Production method of large-granule slow-release fertilizer

A production method and slow-release fertilizer technology, which is applied in the field of large-grain slow-release fertilizer production methods, can solve the problems of complex nutrient release mechanism and high cost, and achieve the effects of short process flow, less returning materials, and convenient and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

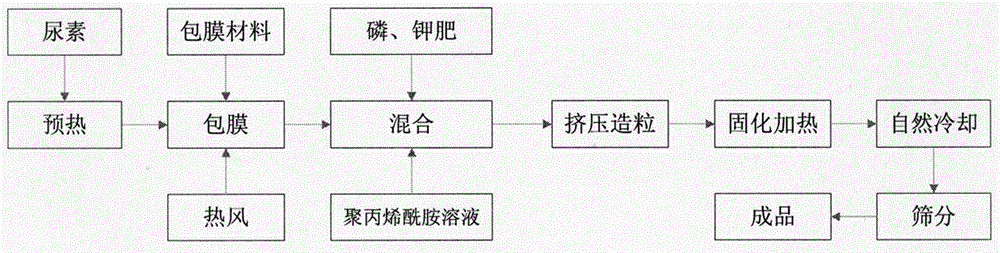

Image

Examples

example 1

[0026] Coating material configuration: Mix 22.5 kg of toluene diisocyanate, 7.5 kg of glycerin, 1.5 kg of epoxy resin, 1.5 kg of xylene, and 1 kg of diatomaceous earth for later use.

[0027] First, 250 kg of granular urea (46% nitrogen) preheated to 70 degrees is added to the drum coating machine, and the coating material configured above is evenly added to the material in the drum coating machine for coating. After the coating is completed, 315 kg of monoammonium phosphate (containing 11% nitrogen and 44% phosphorus pentoxide), 300 kg of potassium chloride (50% of potassium oxide), and 10 kg of 0.5% polyacrylamide solution are evenly added in sequence. Mix evenly, and put the mixture into an extrusion granulator for extrusion granulation. The semi-finished product after granulation is placed at 80 degrees for 5 hours, then naturally cooled and sieved to obtain the finished product.

example 2

[0029] Coating material configuration: Mix 24 kg of toluene diisocyanate, 6 kg of tung oil, 2 kg of epoxy resin, 3 kg of xylene, and 1.5 kg of diatomaceous earth for later use.

[0030] First, 275 kg of granular urea (46% nitrogen) preheated to 75 degrees is added to the drum coating machine, and the coating material configured above is evenly added to the material in the drum coating machine for coating. After the coating is completed, 225 kg of monoammonium phosphate (containing 11% nitrogen and 44% phosphorus pentoxide), 460 kg of potassium sulfate (50% potassium oxide content), and 15 kg of 0.2% polyacrylamide solution are evenly added in sequence, and mixed Evenly, the mixture is added to the extrusion granulator for extrusion granulation. The semi-finished product after granulation was placed at 80 degrees for 2 hours and then naturally cooled and sieved to obtain a finished product with a particle diameter of 40 mm and a single particle weight of 38 grams.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com