Material guiding and dust falling spiral of direct thermal desorption rotary kiln equipment for soil remediation

A soil remediation and thermal desorption technology, which is applied in the field of soil remediation direct thermal desorption rotary kiln equipment, can solve the problems of increasing the pressure of the dust removal system, returning materials, and increasing the amount of flue gas, so as to improve the conveying capacity, The effect of reducing dust and reducing caking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

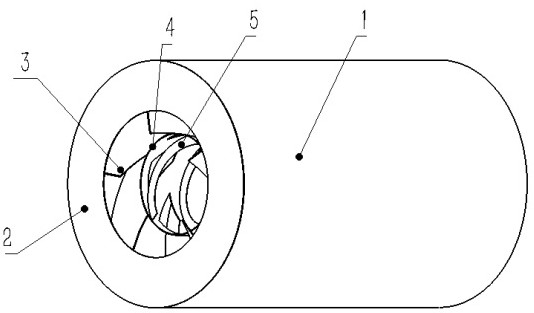

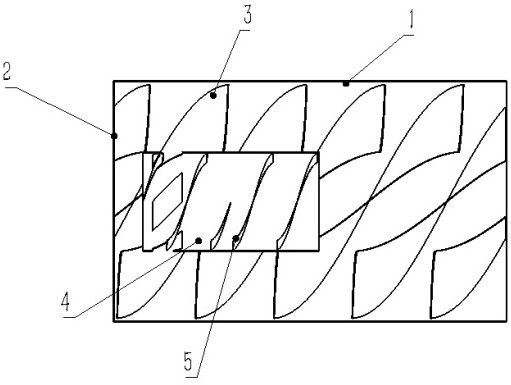

[0017] see figure 1 and figure 2 , this embodiment provides a direct thermal desorption rotary kiln equipment for soil remediation according to the present invention. The sealing port 2 at one end constitutes the outer chamber, the inner cylinder 4 is arranged in the outer chamber, the axis of the inner cylinder 4 and the axis of the shell 1 are on the same line, and several pieces of outer spiral blades 3 are evenly arranged in the outer chamber along the axis The cavity of the shell 1 is divided into several sub-outer cavities, and several pieces of outer spiral blades 3 are evenly sleeved on the outer side of the cylinder wall of the inner cylinder 4, and several pieces of internal spiral blades are evenly distributed along the axis of the inner cylinder 4. The vane 5 and the wall of the inner cylinder 4 are uniformly provided with quadrilateral holes equal to the number of outer spiral blades 3 socketed thereon.

[0018] The end of the shell 1 away from the sealing port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com