Cefalexin tablet and preparation method thereof

A technology for cephalexin tablets and fadroxil tablets, which is applied in the field of medicinal chemistry, can solve problems such as affecting product quality, complex processes, and non-compliance with quality consistency evaluation requirements, and achieves avoiding the generation of related substances, simple coating process, and production. Easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

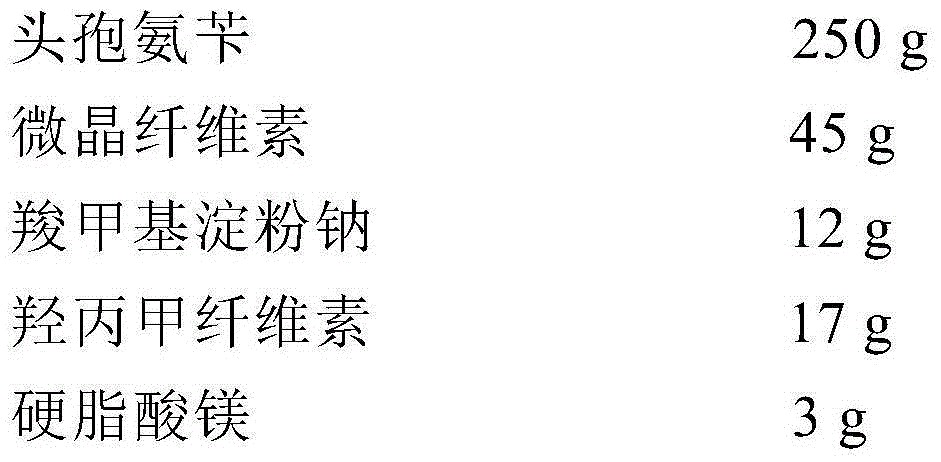

[0025] In the present embodiment, each component of cephalexin tablet is as follows:

[0026]

[0027] Prepare as follows:

[0028] 1) Sieve

[0029] Pass the above raw materials of cephalexin, microcrystalline cellulose, sodium carboxymethyl starch, hypromellose and magnesium stearate through an 80-mesh sieve respectively, and collect the powder under the sieve;

[0030] (2) Premix

[0031] Weigh 250 g of cephalexin, 45 g of microcrystalline cellulose, 6 g of sodium carboxymethyl starch, and 17 g of hypromellose after sieving respectively, add them into a mixer, and pre-mix for 10 minutes.

[0032] (3) Dry granulation

[0033] Use a dry granulator to put the mixed material into the feeder, the main pressure: 7-15MPa; the granulation screen: 24 mesh. Conveying speed: 90-220rpm; speed of pressing wheel: 20-45rpm; one screen for whole grain; speed: 10 mesh; 100-150rpm; two screen for whole grain; speed: 24 mesh; 100-150rpm.

[0034] Sieving: The granules are sieved throu...

Embodiment 2

[0042] In the present embodiment, each component of cephalexin tablet is as follows:

[0043]

[0044] Prepare as follows:

[0045] 1) Sieve

[0046] Pass cephalexin, microcrystalline cellulose, sodium carboxymethyl starch, hypromellose, and magnesium stearate through an 80-mesh sieve respectively, and collect the powder under the sieve;

[0047] (2) Premix

[0048] Weigh 250 g of cephalexin, 45 g of microcrystalline cellulose, 7 g of sodium carboxymethyl starch, and 13 g of hypromellose after sieving respectively, add them into a mixer, and pre-mix for 10 minutes.

[0049] (3) Dry granulation

[0050] Use a dry granulator to put the mixed material into the feeder, the main pressure: 7-15MPa; the granulation screen: 24 mesh. Conveying speed: 90-220rpm; speed of pressing wheel: 20-45rpm; one screen for whole grain; speed: 10 mesh; 100-150rpm; two screen for whole grain; speed: 24 mesh; 100-150rpm.

[0051] Sieving: The granules are sieved through a high-efficiency vibra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| friability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com