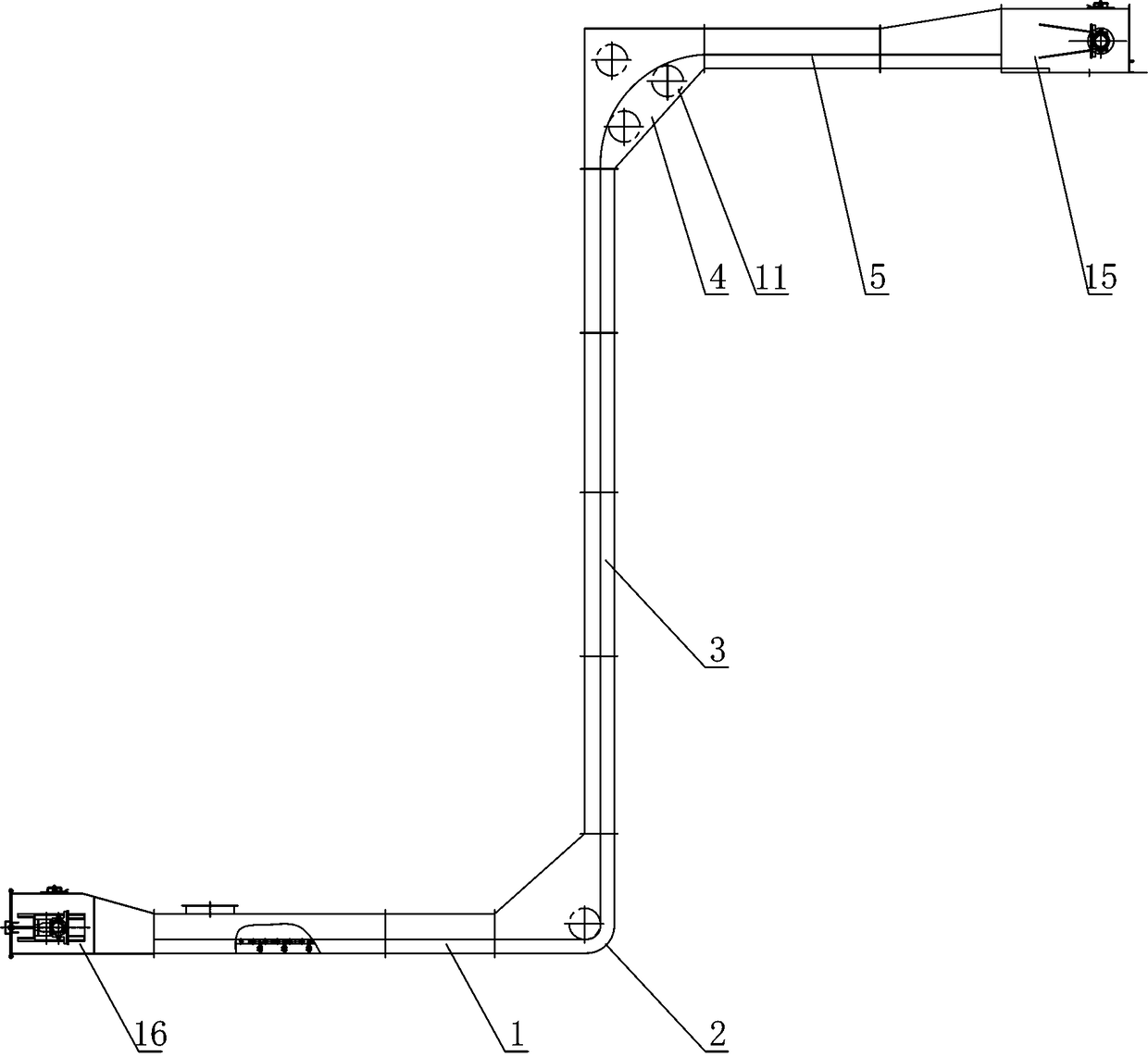

A mz type buried scraper sludge conveyor and its method

The invention relates to an MZ-type buried scraper sludge conveyor and an MZ-type buried scraper sludge conveying method thereof. The MZ-type buried scraper sludge conveyor mainly consists of a tail part, a lower horizontal section, a lower bending section, a vertical section, an upper bending section, an upper horizontal section and a head part, wherein the lower horizontal section, the vertical section and cross section of a shell of the upper horizontal section are of a 'TU'-shaped (a Chinese character) structure, a scraper chain is arranged in the shell, a double row roller chain of the scraper chain is arranged on left and right shoulders of the shell, and a scraper of the scraper chain is arranged in a groove of the shell and keeps a distance with the groove. The MZ-type buried scraper sludge conveyor and the method thereof which are provided by the invention have the advantages that the double row roller chain, an external scraper and a convex shell are arranged, and sludge is avoided from being directly contacted with the roller chain, so that corrosion of the sludge on the roller chain is reduced, and difficult material reverting and discharging caused by the fact that the sludge is bonded on the scraper chain can be avoided.

Owner:HUBEI YIDU ZHONGJI ENVIRONMENTAL ENG

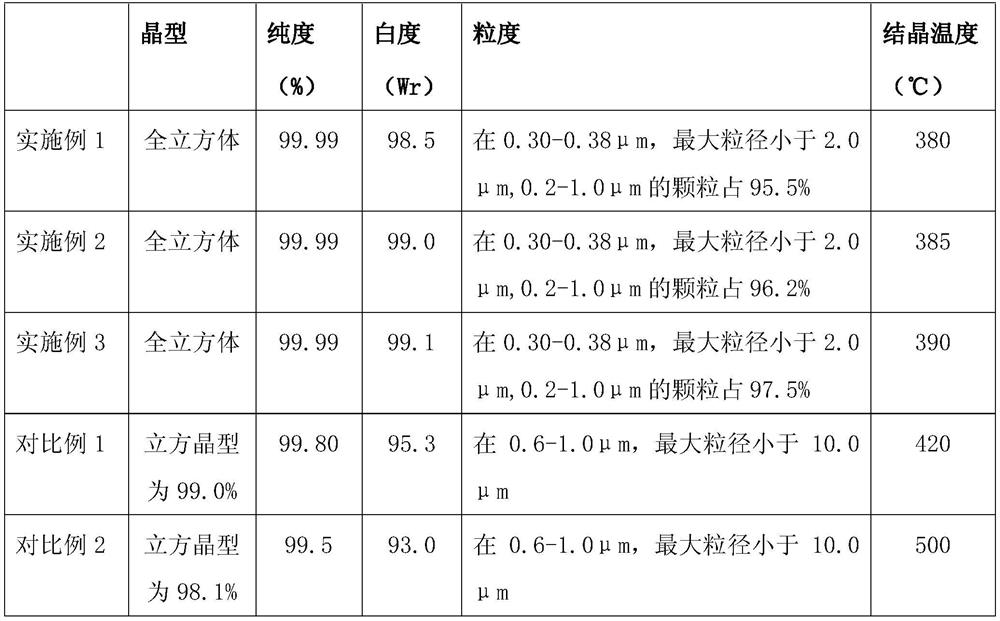

Oxygen-enriched production process of catalyst-grade antimony trioxide

ActiveCN112919538AReduce production energy consumptionWon't explodeAntimony oxides/hydroxides/oxyacidsCombustion systemPtru catalyst

The invention discloses an oxygen-enriched production process of catalyst-grade antimony trioxide. The process comprises the following steps: taking natural gas as fuel and oxygen-enriched air as a combustion improver, supplying heat to an antimony white furnace through a combustion system, after the temperature rises to 700 DEG C, putting high-purity antimony into the furnace to be melted, and spraying oxidized oxygen-enriched air to the surface of antimony liquid to oxidize and volatilize the antimony; and supplying part of heat through heating to increase the temperature in a hearth reaction area to 1100 DEG C or above, at an outlet of a reaction chamber, enabling high-temperature antimony trioxide flue gas to pass through a flue gas quenching system, quenching the high-temperature antimony trioxide flue gas to 60-300 DEG C in the presence of air, and collecting the obtained product by using a cloth bag dust collection system so as to obtain the catalyst-grade antimony trioxide product with a full cubic crystal form, high purity and high whiteness. The clean fuel natural gas is used as production fuel for replacing traditional coke, fire coal or anthracite, energy consumption is reduced, the yield and recovery rate of antimony trioxide are increased, the impurity content in the product is reduced, and the whiteness of the product and other product indexes are improved.

Owner:广西华远金属化工有限公司

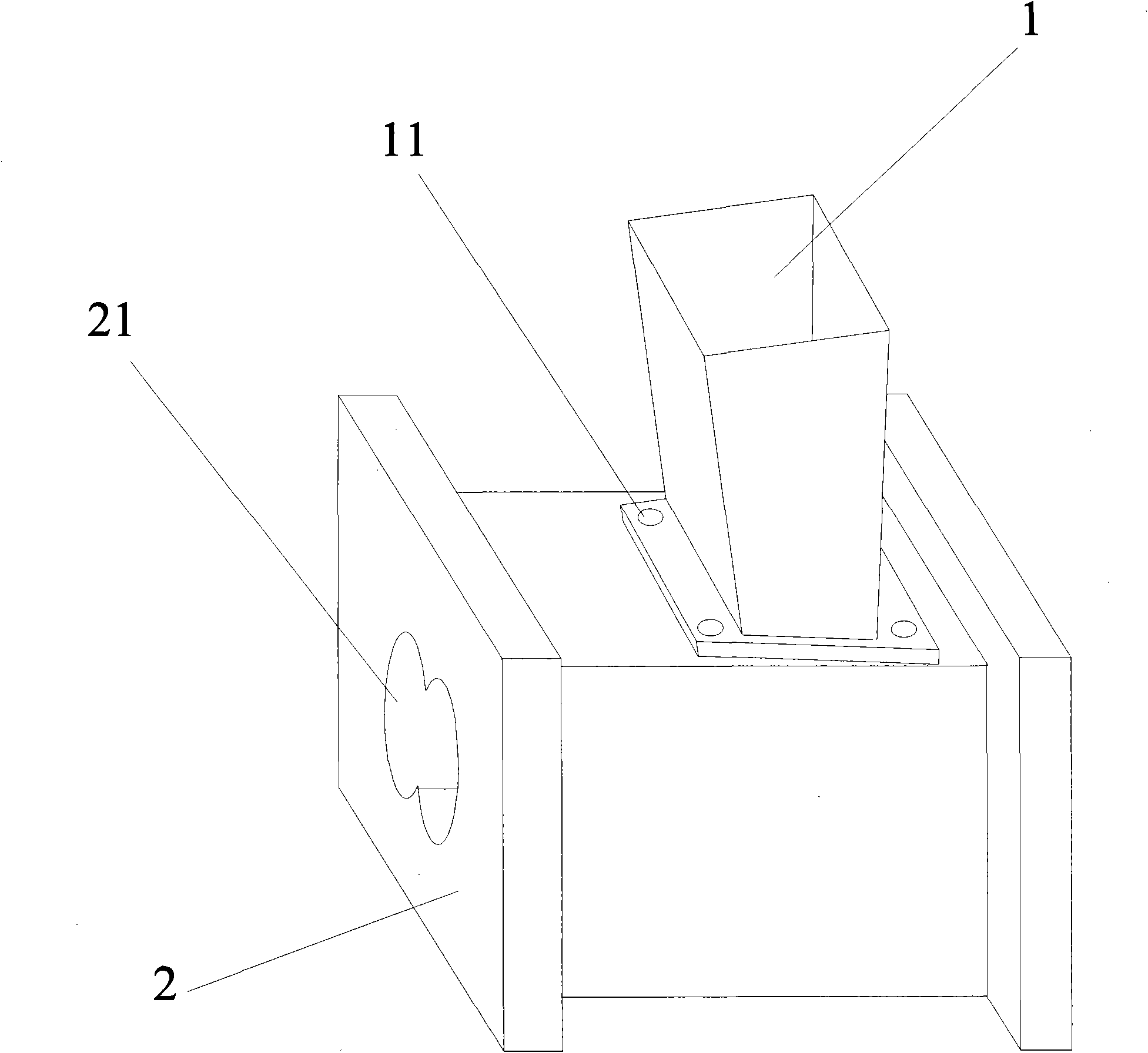

Blanking device for exhausting and feeding

The invention relates to a blanking device for exhausting and feeding, which is arranged on the top of a spiral drum and comprises a feeding cylinder and an exhausting feeding drum, wherein the feeding cylinder and the exhausting feeding cylinder are both arranged on the top of the spiral drum; a feeding input port is arranged on the top of the feeding cylinder while a feeding output port is arranged on the bottom; an exhaust port is arranged on the top of the exhausting feeding cylinder while an air inlet is arranged on the bottom; and the feeding output port of the feeding cylinder is communicated with the air inlet of the exhausting feeding cylinder. Compared with the prior art, the blanking device for exhausting and feeding has the advantages that the structure is simple, the practicability is higher, the gas in the mixed material can be efficiently exhausted, the phenomenon of returning materials is reduced, the machine is conveniently washed when the device is used for feeding resin, and the washing operation is simple, convenient and quick.

Owner:SHANGHAI KINGFA SCI & TECH

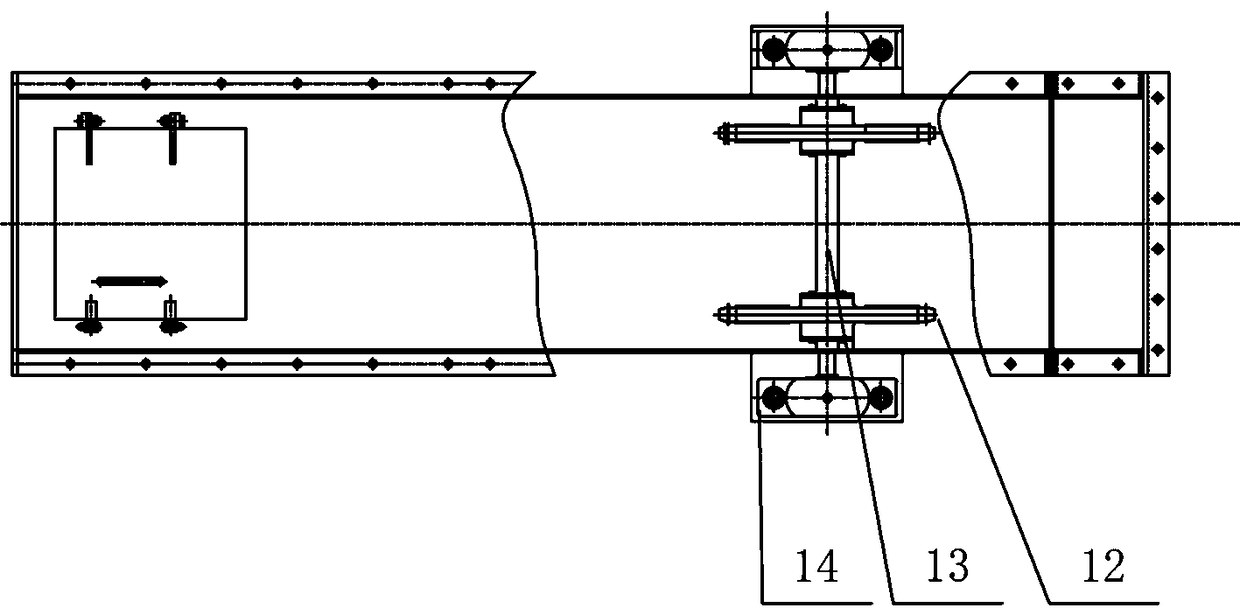

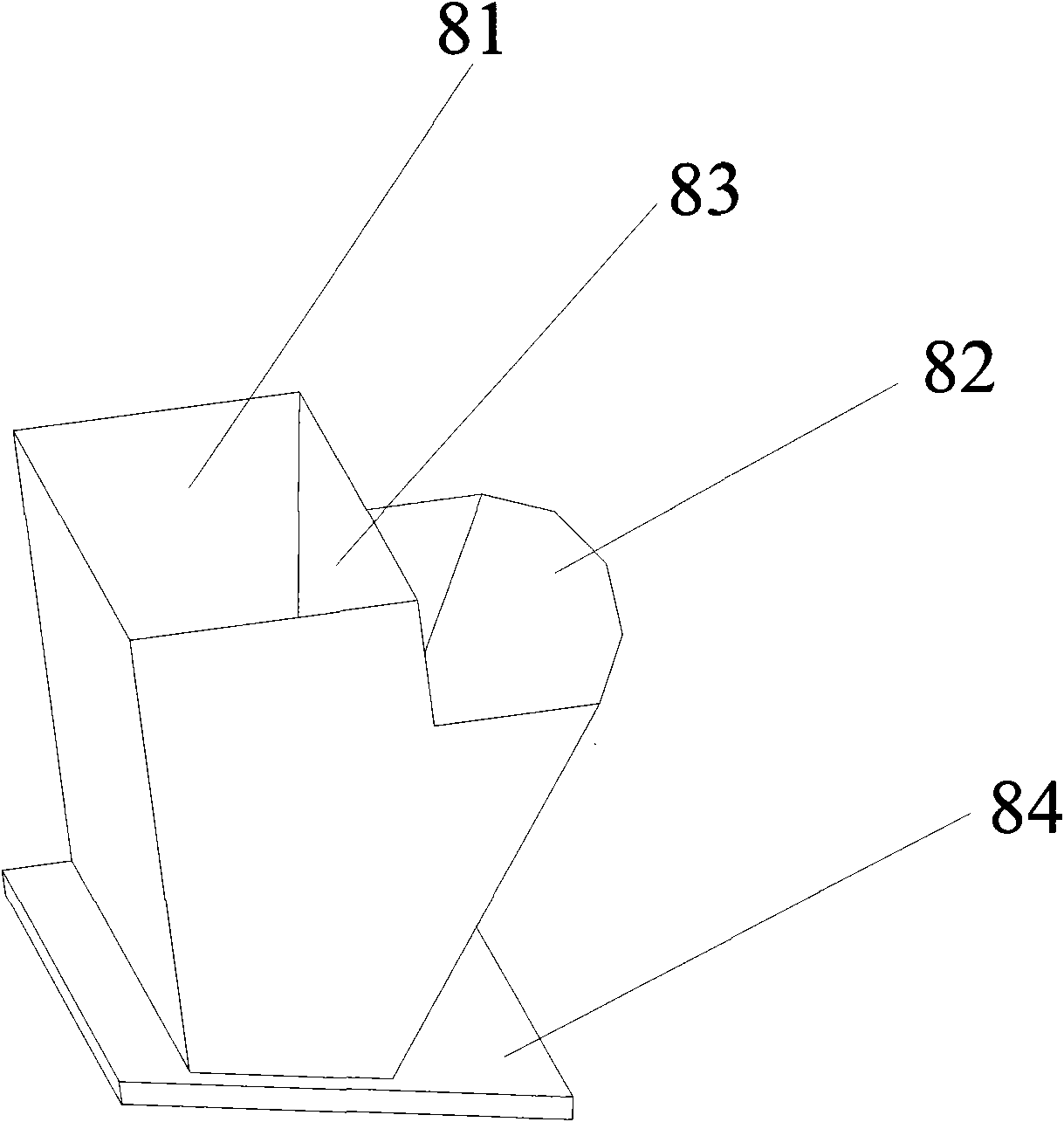

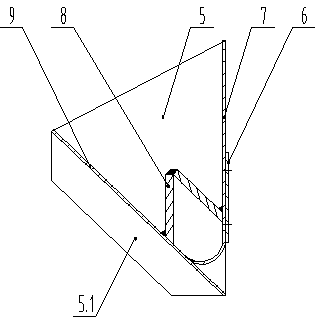

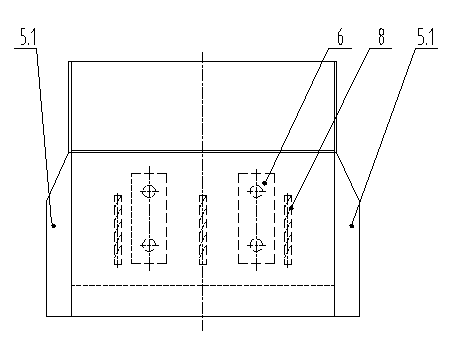

Ilmenite powder lifting hopper

The invention discloses an ilmenite powder lifting hopper. The ilmenite powder lifting hopper comprises a rear base plate, a front base plate, a guide plate and a fixing and reinforcing plate, wherein the lower end of the rear base plate and the lower end of the front base plate are fixedly connected in a sealing mode to form a hopper V-shaped structure with an acute included angle; the guide plate is fixedly connected with the two sides of the rear base plate and the front base plate of the hopper V-shaped structure, and one end of the guide plate extends out of the front base plate to form a guide part; the fixing and reinforcing plate for installing a lifting chain is fixedly connected with the back surface of the rear base plate; the lower end of the rear base plate and the lower end of the front base plate are fixedly connected through an arc plate in a sealed mode. Furthermore, at least one arch breaking device is arranged in the hopper V-shaped structure, and the guide part of the guide plate is splayed outwards. The ilmenite powder lifting hopper can obviously reduce materials stuck to the inner wall of the hopper in the wet mineral lifting process and can unload the materials normally depending on the self weight, the materials will not fall down as blocks, the material returning phenomenon of a hopper lifter is obviously reduced, and the hopper lifter is well protected.

Owner:TAIZHOU DIXIN TRANSPORTATION MACHINERY EQUIP

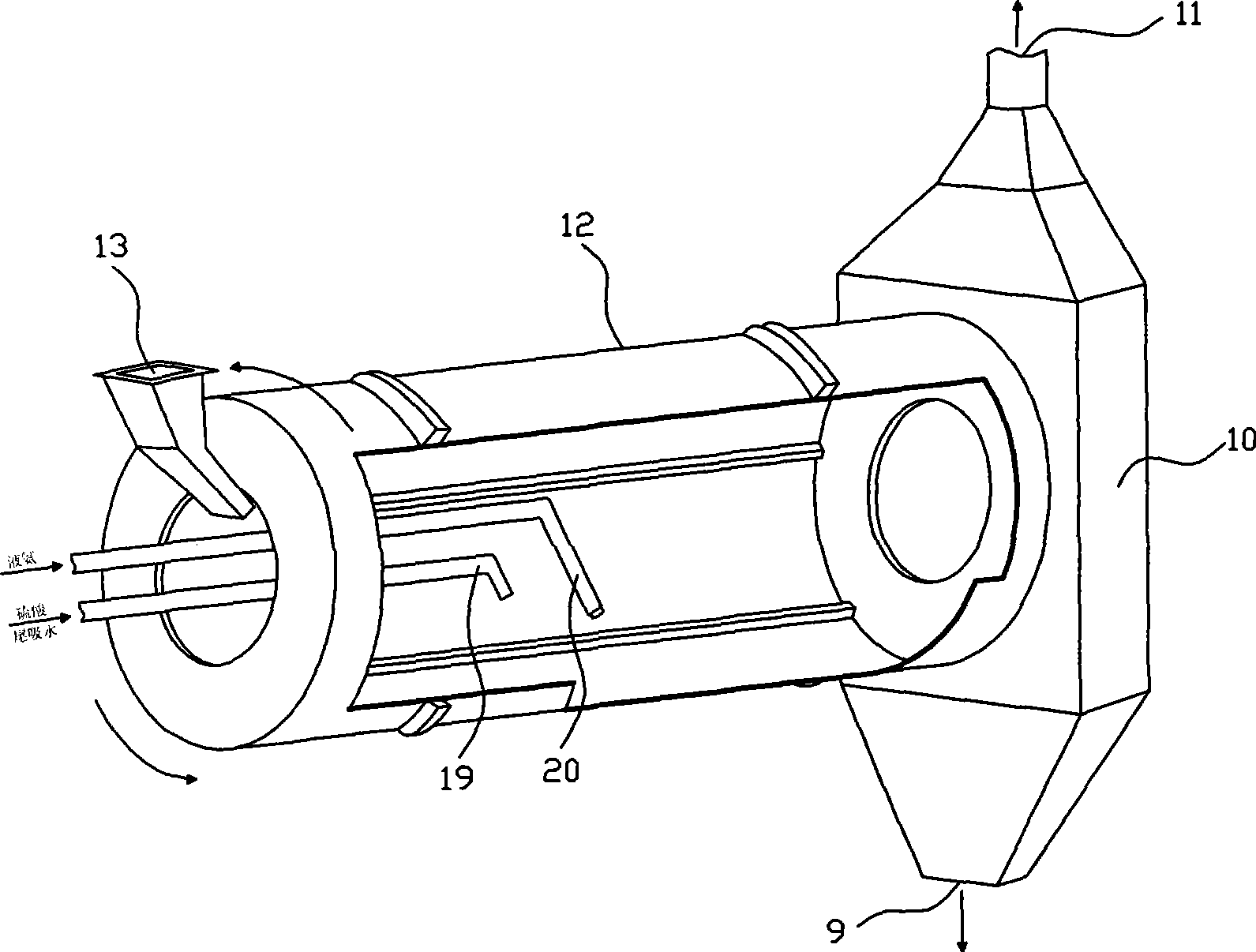

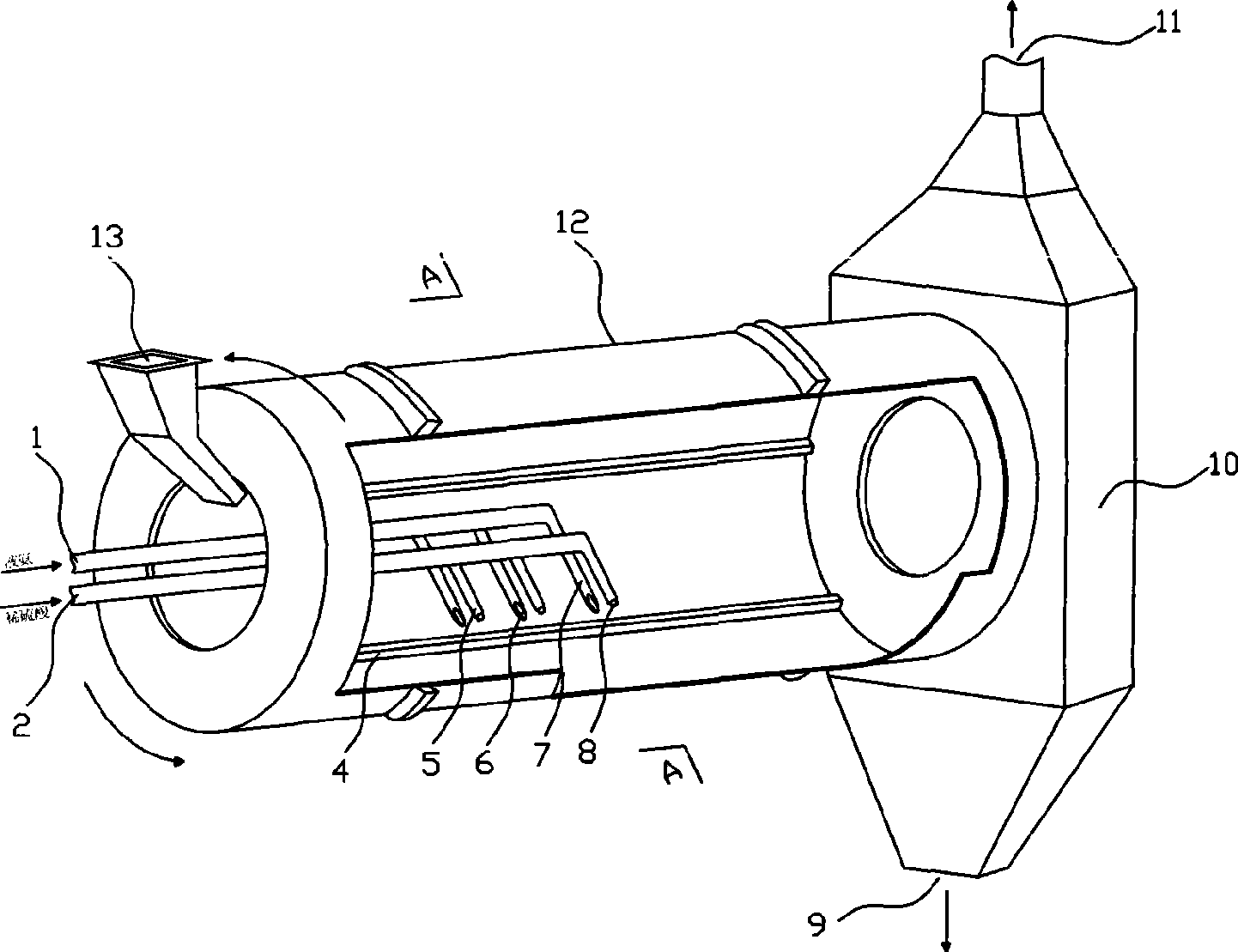

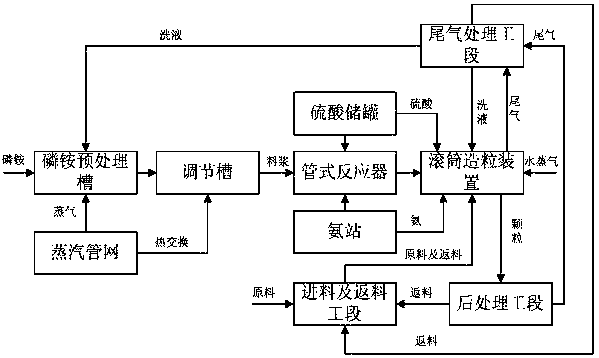

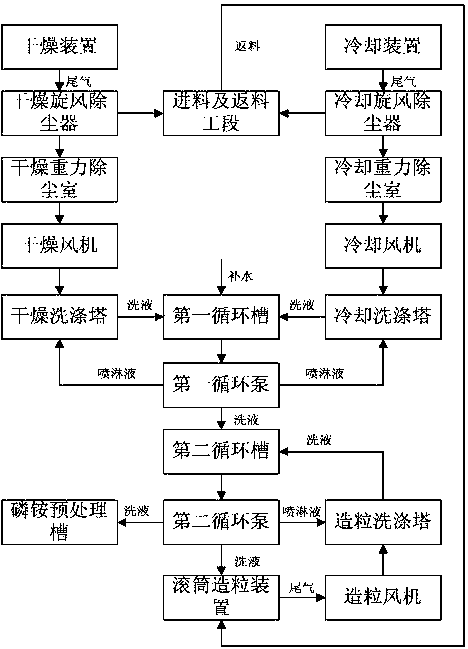

Production system of water-soluble compound fertilizer and production method

InactiveCN108314503AGood product strengthHigh granulation rateAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersFertilizerWater content

The invention discloses a production system of water-soluble compound fertilizer and a production method, and belongs to the technical field of production of compound fertilizer. The production systemcomprises a granulation section, an aftertreatment section, a tail-gas treatment section and a feeding and returning section, wherein the granulation section comprises a roller granulation device, anammonium-phosphate pretreatment groove, a regulating groove and a tubular reactor, and the ammonium-phosphate pretreatment groove, the regulating groove and the tubular reactor are connected in sequence by pipelines; the roller granulation device comprises a roller obliquely arranged in a front-rear direction, a feeding port at the front end of the roller, a discharging structure at the rear endof the roller, an acid mixer extending into the front part of the roller from the front part, and an ammonium tube bundle extending to the front part of the roller from the rear part; the rear part ofthe tubular reactor extends into the front part of the roller. The production system and the production method disclosed by the invention have the beneficial effects that ammonium-phosphate slurry isregulated to a proper condition by utilizing washing liquor, and then is introduced into a special granulation structure to realize granulation; a product with low water content and high granular strength can be obtained, and has the advantages of reduced caking property, strong caking resistance and good water solubility.

Owner:武汉环绿时代环保科技有限公司

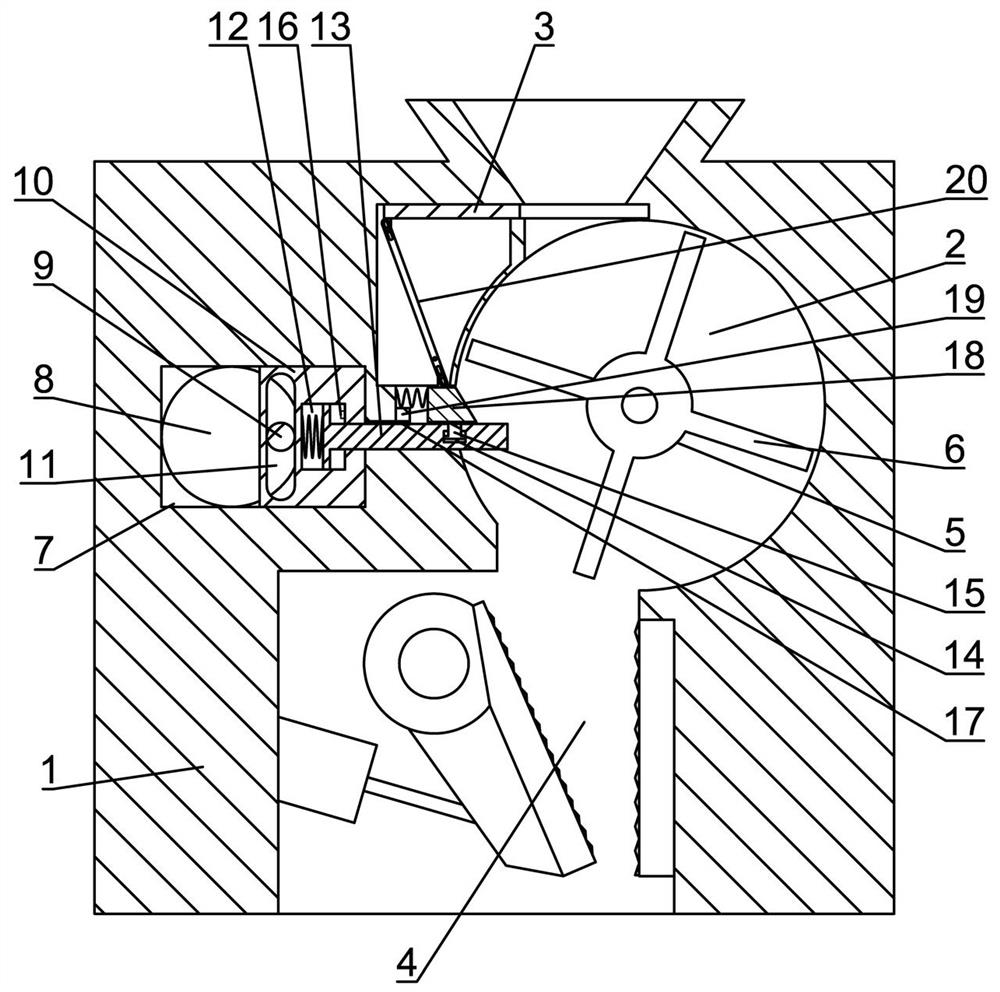

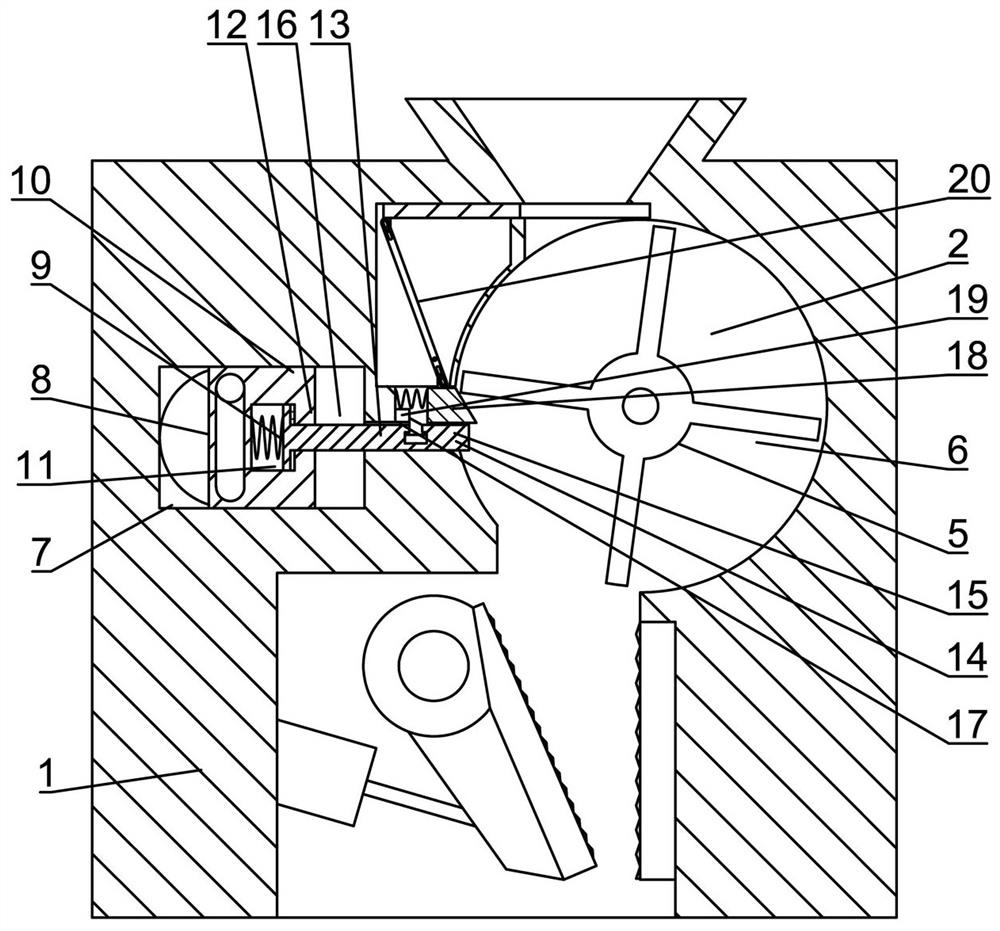

Material returning prevention feeding device of jaw crusher

PendingCN113697400AImprove crushing efficiencyExtended service lifeLoading/unloadingRotary conveyorsEngineeringStructural engineering

The invention relates to a material returning prevention feeding device of a jaw crusher. The material returning prevention feeding device comprises a shell, a material stirring cavity is formed in the shell, an opening is formed at the upper left end of the material stirring cavity, a baffle is arranged at the position of the opening and can open or close the opening, a rotating rod is arranged in the material stirring cavity, four material stirring plates are fixed to the rotating rod, and a rectangular cavity is formed in the shell; and two first sliding blocks alternately sliding left and right are arranged in the rectangular cavity, blocking rods are arranged on the first sliding blocks, when the two blocking rods slide left and right along with the first sliding blocks, the right ends of the two blocking rods can enter and exit from the material stirring cavity, a second sliding block is arranged at the upper ends of the two blocking rods, the right end of the second sliding block extends into the material stirring cavity, and when the second sliding block slides leftwards, the baffle can be driven to close the opening. The second sliding block does not break away from the material stirring cavity, the blocking rods cannot stretch out of the material stirring cavity, and when the two first sliding blocks slide to the position where the main view projections coincide, a first switch is pressed; and the two blocking rods alternately block the material stirring plates, it is ensured that a conveyor belt conducts timed and quantitative discharging on a crushing opening of the jaw crusher, and the material returning phenomenon is reduced.

Owner:河南猎金科技开发有限公司

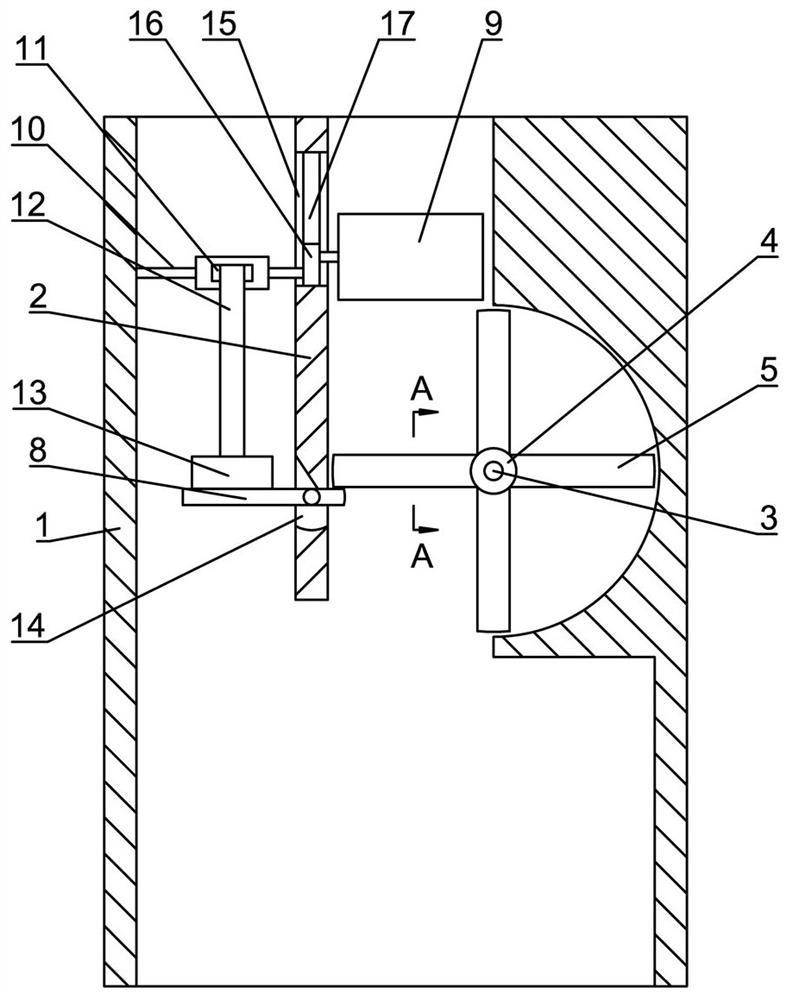

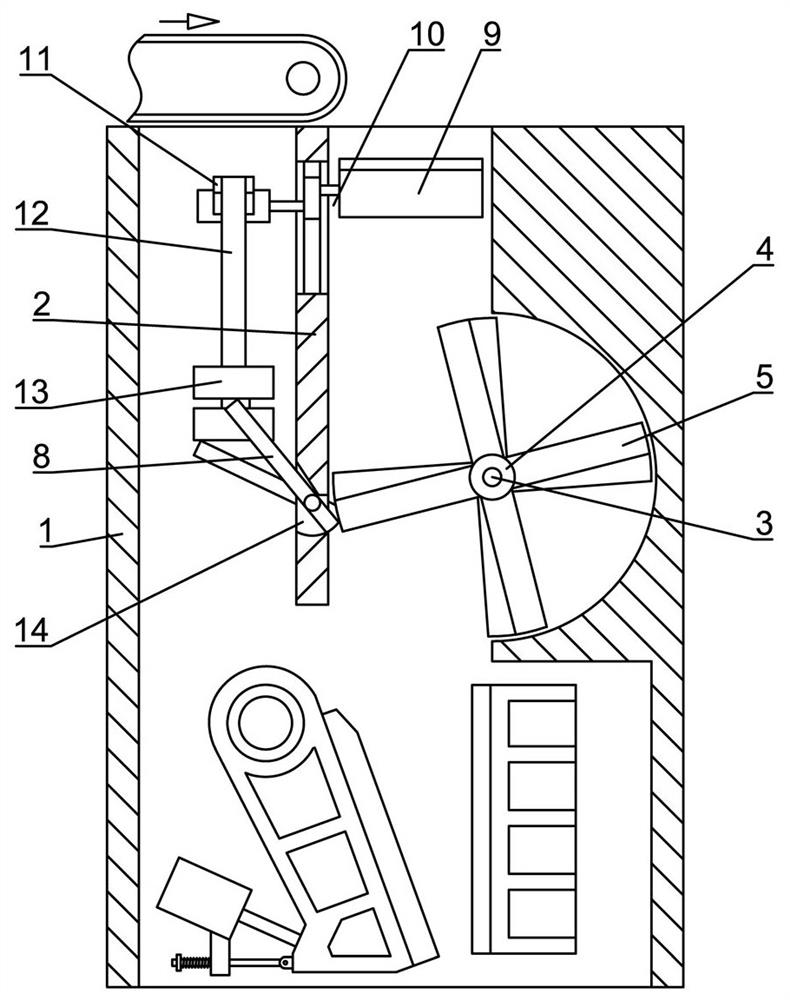

Feeding auxiliary device of jaw crusher

ActiveCN114042524AUniform feedingImprove crushing efficiencyGrain treatmentsStructural engineeringCrusher

The invention relates to a feeding auxiliary device of a jaw crusher, wherein the feeding auxiliary device comprises a shell, a fixing plate is arranged in the shell, a straight rod is arranged on the right side of the fixing plate, the front end and the rear end of the straight rod are each sleeved with a cylinder rotating around the axis, four baffles are evenly distributed on the circumferential face of each cylinder, a groove is formed in the front end face of each baffle at the rear end, and a check block is arranged on the rear end face of each baffle at the front end; the check blocks and the grooves are in spacing fit, through holes are formed in the front side and the rear side of the lower end of the fixing plate, and levers are arranged in the through holes; a sliding block is arranged at the upper end of the fixing plate; transverse rods are arranged at the left end and the right end of the sliding block respectively; the rotating directions of the two transverse rods are opposite; a flat plate is arranged on the right side of the fixing plate, and the middle part of the flat plate is fixed on the transverse rod at the right end; a transverse plate is arranged on the left side of the fixing plate, and the middle of the transverse plate is fixed to the transverse rod at the left end; and vertical rods are respectively hinged to the front and rear ends of the transverse plate. By means of the displacement difference generated by unbalanced stress of baffles on the front side and the rear side, the flat plate rotates to change the discharging amount of the front side and the rear side, uniform discharging of the jaw crusher is achieved, the crushing efficiency is greatly improved, and the material returning phenomenon is reduced.

Owner:河南猎金科技开发有限公司

Material guiding and dust falling spiral of direct thermal desorption rotary kiln equipment for soil remediation

PendingCN113909289AImprove delivery capacityReduce cakingDispersed particle separationContaminated soil reclamationThermodynamicsSoil remediation

The invention relates to a material guiding and dust falling spiral of direct thermal desorption rotary kiln equipment for soil remediation. The material guiding and dust falling spiral comprises an outer shell, a sealing opening, outer spiral blades, an inner cylinder and inner spiral blades; the outer shell and the sealing opening formed in one end of the outer shell form an outer cavity; the inner cylinder is arranged in the outer cavity; the axis of the inner cylinder and the axis of the outer shell are located on the same straight line; the plurality of outer spiral blades are evenly arranged in the outer cavity along the axis to divide the cavity of the shell into a plurality of branch outer cavities; the outer spiral blades are evenly connected to the outer side of the cylinder wall of the inner cylinder in a sleeving mode; the plurality of inner spiral blades are evenly distributed in the inner cavity of the inner cylinder along the axis of the inner cavity; and quadrilateral holes with the number equal to that of the outer spiral blades sleeving the inner cylinder are uniformly formed in the cylinder wall of the inner cylinder. Soil entering the spiral is evenly scattered into the branch cavities through the quadrilateral holes in the inner cylinder and cannot be accumulated at the bottom of the spiral in quantity, the caking and material returning phenomena of the soil are reduced, and the conveying capacity of the spiral is improved.

Owner:CSSC NANJING LUZHOU ENVIRONMENT PROTECTION CO LTD

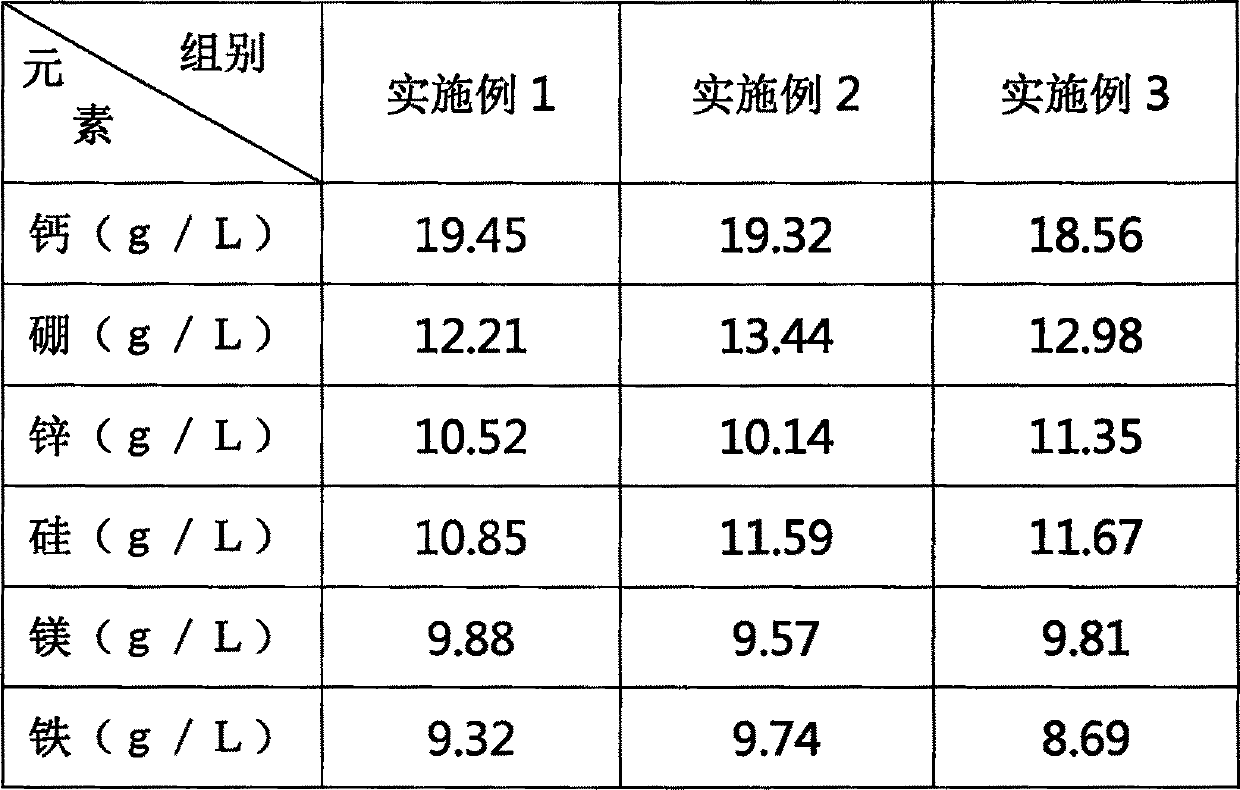

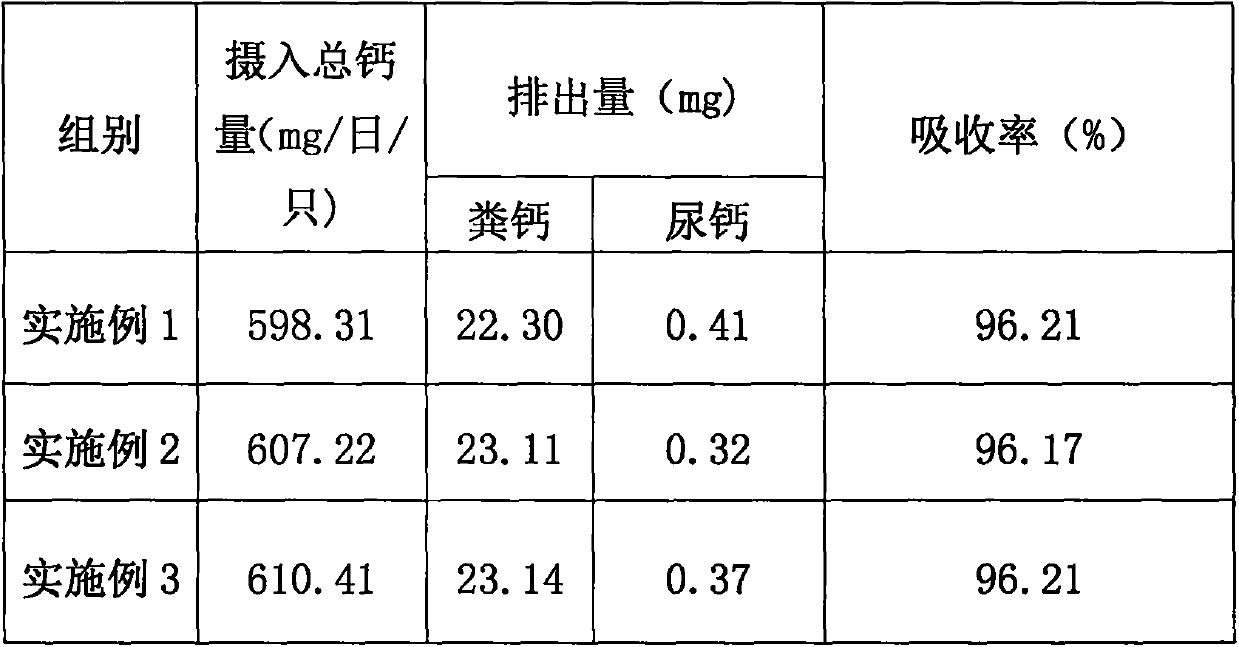

Method for processing multi-trace element ionized products for regulating acid-base balance

The invention relates to a method for processing a multi-trace element ionized product for regulating acid-base balance. Raw materials mainly include oyster shells, pearls, heptagonal conch, bullfrogbones, sea cucumber intestines, egg shell, black ants, red date, haw, lemon, soybean, talcum powder, mica and trace elements. Calcium ions in the raw materials can be fully released by adopting the methods of soaking, crushing, mixing, extrusion granulation, plasma preparation and the like, so that the product contains high-content calcium; powdery solids are obtained by adopting a method of carrying out extrusion granulation after jet milling of solids, so that the physical and chemical stability is improved; the pH value after flushing is 14, the body function is effectively improved, the acid physique of the human body is adjusted, microcirculation is improved, and therefore the self-healing instinct is activated.

Owner:时海棋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com