Material returning prevention feeding device of jaw crusher

An anti-return and feed-in technology, applied in the directions of loading/unloading, transportation and packaging, conveyors, etc., can solve the problem of jaw crusher returning materials, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

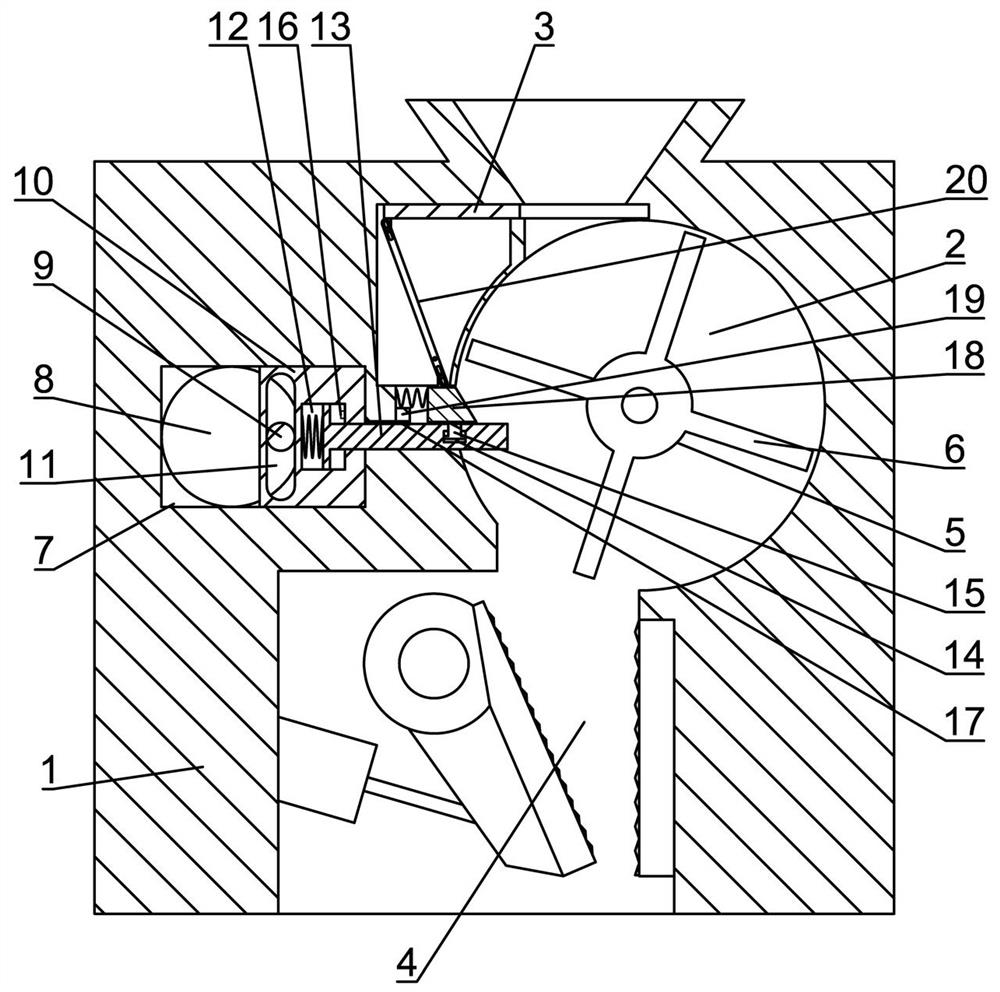

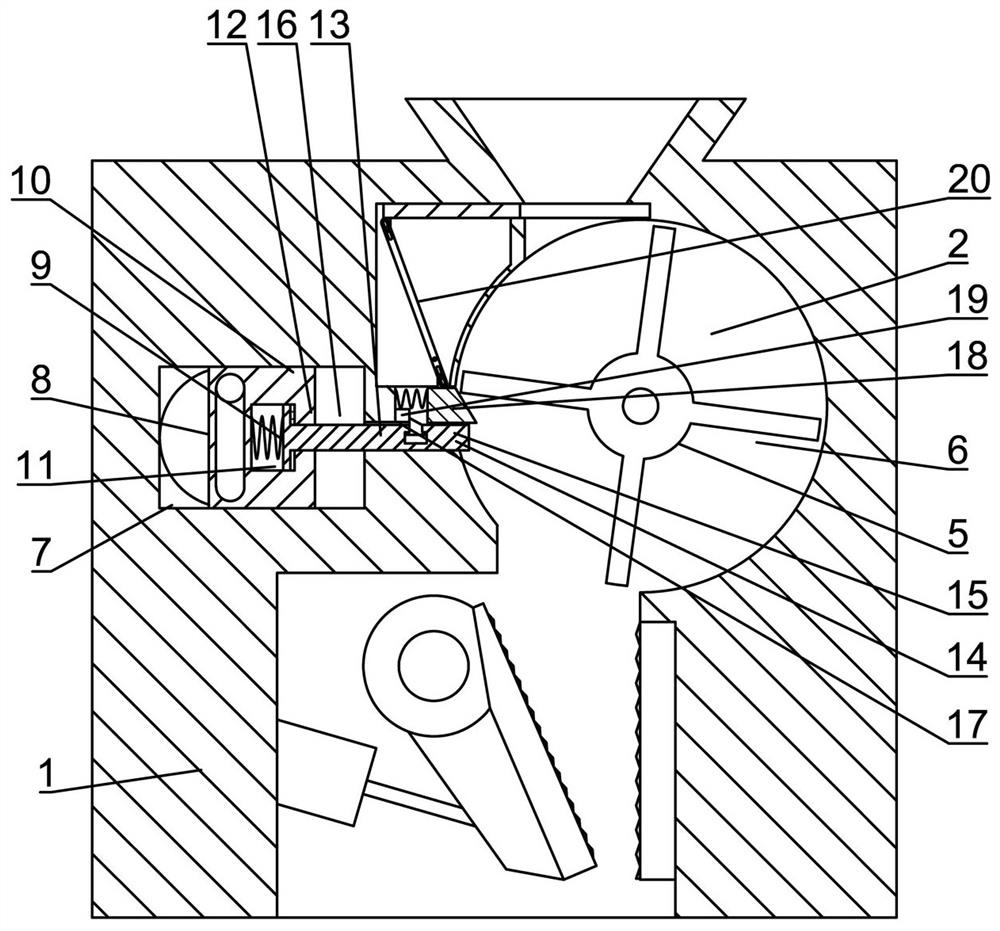

[0021] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] Depend on Figure 1 to Figure 6 Out, the present invention comprises shell 1, and shell 1 is provided with the cylindrical material dialing chamber 2 that places front and back, and the upper left end and the left lower end of the material dialing chamber 2 are provided with the opening that communicates with the exterior of housing 1 respectively, and the material dialing chamber There is a baffle plate 3 at the opening position of the upper left end of the 2, and the baffle plate 3 can slide left and right to open or close the upper left opening of the material dial chamber 2, and a rotating rod 5 is connected in the dial chamber 2, and the rotating rod 5 is connected to the material dial chamber 2 It is coaxial and can only rotate around the axis. Four shifting plates 6 are evenly distributed and fixed on the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com