Method for producing stalk biochemical fodder

A production method and technology of straw, applied in the production field of straw biochemical feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

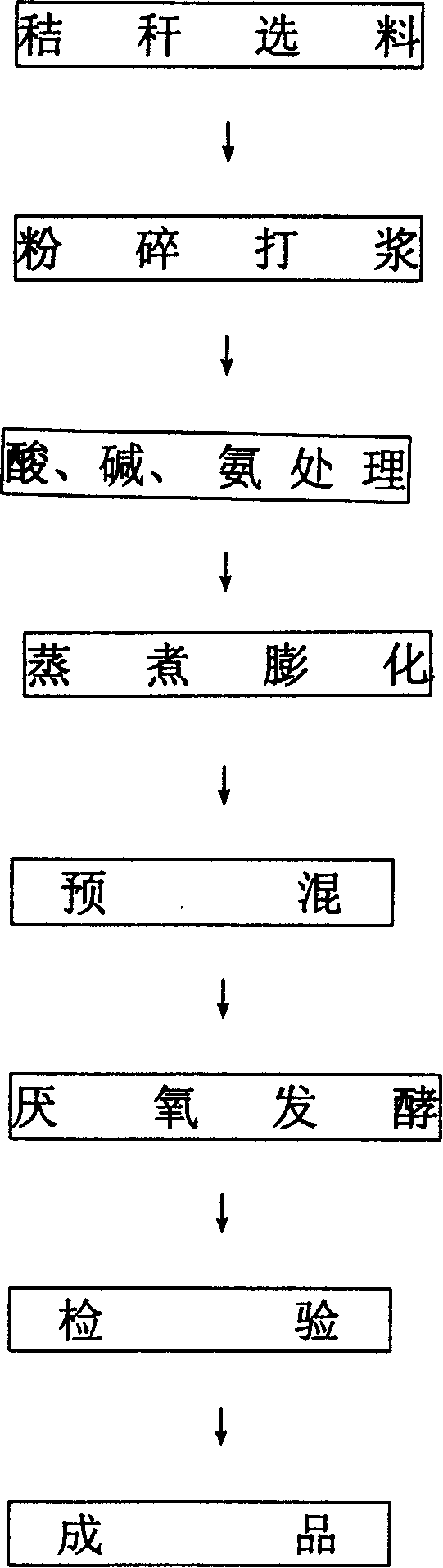

Method used

Image

Examples

Embodiment 1

[0007] Embodiment 1: Taking large livestock such as feeding cattle and horses as example, the production method of its biochemical feed is by weight: get corn stalk or wheat straw 75%, wheat bran 6%, corn flour 6%, bean cake 12%, Fishmeal 0.5% and salt 0.5% are added with water to 56% of the weight of raw materials, and then chemically treated and fermented. The specific method is to crush 75kg of corn stalks to a length of 1cm, add 300g of formic acid for chemical treatment, and then put them in a high-pressure steamer Carry out puffing and cooking, puffing and cooking for 45 minutes at 100 ° C and a pressure of 4 atmospheres, add 6 kg of wheat bran, 6 kg of corn flour, 12 kg of bean cake, 0.5 kg of fish meal, 0.5 kg of salt and water 56kg and grain enzyme 0.1Kg, mixed evenly with a pre-mixer, cooled to 20°C, fermented in the fermentation tank at 20°C for 360 hours, and can be fed to cattle, sheep, horses, etc. after passing the inspection.

Embodiment 2

[0008] Embodiment 2: Take feeding poultry such as chickens as example, the production method of its biochemical feed is by weight, get peanut stalk 65%, wheat bran 7%, corn flour 7%, bean cake 15%, fish meal 5% and salt 1% water is added to 50% of the weight of the raw material, and it is made by chemical treatment and fermentation. The specific production method is to pulverize 65kg of peanut stalks with a pulverizer until the particle size is below 50 mesh, and then add 2.5kg of sodium hydroxide for chemical treatment. , and then put it into a high-pressure steamer, after puffing and cooking at 10 atmospheres and 200°C for 60 minutes, then use a pre-mixer to add 50kg of water and 7kg of wheat bran, 7kg of corn flour, kg of bean cake, 5kg of fish meal and 1kg of salt. Grain enzyme 0.5Kg, after premixing evenly, cool down to 30°C, put it into a fermenter, and anaerobically ferment at 30°C for 360 hours, after passing the inspection.

Embodiment 3

[0009] Embodiment 3: Taking feeding pigs as example, the production method of its biochemical feed is by weight, get 70% of potato seedlings, 6% of wheat bran, 7% of corn flour, 14% of bean cake, 2% of fish meal and 1% of salt Add water until 80% of the raw material is pre-mixed and then add 1% grain enzyme to ferment. Specifically: 70kg of dried sweet potato seedlings are crushed into a 0.01cm coarse powder by a grinder, and 2.5kg of liquid ammonia is added for chemical treatment, and then in In a high-pressure steamer under 5 atmospheric pressure and 150°C, puff and cook for 45 minutes, then use a pre-mixer to mix with 6kg of wheat bran, 7kg of corn flour, 14kg of bean cake, 2kg of fish meal and 1kg of salt, then add 80kg of water and 0.6Kg of grain enzyme , put it into the fermentation tank, cool down to 25°C, and anaerobically ferment at 25°C for 480 hours (ie 20 days), and it can be finished after passing the inspection. The present invention can also be used for fresh gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com