Process for producing urea ammonium sulfate by using by-product of ammonium sulfate from flue gas desulfurization with ammonia process

A technology of ammonium sulfate and urea, which is applied in the direction of urea compound fertilizer, application, ammonium salt fertilizer, etc., can solve the problems of easy to block soil pores, soil compaction, out of the absorption range of plant roots, easy to be wet in deep soil, etc., to improve Profitability, improved grain quality, enhanced cold resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

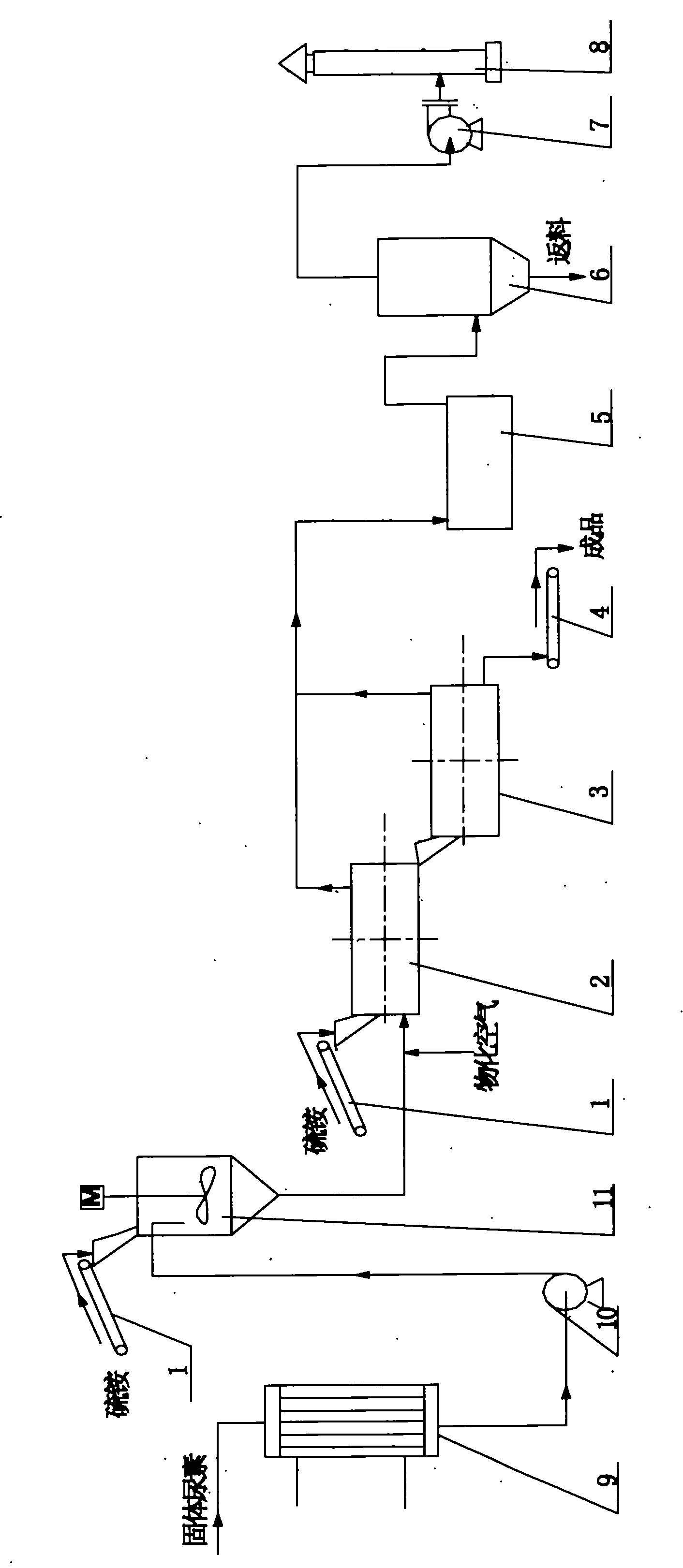

[0022] 1) The solid granular urea is metered and sent to the urea instant melter, the temperature is controlled at 135-140°C, and the 3 Saturated steam heating; granular urea becomes liquid after passing through the urea instant melter, and then sent to the urea ammonium sulfate mixer. The ratio of nitrogen and sulfur content in the product is adjusted through the control of urea to meet the performance requirements of different products.

[0023] 2) Part of the uncooled ammonium sulfate crystals (temperature at 100-120°C) from flue gas desulfurization and drying enters the urea ammonium sulfate mixer for pulping, and the other part is sent to the drum coating granulator as Seed. Reduce external return materials in the production process and reduce energy consumption.

[0024] 3) The urea ammonium sulfate melt from the urea ammonium sulfate mixer is sprayed with the mixed solution on the small ammonium sulfate particles through the air materialization nozzle of the drum gran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com