Production system of water-soluble compound fertilizer and production method

A production system and compound fertilizer technology, which is applied in the direction of urea compound fertilizer, alkaline orthophosphate fertilizer, nitrogen fertilizer, etc., can solve the problems of reduced water solubility of products, poor particle uniformity, and easy caking of products, so as to achieve effective utilization High efficiency, good product strength, and high primary utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

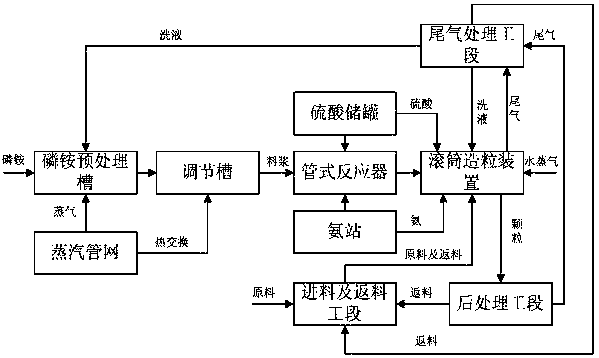

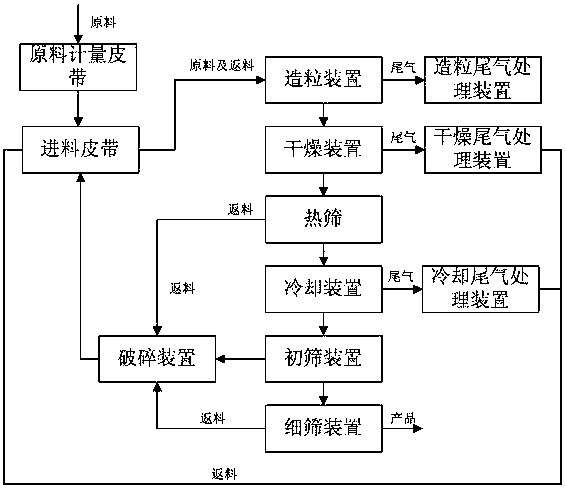

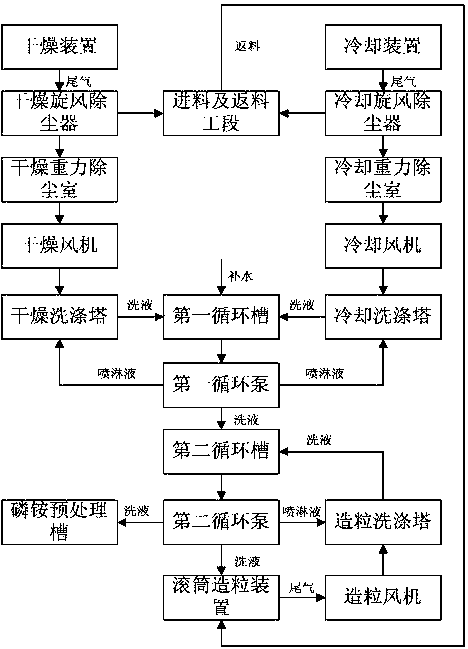

[0040] see Figure 1-4 , the embodiment of the present invention provides a water-soluble compound fertilizer production system, the system includes a granulation section, a post-treatment section, a tail gas treatment section, and a feed and return section, etc., the post-treatment section, the tail gas treatment section and the feed and the return section connection; the aforementioned structure is basically the same as the existing compound fertilizer production system, the difference is that the granulation section in the present invention includes a drum granulation device and ammonium phosphate pretreatment tanks, regulating Tank and tubular reactor 3, the ammonium phosphate pretreatment tank is used to dissolve ammonium phosphate (technical ammonium or agricultural ammonium) by using the washing liquid of the tail gas treatment section, and the regulating tank is used to adjust the temperature, viscosity and density of the ammonium phosphate slurry, etc. parameters to e...

Embodiment 2

[0059] On the other hand, the embodiment of the present invention also provides a production method of water-soluble compound fertilizer, the method adopts the production system of embodiment 1 for production, and the adjustment tank adjusts the ammonium phosphate slurry to a slurry density of 1.33-1.38g / cm³, the moisture content is greater than 35%, the temperature is adjusted to 120-135°C, and the adjustment tank adjusts the slurry to facilitate the flow reaction of the tubular reactor and facilitate spraying. The degree of neutralization in the tubular reactor 3 is 0.45-0.48 (slightly excess sulfuric acid), and the particle size of the ejected core particles is 1.5-2.5mm. The reaction in the tubular reactor 3 not only provides heat to make the slurry boil (the temperature is greater than 160°C), but also can synthesize ammonium sulfate and ammonium phosphate to obtain relatively round core particles with suitable size and strength. The neutralization degree in drum 1 is 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com