Muffler for exhaust gas

a technology for exhaust gas and mufflers, which is applied in the direction of engines, mechanical equipment, machines/engines, etc., can solve the problems of easy accumulation of dirt particles or adhesion to spark arrestors, and achieve the effects of low weight, no noticeable impact on the overall weight of the implement, and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

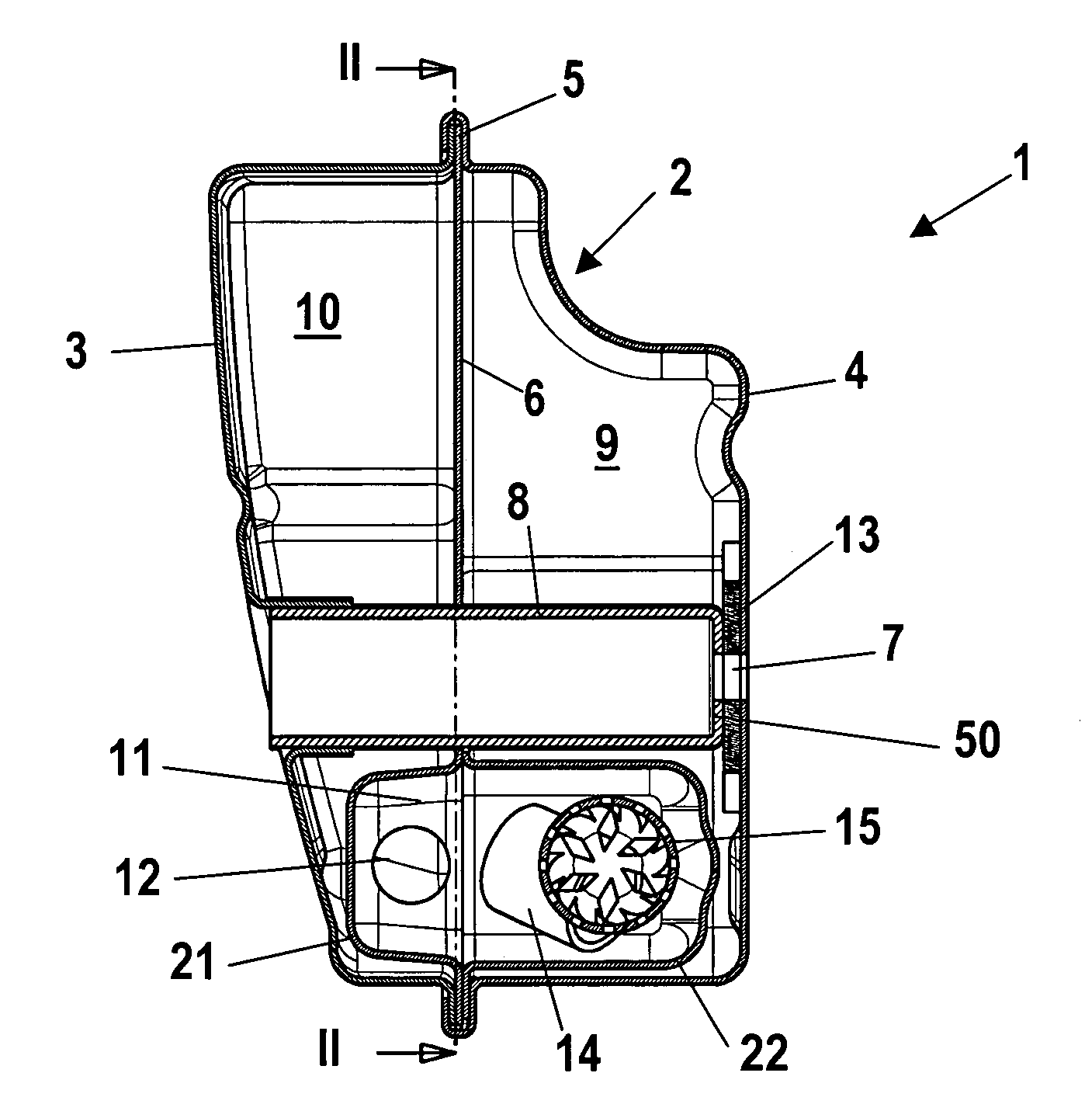

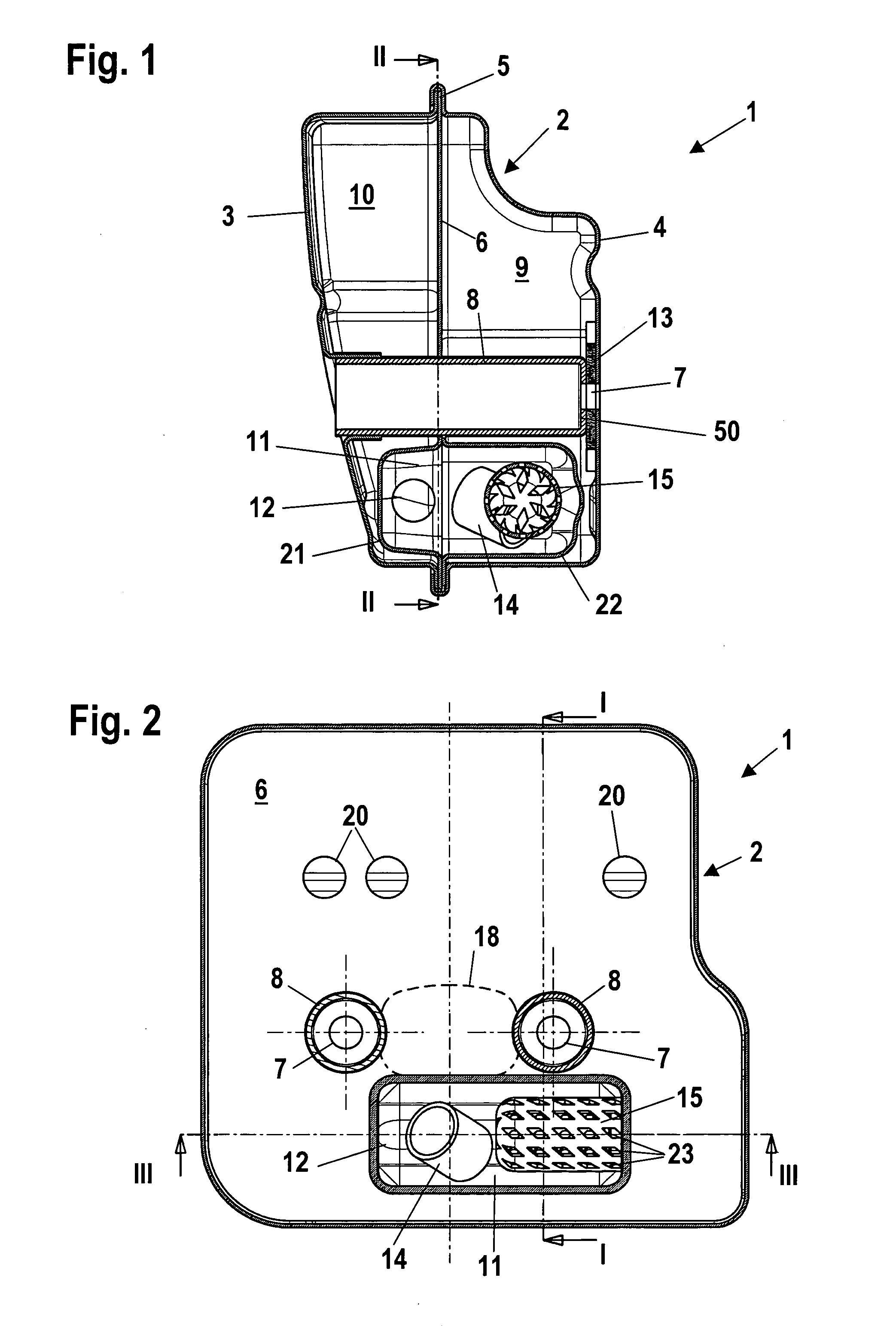

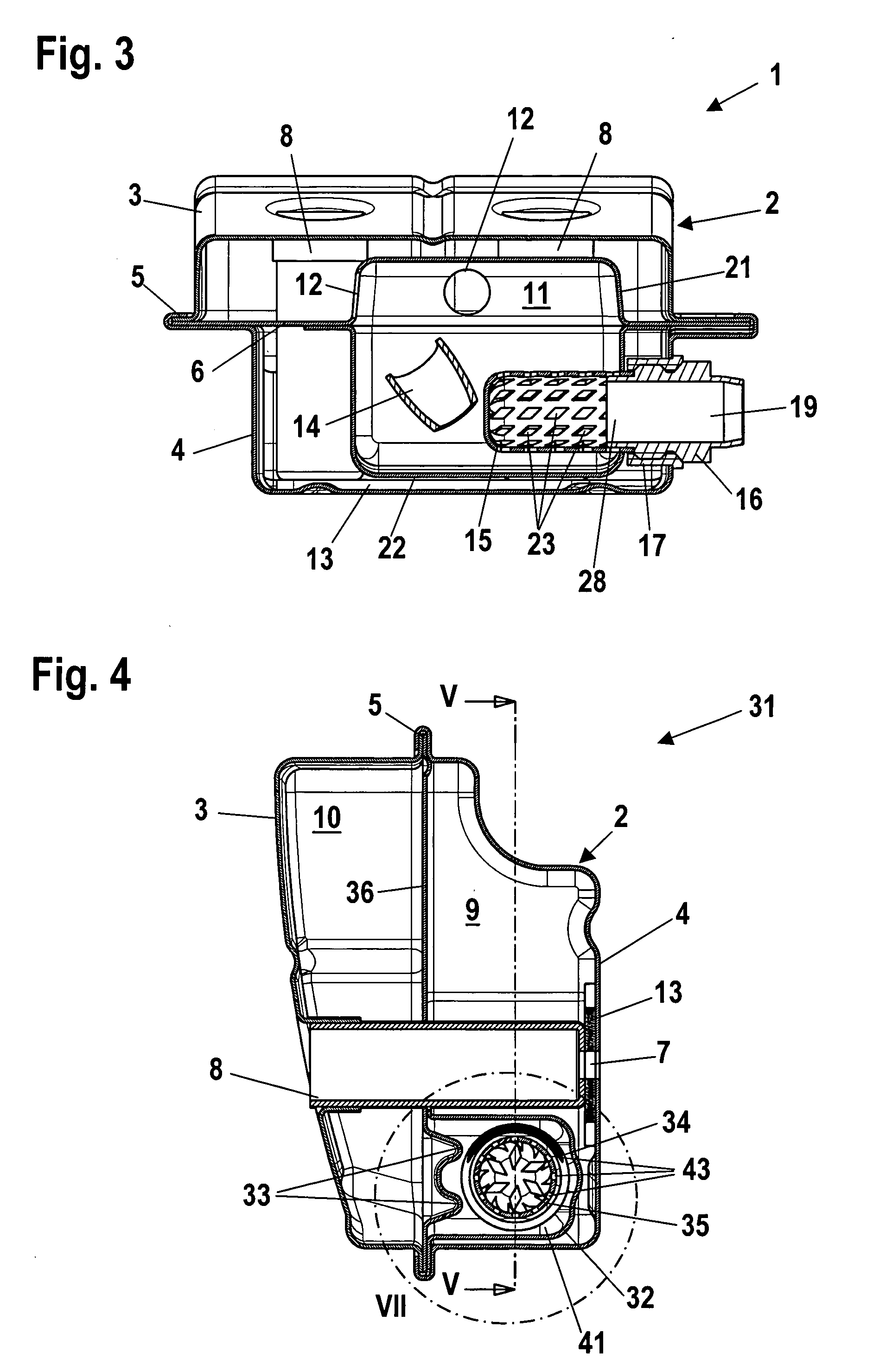

[0023] Referring now to the drawings in detail, the muffler 1 illustrated in FIG. 1 has a housing 2, which is formed from a first half shell 3 and a second half shell 4. The two half shells 3 and 4 are interconnected at a rim 5 by being folded over. Disposed between the two half shells3 and 4 is a partition 6 which is held at the rim 5. The partition 6 separates a first chamber 9, into which flow the exhaust gases of an internal combustion engine, especially a two-cycle engine, from a second chamber 10.

[0024] The exhaust gases flow into the muffler 1, i.e. into the housing 2 thereof, via the inlet 18, which is indicated by dashed lines in FIG. 2. As furthermore shown in FIG. 2, the partition 6 is provided with openings 20 by means of which the exhaust gases can pass out of the first chamber 9 and into the second chamber 10. As shown in FIGS. 1 and 2, two sleeves 8 extend through the housing 2 approximately perpendicular to the partition 6. On that side that faces the first half she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com