Color drought-resistance water-retention sustained-release compound fertilizer and method for producing same

A compound fertilizer and color technology, applied in the form of fertilizer, fertilizer mixture, fertilization device, etc., can solve the problems of large amount of ordinary water-soluble chemical fertilizers, excessive nitrate nitrogen in groundwater, and reduced water retention and water absorption capacity, etc., to improve nutrients and moisture Utilization rate, slow and stable nutrient release, and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

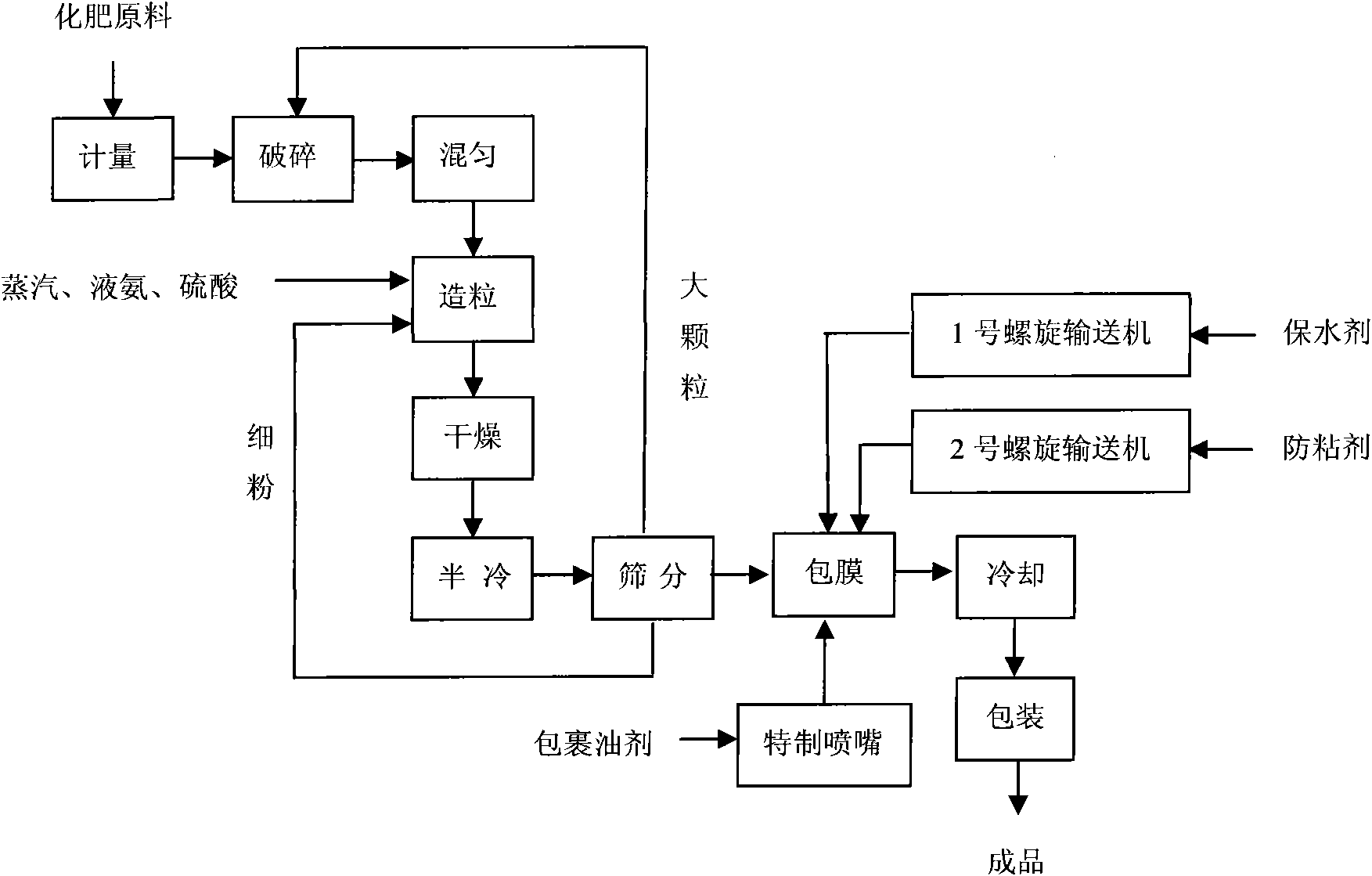

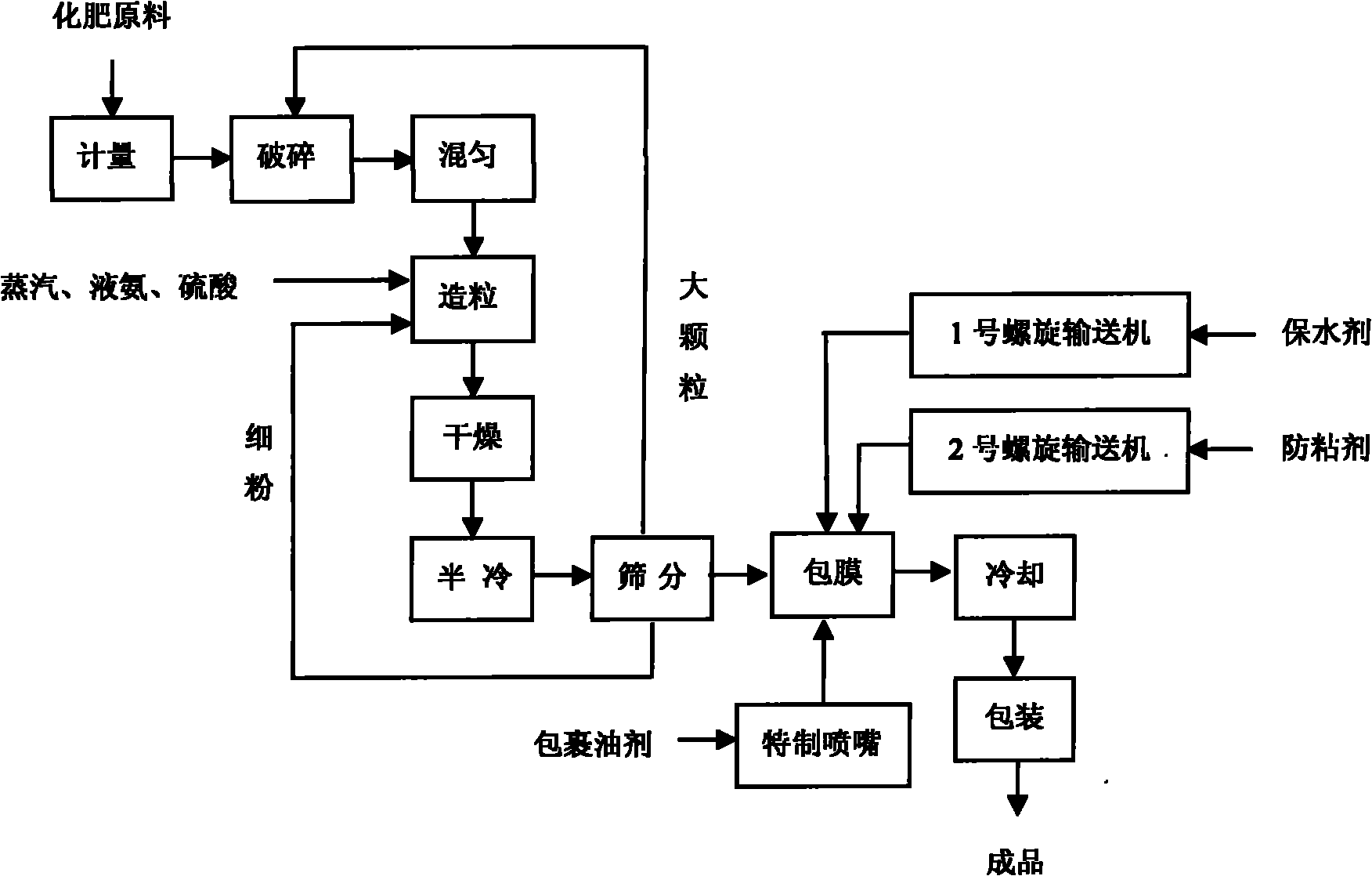

Method used

Image

Examples

Embodiment 1

[0030] Total nutrients (N+P 2 o 5 +K 2 O) ≥ 25%, the specification is 8-10-6 (chlorine-containing) colored drought-resistant, water-retaining slow-release compound fertilizer, and the specific process steps are as follows:

[0031] (1) Weigh mineral oil, polyethylene and oil-soluble yellow according to the weight ratio of 2.5:1.0:0.05, first add mineral oil to the chemical tank to heat up, then pour polyethylene and oil-soluble yellow into it, and stir While heating the wrapping oil with steam, after the wrapping raw material is completely melted, use the oil pump to slowly add the colored wrapping oil to the heat preservation storage tank;

[0032] (2), respectively measure 11.0 parts by weight of potassium chloride (containing K 2 O-60.3%), 43.9 parts by weight superphosphate (containing P 2 o 5 -14.0%), 11.0 parts by weight of monoammonium phosphate (containing N-10.5%, containing P 2 o 5 -44.5%), 6.6 parts by weight of ammonium sulfate (containing N20.5%), 27.5 part...

Embodiment 2

[0038] Total nutrients (N+P 2 o 5 +K 2 O) ≥ 35%, the specification is 12-13-10 (chlorine-containing) colored drought-resistant water-retaining slow-release compound fertilizer, and the specific process operation steps are as follows:

[0039] (1), weigh mineral oil, polyethylene wax, natural resin and oil-soluble red in the weight ratio of 1.0: 1.2: 0.5: 0.06, first add mineral oil to heat up in the chemical feed tank, then add polyethylene wax, natural Pour the resin and oil-soluble red, and heat the wrapping oil with steam while stirring. After the wrapping raw materials are completely melted, use the oil pump to slowly add the colored wrapping oil to the heat preservation storage tank;

[0040] (2), respectively measure 19.7 parts by weight of potassium chloride (containing K 2 O-60.3%), 37.1 parts by weight of monoammonium phosphate (containing N-10.5%, containing P 2 o 5 -44.5%), 12.3 parts by weight of ammonium sulfate (containing N20.5%), 30.9 parts by weight of ammo...

Embodiment 3

[0046] Total nutrients (N+P 2 o 5 +K 2 O) ≥ 40%, the specification is 14-12-14 (chlorine-containing) colored drought-resistant water-retaining slow-release compound fertilizer, and the specific process operation steps are as follows:

[0047] (1) Weigh mineral oil, paraffin and oil soluble blue according to the weight ratio of 1.0: 1.0: 0.02, first add the mineral oil to the chemical feed tank to heat up, then pour the paraffin and oil soluble blue, and use it while stirring Steam heats the wrapping oil, and after the wrapping raw materials are completely melted, use the oil pump to slowly add the colored wrapping oil to the heat preservation storage tank;

[0048] (2), respectively measure 25.0 parts by weight of potassium chloride (containing K 2 O-60.3%), 28.7 parts by weight of monoammonium phosphate (containing N-10.5%, containing P 2 o 5 -44.5%), 12.5 parts by weight of ammonium sulfate (containing N20.5%), 20.0 parts by weight of ammonium chloride (containing N23.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com