Binder special for coal-based activated carbon and preparation method of binder

A coal-based activated carbon and binder technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of large changes in the quality of coal tar and large fluctuations in the quality of product binders, and achieve good product strength, It shows the effect of smooth and less floating dust and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

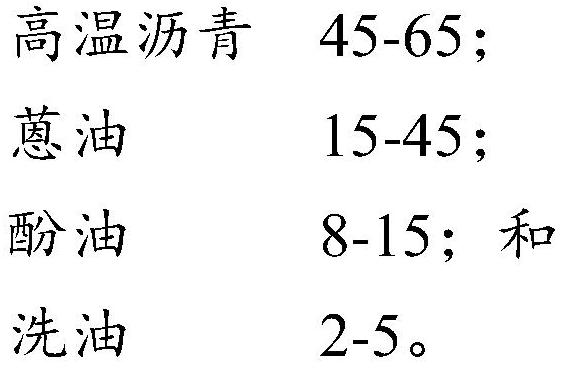

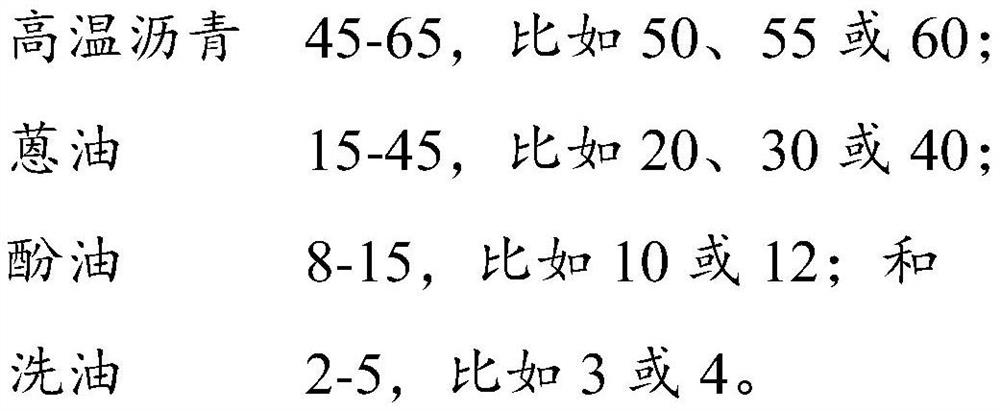

Method used

Image

Examples

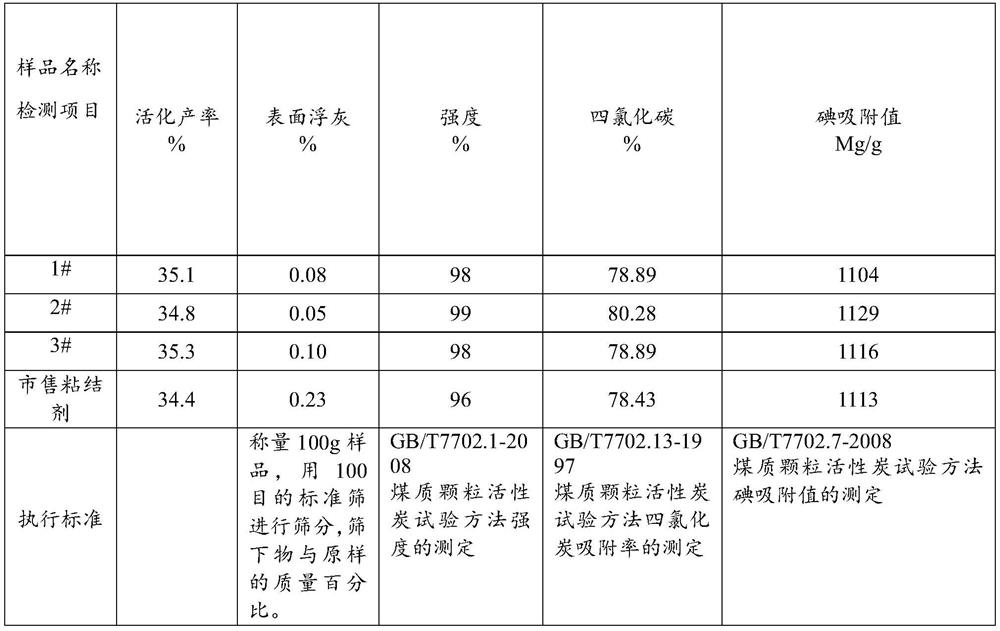

Embodiment 1

[0028] Add 20% anthracene oil in a mass ratio (that is, the mass ratio of the total raw material, the same below) to a reaction kettle at 160°C, turn on the stirring paddle, control the speed at 10r / min, and add high-temperature asphalt with a mass ratio of 7.5% After stirring for 15 minutes, add the same amount of high-temperature asphalt for 4 times and repeat the above steps;

[0029] Then adding mass ratio of 15% wash oil to continue stirring, the speed is controlled at 5r / min, after stirring for 10min, the mass ratio of 7.5% high-temperature asphalt (softening point 95-100 ° C, the same below) is added to the reactor, the speed Control at 10r / min, after stirring for 15min, add 2 equal amounts of high-temperature asphalt and repeat the above steps;

[0030] Then add phenol oil with a mass ratio of 5%, control the rotation speed at 5 r / min, continue stirring for 2 hours, and transport the homogenized active carbon special binder to the storage tank. The asphalt content of ...

Embodiment 2

[0032] Add anthracene oil with a mass ratio of 30% to the reactor at 160°C, turn on the stirring paddle, and control the rotation speed at 8r / min, add high-temperature asphalt with a mass ratio of 6.88% into the reactor, stir for 15 minutes, and then add 4 Repeat the above steps for the high-temperature asphalt of the next equal amount;

[0033] Then add the washing oil with a mass ratio of 12% and continue to stir, the speed is controlled at 4r / min, after stirring for 10min, the high-temperature asphalt with a mass ratio of 6.88% is added to the reactor, the speed is controlled at 8r / min, after stirring for 15min, Then add 2 equal amounts of high-temperature asphalt and repeat the above steps;

[0034] Then add phenol oil with a mass ratio of 3%, control the rotation speed at 5 r / min, continue stirring for 2 hours, and transport the homogenized active carbon special binder to the storage tank. The asphalt content of binder 2# was detected to be 57wt%.

Embodiment 3

[0036] Add anthracene oil with a mass ratio of 40% into the reactor at 160°C, turn on the stirring paddle, and control the rotation speed at 8r / min, add high-temperature asphalt with a mass ratio of 6.25% into the reactor, stir for 15 minutes, and then add 4 Repeat the above steps for the high-temperature asphalt of the next equal amount;

[0037] Then add the washing oil with a mass ratio of 8% and continue to stir, the speed is controlled at 4r / min, after stirring for 10min, the high-temperature asphalt with a mass ratio of 6.25% is added to the reactor, the speed is controlled at 10r / min, after stirring for 15min, Then add 2 equal amounts of high-temperature asphalt and repeat the above steps;

[0038] Then add phenol oil with a mass ratio of 2%, control the rotation speed at 5 r / min, continue stirring for 2 hours, and transport the homogenized active carbon special binder to the storage tank. The asphalt content of binder 3# was detected to be 51wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com