Tower pulping production system and process for tower production compound fertilizers

A technology of production system and production process, which is applied in the direction of fertilization device, fertilizer mixture, application, etc., can solve the problems of difficult equipment layout, inconvenient evacuation of personnel, large investment in tower top civil engineering foundation, etc., and achieve the goal of reducing maintenance and replacing and repairing cost, reduction of environmental pollution and impact on human health, considerable economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

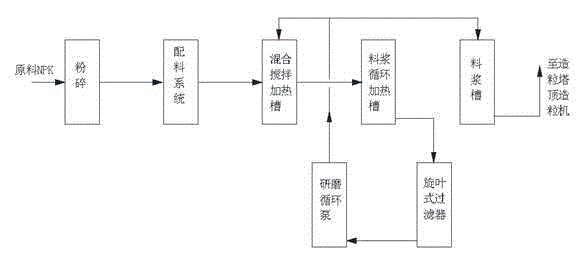

[0033] Pulping production system under tower for compound fertilizer production such as figure 1 As shown, the system includes: a pulverizer and a batching system. After the batching system, there are in series a mixing and stirring heating tank, a slurry circulation heating tank, a filter, a grinding circulation pump, a slurry delivery pump, a rotary manufacturing Granulator; the mixing and stirring heating tank is connected to the slurry circulation heating tank; the slurry delivery pump is connected to the granulator; between the mixing and stirring heating tank and the slurry circulation heating tank A grinding circulation pump is provided. A rotary vane type online cleaning slag discharge filter is arranged between the slurry circulation heating tank and the grinding circulation pump.

[0034] The production process of the pulping production system under the high tower production compound fertilizer tower based on the high tower described in the present embodiment is:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com