Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Minimal generation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

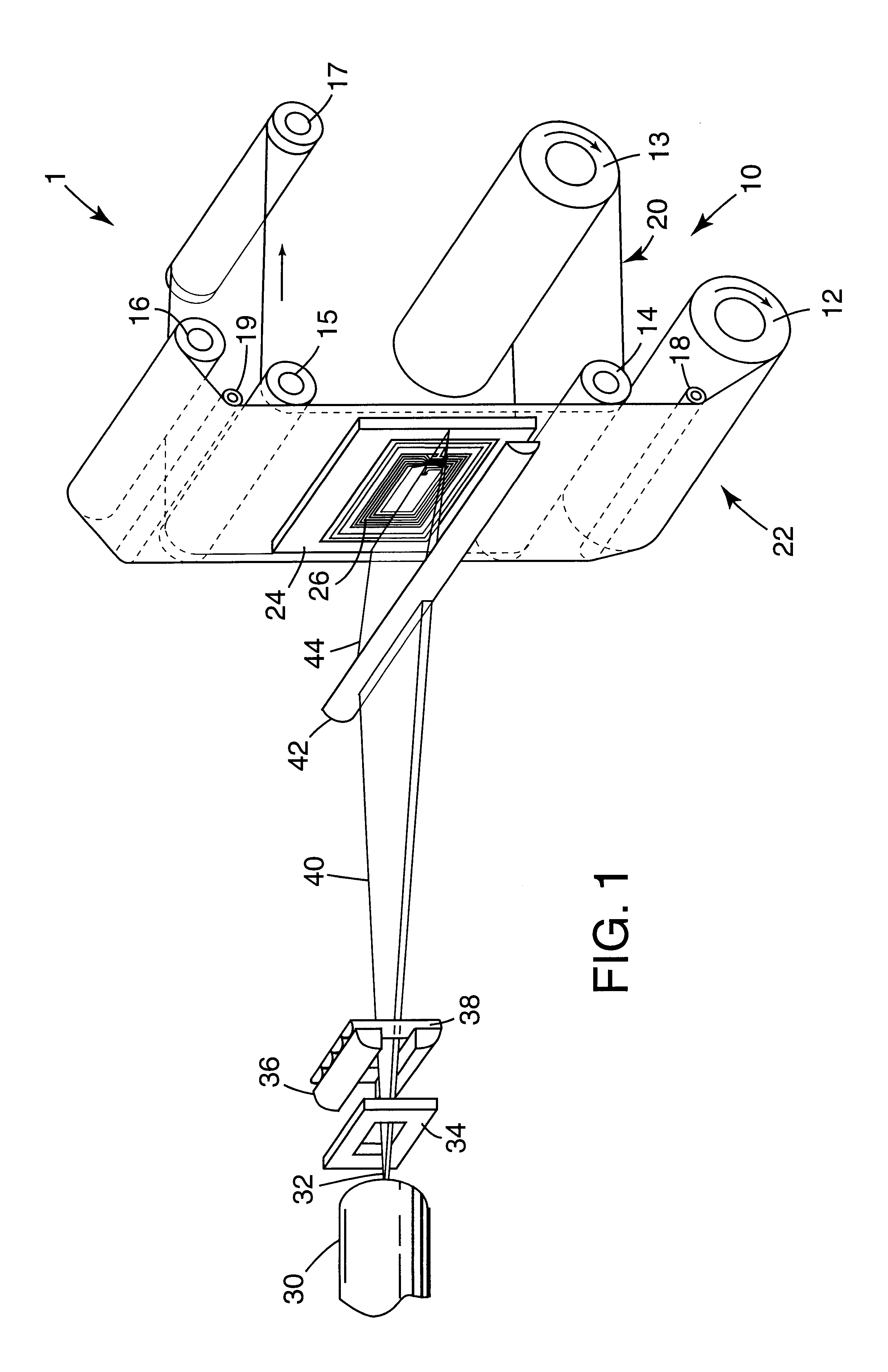

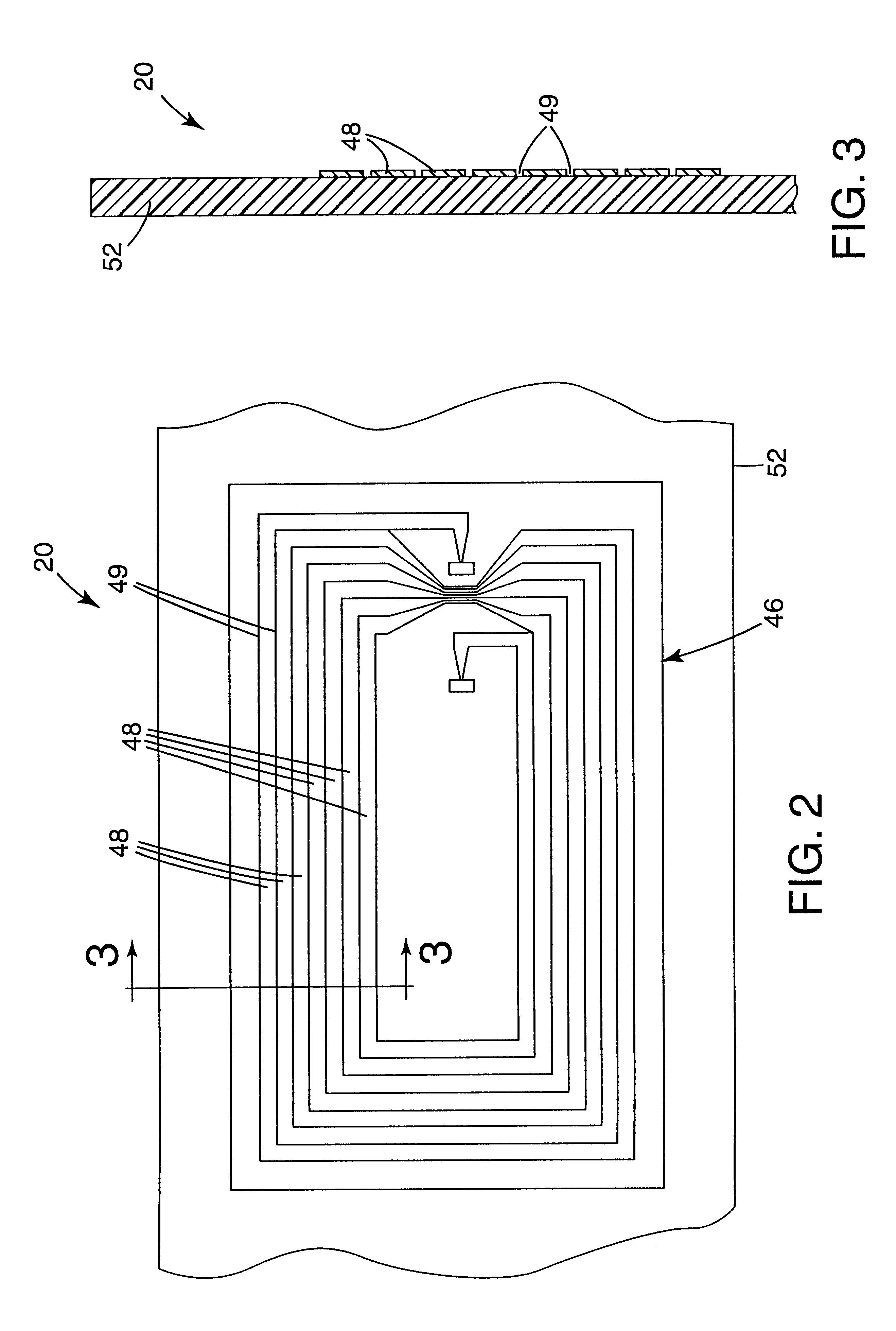

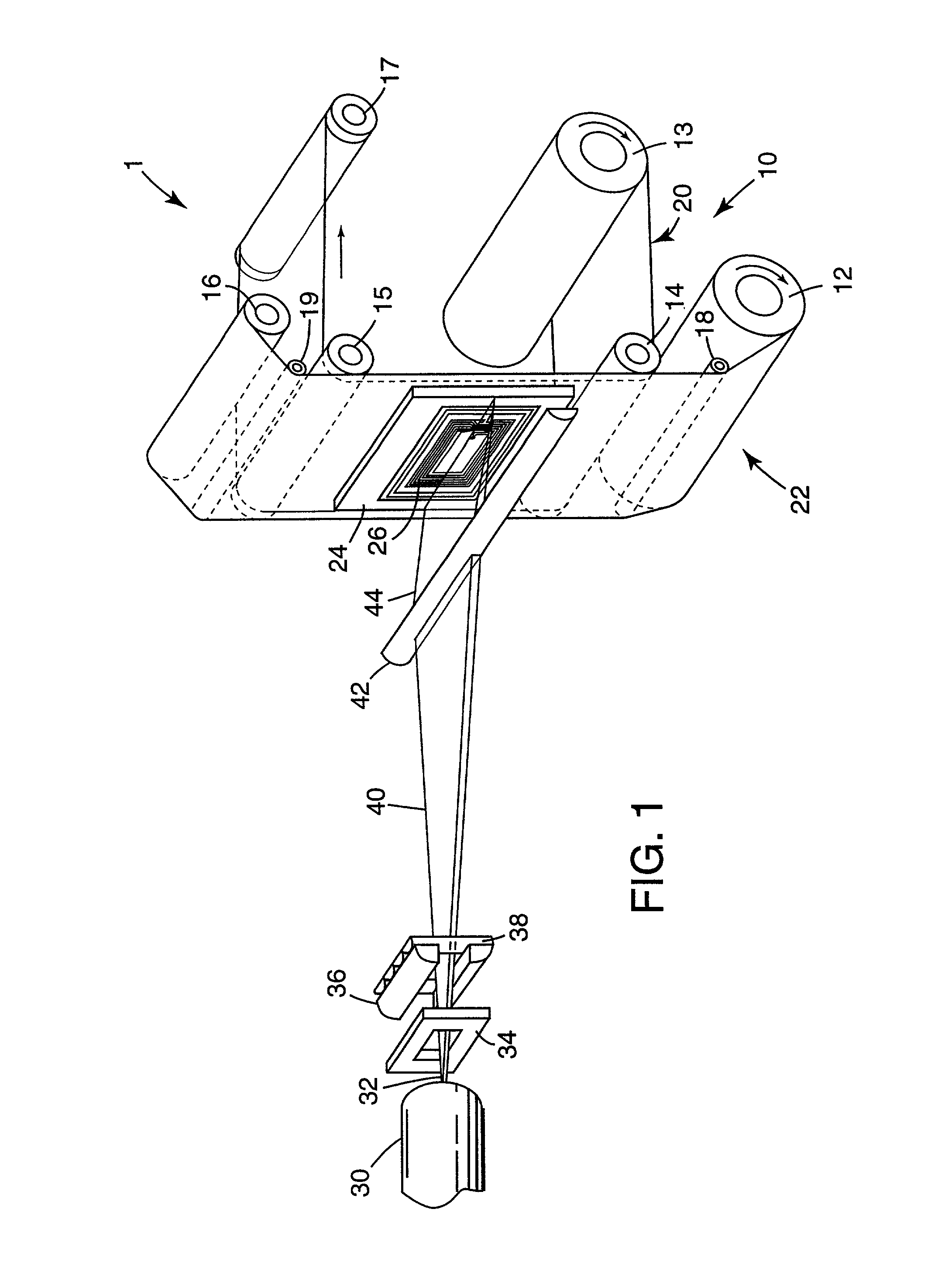

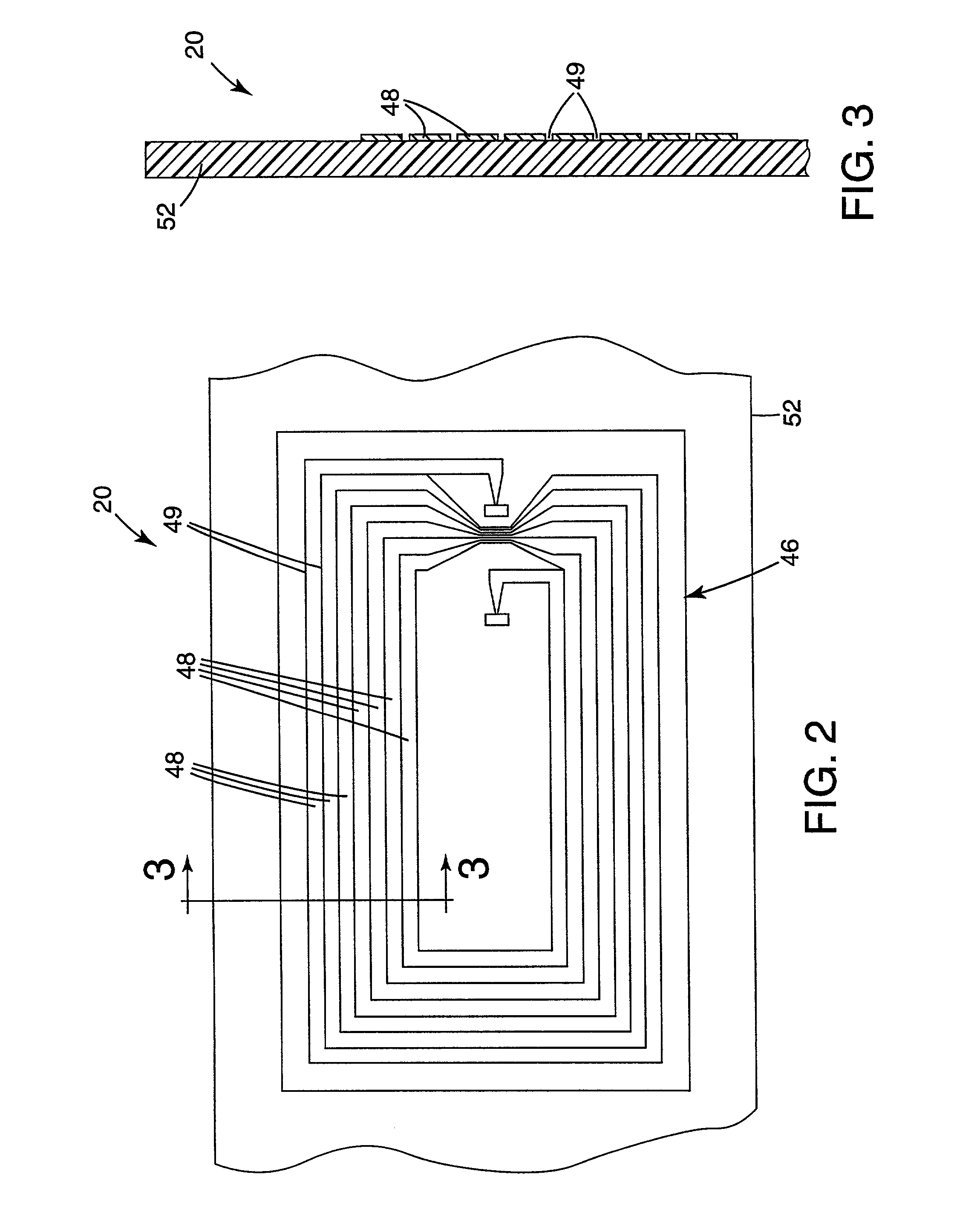

Imaged article on polymeric substrate

InactiveUS6203952B1Increasing the thicknessSmooth peelingAntenna supports/mountingsLoop antennasResistPolymer substrate

Patterned articles, such as RFID antenna, are made by subablation, a process comprising the steps of:A. providing a substrate having a coating, such as a metal or metal oxide, and an interface comprising the thin region where the coating and the substrate are closest to each other;B. exposing at least one part of the total area of the coating to a flux of electromagnetic energy, such as a focused excimer laser beam, sufficient to disrupt the interface but insufficient to ablate the coating; andC. removing the parts of the coating in registry with the portion of the interface area that was disrupted, by means such as ultrasonic agitation.The process has advantages over photo-resist processes in that there is no residual chemical resist left on the product and no undercutting of the pattern or image. It has advantages over laser ablation processes in that higher throughput is possible at the same energy level and there is no microscopic debris left on the product surface.

Owner:3M INNOVATIVE PROPERTIES CO

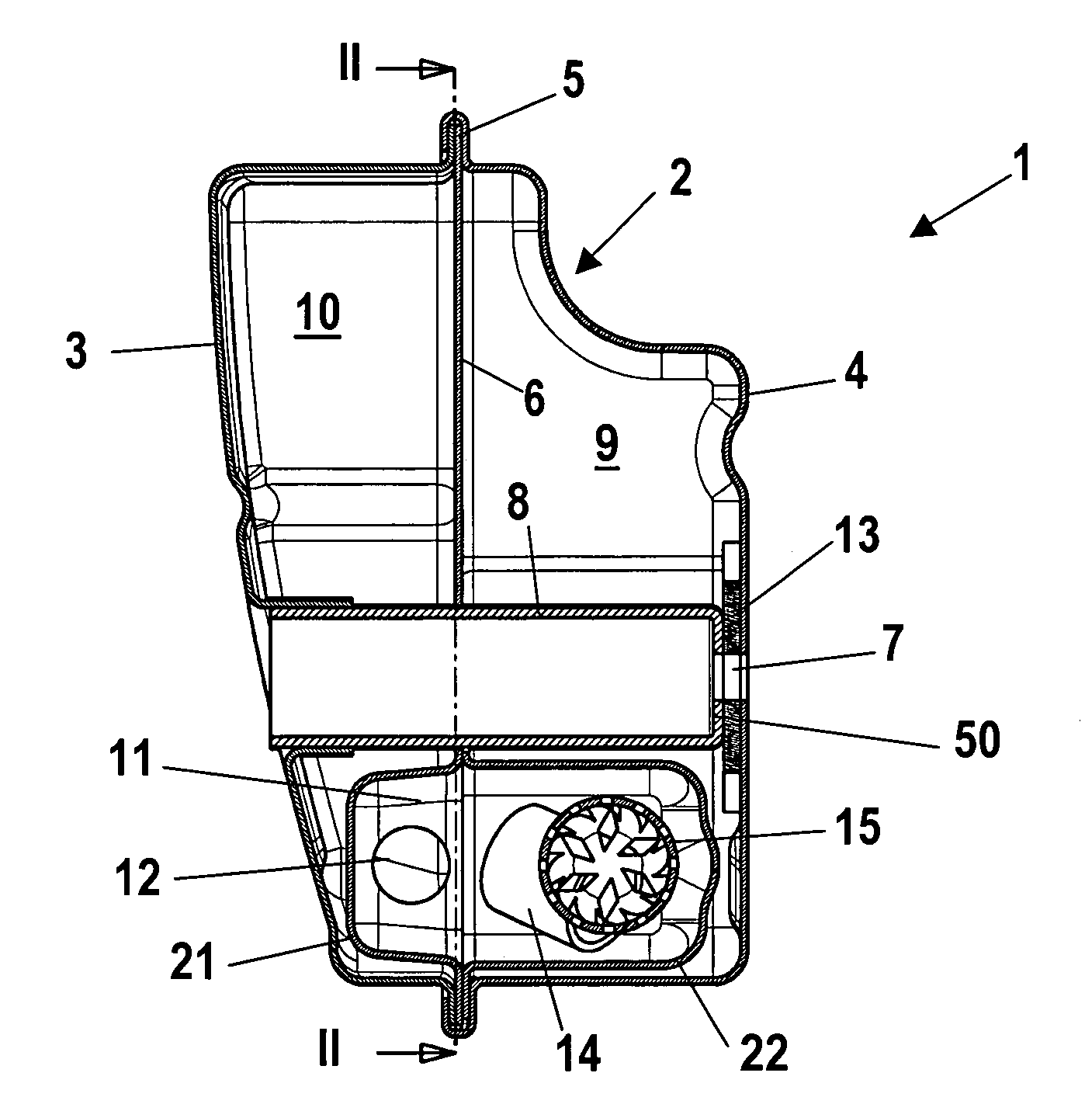

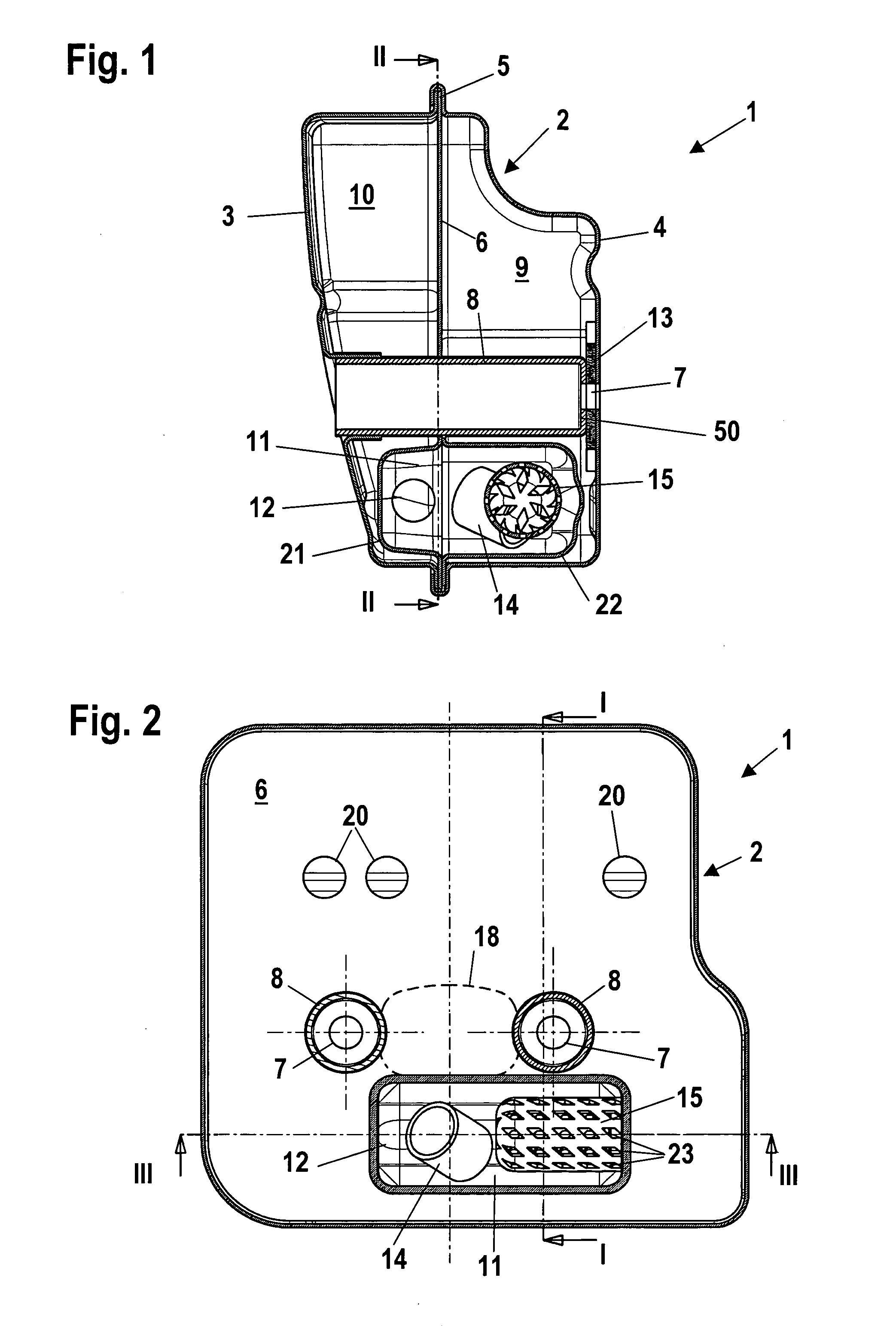

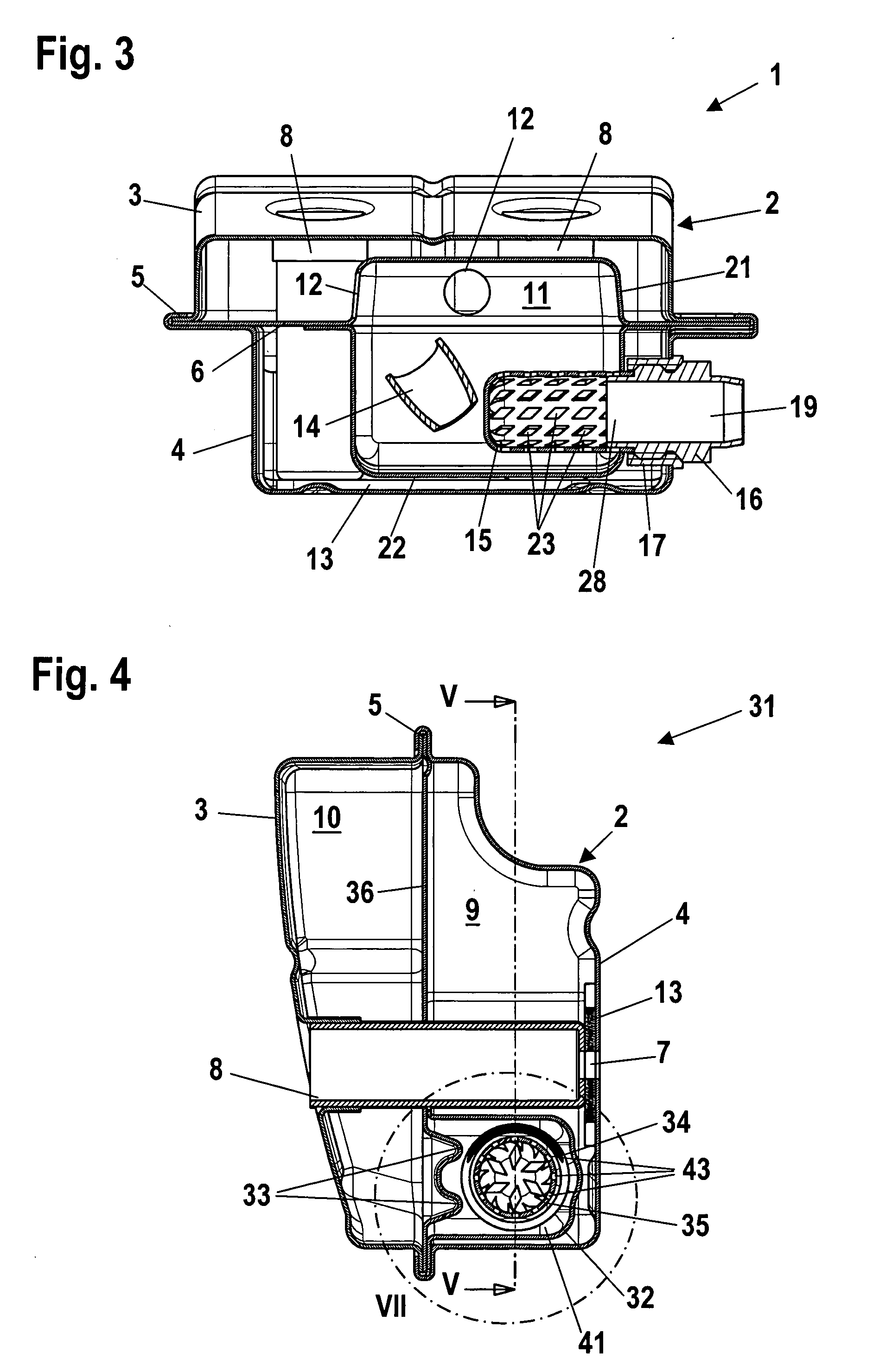

Muffler for exhaust gas

InactiveUS20060102420A1Easy constructionReduce weightSilencing apparatusMachines/enginesEngineeringMuffler

Owner:ANDREAS STIHL AG & CO KG

Method for patterning thin films

InactiveUS20010006766A1Great throughput and outputReduce impactPhotography auxillary processesAntenna supports/mountingsResistMicroscopic scale

Patterned articles, such as RFID antenna, are made by subablation, a process comprising the steps of: A. providing a substrate having a coating, such as a metal or metal oxide, and an interface comprising the thin region where the coating and the substrate are closest to each other; B. exposing at least one part of the total area of the coating to a flux of electromagnetic energy, Such as a focused excimer laser beam, sufficient to disrupt the interface but insufficient to ablate the coating, and C. removing the parts of the coating in registry with the portion of the interface area that was disrupted, by means such as ultrasonic agitation. The process has advantages over photo-resist processes in that there is no residual chemical resist left on the product and no undercutting of the pattern or image. It has advantages over laser ablation processes in that higher throughput is possible at the same energy level and there is no microscopic debris left on the product surface.

Owner:3M INNOVATIVE PROPERTIES CO

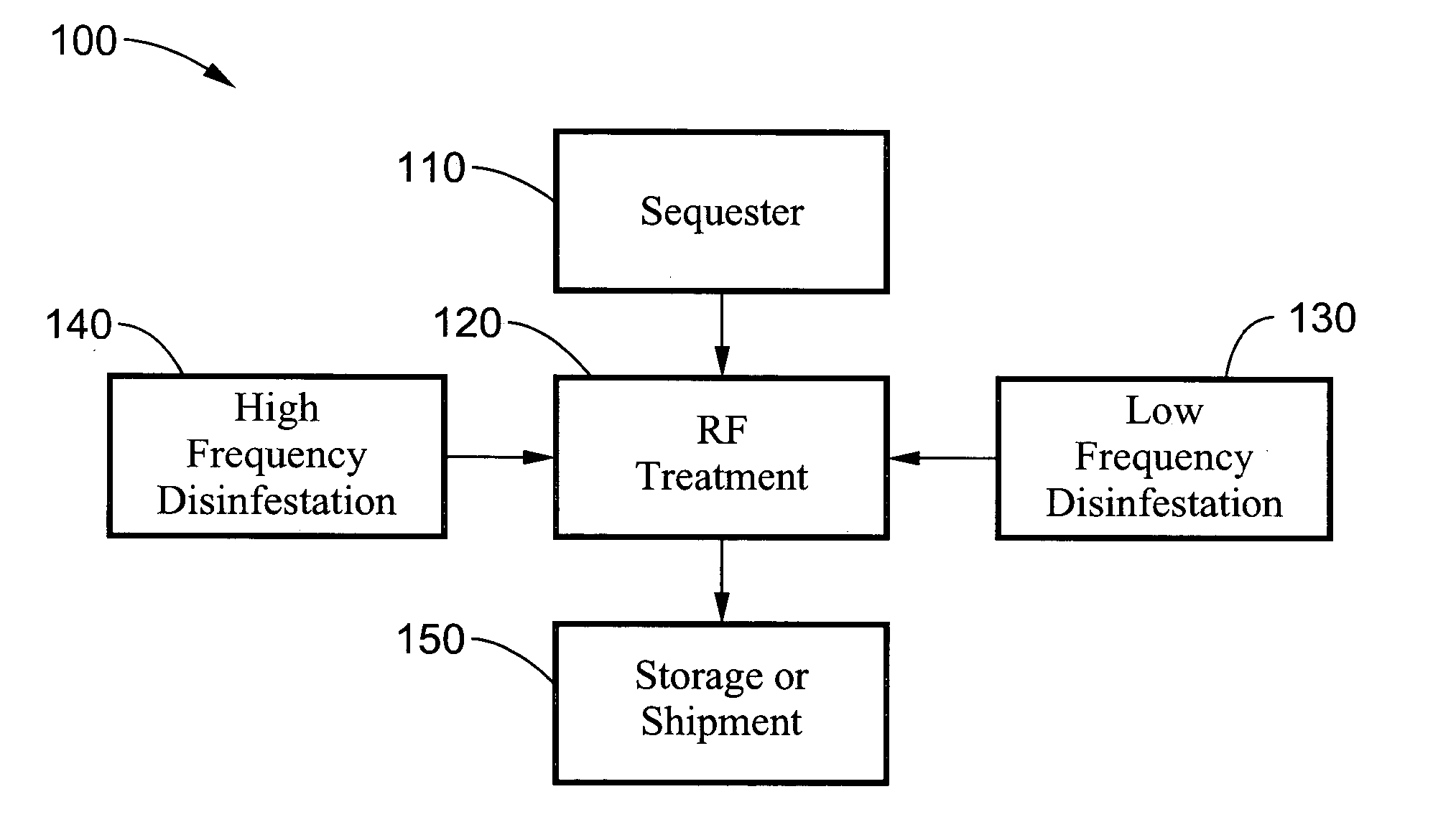

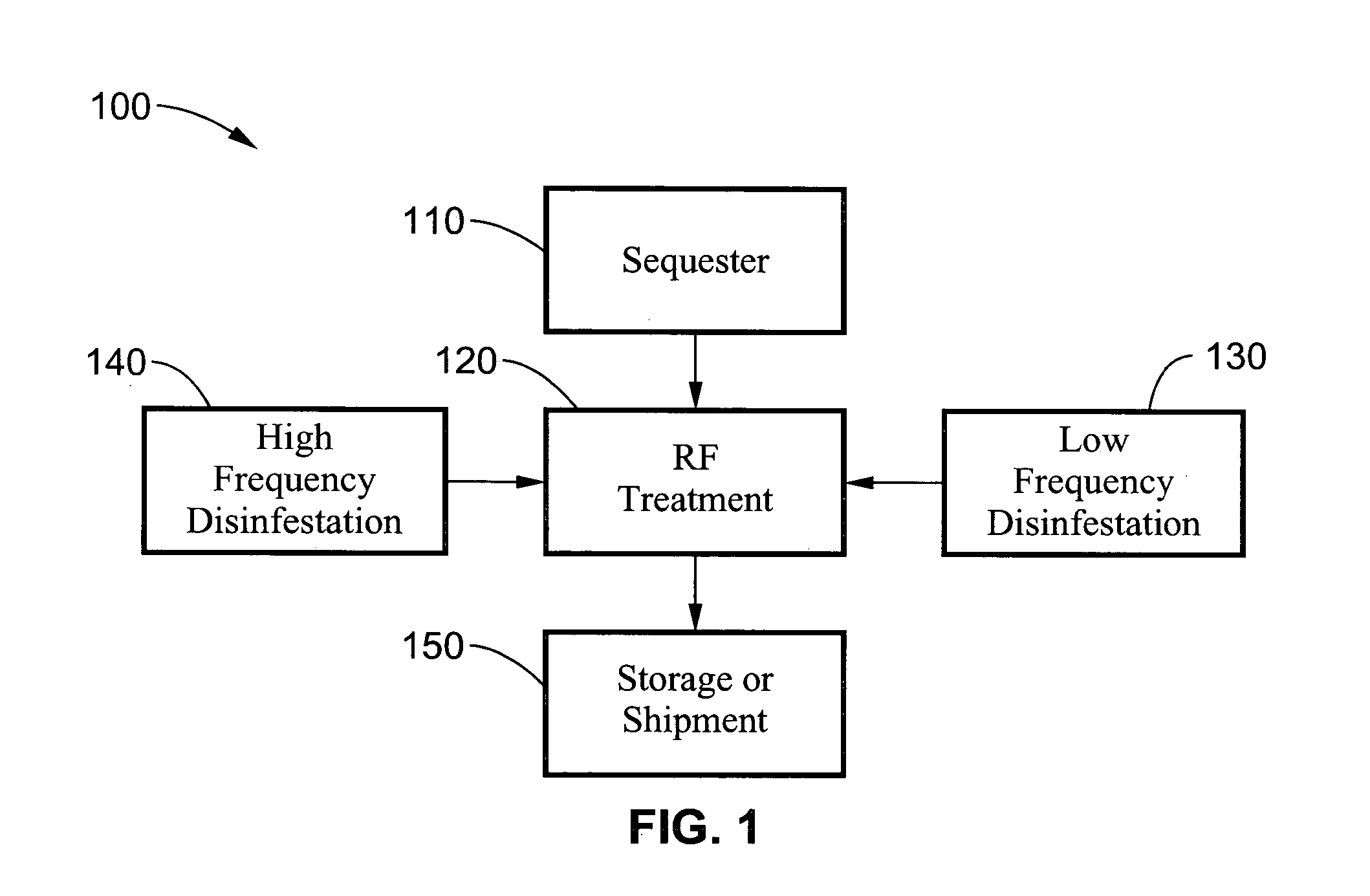

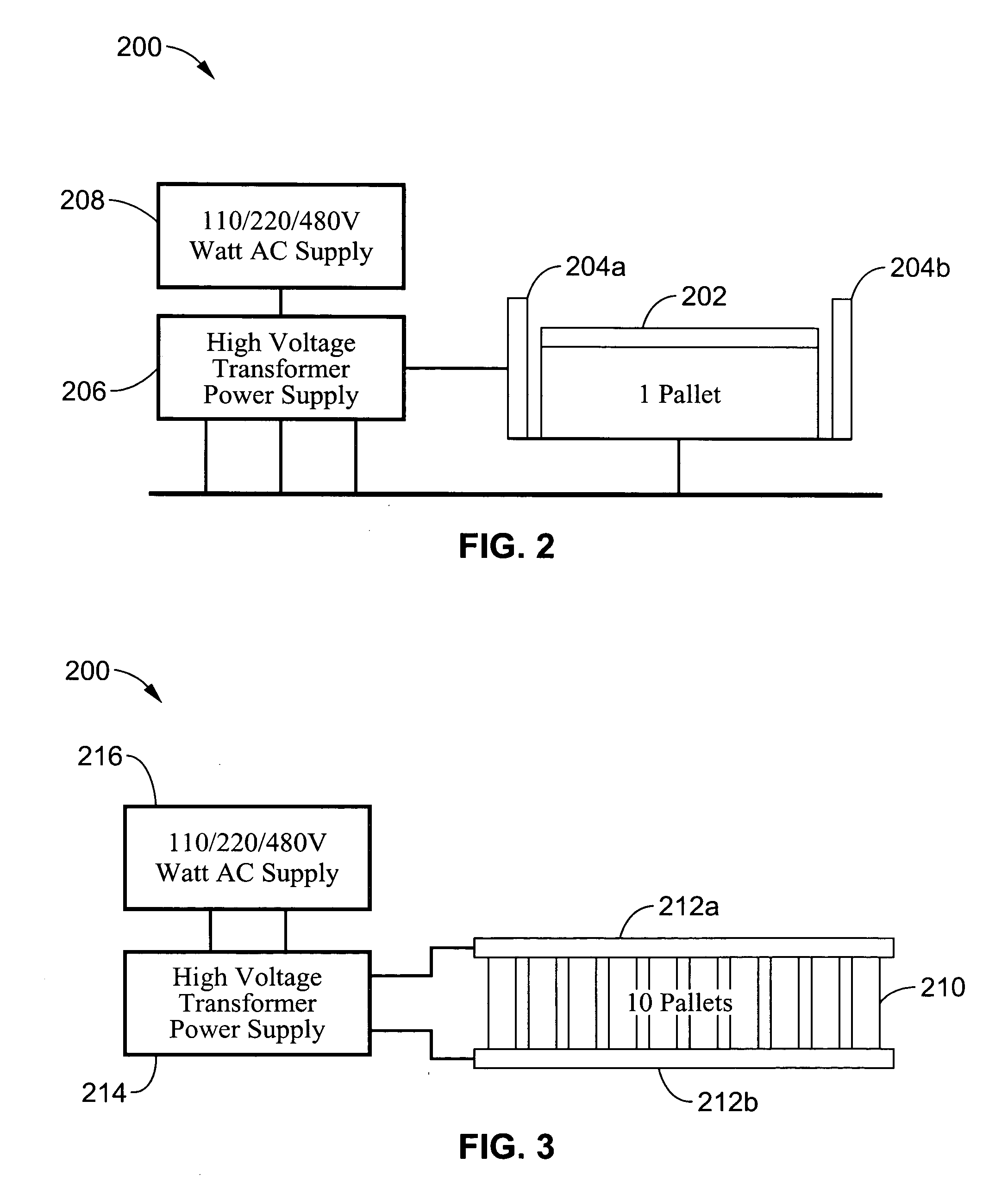

Non-thermal disinfestation of biological pests with pulsed radio frequency power systems

InactiveUS20060024195A1Maximize RF peak powerFast rise timeLavatory sanitoryInsect catchers and killersBatch processingEngineering

An apparatus and method for disinfestation of temperature sensitive and other commodities using short duration, high peak power radio frequency pulses and intense electric fields to preferentially induce drift of conduction charges, spot heating and other mortal damage to infesting insects and mites without raising the temperature of the host commodity. A low frequency mode is provided with a frequency range of approximately 10 Hz to 1 MHz and is particularly suited for large batch processing of pallets or field containers. A high frequency mode is also provided that is suited for continuous or small batch processing and uses a preferred frequency range of approximately 1 MHz to 150 MHz. Both modes preferably have an electric field strength of greater than approximately 5 kV / cm and pulse repetition rates of between one pulse and approximately 10 million pulses per second. The method is non-contact, residue free and effective with all biological stages of an infesting insect, mite or other biological pest including egg, pupa, larvae, juvenile and adult forms. The apparatus and methods of the invention are an effective alternative to methyl bromide fumigation that does not leave any toxic residues or damage the cosmetic appearance or flavor of the commodity.

Owner:RGT UNIV OF CALIFORNIA

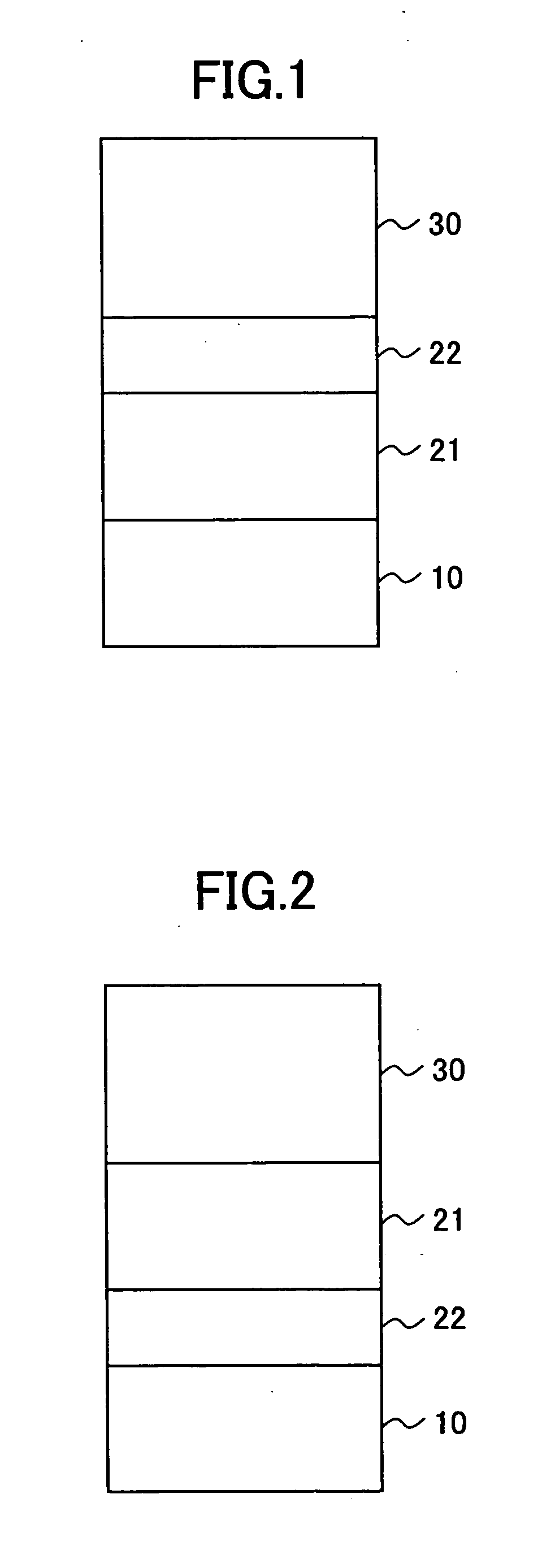

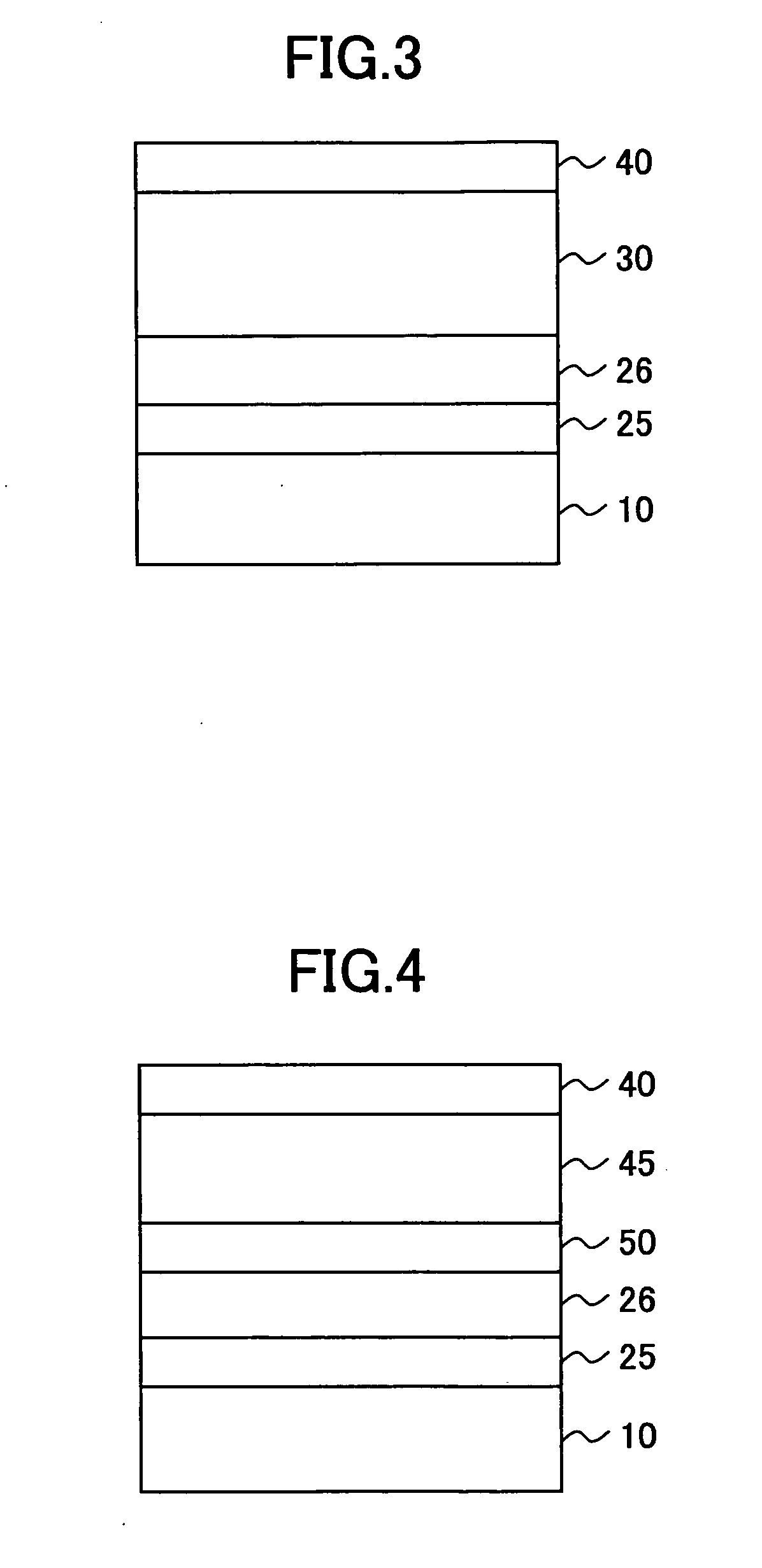

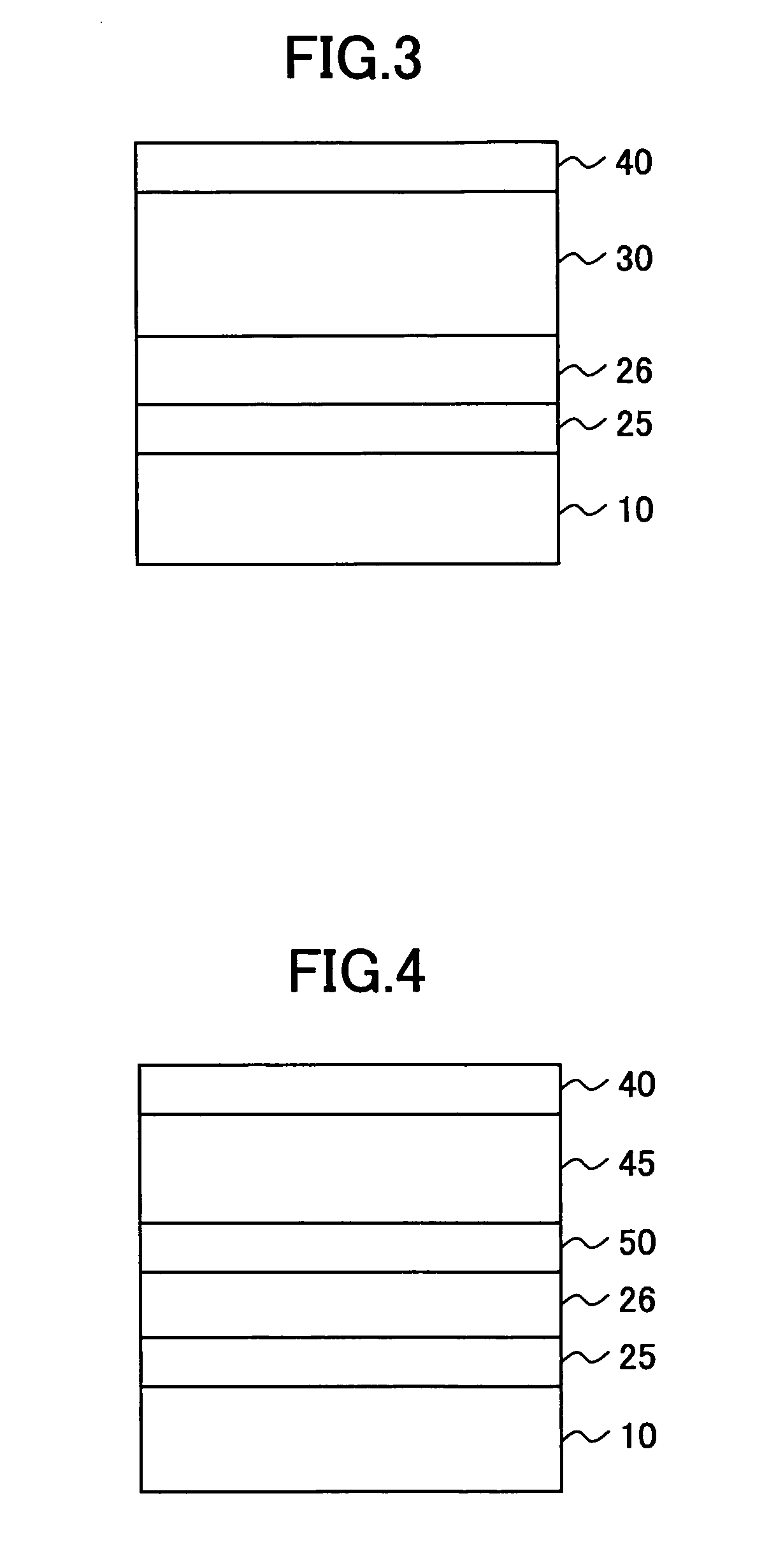

Electrophotographic photoreceptor, method of image formation, image formation apparatus and process cartridge for image formation apparatus

ActiveUS20070154825A1Suppress generationLittle changeElectrographic process apparatusCorona dischargeElectrical conductorImaging quality

An electrophotographic photoconductor that is excellent in the stability of image quality and can realize high durability is provided. In an electrophotographic photoconductor in which an underlying layer, a photoconductive layer, and a crosslinked-type charge transportation layer are stacked on an electrically conductive support in order, the underlying layer is composed of at least two layers being a layer containing an inorganic pigment and a layer including no inorganic pigment, and the crosslinked-type charge transportation layer is formed by curing, at least, a three-or-more-functional radical-polymerizable monomer having no charge transporting structure and a radical-polymerizable compound having one-functional charge transporting structure.

Owner:RICOH KK

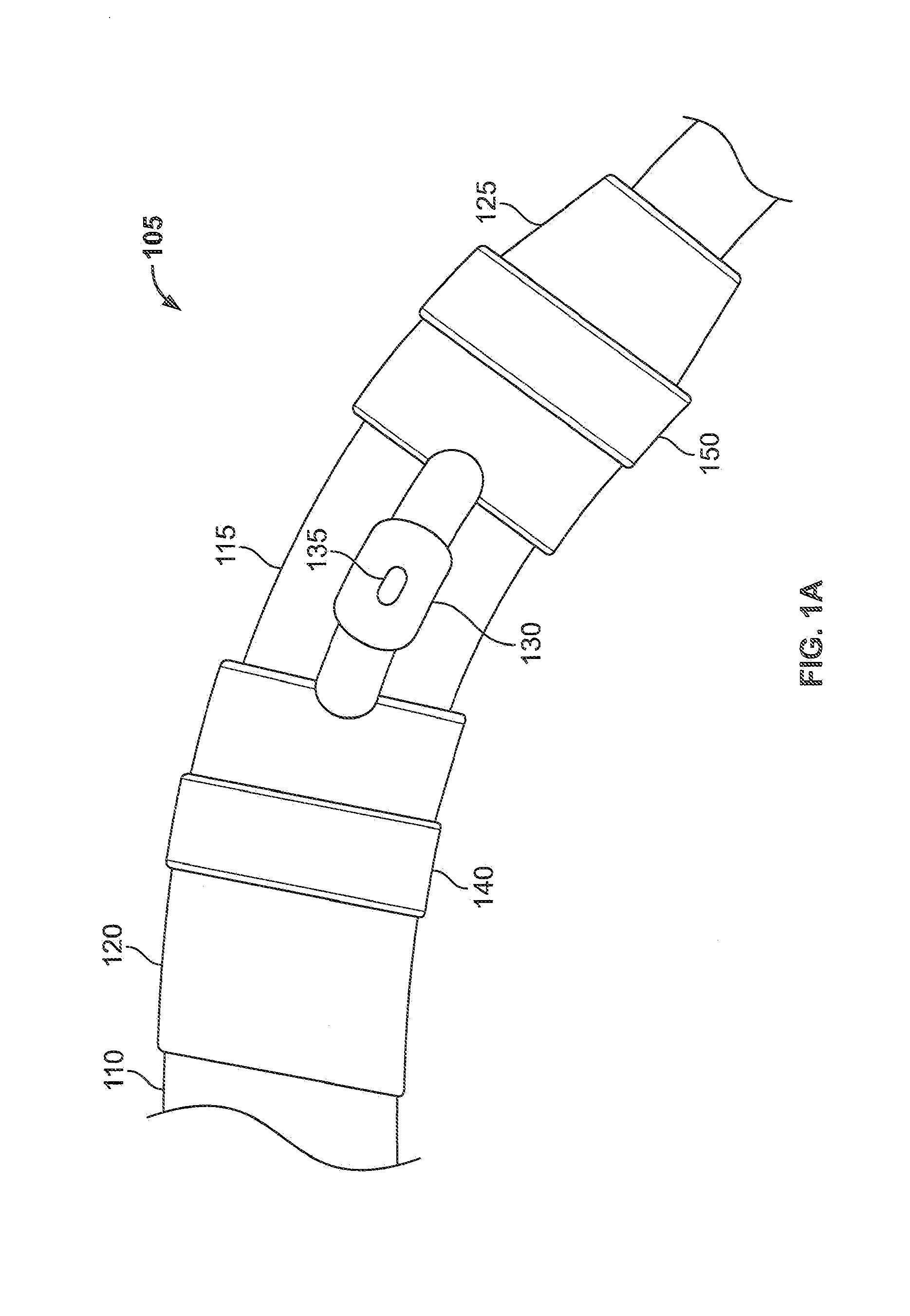

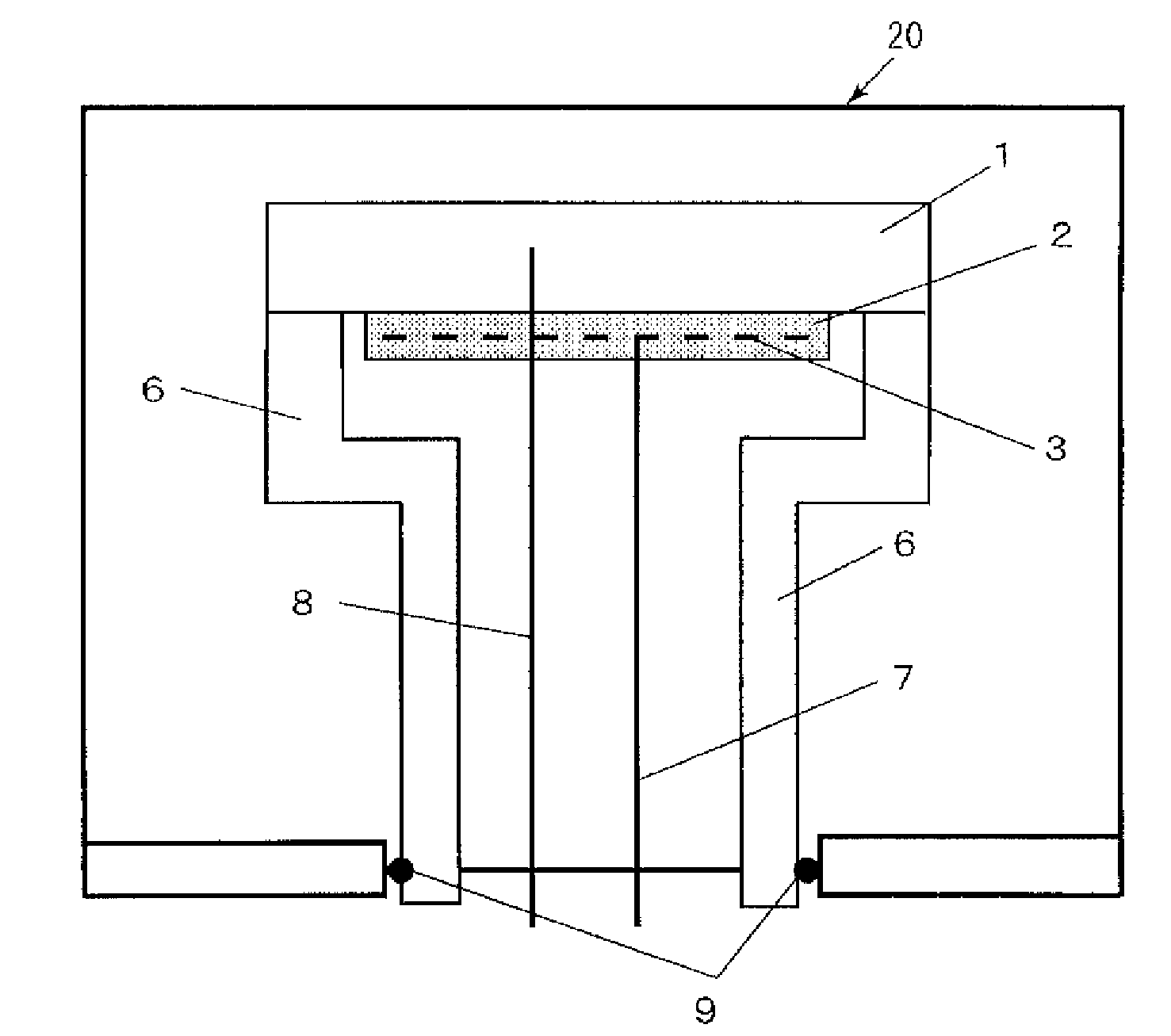

System and methods for treating or supporting human joints or a portion of the human body

ActiveUS20140276298A1Eliminating time divisionPrevent radiative couplingElectrotherapyNon-surgical orthopedic devicesElectricityHuman body

Disclosed is a system including a good comprising a sensor in contact with human tissues of a patient and configured to obtain a power dissipation reading of the human tissues. The good also includes a storage medium for tangibly storing thereon a program for execution by a processor. The system also includes a control unit in communication with the good to form an electrical muscular stimulation (EMS) system that uses feedback in a closed loop manner to self tune electrical properties of the output. The control unit is configured to instruct the sensor to (a) apply a sense pulse to the human tissues, (b) measure power dissipation of the sense pulse, (c) adjust a stimulation pulse based on the measured power dissipation, (d) apply the stimulation pulse to the human tissues based on the power dissipation and based on the program in order to maintain constant power output across each pulse, and (e) repeat steps (a)-(d).

Owner:MOTIVE HEALTH INC

Dry-powder film coating composition and method of preparation

InactiveUS6884288B2Component is expensiveLow costPowder deliveryOrganic active ingredientsPlasticizerGum acacia

An edible dry-powder formulation of a film coating for pharmaceuticals and confectioneries using gum acacia as a low-cost film former is provided. A cellulosic polymer such as hydroxypropyl methylcellulose is used in addition to the gum acacia. A plasticizer such as propylene glycol is also added. The resulting formulation is a dry, free flowing powder that can be put into solution and applied to a tablet or other substrate without an extended waiting period. The resulting film coating is clear, shiny, durable and extremely economical. Because the formulation is a dry powder, it has along shelf life and low shipping costs.

Owner:BPSI HLDG LLC

Sizing agent for carbon fiber, method for sizing carbon fiber by said sizing agent, sized carbon fiber and knitted or woven fabric Using said carbon fiber

InactiveUS20040197555A1Superior processability and other workabilityMinimal generationCarbon fibresLayered productsFiber sizeWoven fabric

Owner:MITSUBISHI CHEM CORP

Electrophotographic photoreceptor, method of image formation, image formation apparatus and process cartridge for image formation apparatus

ActiveUS7560203B2Improve image qualityIncreased durabilityElectrographic process apparatusCorona dischargeElectrical conductorImaging quality

Owner:RICOH KK

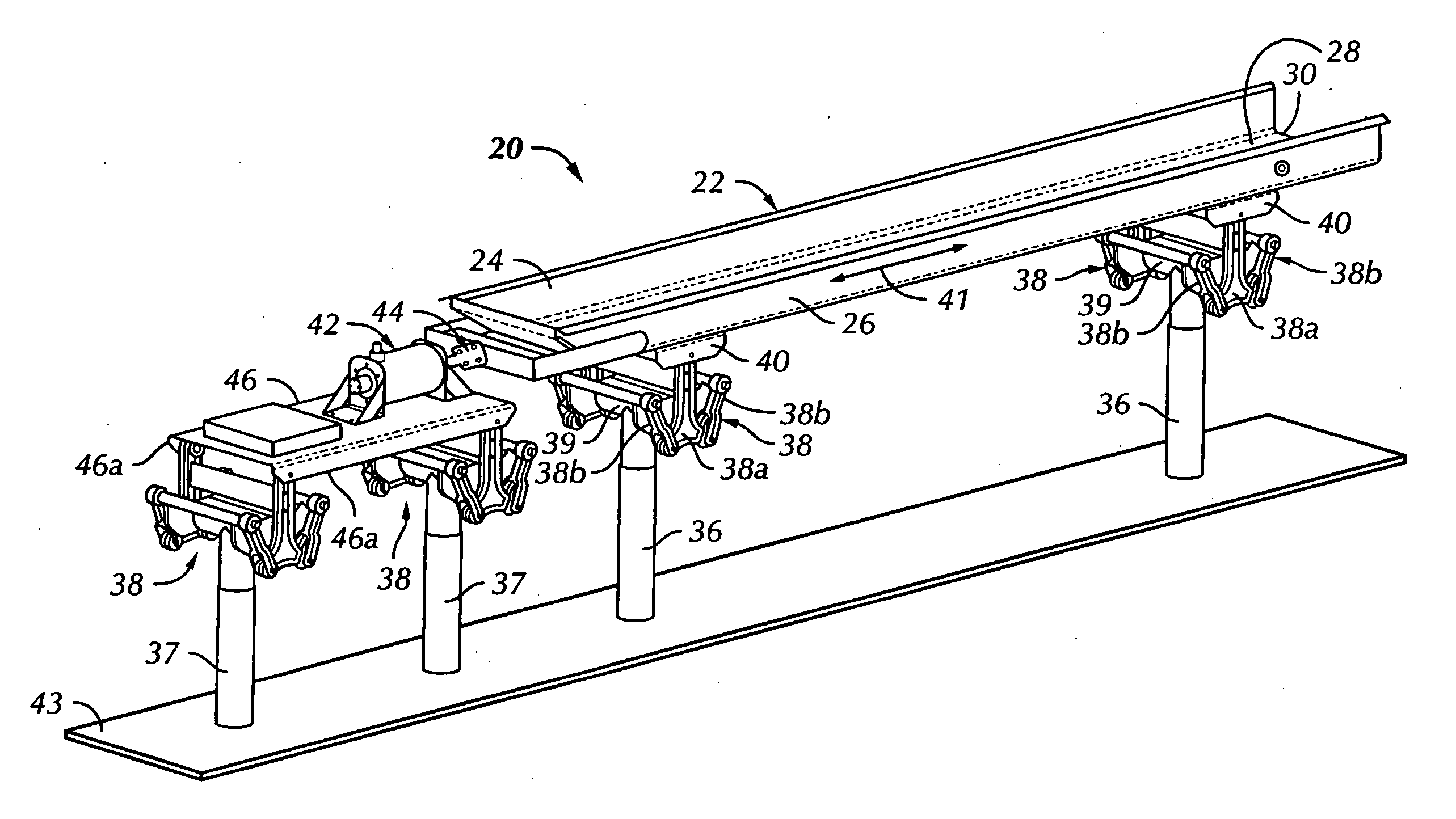

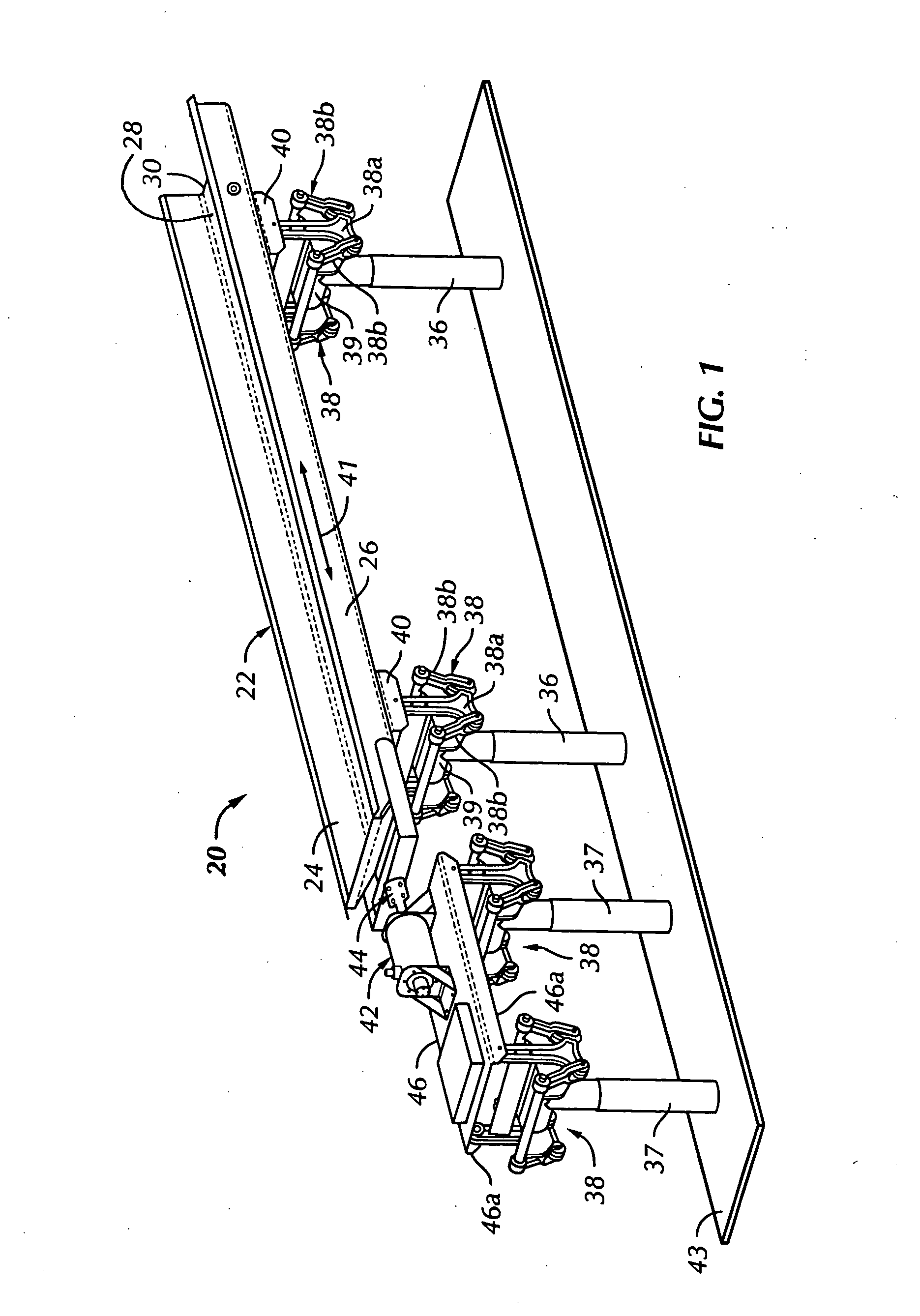

Reciprocating conveyor system and method

InactiveUS20070193858A1Frictional heat is generatedMinimal generationJigging conveyorsAir bearingReciprocating motion

A linear reciprocating conveyor system includes an elongated tray connected to a linear electric motor, the tray and motor each being supported on linkages allowing linear reciprocating motion without transferring vibration to system support structure. The linear electric motor is adapted for control by a method which provides a current profile to effect reciprocation of the motor to convey articles or material with the tray in one direction and acceleration of the tray in the opposite direction to provide slippage of the material or articles, thus causing the material or articles to move toward a tray discharge end. The motor armature may be supported with respect to the motor stator by an air bearing system. Plural motors may be connected to the tray and also supported by an air bearing system.

Owner:TRIPLES DYNAMICS

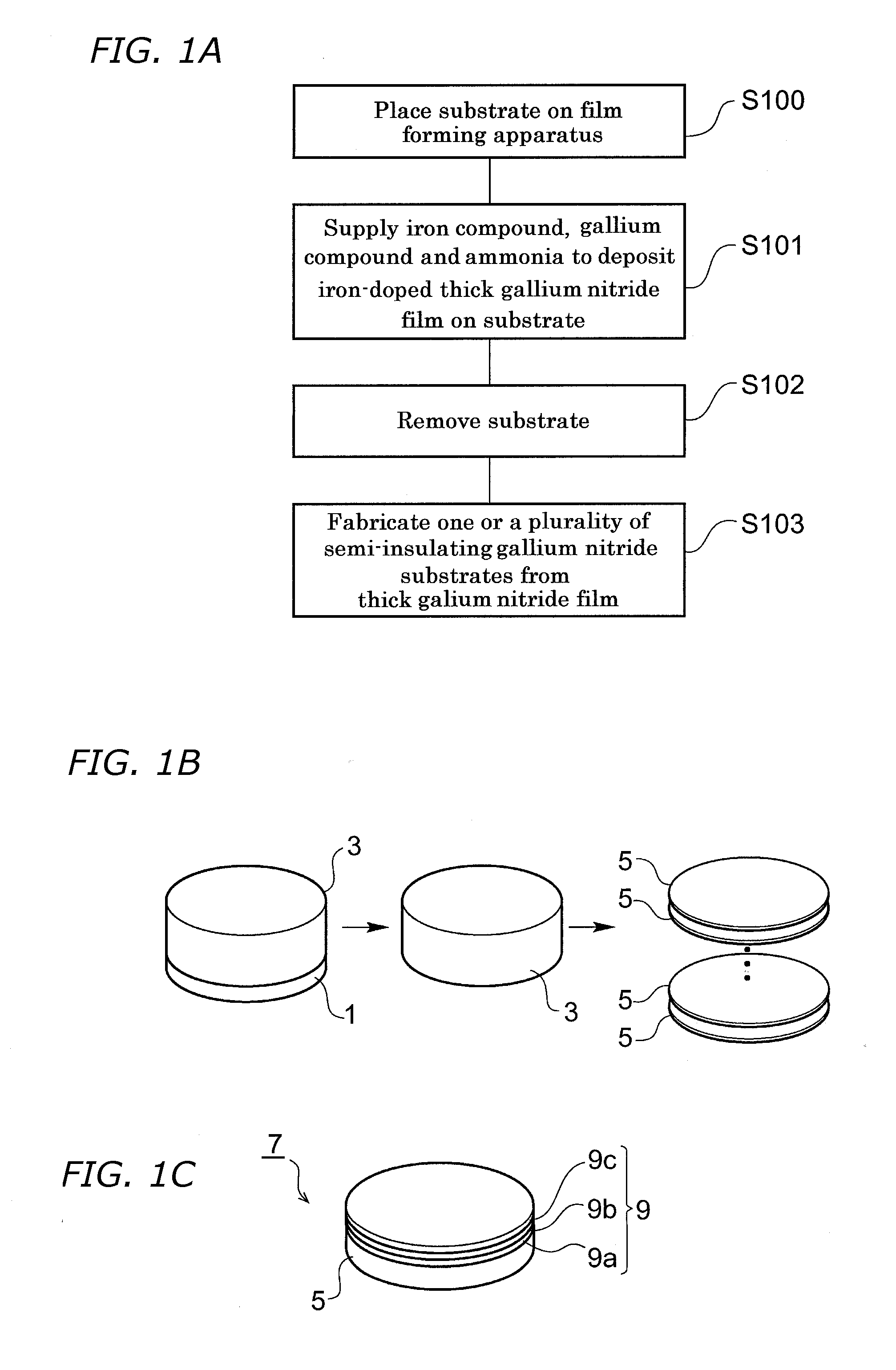

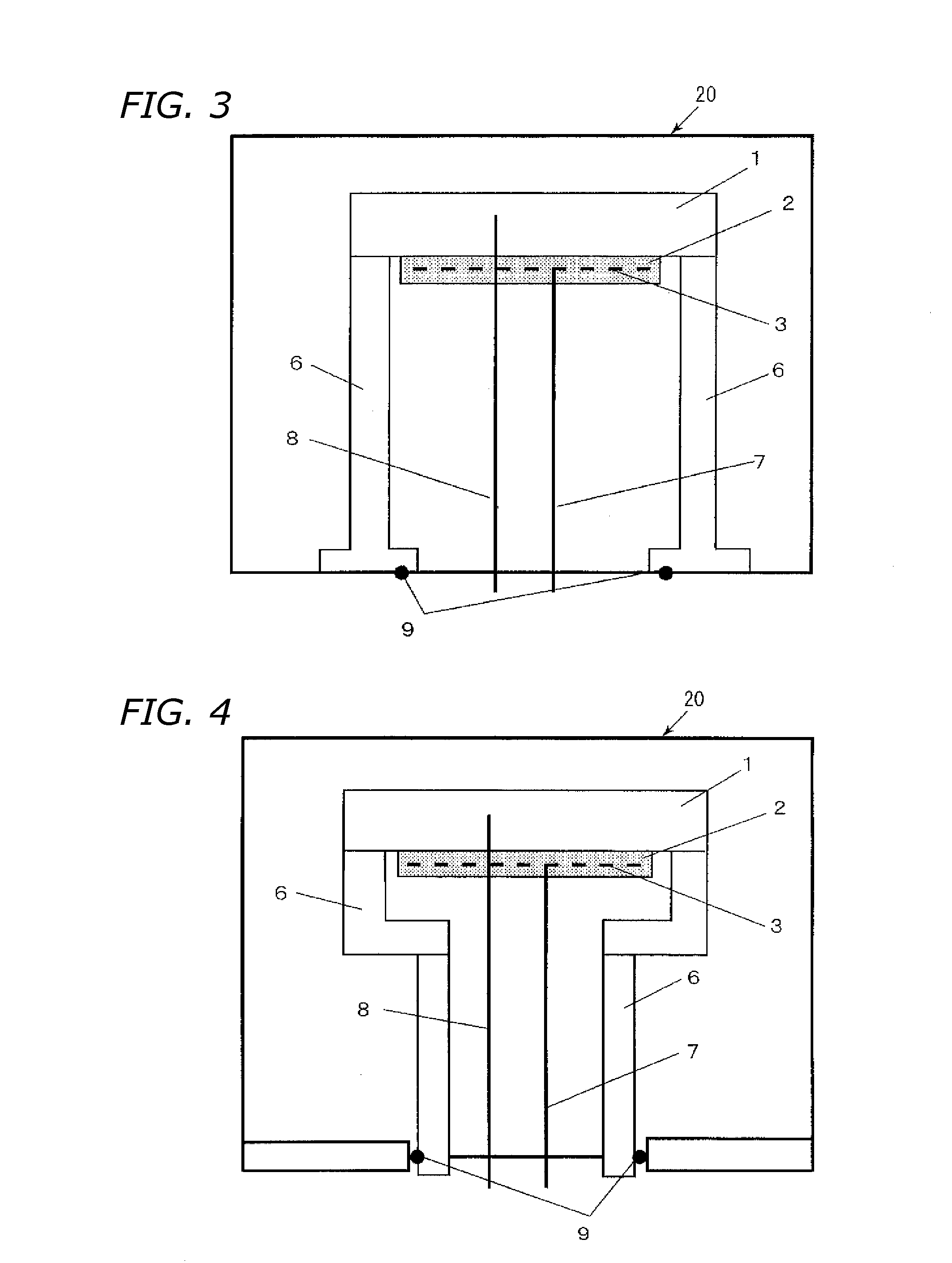

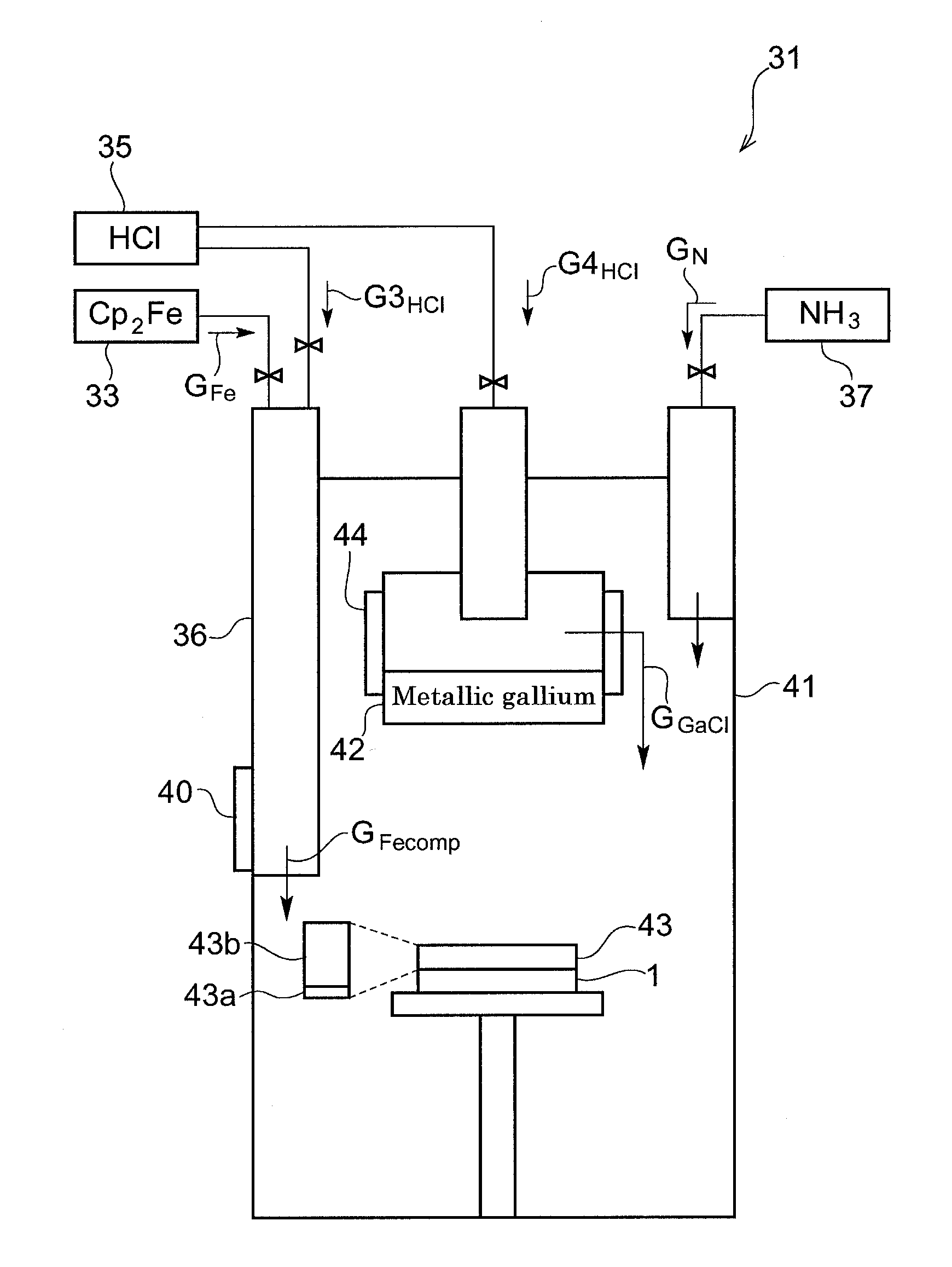

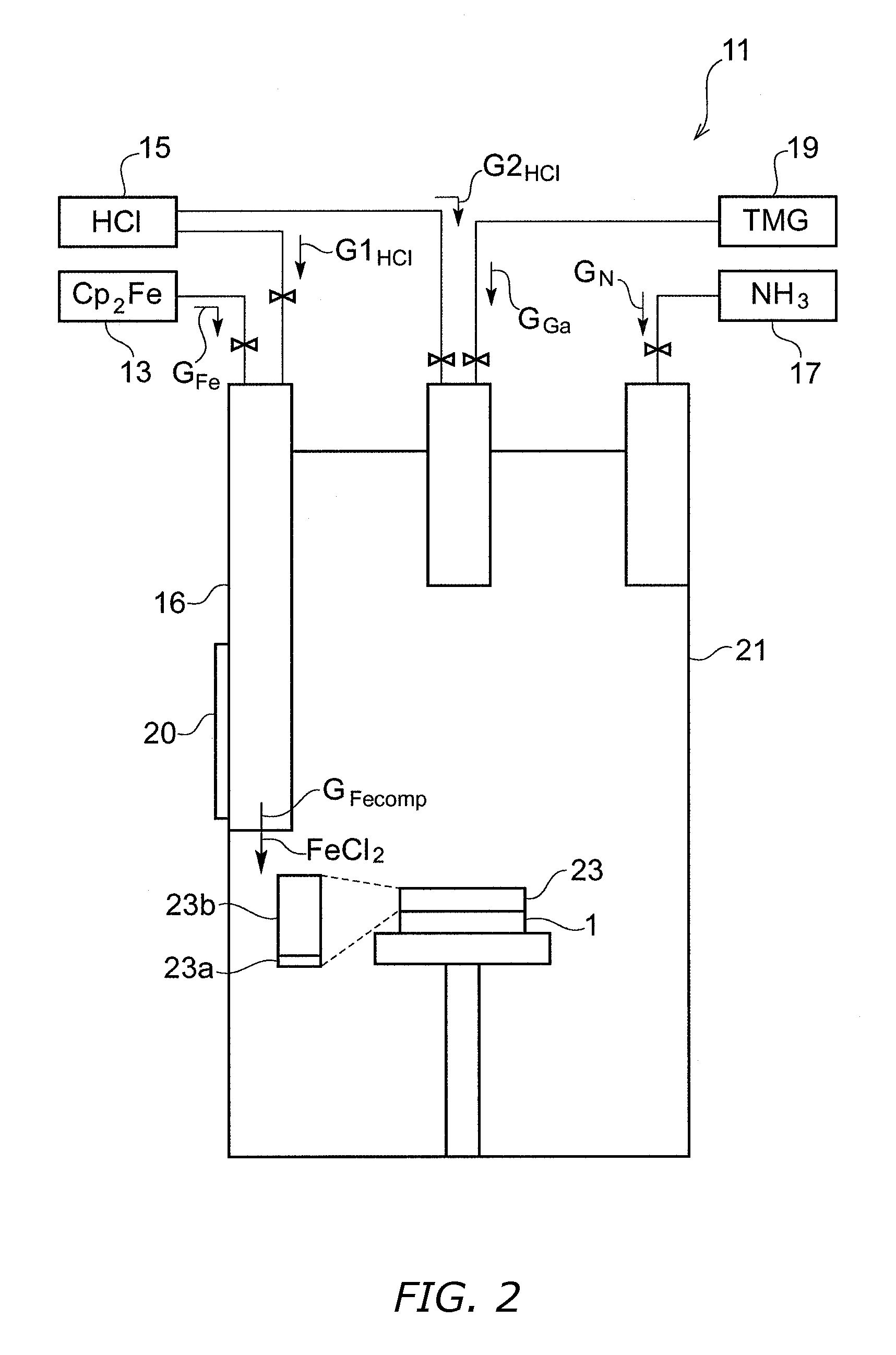

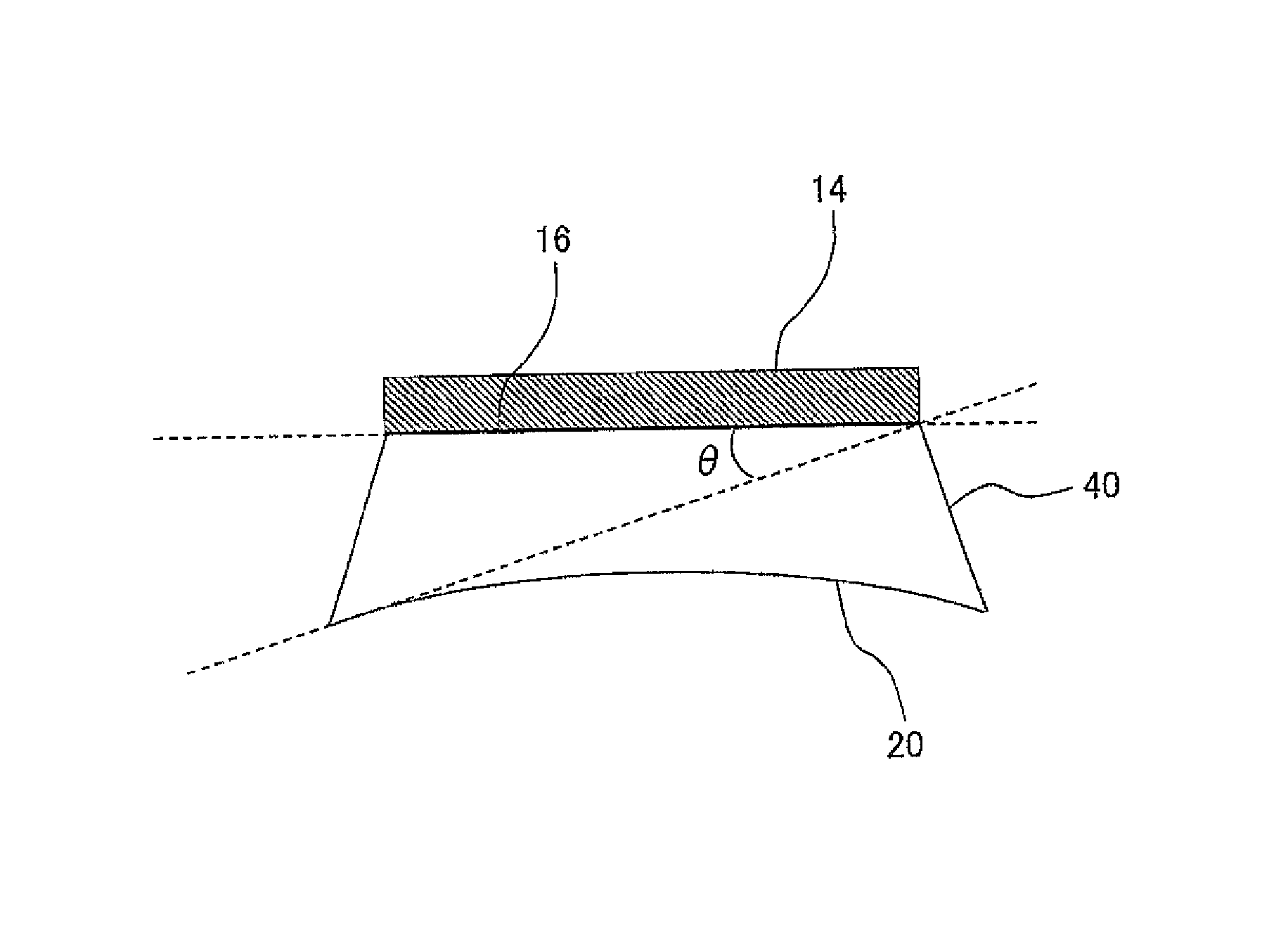

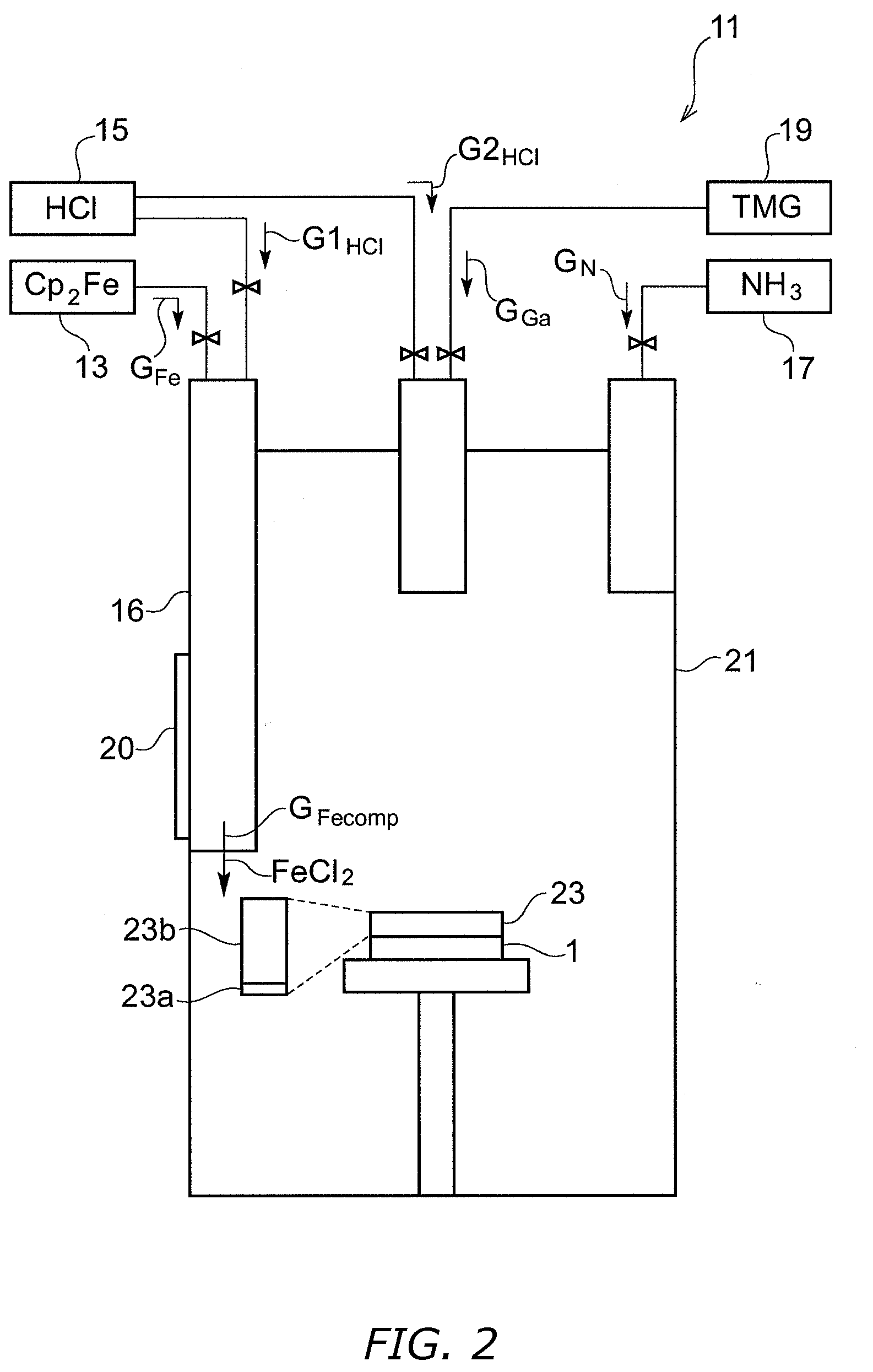

Gallium Nitride Baseplate, Epitaxial Substrate, and Method of Forming Gallium Nitride

InactiveUS20070215982A1Degradation in crystallinityLow resistivityPolycrystalline material growthSemiconductor/solid-state device manufacturingSusceptorGallium nitride

A method of forming an iron-doped gallium nitride for a semi-insulating GaN substrate is provided. A substrate 1, such as a sapphire substrate having the (0001) plane, is placed on a susceptor of a metalorganic hydrogen chloride vapor phase apparatus 11. Next, gaseous iron compound GFe from a source 13 for an iron compound, such as ferrocene, and hydrogen chloride gas G1HCl from a hydrogen chloride source 15 are caused to react with each other in a mixing container 16 to generate gas GFeComp of an iron-containing reaction product, such as iron chloride (FeCl2). In association with the generation, the iron-containing reaction product GFeComp, first substance gas GN containing elemental nitrogen from a nitrogen source 17, and second substance gas GGa containing elemental gallium are supplied to a reaction tube 21 to form iron-doped gallium nitride 23 on the substrate 1.

Owner:SUMITOMO ELECTRIC IND LTD

Polyester fiber and method for its production, and tire cord, tire, belt-reinforcing fiber material and belt comprising the polyester fiber

InactiveUS20110017378A1Few defectSlow changeGroup 5/15 element organic compoundsConductive materialFiberPolyester

There is provided a polyester fiber which has few defects such as voids due to catalyst particles, and low variation in physical properties and minimal fluff generation. The polyester fiber of the invention comprises laminar nanoparticles composed of a divalent metal and a phosphorus compound and having side lengths of 5-100 nm and an interlayer spacing of 1-5 nm. There are also provided a tire cord, tire, belt-reinforcing fiber material and belt, comprising the polyester fiber.

Owner:TEIJIN FRONTIER CO LTD

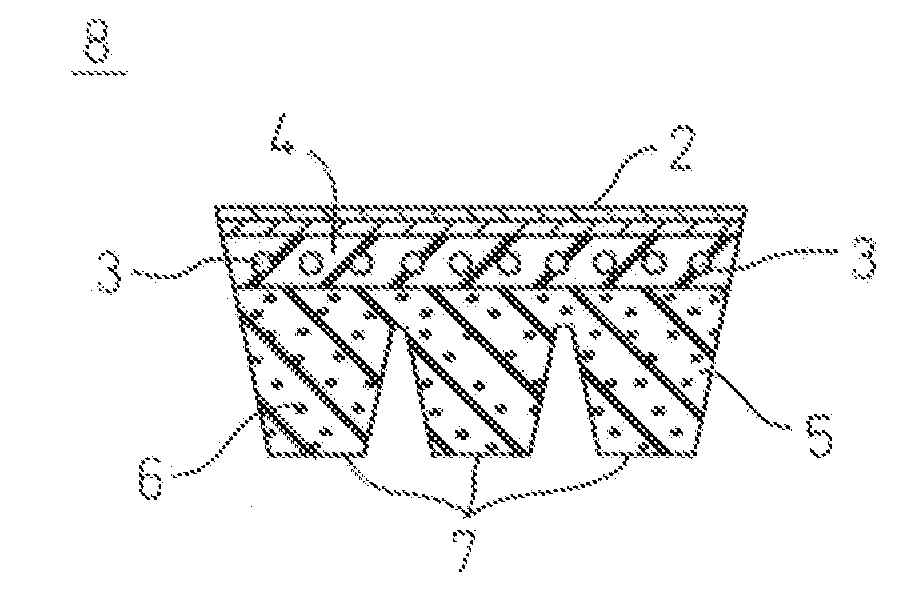

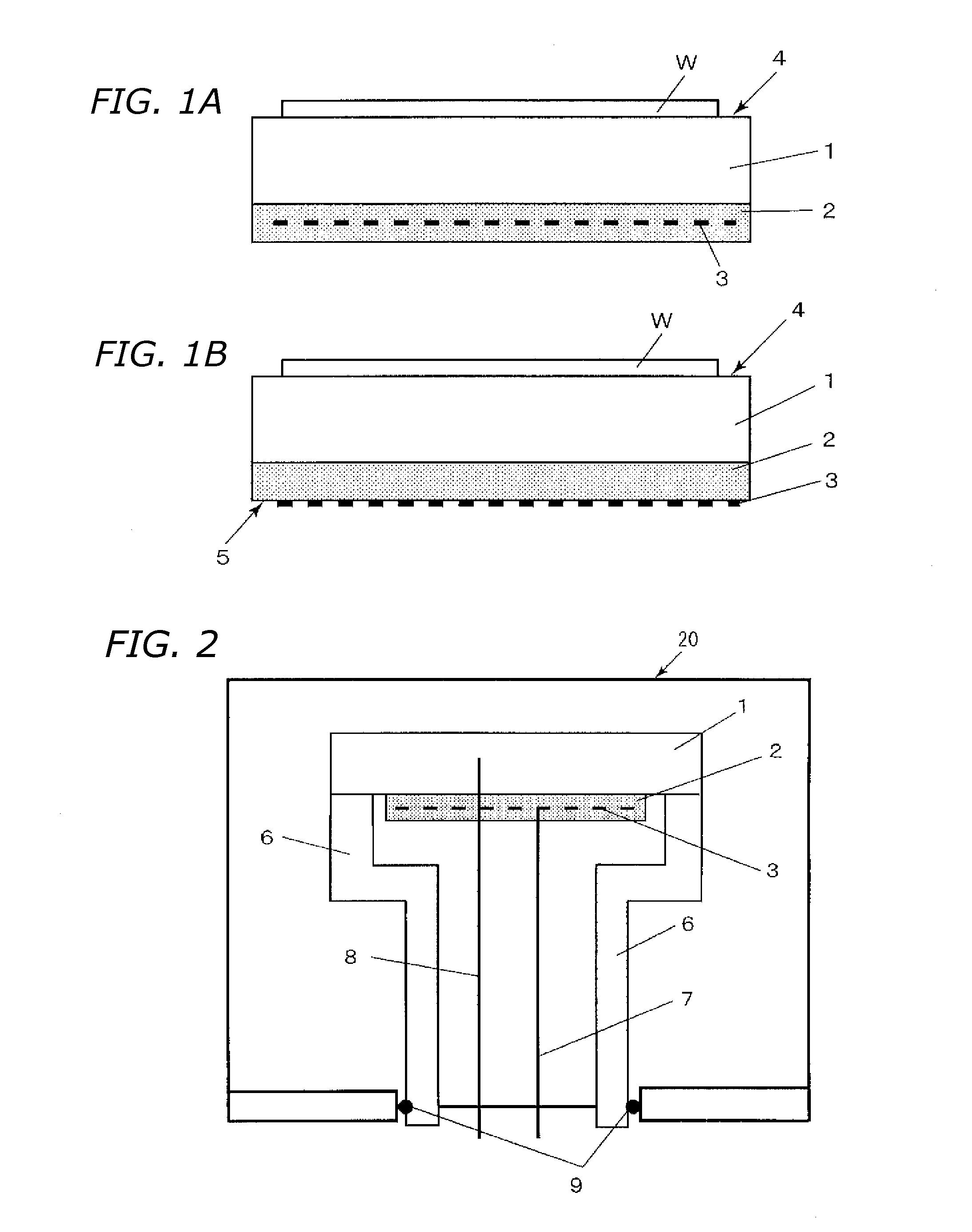

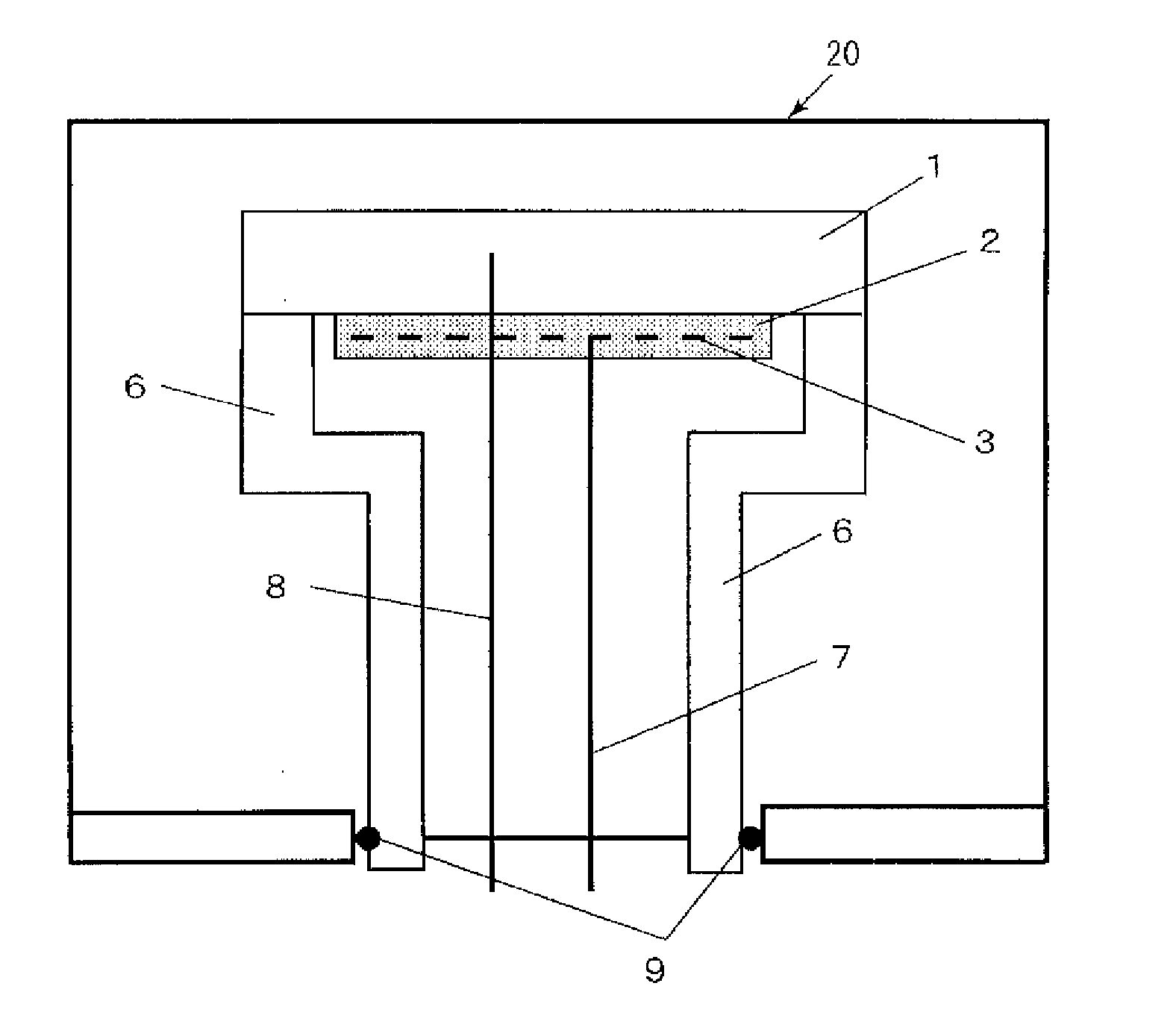

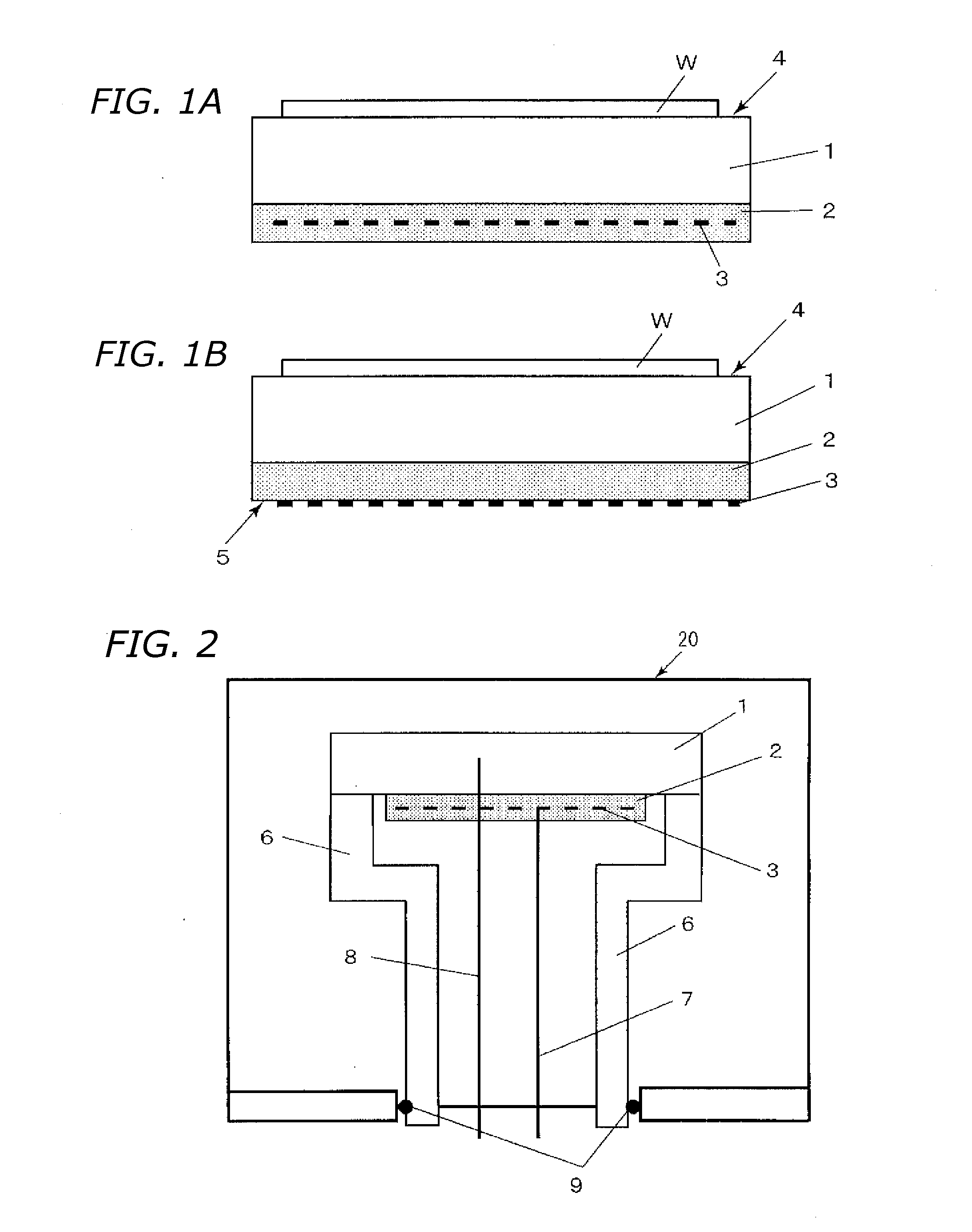

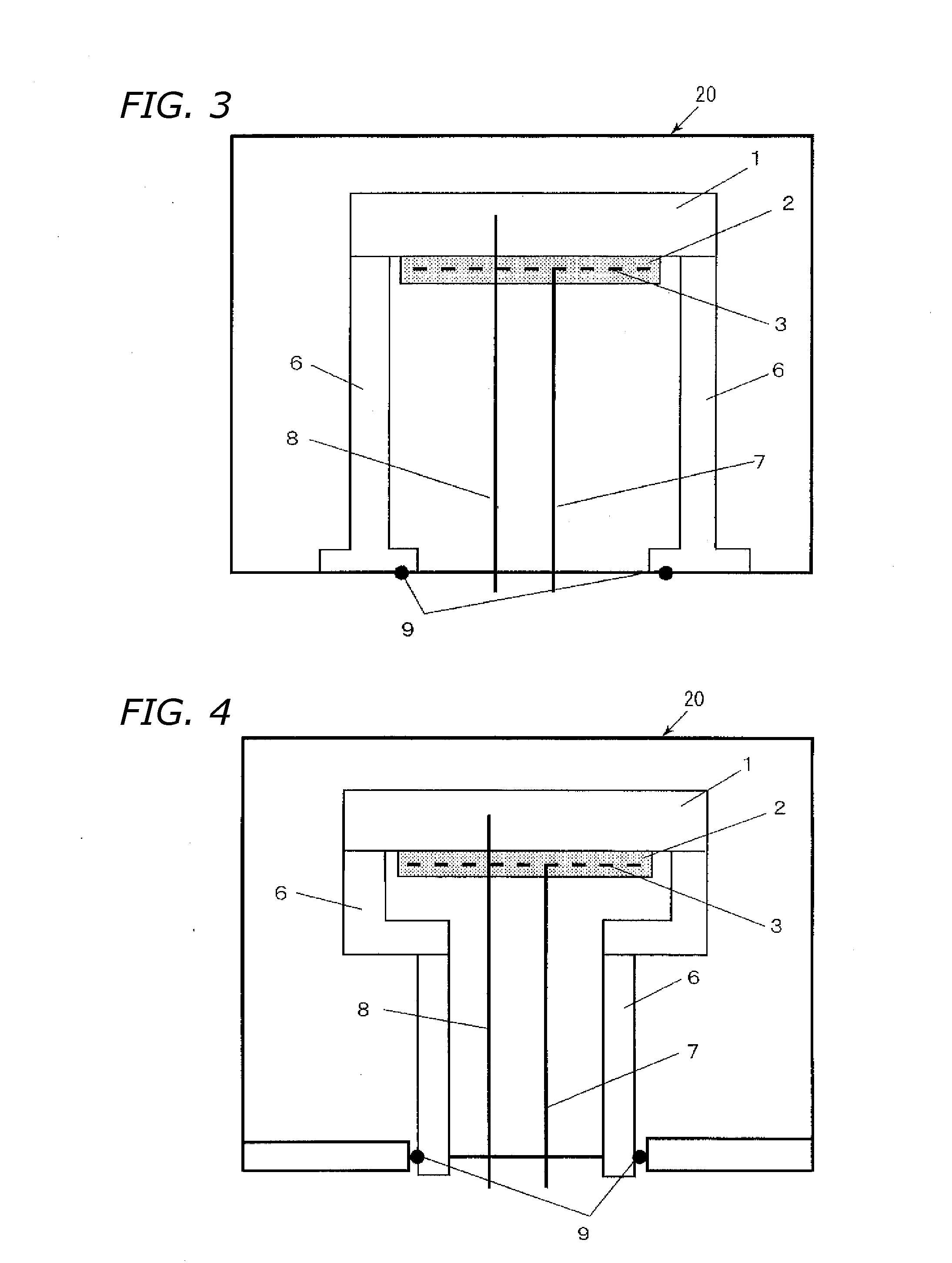

Holder for use in semiconductor or liquid-crystal manufacturing device and semiconductor or liquid-crystal manufacturing device in which the holder is installed

InactiveUS7414823B2Minimal generationImprove the immunityCircuit-breaking switches for excess currentsOhmic-resistance electrodesProduction rateParticulates

Affords a holder for use in semiconductor or liquid-crystal manufacturing devices—as well as semiconductor or liquid-crystal manufacturing devices in which the holder is installed—in which temperature uniformity in the processed-object retaining face is heightened. Configuring the holder with, furnished atop a ceramic susceptor, a composite of a ceramic and a metal improves the temperature uniformity in the holder's processed-object retaining face and makes for curtailing the generation of particulates and other contaminants. In addition, putting a coating on at least the retaining face improves the durability of the holder. Installing a holder of this sort in a semiconductor manufacturing device or a liquid-crystal manufacturing device contributes to making available semiconductor or liquid-crystal manufacturing devices whose productivity and throughput are excellent.

Owner:SUMITOMO ELECTRIC IND LTD

System and methods for treating or supporting human joints or a portion of the human body

ActiveUS9072898B2Less painful to the userLower resistanceNon-surgical orthopedic devicesExternal electrodesElectricityHuman body

Disclosed is a system including a good comprising a sensor in contact with human tissues of a patient and configured to obtain a power dissipation reading of the human tissues. The good also includes a storage medium for tangibly storing thereon a program for execution by a processor. The system also includes a control unit in communication with the good to form an electrical muscular stimulation (EMS) system that uses feedback in a closed loop manner to self tune electrical properties of the output. The control unit is configured to instruct the sensor to (a) apply a sense pulse to the human tissues, (b) measure power dissipation of the sense pulse, (c) adjust a stimulation pulse based on the measured power dissipation, (d) apply the stimulation pulse to the human tissues based on the power dissipation and based on the program in order to maintain constant power output across each pulse, and (e) repeat steps (a)-(d).

Owner:MOTIVE HEALTH INC

Gallium nitride baseplate, epitaxial substrate, and method of forming gallium nitride

InactiveUS7518216B2Degradation in crystallinityLow resistivityPolycrystalline material growthSemiconductor/solid-state device manufacturingSusceptorGallium nitride

Owner:SUMITOMO ELECTRIC IND LTD

Polyester fiber and method for its production, and tire cord, tire, belt-reinforcing fiber material and belt comprising the polyester fiber

InactiveUS8476372B2Few defectSlow changeGroup 5/15 element organic compoundsConductive materialPolyesterFiber

Owner:TEIJIN FRONTIER CO LTD

Holder for Use in Semiconductor or Liquid-Crystal Manufacturing Device and Semiconductor or Liquid-Crystal Manufacturing Device in Which the Holder Is Installed

InactiveUS20070095291A9Improve throughputImprove the immunityCircuit-breaking switches for excess currentsOhmic-resistance electrodesParticulatesProduction rate

Affords a holder for use in semiconductor or liquid-crystal manufacturing devices—as well as semiconductor or liquid-crystal manufacturing devices in which the holder is installed—in which temperature uniformity in the processed-object retaining face is heightened. Configuring the holder with, furnished atop a ceramic susceptor, a composite of a ceramic and a metal improves the temperature uniformity in the holder's processed-object retaining face and makes for curtailing the generation of particulates and other contaminants. In addition, putting a coating on at least the retaining face improves the durability of the holder. Installing a holder of this sort in a semiconductor manufacturing device or a liquid-crystal manufacturing device contributes to making available semiconductor or liquid-crystal manufacturing devices whose productivity and throughput are excellent.

Owner:SUMITOMO ELECTRIC IND LTD

LiCoO2 Sputtering Target, Production Method Therefor, And Positive Electrode Material Thin Film

ActiveUS20170148614A1Low resistivityGood effectElectric discharge tubesFinal product manufactureAll solid stateSputtering

A sputtering target having a composition of LiCoO2, wherein a resistivity of the target is 100 Ωcm or less, and a relative density is 80% or higher. The sputtering target of the present invention is effective for use in forming a positive electrode thin film in all-solid-state thin-film lithium ion secondary batteries equipped in vehicles, information and communication electronics, household appliances, and the like.

Owner:JX NIPPON MINING& METALS CORP

Reduced Corrosion Iron Sulfide Scale Removing Fluids

ActiveUS20190040300A1Reduce and remove iron sulfide scale build-upMinimal damageCleaning apparatusDrilling compositionIron sulfideRoom temperature

A low-corrosivity composition suitable for dissolving scale on metals. The scale includes iron sulfide scale. The composition includes an aqueous hydrogen peroxide solution comprising hydrogen peroxide; and an acidic solution comprising at least one acid, where the hydrogen peroxide and acid are present at concentrations such that the hydrogen peroxide does not break down to form visible bubbles at about room temperature, where the hydrogen peroxide and acid are present at concentrations such that iron sulfide scale is removed from a metal with iron sulfide scale, after the composition contacts the metal and iron sulfide scale at an elevated temperature greater than room temperature, and where the hydrogen peroxide and acid are present at concentrations such that pitting is not caused on the metal, the metal comprising carbon steel.

Owner:SAUDI ARABIAN OIL CO

SiC single crystal ingot and production method therefor

ActiveUS9523156B2Minimal generationPolycrystalline material growthLiquid-phase epitaxial-layer growthSingle crystal substrateIngot

Provided are: a high-quality SiC single crystal ingot that suppresses the generation of inclusions; and a production method for said SiC single crystal ingot. The present invention pertains to a SiC single crystal ingot including a seed crystal substrate and a SiC growth crystal grown using the solution method and using the seed crystal substrate as the origin thereof, the growth crystal having a recessed crystal growth surface and not including inclusions.

Owner:TOYOTA JIDOSHA KK

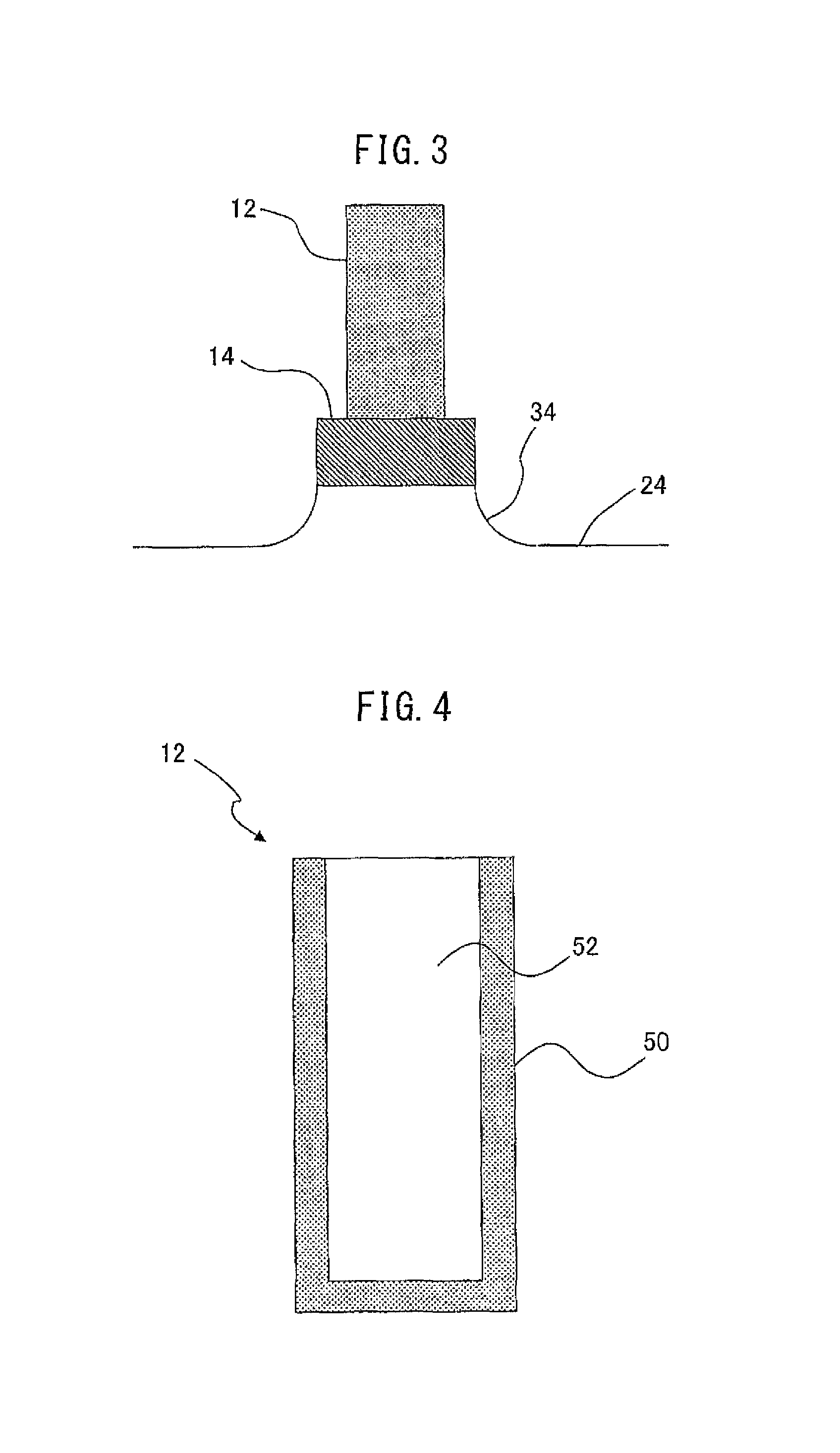

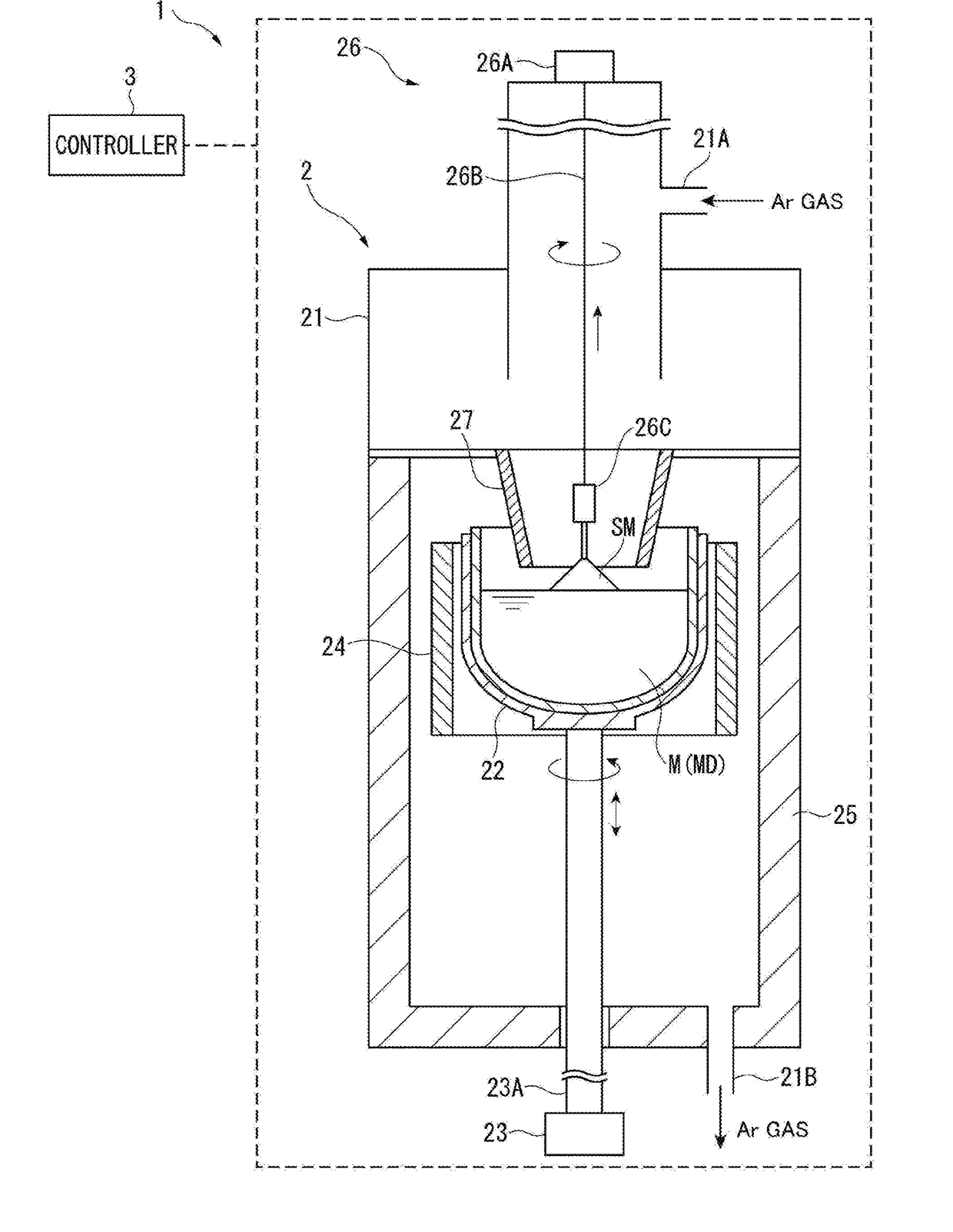

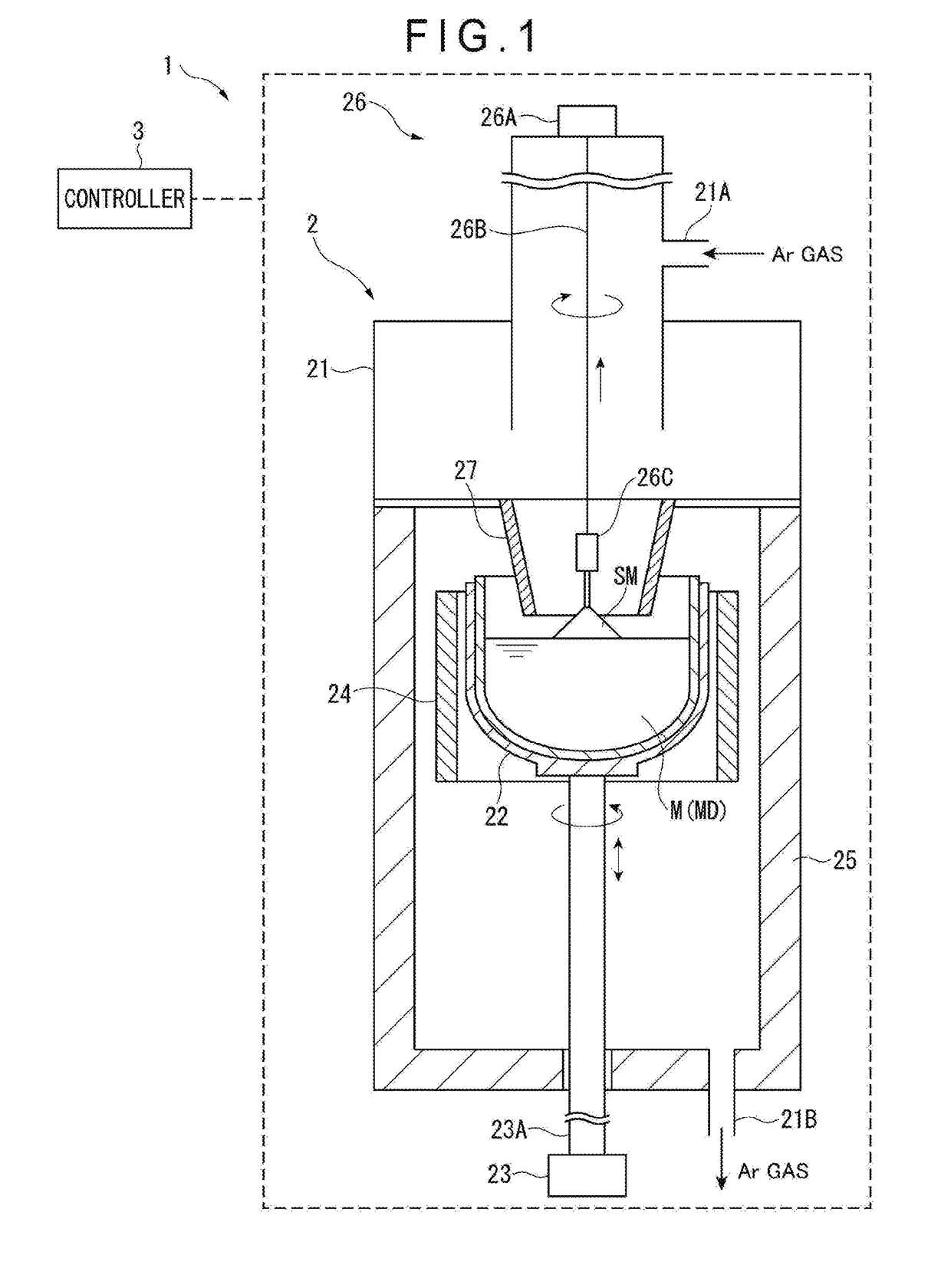

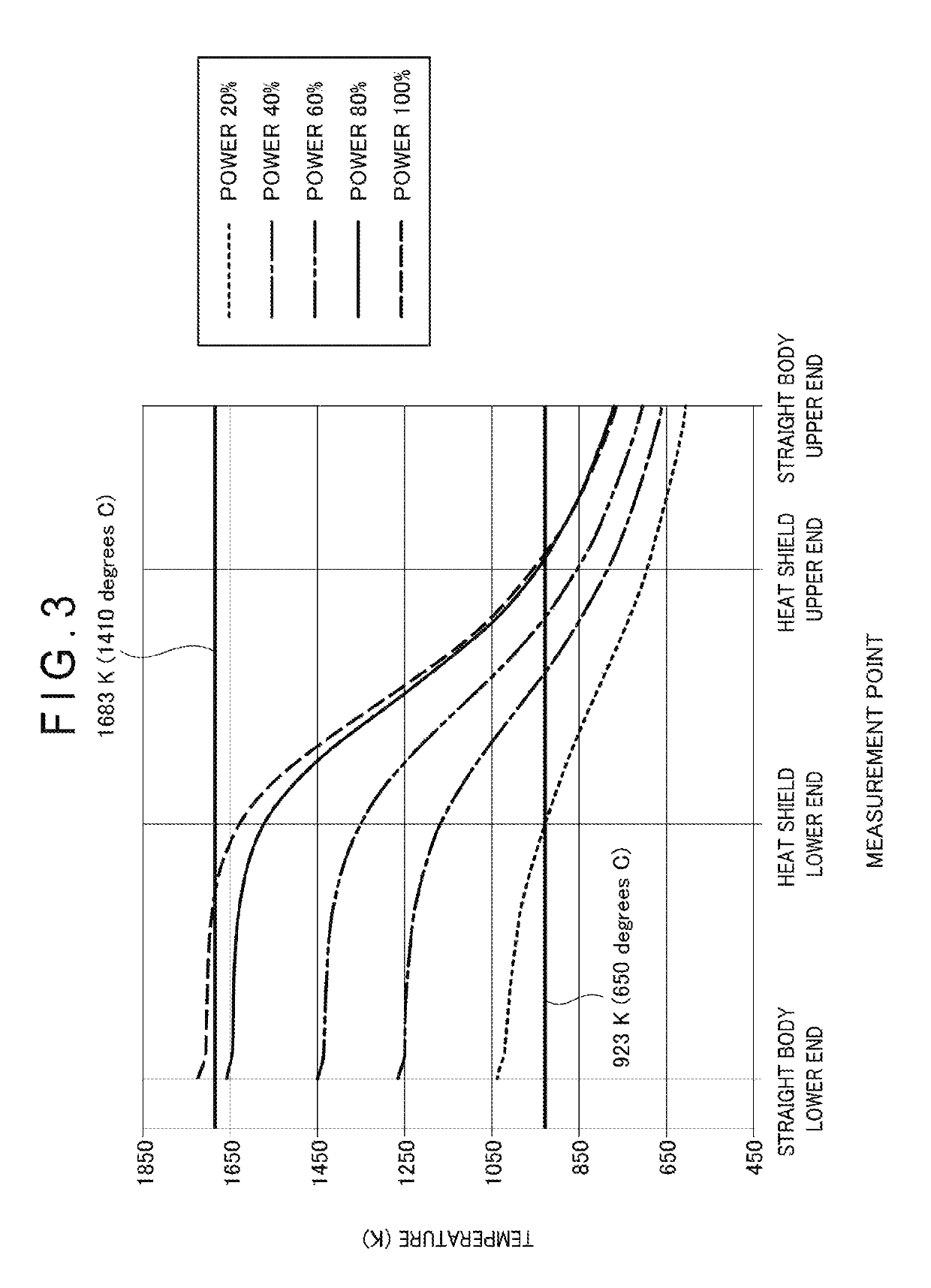

Manufacturing method of monocrystalline silicon and monocrystalline silicon

ActiveUS20170338098A1Increase productivityShorten the timePolycrystalline material growthSemiconductor/solid-state device manufacturingCrucibleSeed crystal

A manufacturing method of a monocrystalline silicon includes: a growth step in which a seed crystal having contacted a silicon melt is pulled up and a crucible is rotated and raised to form a straight body of the monocrystalline silicon; a separating step in which the monocrystalline silicon is separated from the silicon melt; a state holding step in which the crucible and the monocrystalline silicon are lowered and the monocrystalline silicon is kept at a level at which an upper end of the straight body is located at the same level as an upper end of a heat shield or is located below the upper end of the heat shield for a predetermined time; and a draw-out step in which the monocrystalline silicon is drawn out of a chamber.

Owner:SUMCO CORP

Manufacturing method of monocrystalline silicon and monocrystalline silicon

ActiveUS10490398B2Reduce processingResistivity can be restrainedPolycrystalline material growthSemiconductor/solid-state device manufacturingCrucibleSeed crystal

A manufacturing method of a monocrystalline silicon includes: a growth step in which a seed crystal having contacted a silicon melt is pulled up and a crucible is rotated and raised to form a straight body of the monocrystalline silicon; a separating step in which the monocrystalline silicon is separated from the silicon melt; a state holding step in which the crucible and the monocrystalline silicon are lowered and the monocrystalline silicon is kept at a level at which an upper end of the straight body is located at the same level as an upper end of a heat shield or is located below the upper end of the heat shield for a predetermined time; and a draw-out step in which the monocrystalline silicon is drawn out of a chamber.

Owner:SUMCO CORP

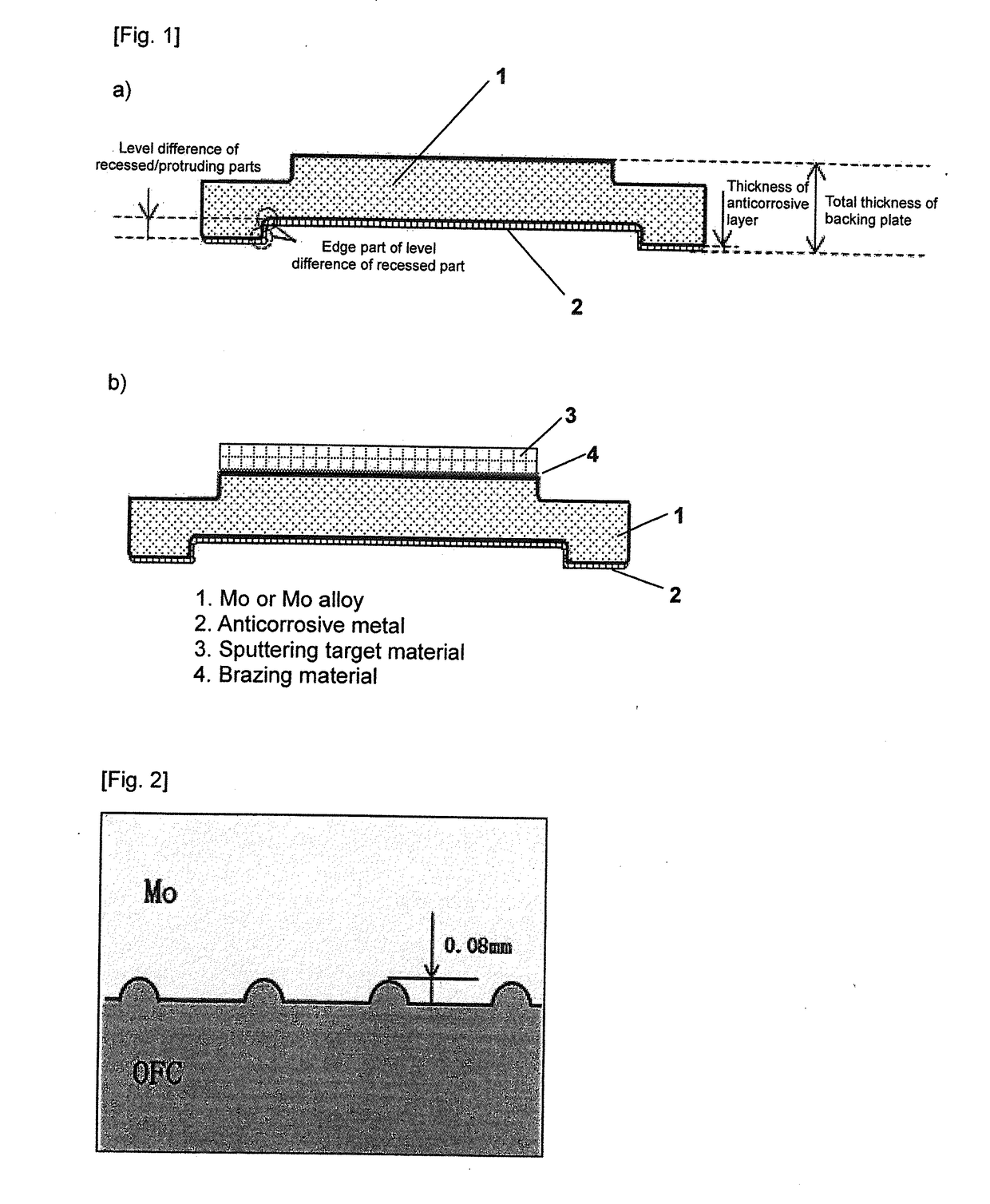

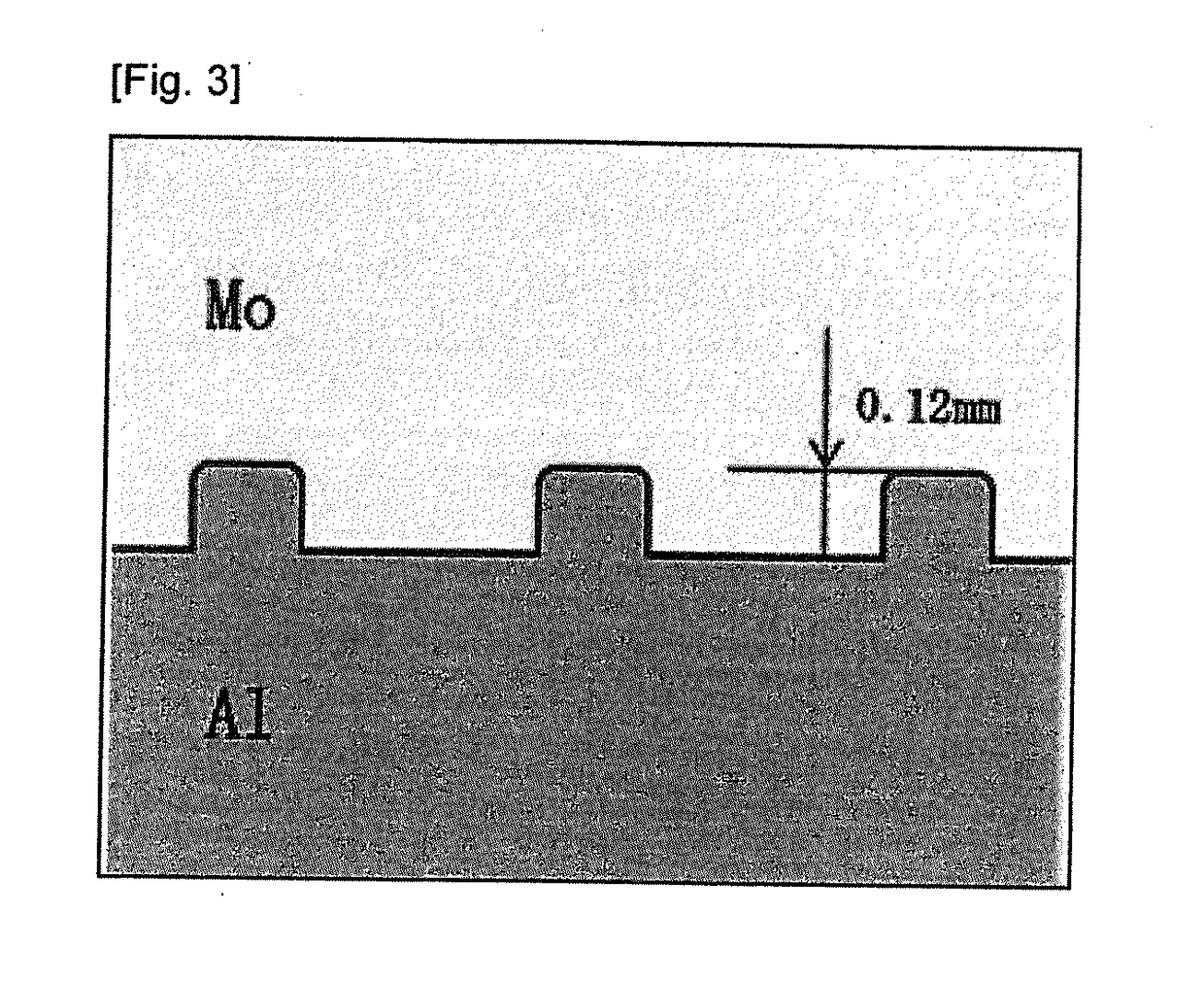

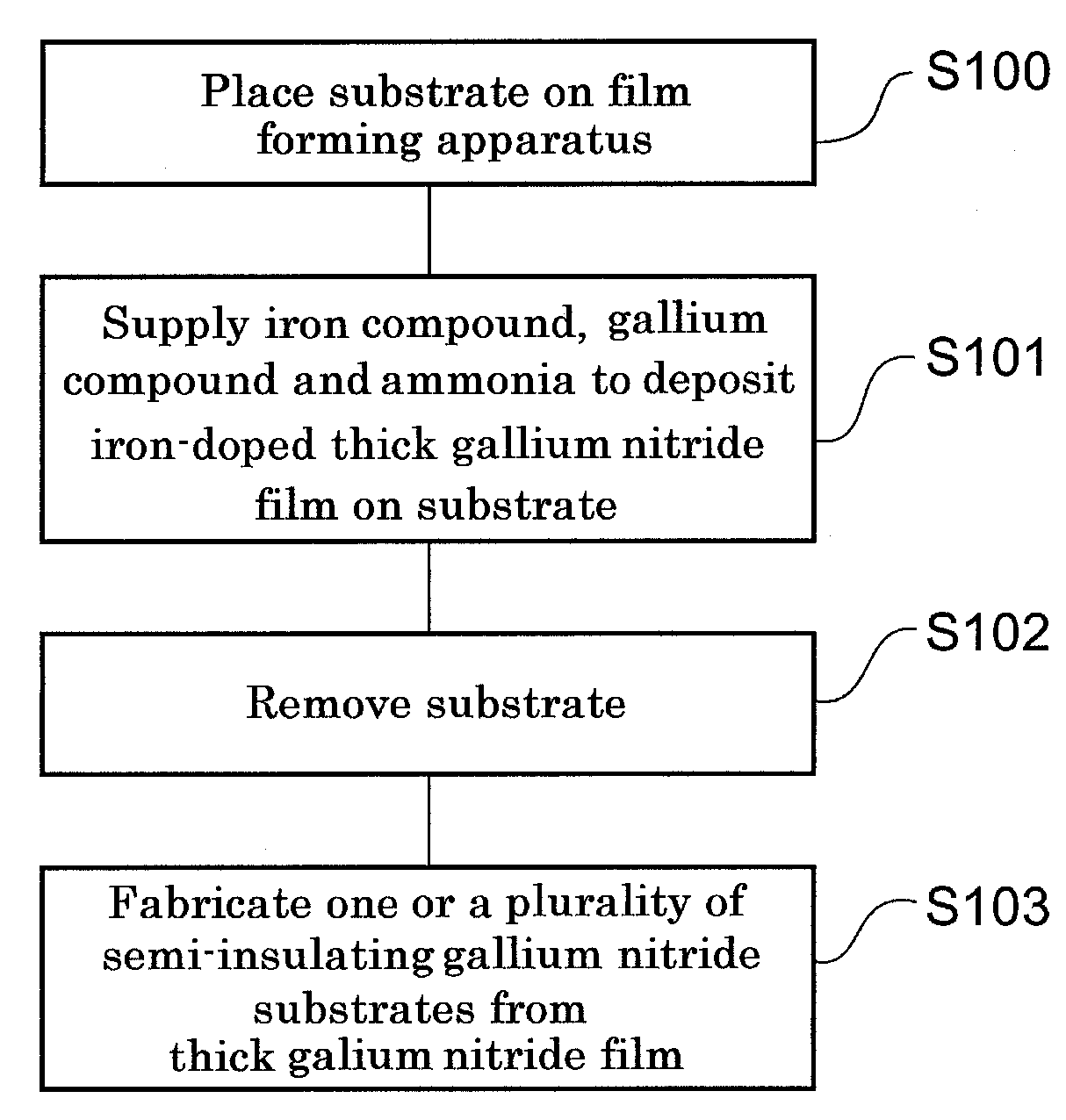

Backing Plate Obtained by Diffusion-Bonding Anticorrosive Metal and Mo or Mo Alloy, and Sputtering Target-Backing Plate Assembly Provided with Said Backing Plate

ActiveUS20170213712A1Avoid corrosionReduce warpageElectric discharge tubesVacuum evaporation coatingSputteringThermal expansion

Provided is a backing plate obtaining by bonding an anticorrosive metal and Mo or a Mo alloy, wherein the backing plate comprises, on a surface of the Mo or Mo alloy backing plate to be cooled (cooling surface side), a layer having a thickness corresponding to 1 / 40 to ⅛ of a total thickness of the backing plate and formed from an anticorrosive metal obtained by bonding one or more types of metals selected from among Cu, Al and Ti, or an alloy thereof. Additionally provided is a sputtering target-backing plate assembly obtained by bonding the foregoing Mo or Mo alloy backing plate and a target formed from a low thermal expansion material.Particularly in semiconductor applications, reductions in size have progressed and control of particles during sputtering has become stricter. The present invention aims to resolve the problem of warpage of sputtering targets formed from low thermal expansion materials and problems occurring with respect to the anticorrosive properties of Mo or Mo alloy backing plates.

Owner:JX NIPPON MINING & METALS CO LTD

Gallium Nitride Baseplate and Epitaxial Substrate

ActiveUS20090079036A1Degradation in crystallinityLow resistivityPolycrystalline material growthSemiconductor/solid-state device manufacturingSusceptorGallium nitride

A method of forming an iron-doped gallium nitride for a semi-insulating GaN substrate is provided. A substrate (1), such as a (0001)-cut sapphire substrate, is placed on a susceptor of a metalorganic hydrogen chloride vapor phase apparatus (11). Next, gaseous iron compound GFe from a source (13) for an iron compound, such as ferrocene, and hydrogen chloride gas G1HCl from a hydrogen chloride source (15) are caused to react with each other in a mixing container (16) to generate gas GFeComp of an iron-containing reaction product, such as iron chloride (FeCl2). In association with the generation, the iron-containing reaction product GFeComp, first substance gas GN containing elemental nitrogen from a nitrogen source (17), and second substance gas GGa containing elemental gallium are supplied to a reaction tube (21) to form iron-doped gallium nitride (23) on the substrate (1).

Owner:SUMITOMO ELECTRIC IND LTD

Process for producing dihalopyridines

InactiveUS8293918B2Speed up the processMinimal generationOrganic chemistryOrganic chemistryIndustrial scale

Disclosed herein an improved process for producing 2,3-dihalopyridine with high purity at industrial scale with minimum effluent.

Owner:JUBILANT ORGANOSYS LTD

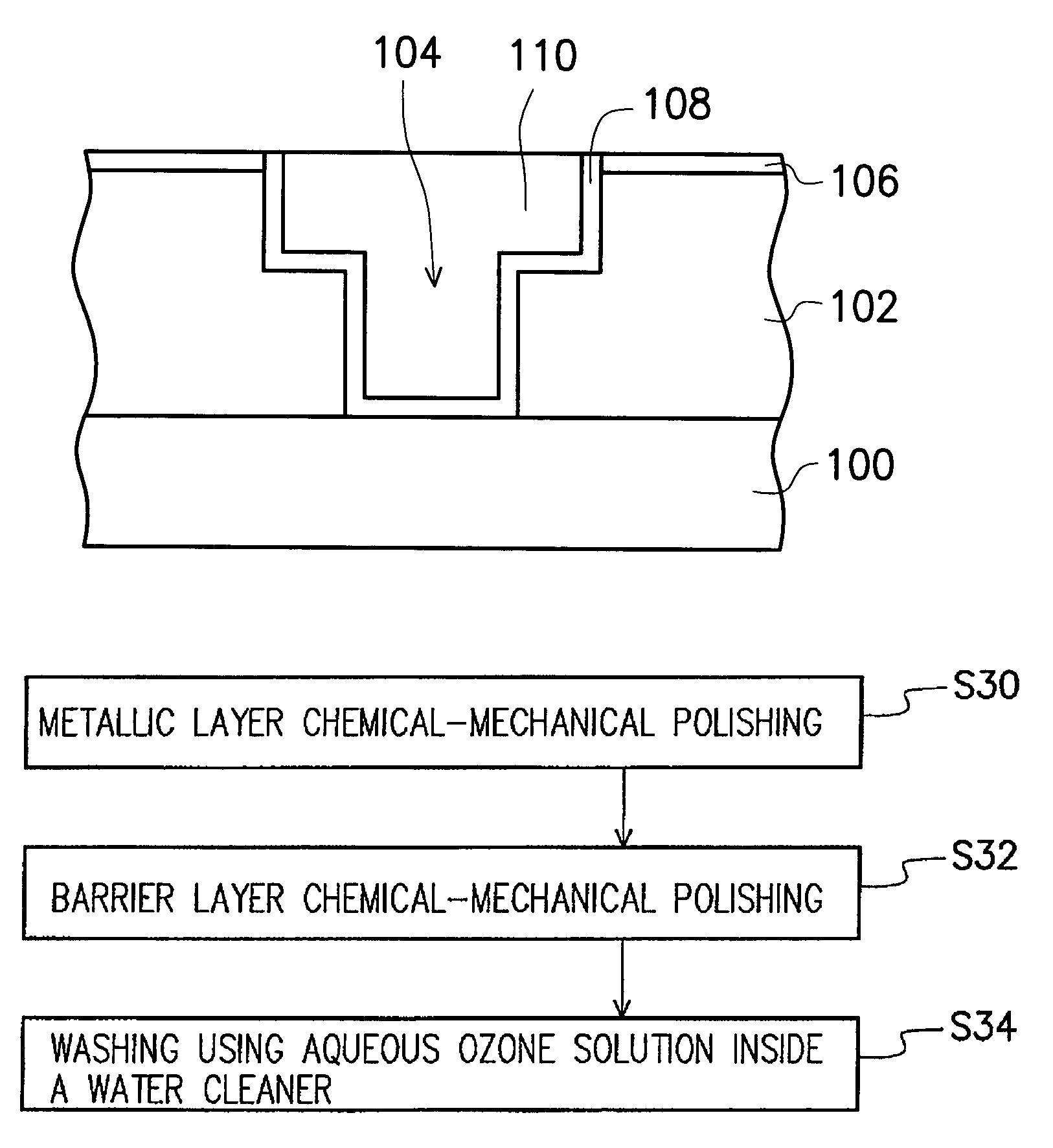

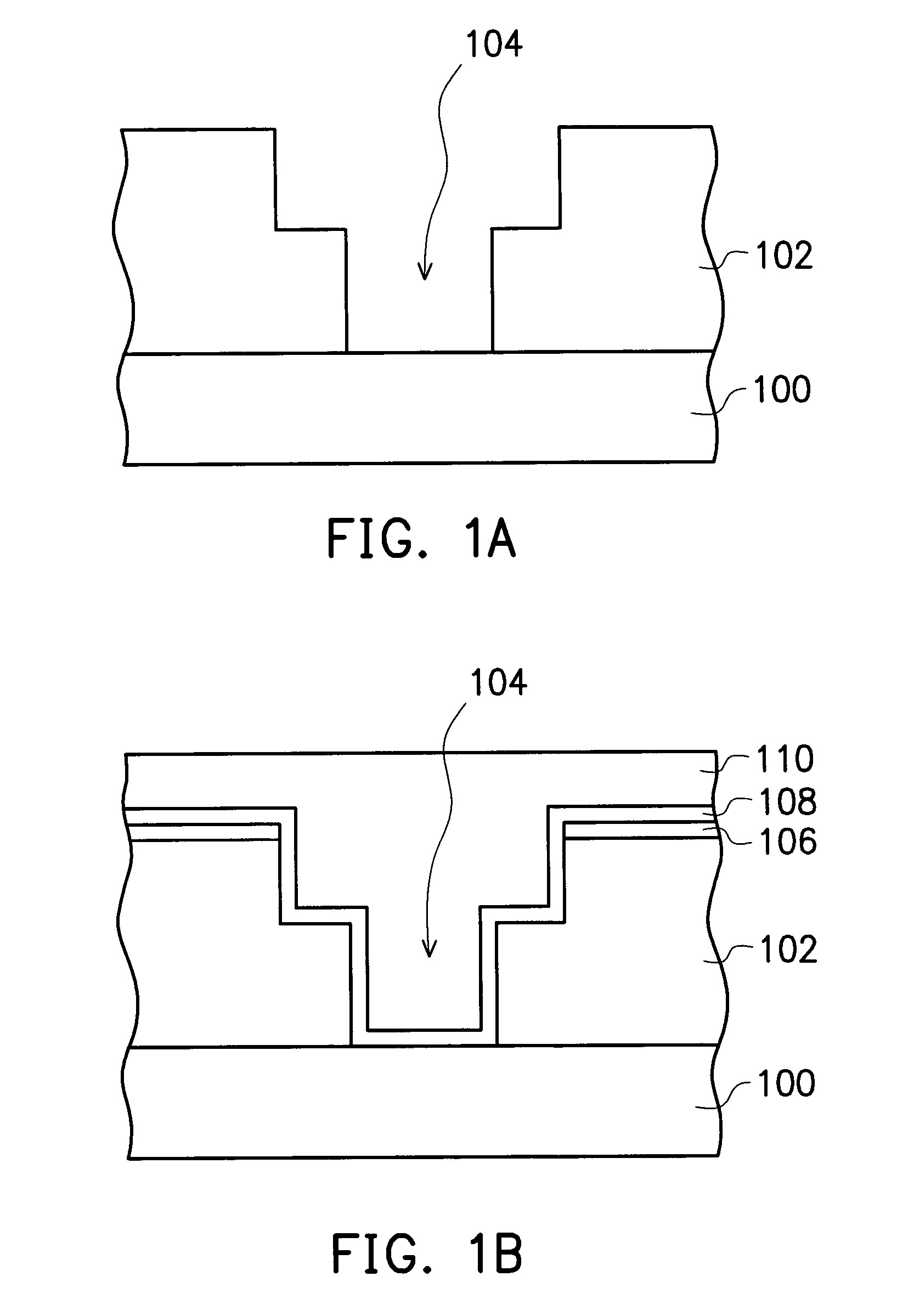

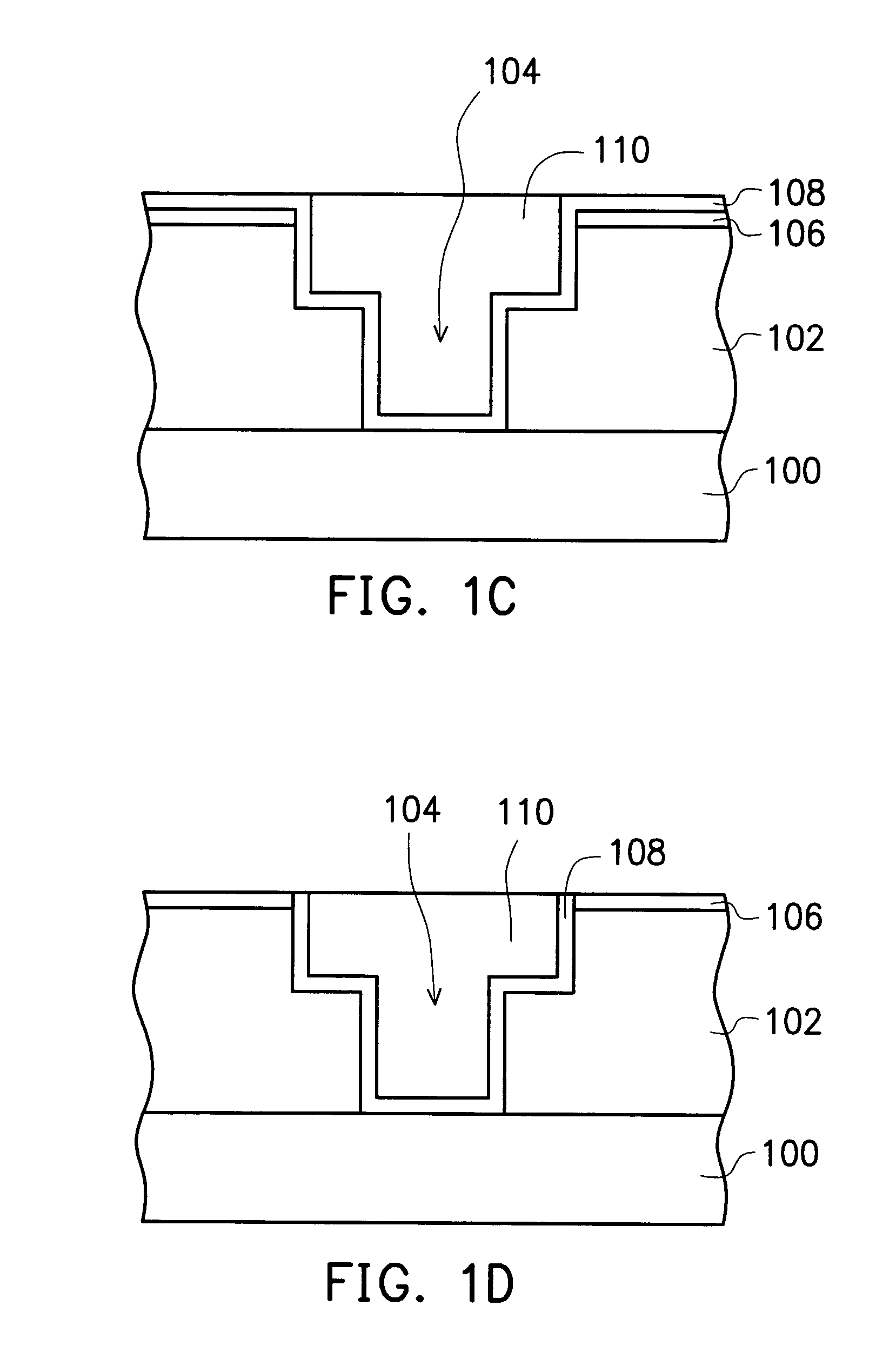

Method of removing contaminants from a silicon wafer after chemical-mechanical polishing operation

InactiveUS7232752B2Exceptional atomic cleansing effectMinimal by-product generationSemiconductor/solid-state device manufacturingChemical solutionCompound (substance)

A method of removing contaminants from a silicon wafer after chemical-mechanical polishing (CMP). After a copper chemical-mechanical polishing and a subsequent barrier chemical-mechanical polishing operation, an aqueous solution of ozone in de-ionized water is applied to clean the silicon wafer so that contaminants on the wafer are removed. Alternatively, an ozone / de-ionized water buffer-polishing process is conducted after copper and barrier CMP and then the wafer is cleaned using a chemical solution or de-ionized water. Alternatively, an ozone / de-ionized water buffer-polishing process is conducted after both copper-CMP and barrier-CMP and then the wafer is cleaned using a chemical solution or de-ionized water.

Owner:UNITED MICROELECTRONICS CORP

Water treatment system with low waste volume

InactiveUS20050127007A1Easy dischargeLow costIon-exchange column/bed processesIon-exchanger regenerationWater treatment systemIon-exchange resin

A continuous water treatment system comprising at least two stationary cylindrical vessels, wherein each vessel contains an ion exchange resin, and each vessel has at each end a flat head and a fractal liquid distributor.

Owner:MIERS JAY ALFRED JR +1

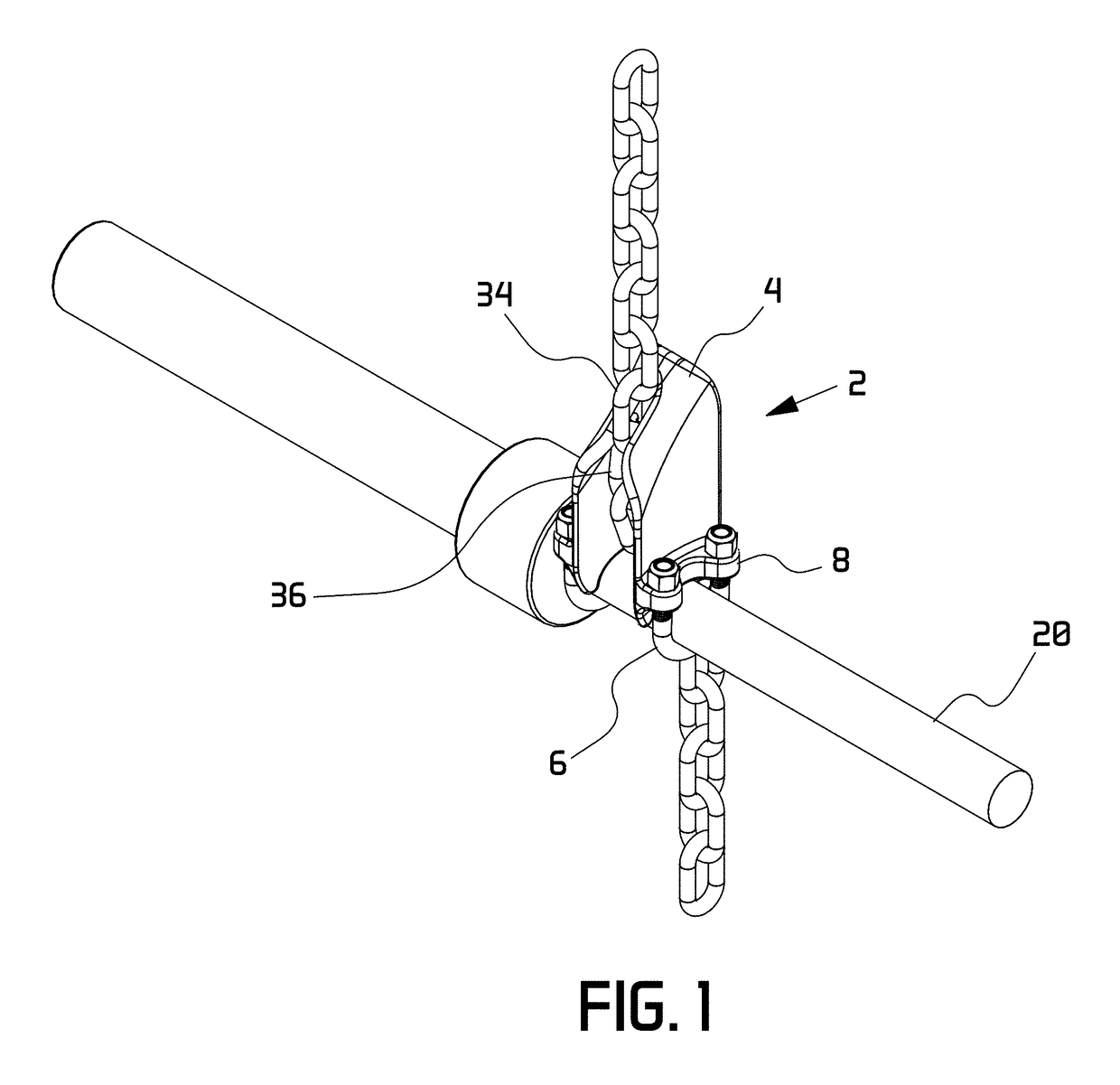

Chain trap

ActiveUS9939046B2Firmly connectedQuick and secure affixationShacklesMachine supportsLower bodyVertical orientation

A chain catch that is capable of being attached to various bases so as to allow the quick and simple affixation of the chain catch to any vertical chain. The chain catch has an upper body and a lower body. The upper body is designed to trap a vertical chain within its internal design while it remains within its vertical orientation, and the lower body is designed to attach to a load and to the upper body. When the tension is taken off of the chain within the chain catch and the upper body is tilted, the chain may be vertically raised, free from the chain catch or the chain catch and its attached barbell can be vertically raised.

Owner:JOHNSON JOEL ANTHONY

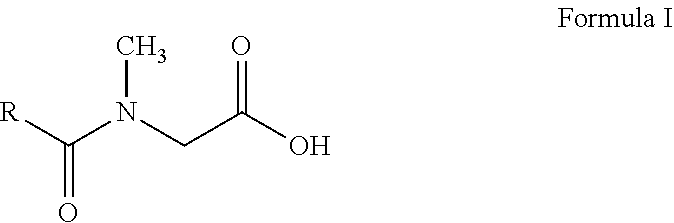

N-acyl sarcosines as antimicrobials for preservation of home and personal care products

N-Acyl sarcosines of Formula I, wherein, R═C7 alkyl and C10 alkenyl group with terminal double bond, are described as new antimicrobial preservatives for home and personal care products.Lipidated sarcosines of this patent application preserve creams, lotions, emulsions, solutions or suspensions types of formulations of personal care industry. These are used in: leave-on ̆ (cold cream, sunscreen) as well as: rinse-off ̆ (facewash, body wash, shampoo) formulations either alone or in combination with other antimicrobials.

Owner:GALAXY SURFACTANTS LTD

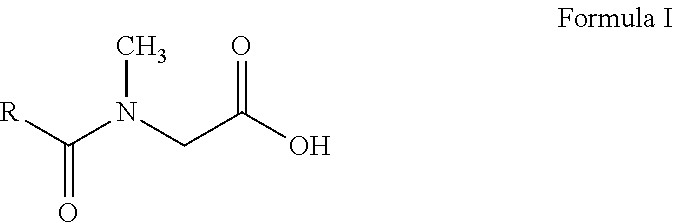

Process for uranium removal from near neutral aqueous solutions by freshly prepared fine ferrihydrite generated during ultrasonic assisted corrosion of mild steel wool

InactiveUS20210205779A1Simple and scalable processMinimal generationUranium compounds preparationOther chemical processesCorrosionAqueous solution

A Process for uranium removal from near neutral aqueous solutions by freshly prepared fine ferrihydrite generated during ultrasonic assisted corrosion of mild steel wool is disclosed. The above process is a simple and scalable process which minimizes agglomeration and reduces likelihood of aging of the ferrihydrite.

Owner:SEC DEPT OF ATOMIC ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com