Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

482results about How to "Maximize" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

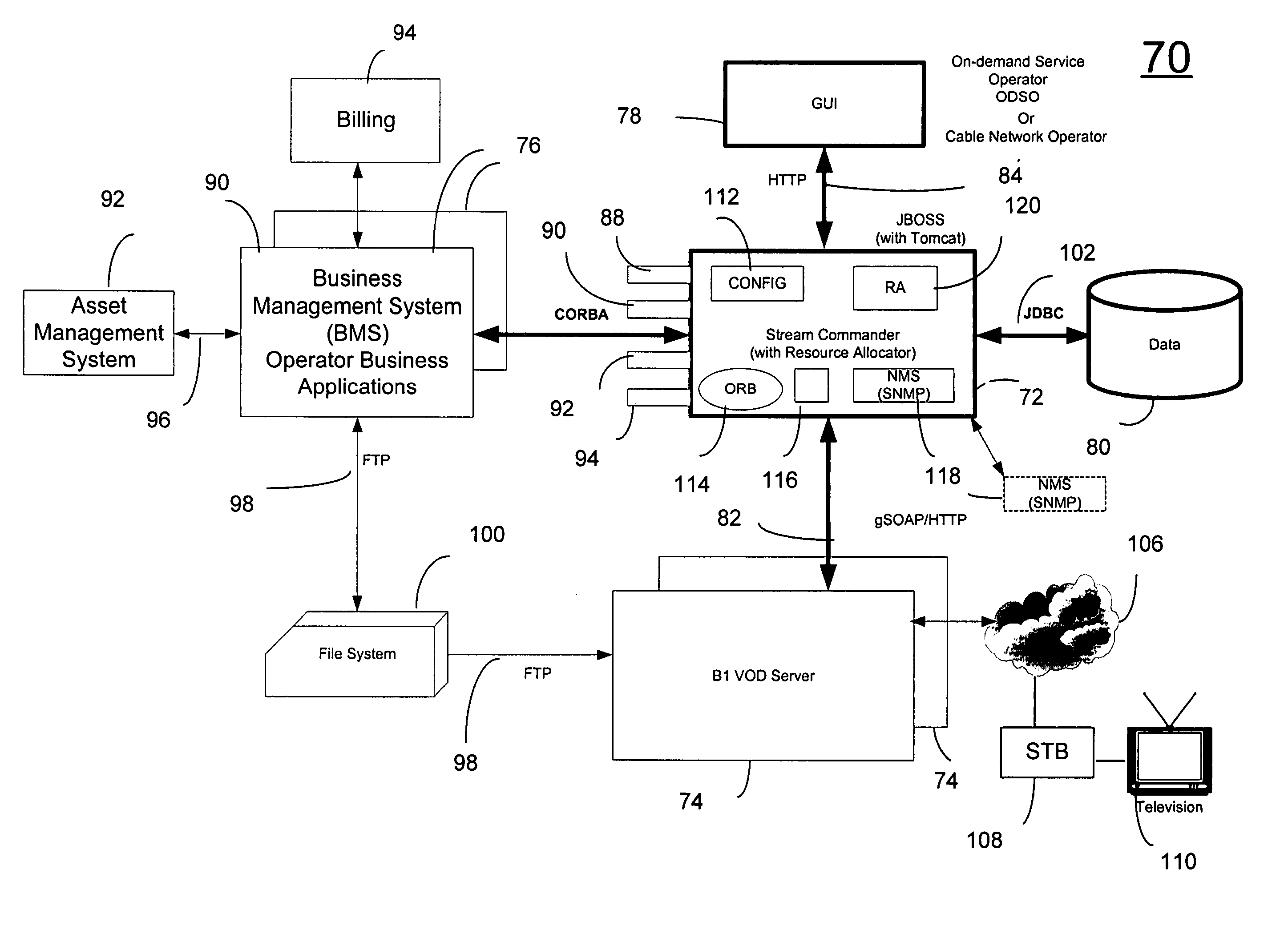

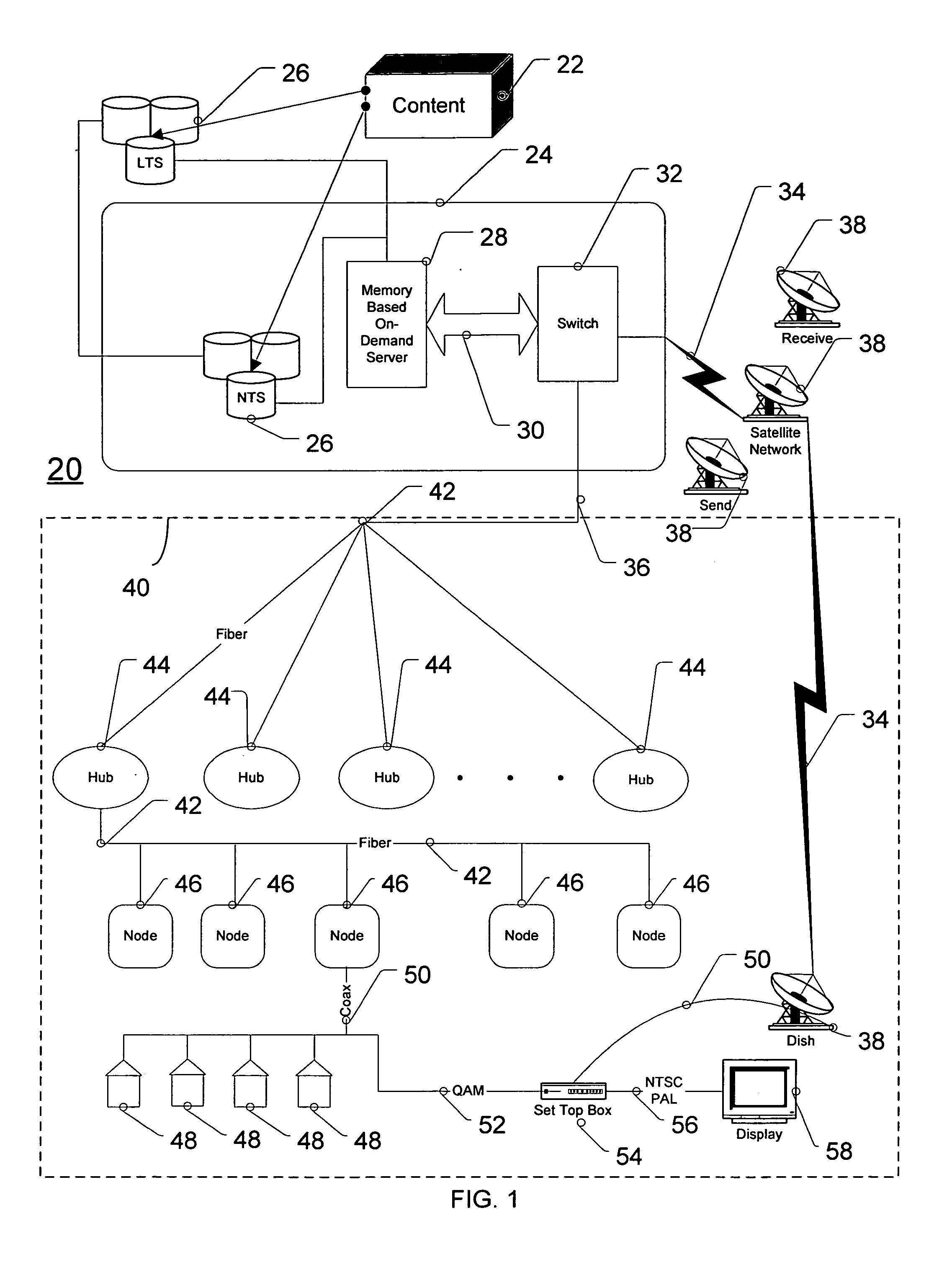

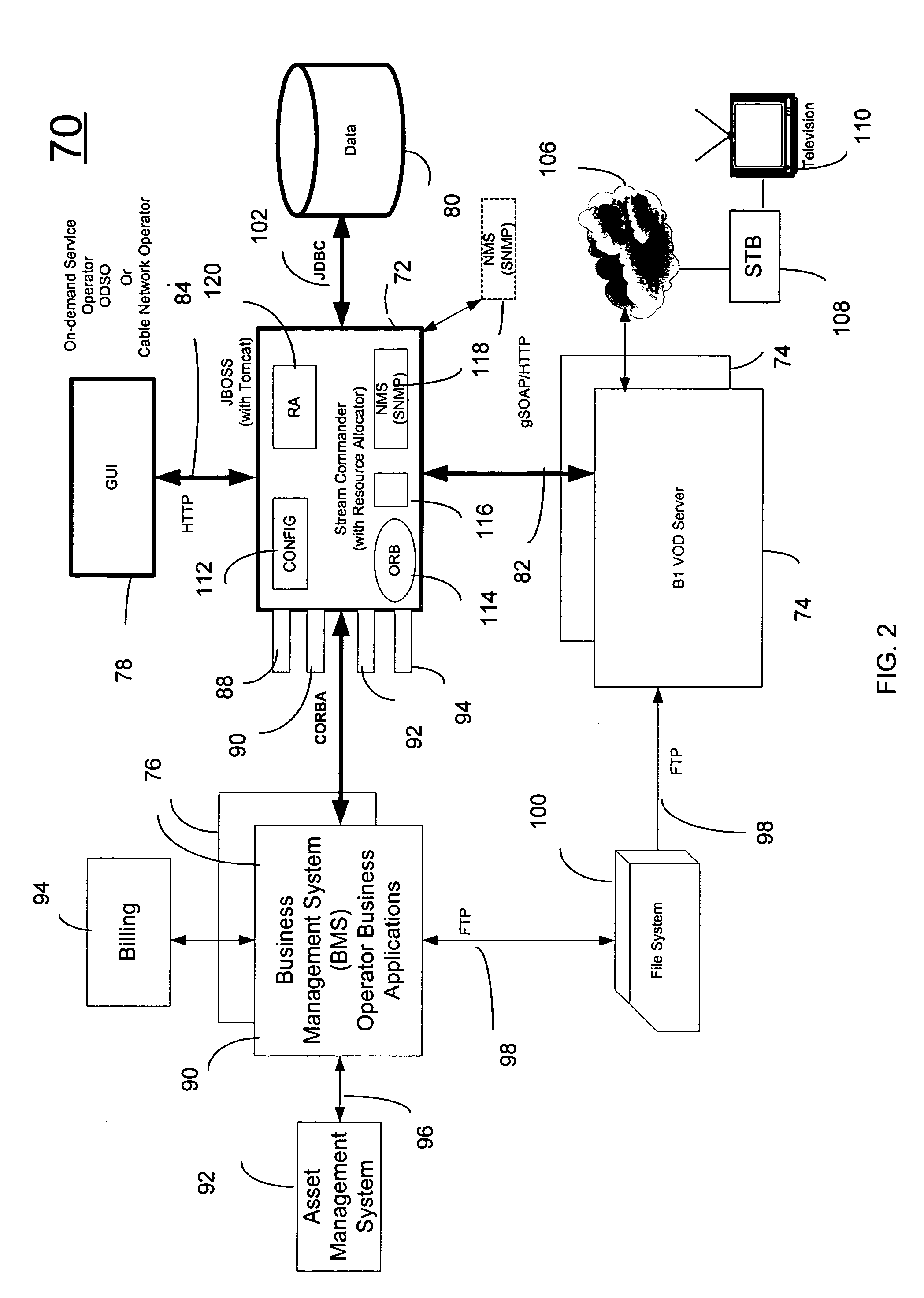

Method and system for controlling streaming in an on-demand server

InactiveUS20050278760A1MaximizeOptimizing memory utilizationAnalogue secracy/subscription systemsTwo-way working systemsApplication serverOracle database

A method and system configured for managing and controlling one or more on-demand servers in order to ingest content files, set-up on-demand sessions at a subscriber request and record status information about the on-demand streams in the operational framework of an on demand service operator (ODSO) with and without the support of the Business Management System (BMS) platform to provide video-on-demand (VOD), subscription video on demand (SVOD), television on demand (TOD), and audio on demand (AOD) services by streaming content to on-demand to a customer. The method can be implemented as software running on an application server with a a web application GUI, a CORBA-based interface to the BMS, a SOAP-based interface to the VOD server, and a set of internal services that glue the other components together on top of an Oracle database all configured to managing and controlling one or more on-demand servers.

Owner:BROADBUS TECH

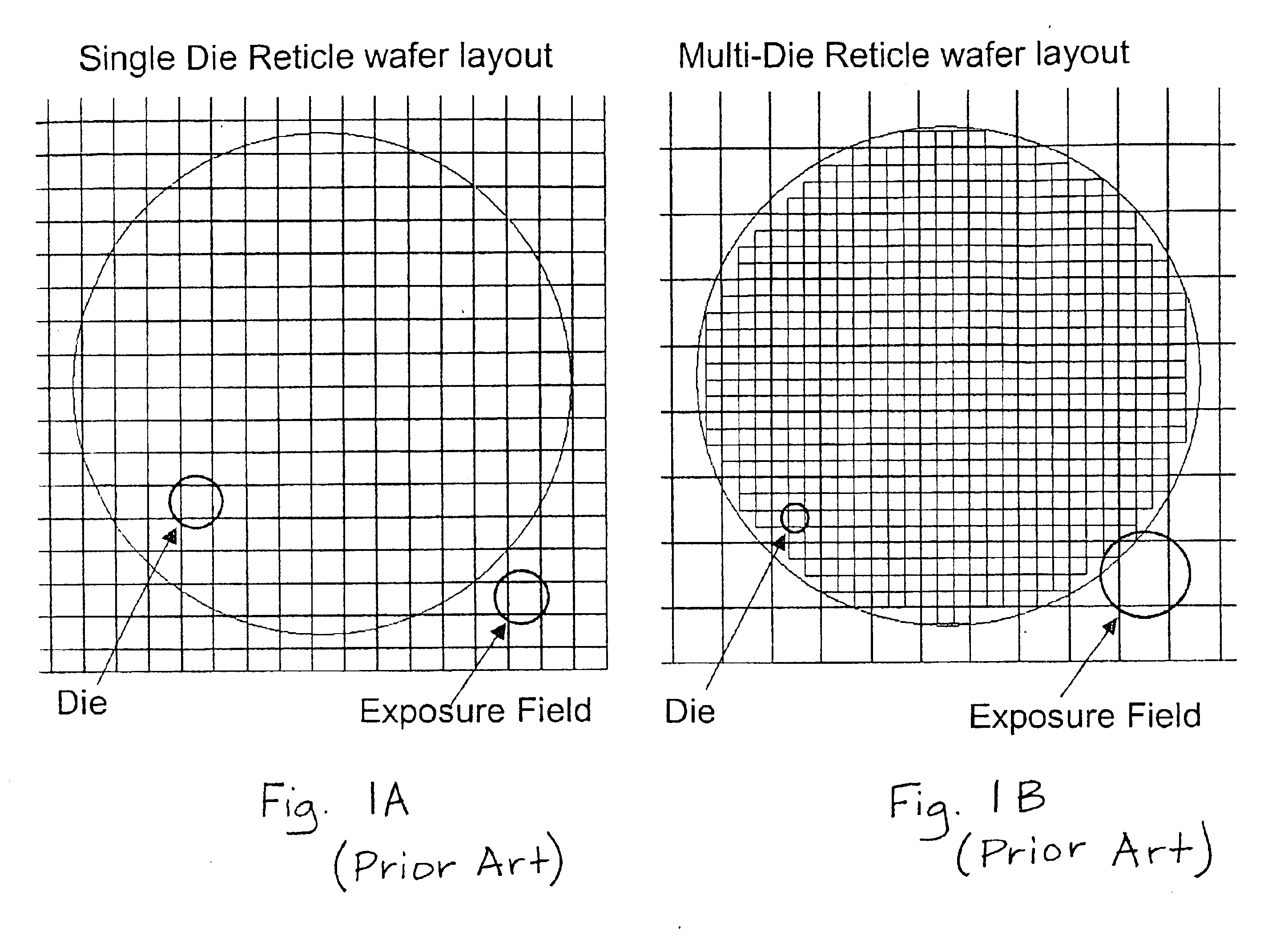

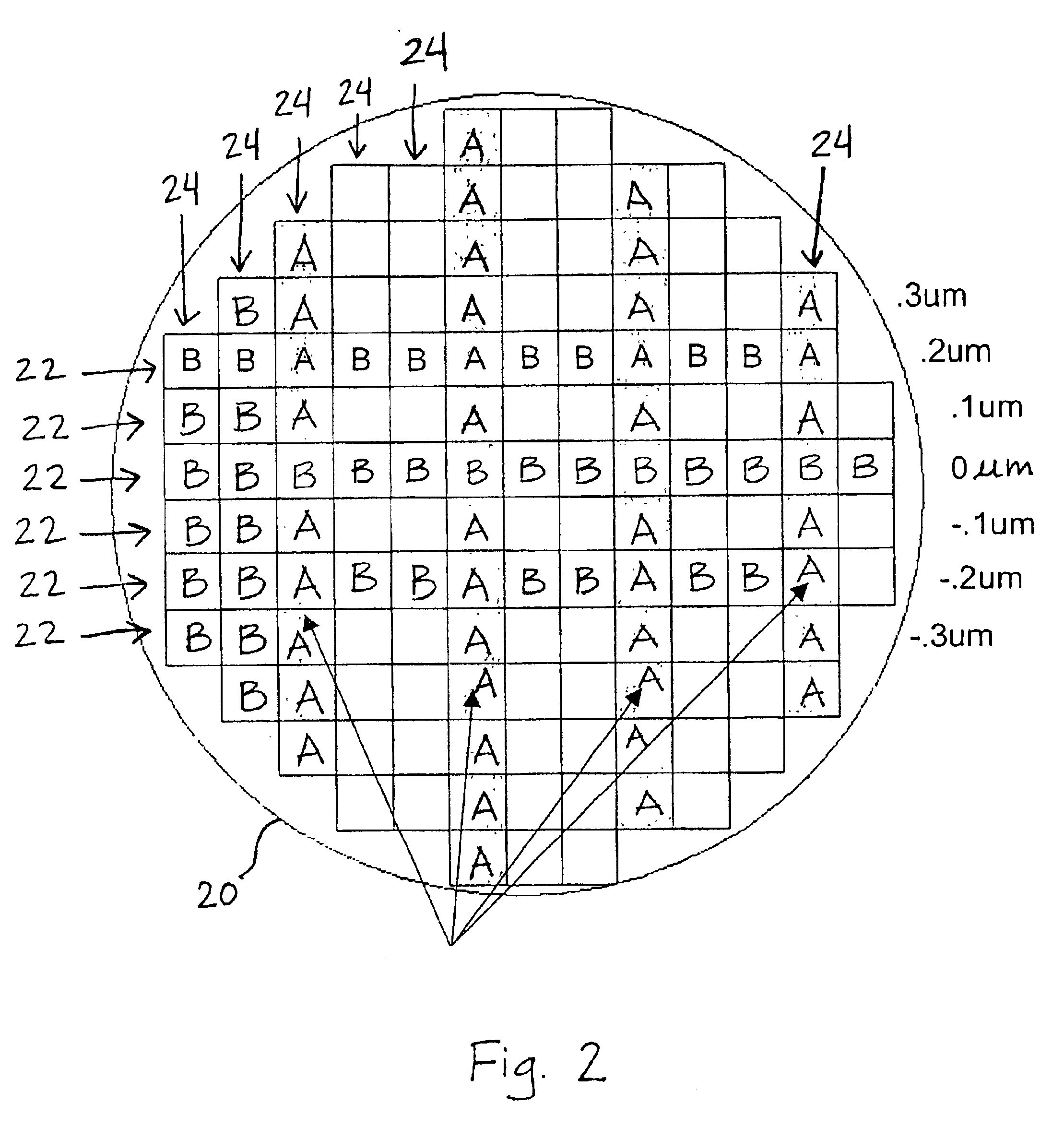

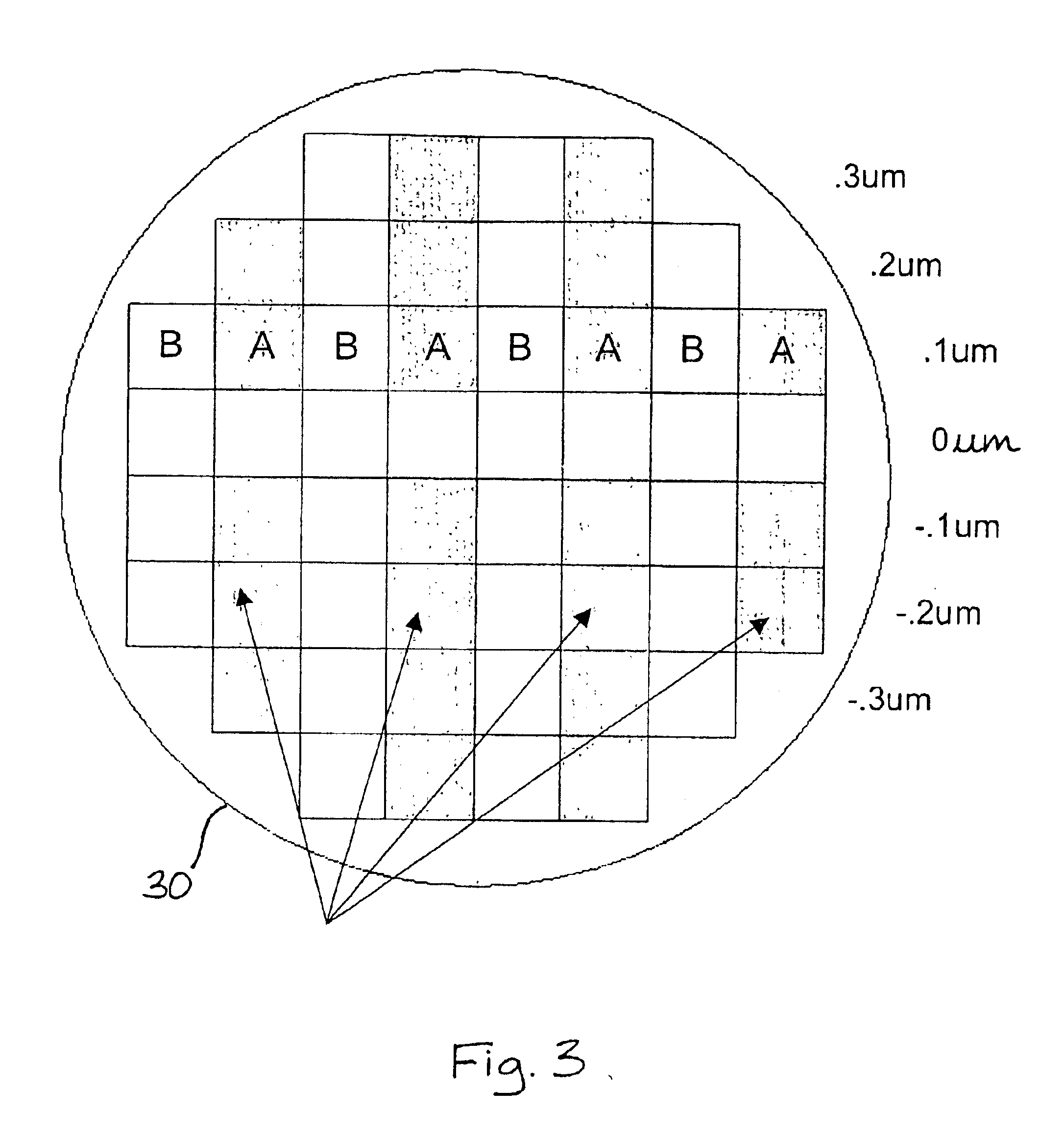

Qualifying patterns, patterning processes, or patterning apparatus in the fabrication of microlithographic patterns

InactiveUS6902855B2MaximizeIncrease catch ratePhotomechanical apparatusSemiconductor/solid-state device manufacturingProcess windowDesign rule checking

The invention is a method of determining the presence of an anomaly in qualifying a pattern, patterning process, or patterning apparatus used in the fabrication of microlithographic patterns. A preferred implementation of the method qualifies incoming reticles and process conditions on test wafers to maximize the available usable process window for a given reticle exposure tool combination. Practicing this method on test wafers enables the identification of spatial areas where a process will fail first and candidate regions for carrying out defect inspection and metrology. Other preferred implementations of the method qualify masks, reticles, or other patterns characterized by data bases on which are stored image data acquired by practice of aerial image measurement system (AIMS) or design rule checking (DRC) techniques.

Owner:KLA TENCOR CORP

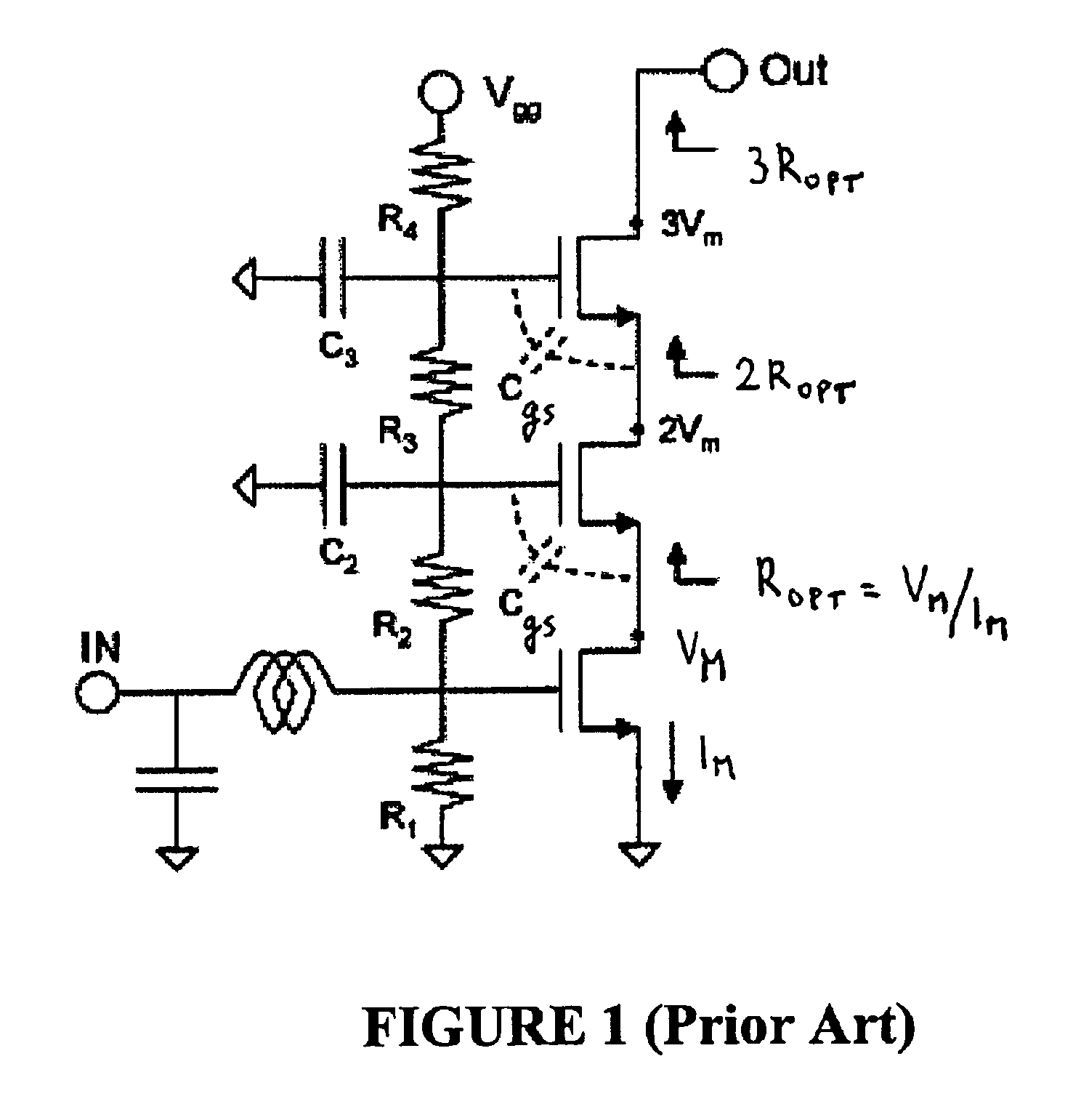

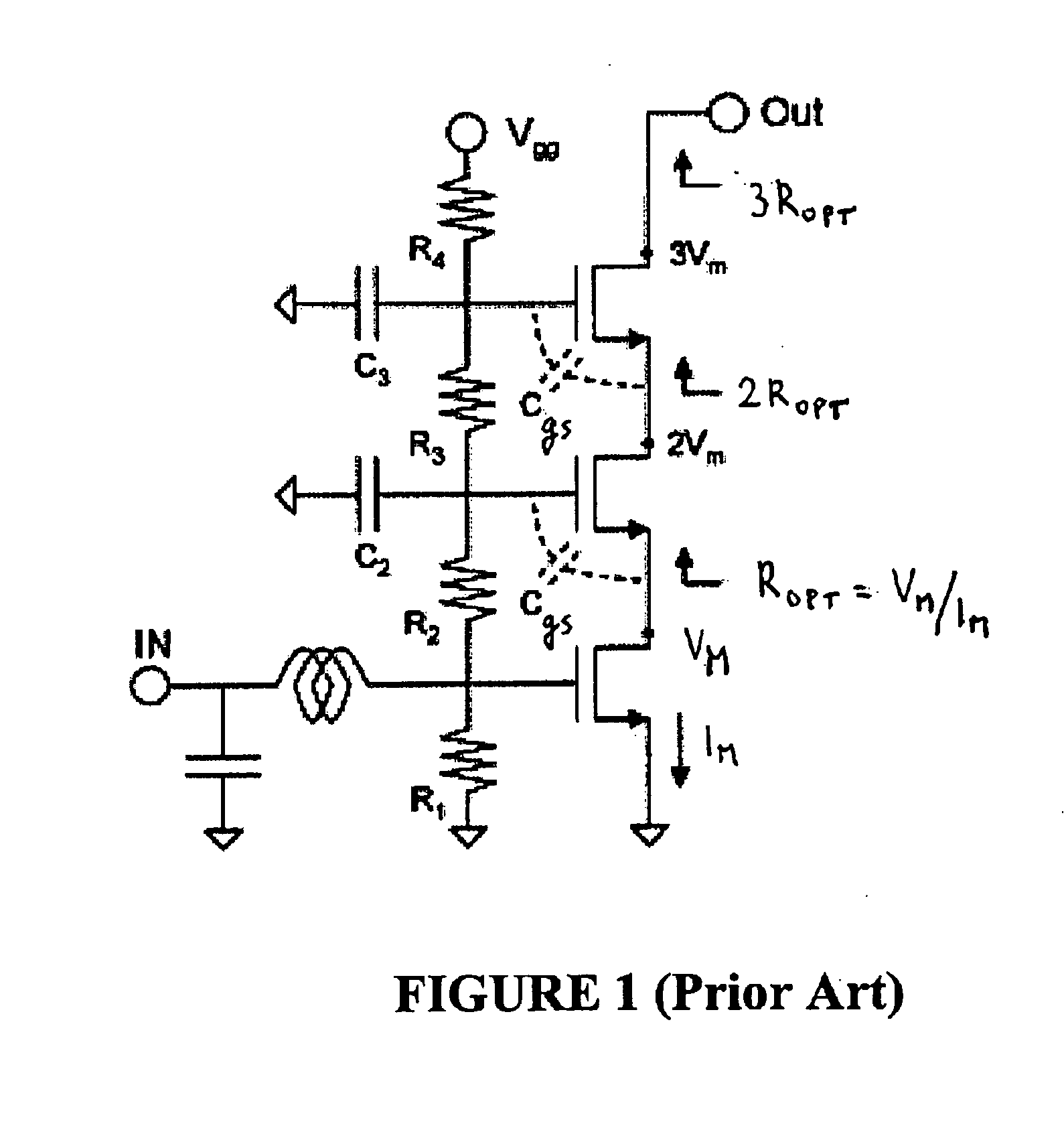

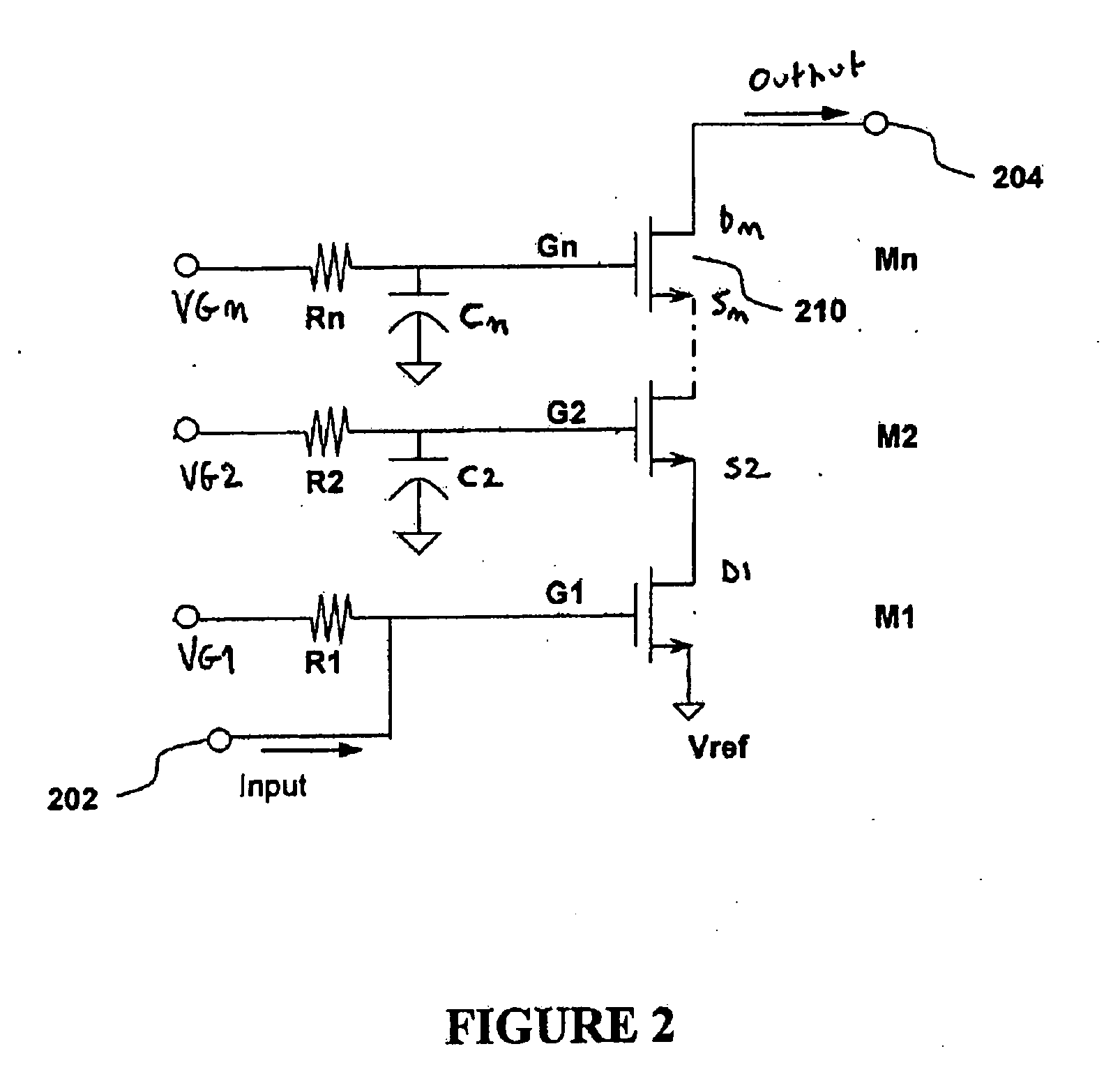

Stacked linear power amplifier with capacitor feedback and resistor isolation

ActiveUS8487706B2MinimizationMaximizeAmplifier combinationsAmplififers with field-effect devicesCapacitanceLinear power amplifier

A power amplifier with stacked, serially connected, field effect transistors is described. DC control voltage inputs are fed to the gates of each transistor. Capacitors are coupled to the transistors. The inputs and the capacitors are controlled to minimize generation of non-linearities of each field effect transistor and / or to maximize cancellation of distortions between the field effect transistors of the power amplifier in order to improve linearity of the power amplifier output.

Owner:PSEMI CORP

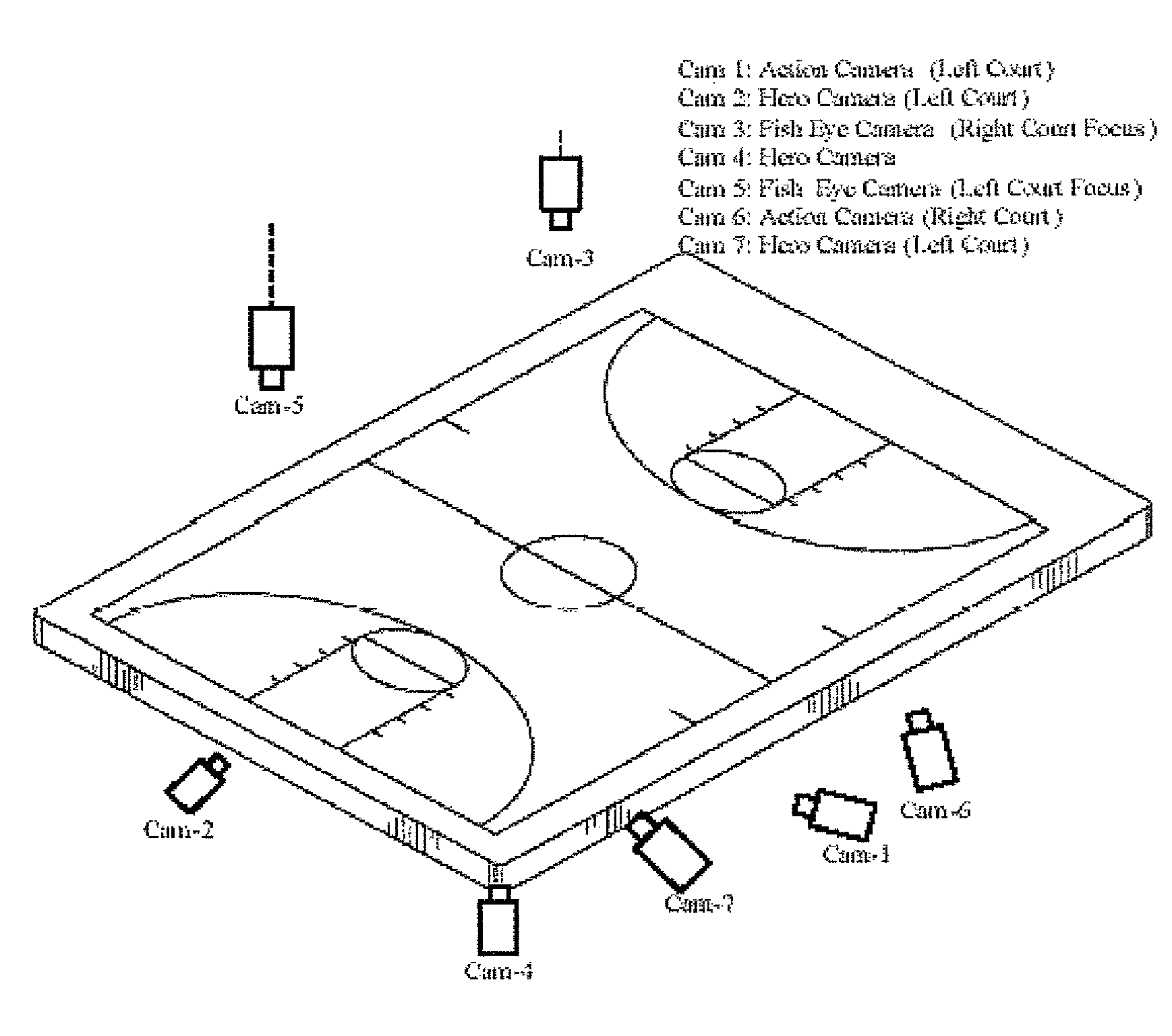

Systems and methods for the autonomous production of videos from multi-sensored data

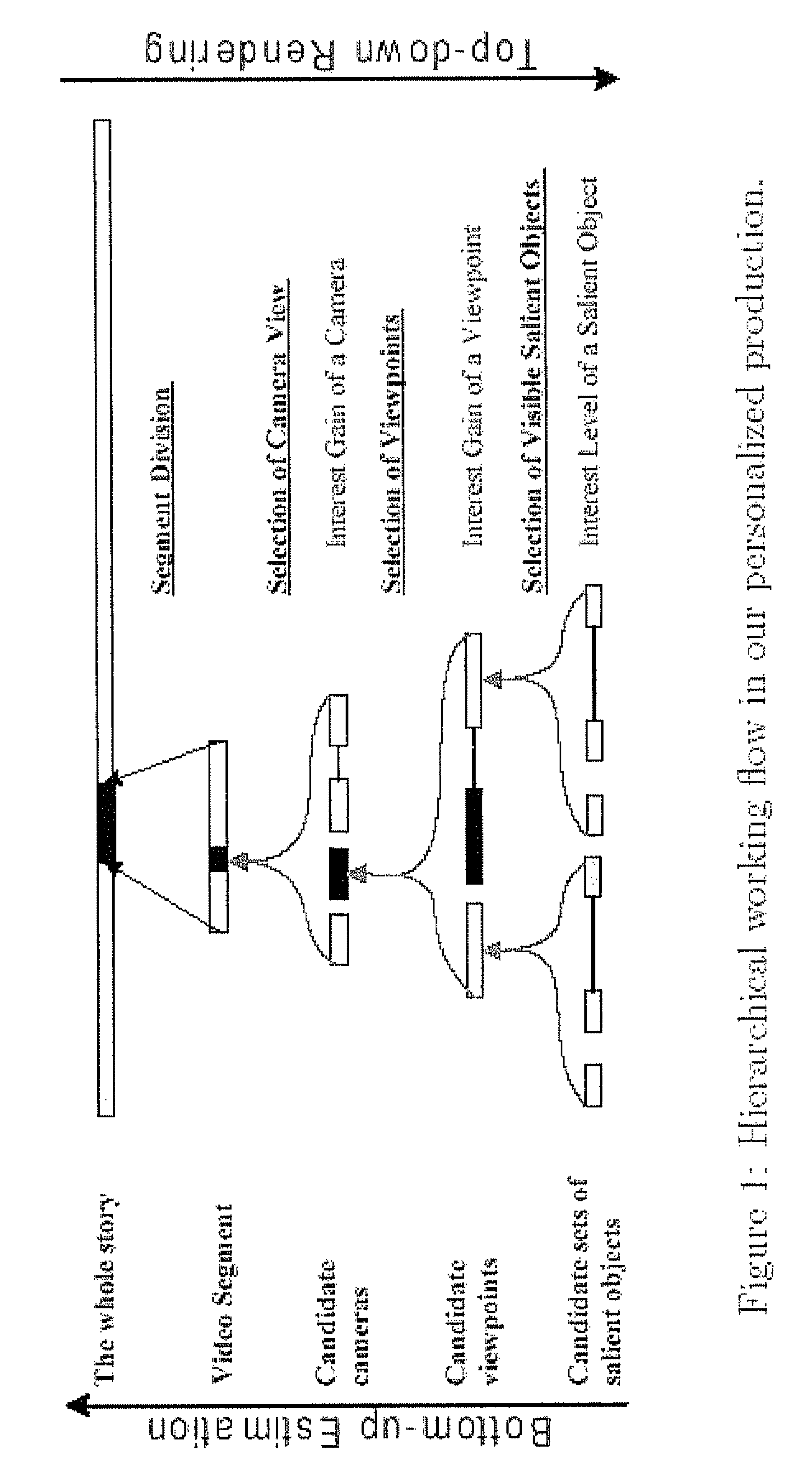

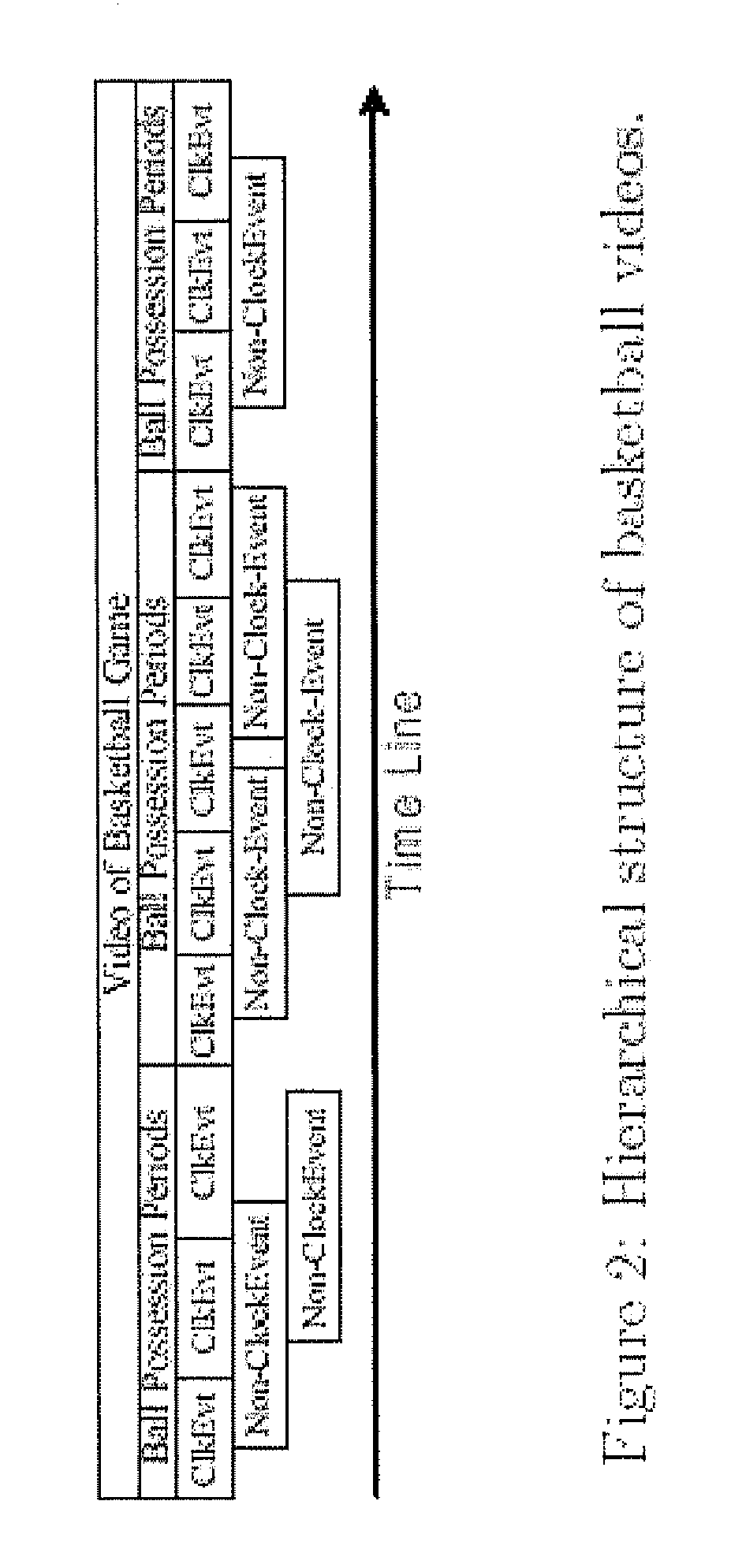

ActiveUS8854457B2MaximizeSmoothness of transitionsTelevision system detailsElectronic editing digitised analogue information signalsPersonalizationViewpoints

An autonomous computer based method and system is described for personalized production of videos such as team sport videos such as basketball videos from multi-sensored data under limited display resolution. Embodiments of the present invention relate to the selection of a view to display from among the multiple video streams captured by the camera network. Technical solutions are provided to provide perceptual comfort as well as an efficient integration of contextual information, which is implemented, for example, by smoothing generated viewpoint / camera sequences to alleviate flickering visual artifacts and discontinuous story-telling artifacts. A design and implementation of the viewpoint selection process is disclosed that has been verified by experiments, which shows that the method and system of the present invention efficiently distribute the processing load across cameras, and effectively selects viewpoints that cover the team action at hand while avoiding major perceptual artifacts.

Owner:KEEMOTION

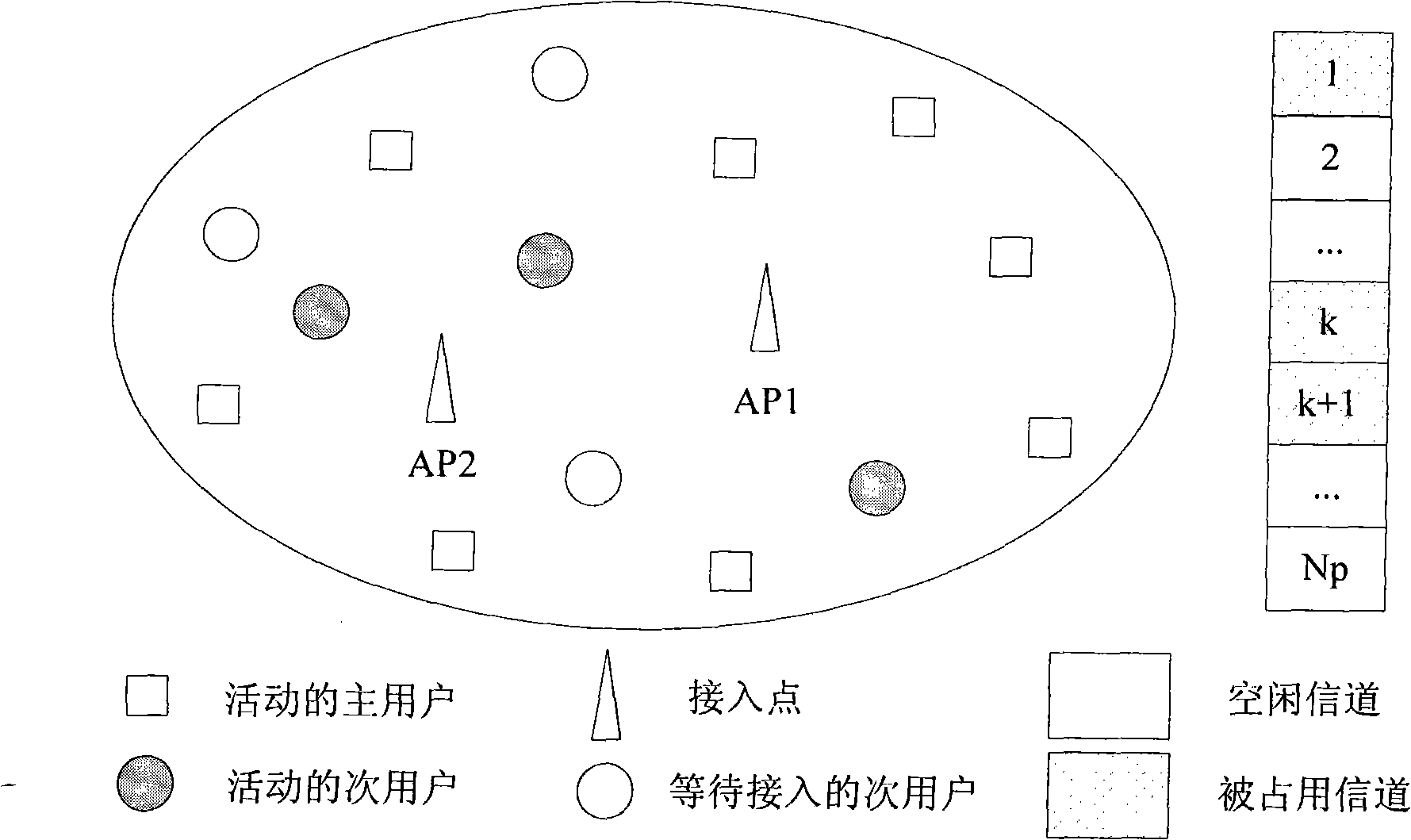

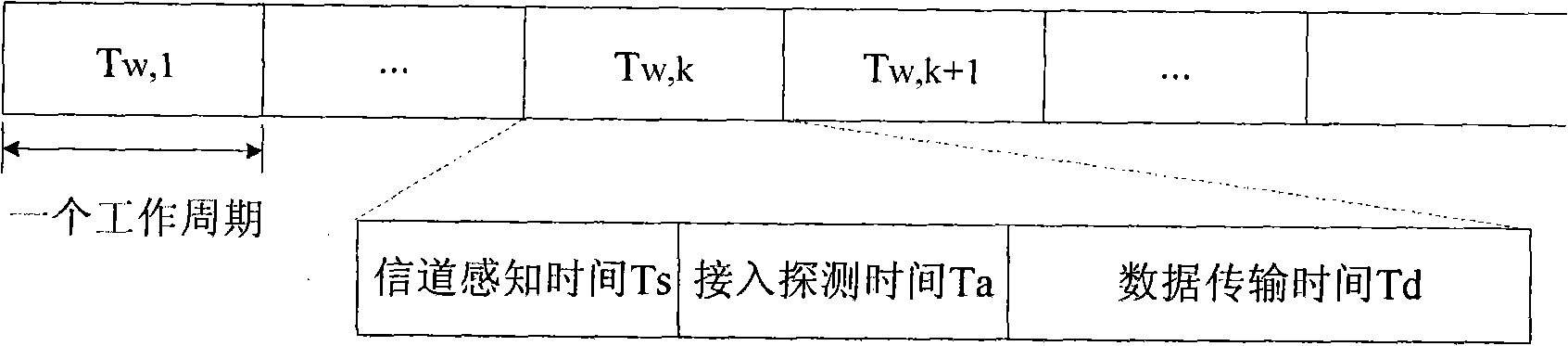

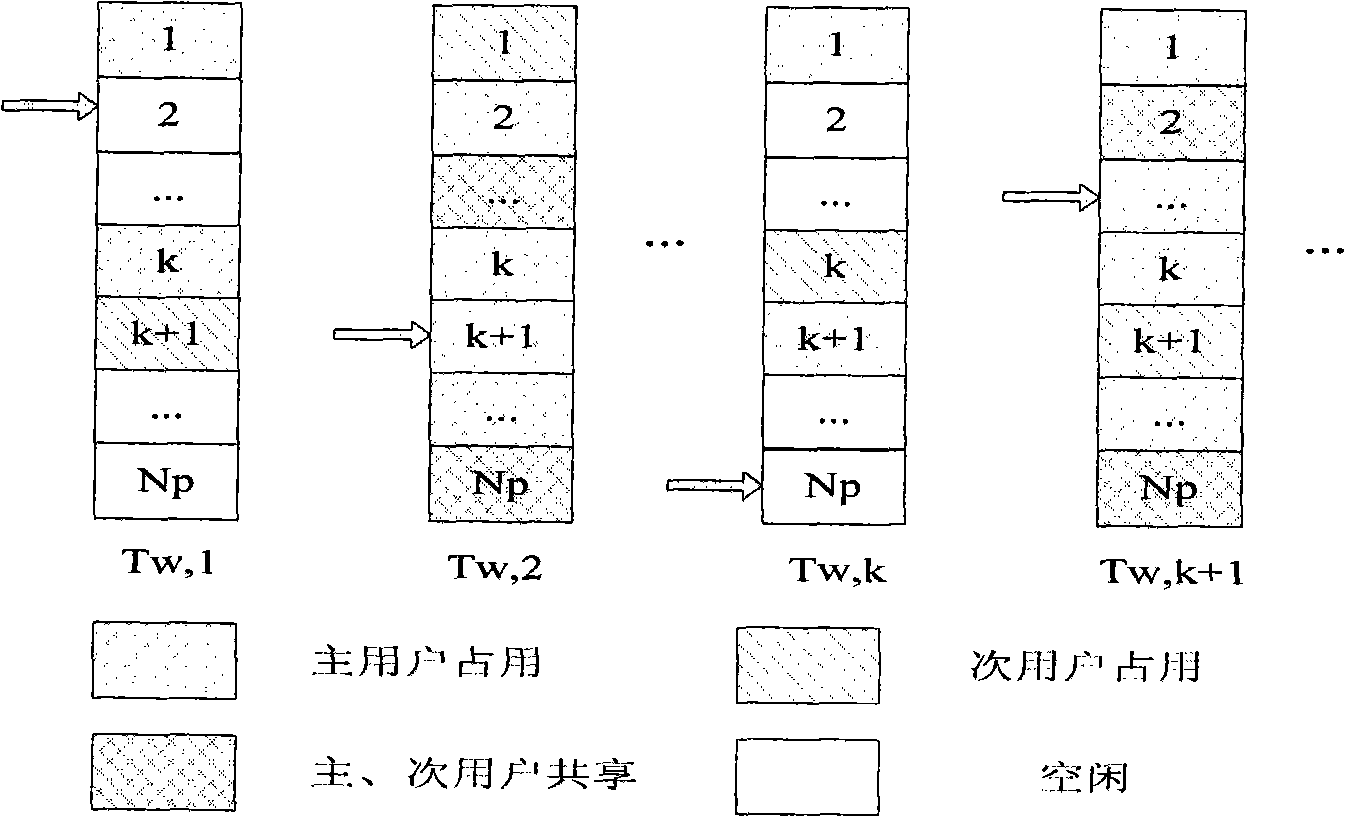

Secondary user access method for maximization of capacity of dynamic spectrum sharing system

InactiveCN101801000ALarge capacityMaximizeAssess restrictionNetwork planningTelecommunicationsAccess method

The invention relates to a secondary user access method for maximization of capacity of a dynamic spectrum sharing system, in particular to a secondary user access method which can maximize the capacity of a dynamic spectrum sharing system. In the method, a secondary user selects a channel with the highest transmission power for access during each working cycle of each secondary user, the channel can be known according to a Shannon formula, and each secondary user can obtain the maximum capacity available at present during each working cycle. Therefore, each secondary user can obtain the maximum average capacity in the whole communication period, and the sum of the average capacities of all secondary users can be the maximum, thereby realizing the maximization of the average capacity of the dynamic spectrum sharing system.

Owner:NANJING UNIV OF POSTS & TELECOMM

Smart cloud management system based on cloud computing for enterprise infrastructure

InactiveCN104125286AIncrease profitImprove IT management levelResourcesTransmissionResource poolVirtualization

The invention discloses a smart cloud management system based on cloud computing for enterprise infrastructure. The system comprises a cloud computing foundation platform and a smart cloud service portal; the cloud computing foundation platform is used for abstracting a hardware resource into a resource pool and performing unified resource distribution, scheduling and managing in order to realize seamless integration of the existing resources; the smart cloud service portal is used for hiding the underlying implementation logic for an end user, and the user can realize the function of the cloud computing foundation platform by operating a web interface. According to the system, the computing, storage, network and other hardware resources are virtualized, in order to raise the utilization rate of the hardware resources, and the fixed hardware is converted into flexible resources, and as a result, the IT resources of an enterprise is maximized, the IT operation mode is simplified, elastic IT framework is realized, variable business developments are supported, the important revolution is brought to the IT platform of the enterprise, and the IT management level of the enterprise is greatly raised.

Owner:浙江网新恒天软件有限公司

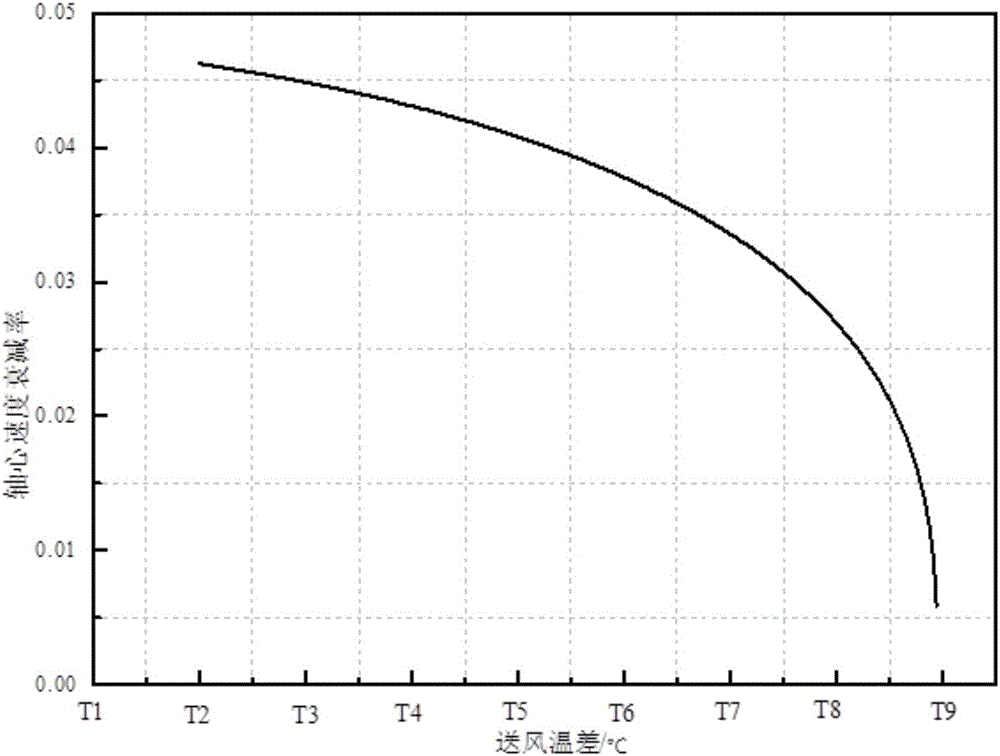

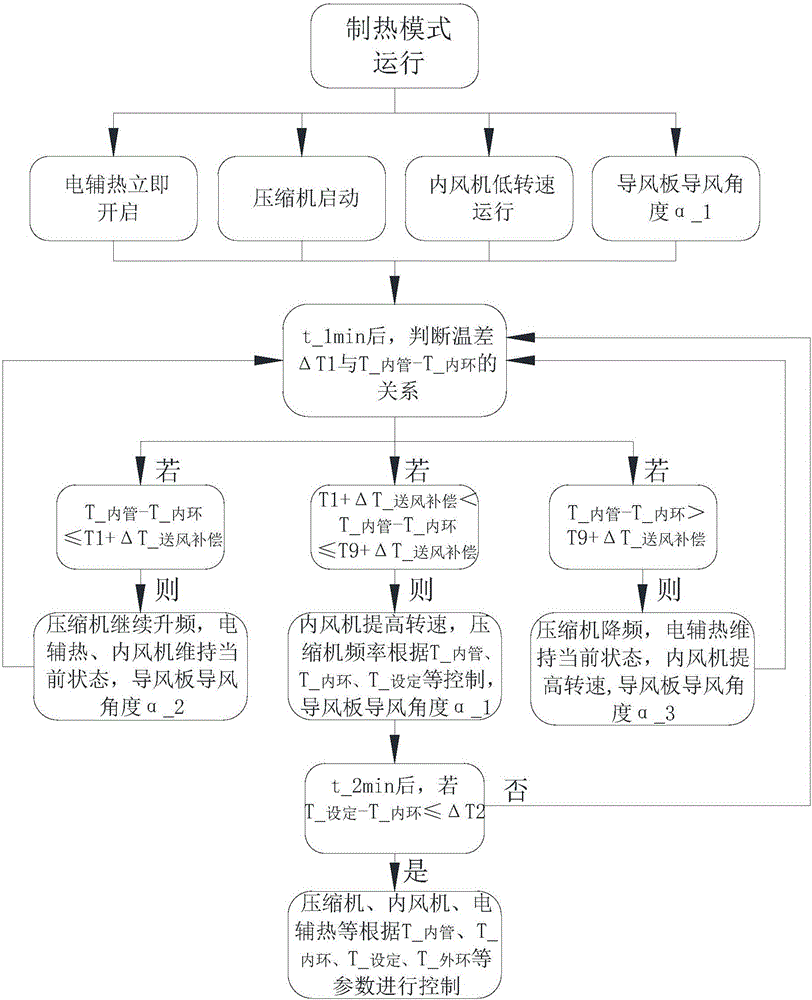

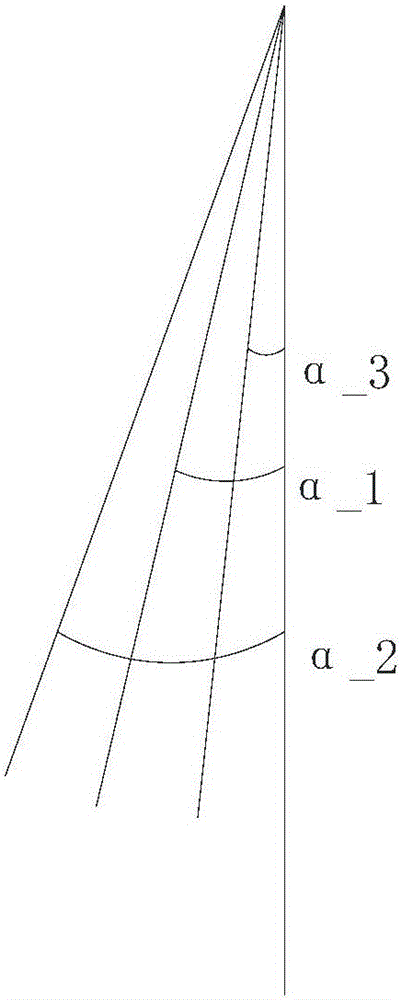

Method and device for controlling heating of air conditioner

ActiveCN105757886AMaximizeMechanical apparatusSpace heating and ventilation safety systemsEngineeringHeating effect

The invention discloses a method and a device for controlling heating of an air conditioner. The method comprises the following steps: step one, starting an electric auxiliary heating device and a compressor after entering a heating mode, controlling an air deflector to be at a first air guiding angle and running an inner fan at a first rotating speed; step two, after reaching the first preset time of the heating mode, acquiring a first temperature difference for expressing blowing temperature difference and a second temperature difference for expressing the difference between the tube temperature of an internal engine heat exchanger and the indoor environment temperature; step three, comparing the magnitude relationship between the first temperature difference and the second temperature difference; and step four, controlling the frequency of the compressor and / or the starting / stopping of the electric auxiliary heating device and / or the air guiding angle of the air defector and / or the rotating speed of the fan according to the magnitude relationship. According to the method provided by the invention, the purposes of hot wind landing and quick rise of indoor temperature can be achieved and the maximization of the heating effect of the air conditioner can be realized.

Owner:GREE ELECTRIC APPLIANCES INC

Intensive processing method for stalk articles or agricultural castoff

InactiveCN101492700AEasily hydrolyzedCompletely hydrolyzedBiofuelsMicroorganism based processesFiltrationMonopotassium phosphate

The invention provides a method for intensive processing of straw-type materials or wastes of agriculture and forestry. The method has the following steps: the straw-type materials or the wastes of agriculture and forestry are first ground and then soaked in hot water; hydrolyzation is carried out by diluted acid or monopotassium phosphate solution, the hydrolyzate is used for producing furfural or xylose, solid content after the hydrolyzation is washed and added with alkali substances for neutralization, then cellulase and feruloyl esterase are added to synergetically hydrolyze cellulose in solid content, the cellulose is broken down into 6-carbon monosaccharide and exists in sugar liquor; adsorption filtration is carried out on the sugar liquor by activated carbon, then high-temperature sterilization and cooling are carried out on the sugar liquor before inoculation of fermentation strain to produce acetone, butanol and ethanol by fermentation; the method of the invention maximizes the application of the straw-type materials or the wastes of agriculture and forestry, thus turning existing wastes into the valuables while finding new raw material sources and a new method for producing acetone, butanol and ethanol and bringing more economic and social benefits to the enterprises and the society.

Owner:ZHENGZHOU DAYANG GREASE CHEM EQUIP

Real-time rail transit passenger flow prediction and passenger guiding system

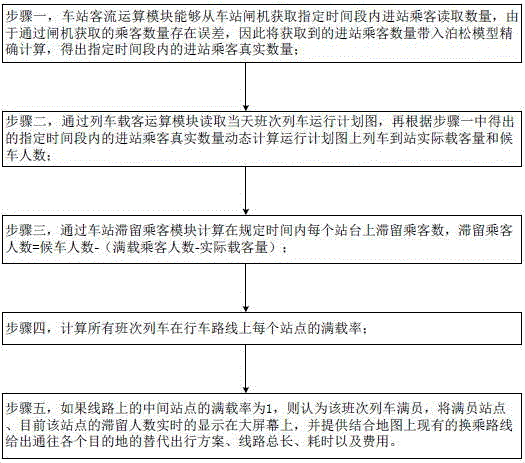

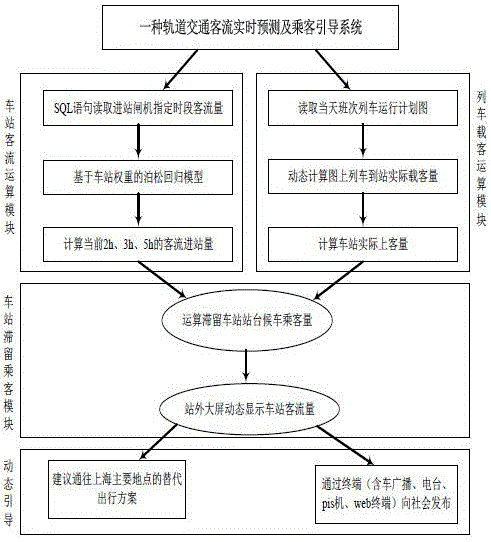

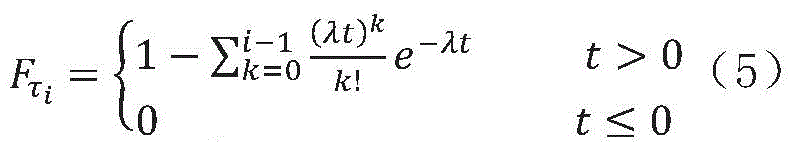

The invention relates to the technical field of urban rail transit and transportation and provides a real-time rail transit passenger flow prediction and passenger guiding system.The real-time rail transit passenger flow prediction and passenger guiding system comprises a station passenger flow operation module for reading the number of passengers entering stations, substituting a Poisson model and performing accurate calculation to obtain the true number of passengers entering the stations, a train carried passenger operation module for reading an operation planning map of trains running on the same day and calculating the actual passenger capacity and the number of passengers waiting for the trains when the trains arrive at the stations, and a station stranded passenger operation module for calculating the number of stranded passengers at each station and calculating the load factor of each station of running routes of all trains, wherein if the load factors of middle stations of the routes are 1, it is indicated that the trains running along the routes are full, the stations at full strength and the number of stranded passengers at the current stations are displayed on a large screen in real time, and alternative trip plans leading to all destinations are provided.The real-time rail transit passenger flow prediction and passenger guiding system can predict stranded passenger flows at stations, takes preventive measures, avoids passenger stranding, reduces the peak pressure of rail transit and makes citizens' trips more convenient and safer.

Owner:SHANGHAI UNIV OF ENG SCI

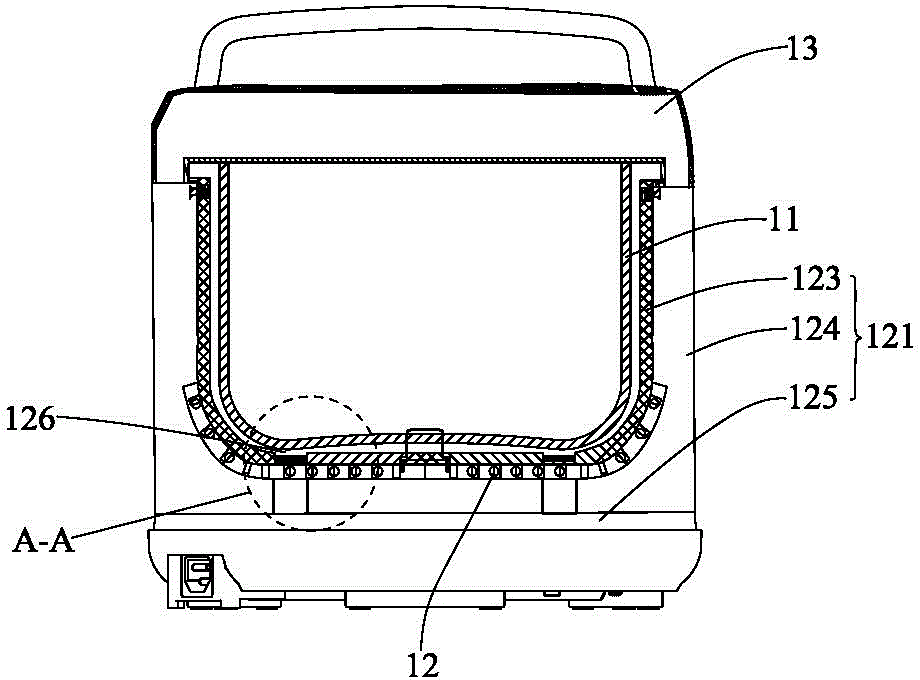

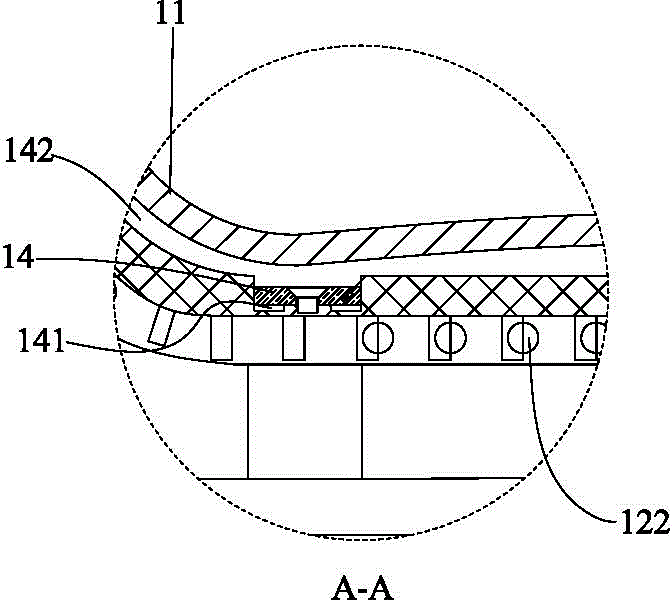

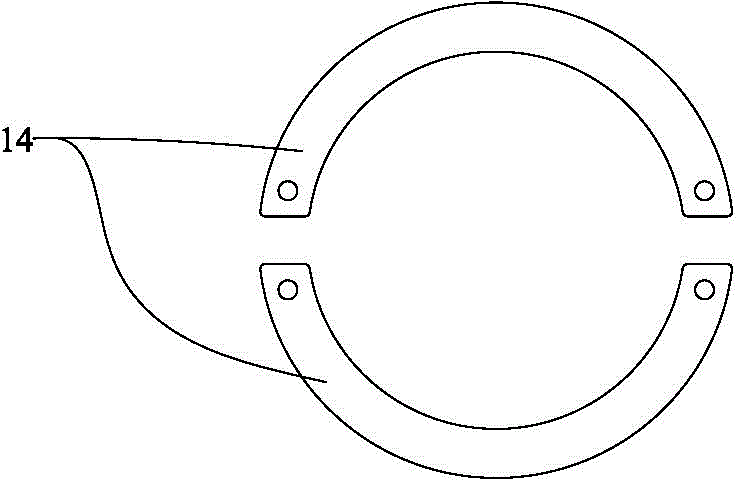

Food cooking utensil

The invention relates to a food cooking utensil comprising a food container and an electromagnetic heating device. The food container is placed on the electromagnetic heating device; the electromagnetic heating device comprises a machine body, electromagnetic coils and a control circuit board, the electromagnetic coils are located in the machine body, and the control circuit board is electrically connected with the electromagnetic coils; the electromagnetic heating device is further provided with vibrating reeds, vibrating spaces are arranged between the vibrating reeds and the upper surfaces of the electromagnetic coils and between the vibrating reeds and the bottom surface of the food container, and the vibrating reeds induce an alternating magnetic field of the electromagnetic coils to generate ultrasonic waves. The vibrating reeds are arranged above the electromagnetic coils to induce the electromagnetic field to generate the ultrasonic waves which act on food in the food container, mouthfeel of the food is improved, and application of the ultrasonic waves to kitchen household appliances is achieved. The ultrasonic waves are generated and transmitted in a non-contact mode, direct contact with the high-temperature food container and the high-temperature electromagnetic coils can be avoided, temperature influences are small, and performance is stable and reliable. In addition, no driving circuit needs to be added, the structure is simple, and cost is low.

Owner:JOYOUNG CO LTD

Stacked linear power amplifier with capacitor feedback and resistor isolation

ActiveUS20110181360A1MinimizationMinimize generation of non-linearitiesAmplifier combinationsAmplififers with field-effect devicesCapacitanceAudio power amplifier

A power amplifier with stacked, serially connected, field effect transistors is described. DC control voltage inputs are fed to the gates of each transistor. Capacitors are coupled to the transistors. The inputs and the capacitors are controlled to minimize generation of non-linearities of each field effect transistor and / or to maximize cancellation of distortions between the field effect transistors of the power amplifier in order to improve linearity of the power amplifier output.

Owner:PSEMI CORP

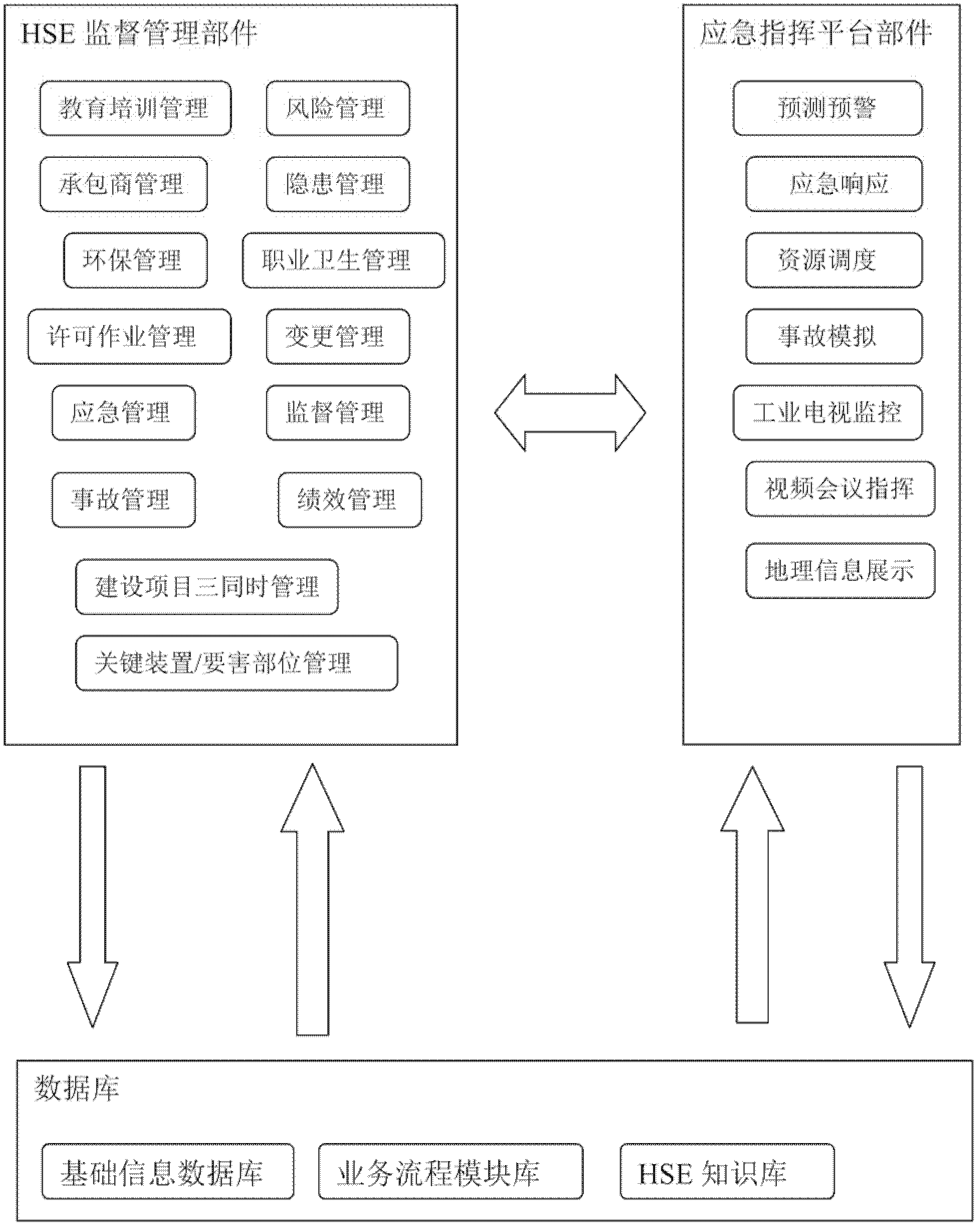

HSE management system using computer technology, and application of the same

InactiveCN102496087AImprove applicabilityEnsure safetyResourcesHigh effectivenessComputers technology

The invention discloses a HSE (Health, Safety and Environment) management system using the computer technology. The HSE management system comprises a database, a HSE supervision and administration component and an emergency command component, wherein the database includes a basic database. The HSE management system of the invention not only ensures the safety and the stability of the system, but also has enough expandability; simultaneously, normalized and standardized HSE management flows are designed, and the system is flexibly customized according to actual conditions of enterprise HSE management, so that the applicability of software is enhanced. The HSE management system of the invention is further featured by convenient operation, steady running, high efficiency, low cost and the like, and can solve the problems of non-uniform standard and non-standard business operation in enterprise HSE management running process. With the HSE management system, the enterprises can be helped to control production running risk, the emergency disposal capability to accident events is improved, and powerful information technical support for preventing accidents, reducing accident loss and realizing maximization of overall benefits of enterprises is provided.

Owner:CHINA PETROLEUM & CHEM CORP +1

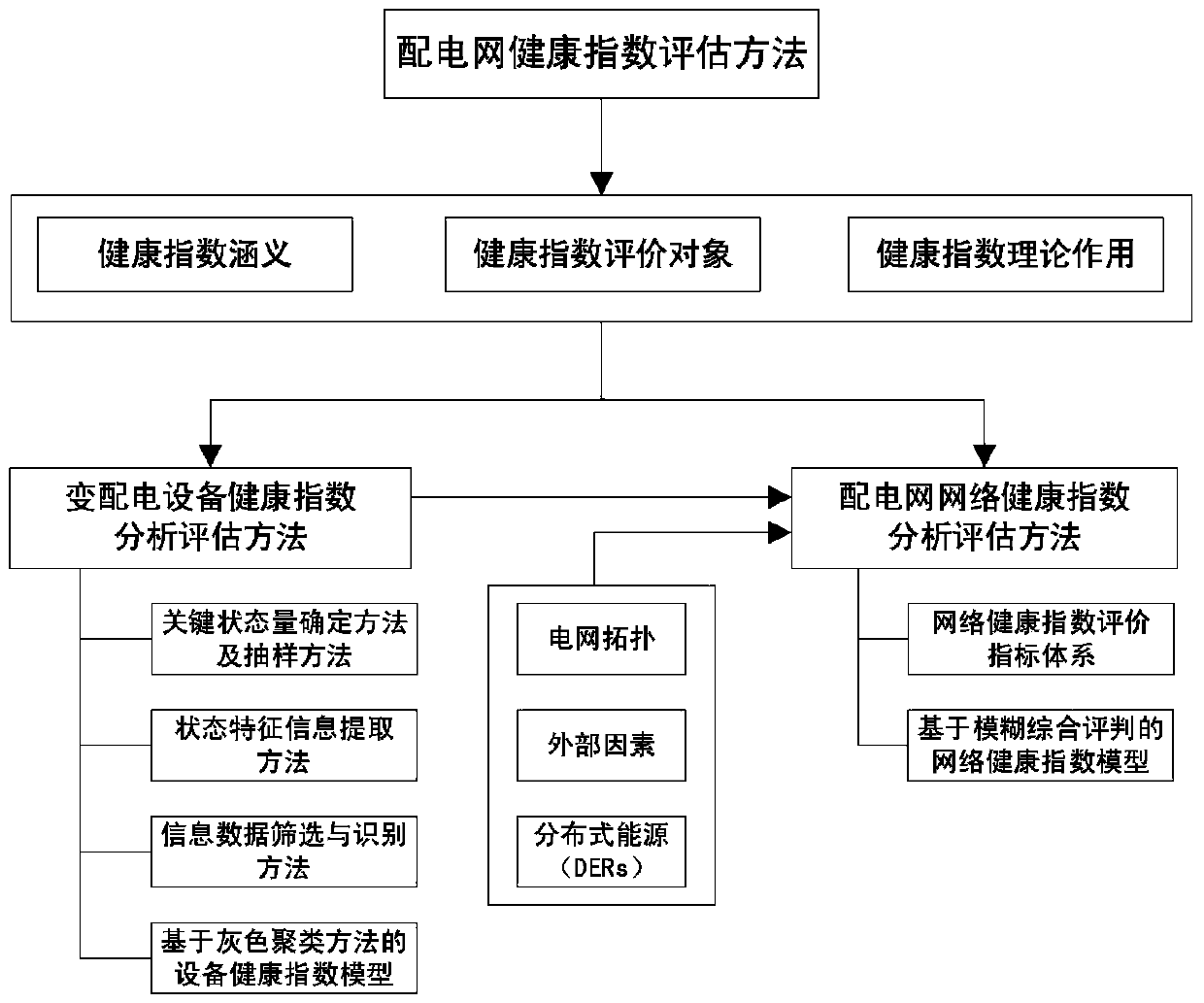

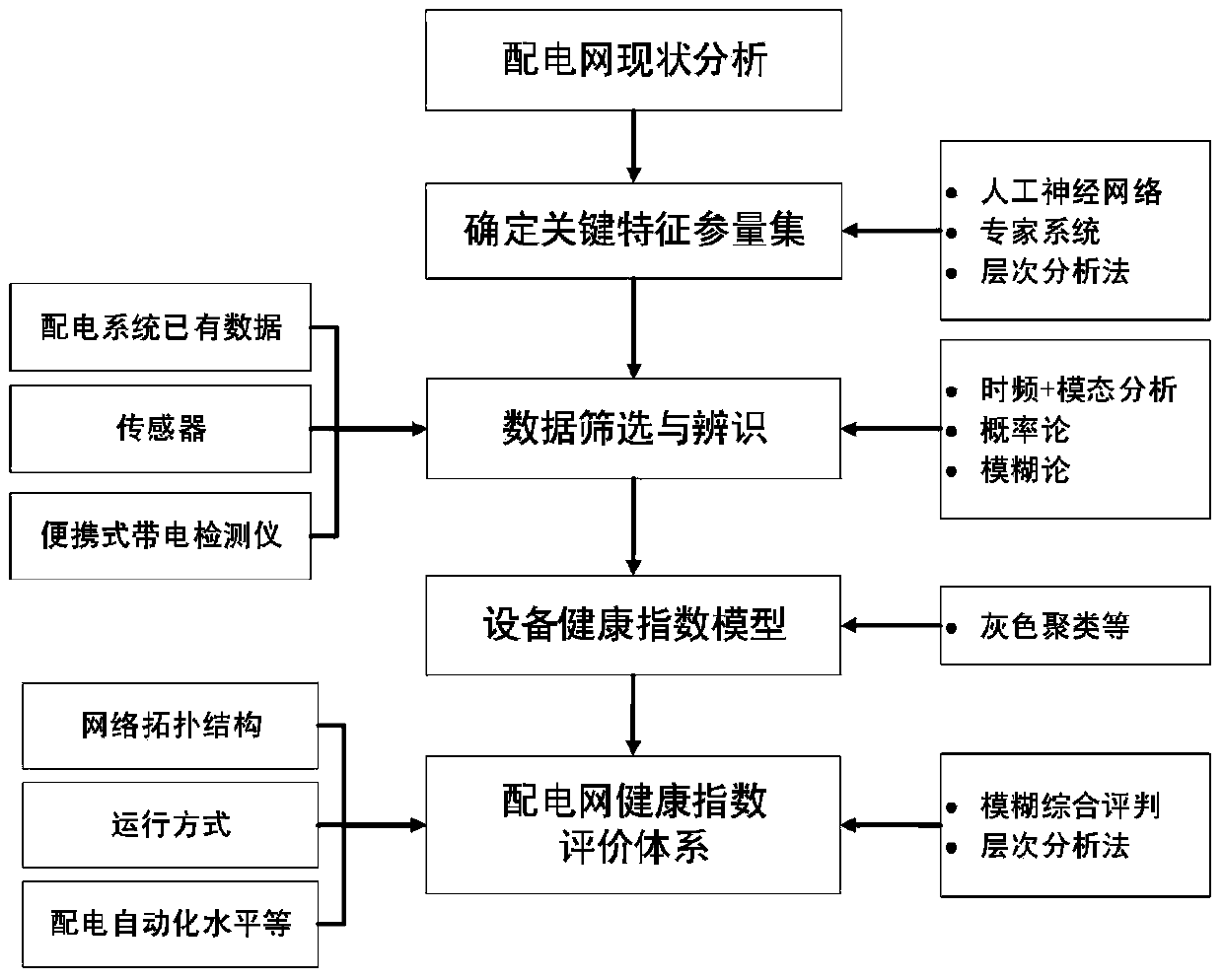

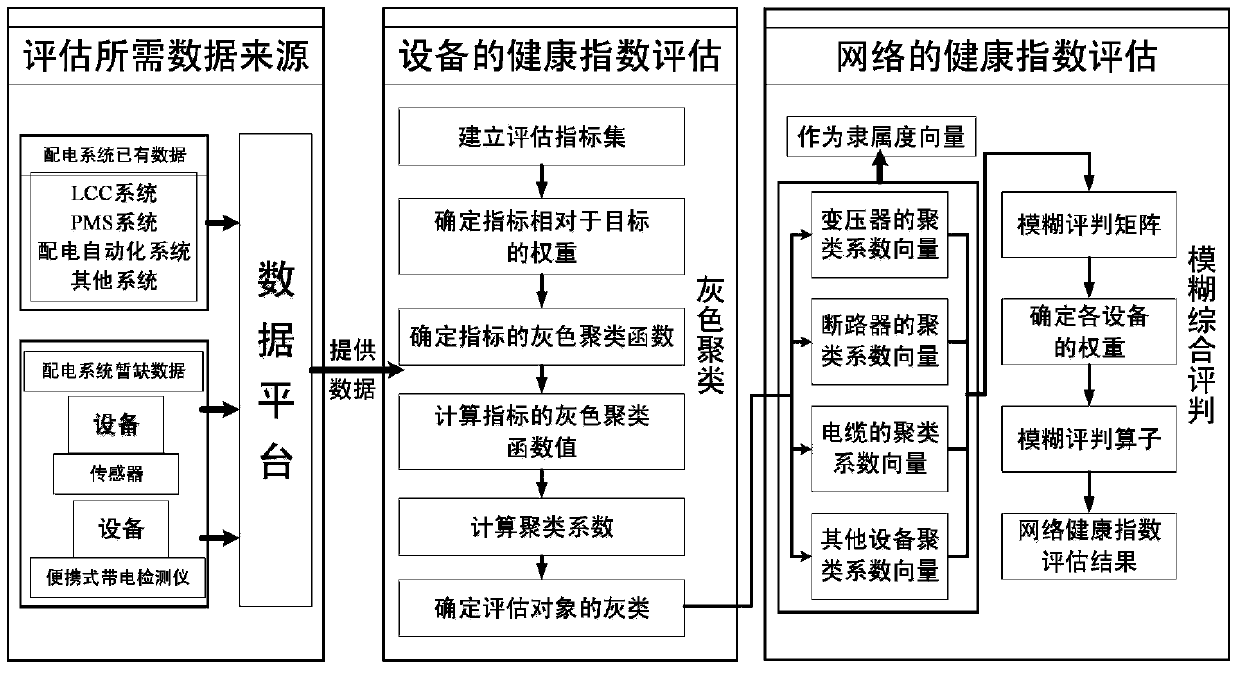

Power distribution network health index assessment method

ActiveCN105512448AAsset Management LeapsImprove power supply reliabilitySpecial data processing applicationsHealth indexTransformer

The invention relates to a power distribution network health index assessment method comprising the following steps: 1, determining power distribution network health index connotation and purpose; 2, determining a power distribution network health index assessment object; 3, determining a power distribution network health index assessment index system; 4, evaluating a transformer and distribution equipment health index; 5, evaluating the power distribution network health index. In a long term, the reliability research pays more attention on a single device at certain moment, a single section (static state), a fault result, and a cause and effect relation; the novel method provides a colony equipment and network health index assessment method, can study the colony equipment and network dynamic health level and power supply reliability, can guide power distribution network planning and operation unkeep asset management, can provide equipment and network health status quantification analysis, and macroscopic and microscopic are combined to provide base theory and practical technical means.

Owner:CHINA ELECTRIC POWER RES INST +2

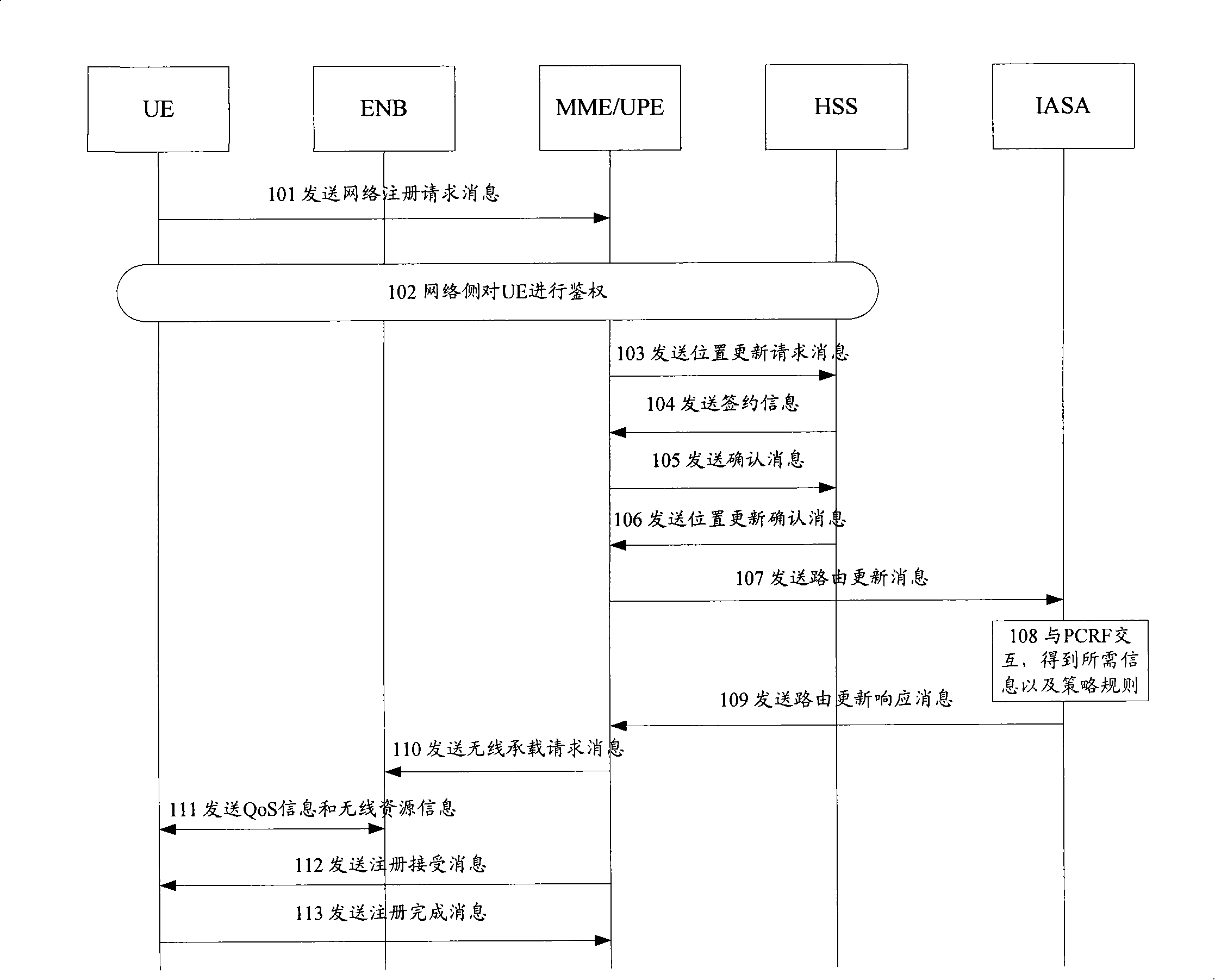

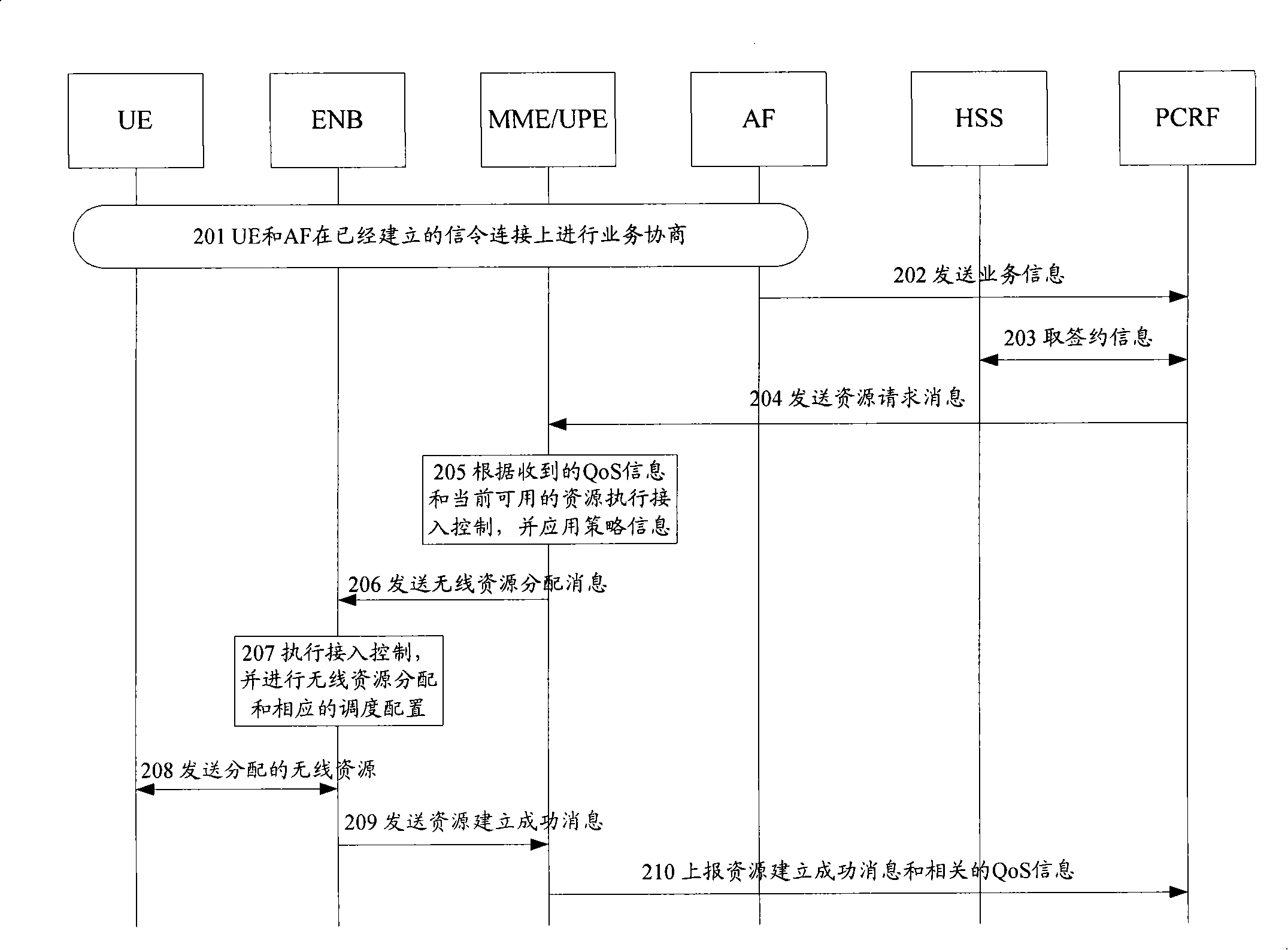

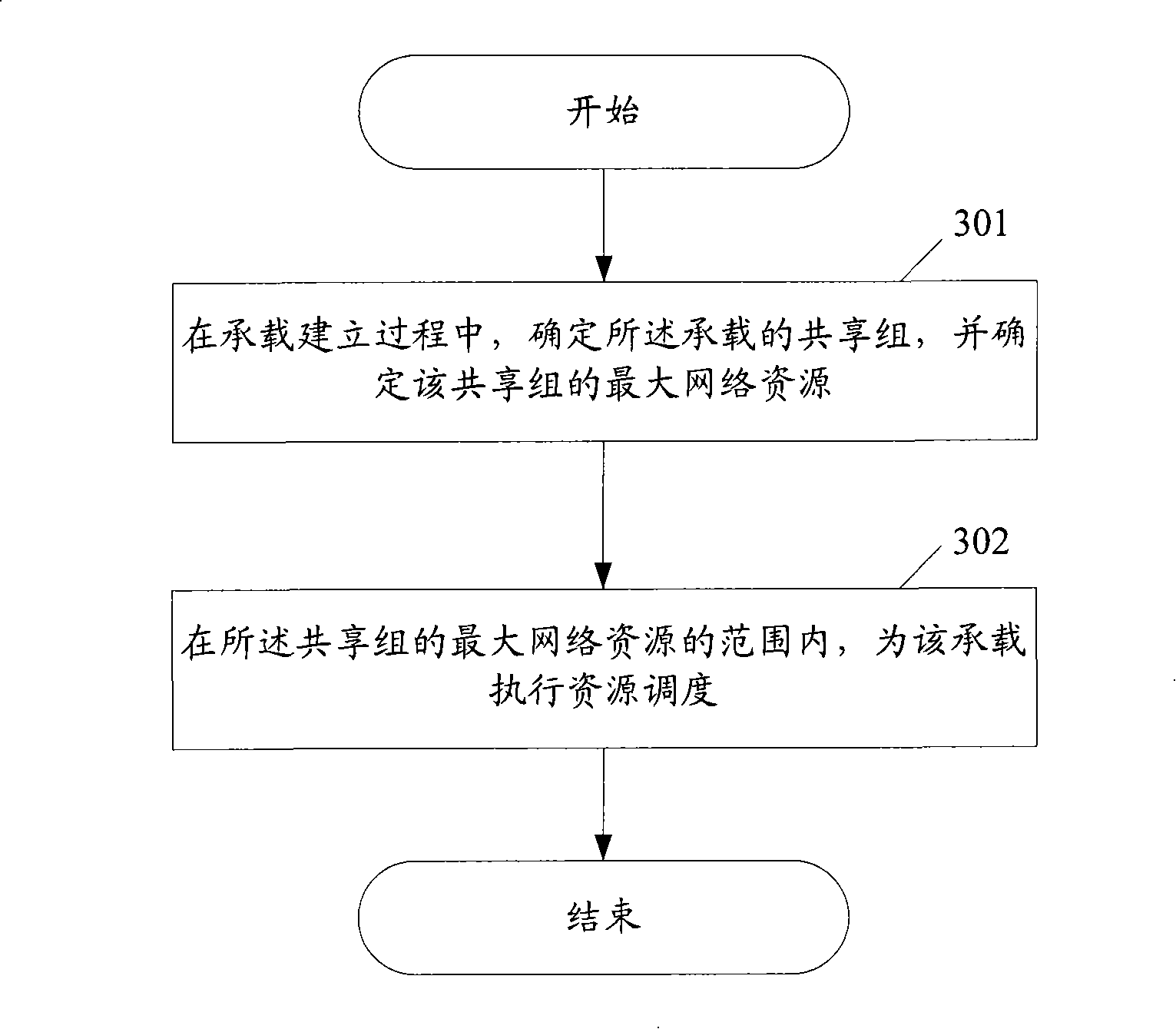

System, apparatus and method for sharing network resource

ActiveCN101227714AAddressing Utilization DecreasesMaximizeNetwork traffic/resource managementRadio/inductive link selection arrangementsResource utilizationDistributed computing

The invention discloses a method for sharing network resources, which sets a sharing group according to service types, and assures the maximum network resource of the sharing group. The method comprises assuring the sharing group which is borne in the process of establishing the bearing, and assuring the maximum network resource of the sharing group, and resource scheduling is executed for the bearing in the range of the maximum network resource of the sharing group. In addition, the invention also provides a device for sharing network resource. And meanwhile, the invention provides a method, a system, a corresponded data grouping network gateway and an evaluating base station. A method for sharing maximum transmission speed in multi-strip bearing in an evaluating network is achieved through the method and device which are provided by the invention, and the problems that the lowering of network resource utilization ratio which is caused by that each strip of bearing occupies fixed bandwidth resource is solved, and the invention achieves the maximization of network resource utilization ratio.

Owner:HUAWEI TECH CO LTD

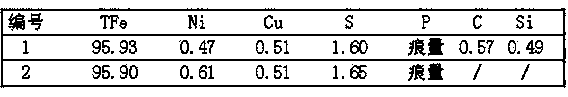

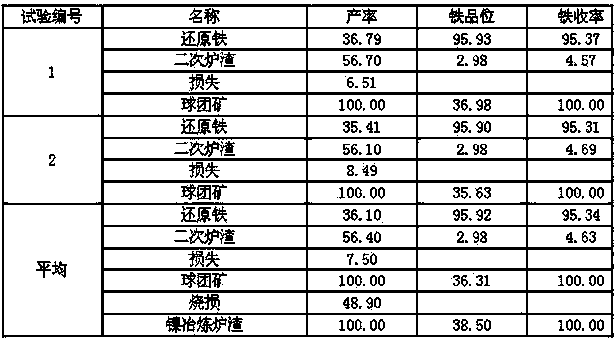

Method for treating nickel smelting furnace slag

The invention method provides a method for treating nickel smelting furnace slag and relates to a method for treating nickel smelting furnace slag by a rotary hearth furnace reduction-gas furnace melting separation combined process. The method is characterized by sequentially comprising the following process steps: (1) adding a reducing agent, a fusing agent and an adhesive into the nickel smelting furnace slag and mixing; (2) pressing into pellets; (3) drying the pressed pellets; (4) charging the dried carbon-containing pellets into a preheating section of a rotary hearth furnace and preheating; (5) reducing the carbon-containing pellets in a reducing section of the rotary hearth furnace to obtain thermal-state metallized pellets; and (6) adding the hot pellets into the gas furnace for melting separation to realize final reduction and scrap iron melting separation. By the method, valuable elements in the nickel smelting furnace slag can be comprehensively recovered, continuity of a preparation process is realized, molten iron for steel-making can be provided, and secondary slag for developing and producing products such as slag micropowder, foamed ceramic and aerated concrete blocks also can be provided, and zero emission of solid wastes is realized.

Owner:JINCHUAN GROUP LIMITED

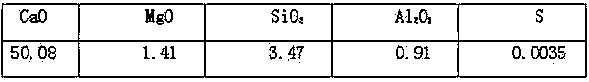

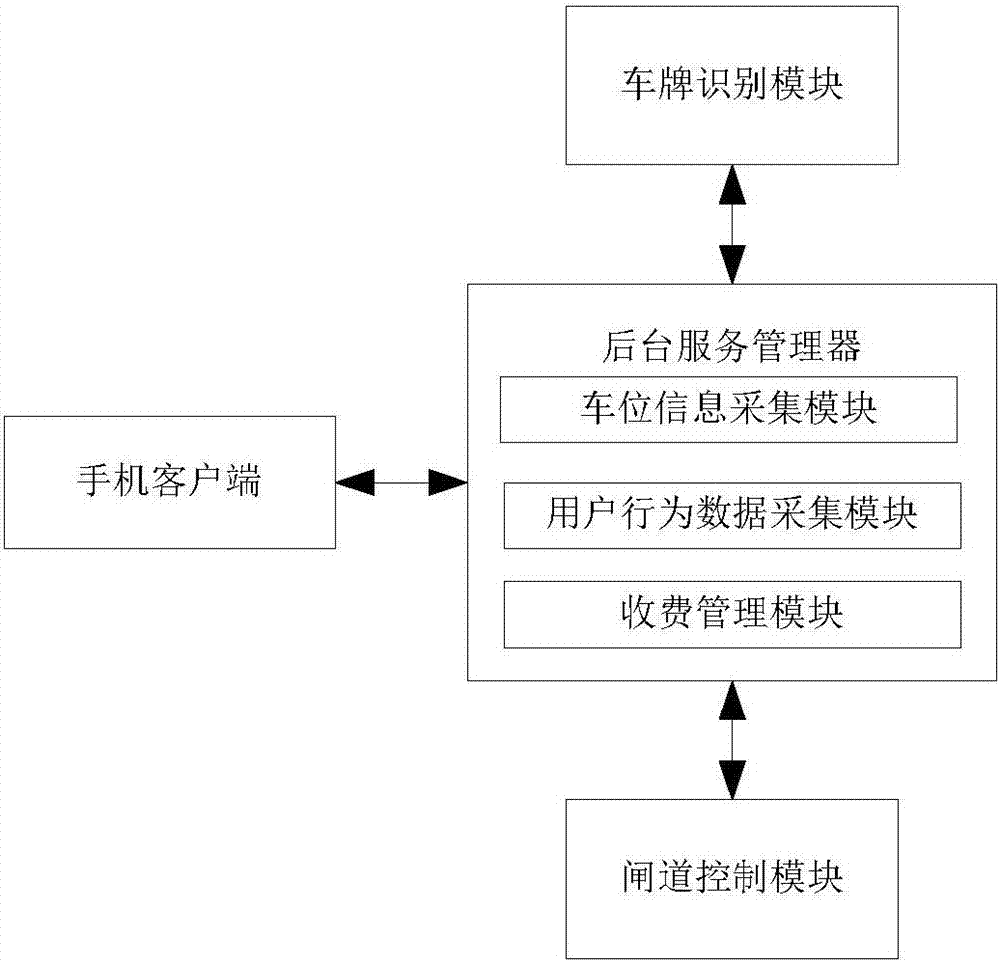

System and method for intelligent reservation of district temporary parking stalls

InactiveCN107545769AOptimize parking time and space layoutAvoid wastingTicket-issuing apparatusIndication of parksing free spacesParking spaceCollections data

The present invention discloses a system and a method for intelligent reservation of district temporary parking stalls. The system comprises: a mobile phone client used for parking stall reservation,reservation cancel, route guidance and expense payment operation; a license plate identification module configured to collect and identify information of a reservation vehicle; a gateway control module configured to control closure and opening of a district gateway; and a background management server comprising a parking stall information collection module, a user behavior data collection module and a payment management module, wherein the parking stall information collection module is configured to collect and update usage states of parking stalls in each district to form a parking stall information database, the user behavior data collection module configured to record users' daily trips, reservation time, parking time periods and parking duration to form a user behavior database, the payment management module is configured to calculate cost generated by user parking and user credit grade evaluation, and the mobile phone client, the parking stall information collection module and thelicense plate identification module are connected with the background management server.

Owner:WUHAN SHENJIE TECH CORP LTD

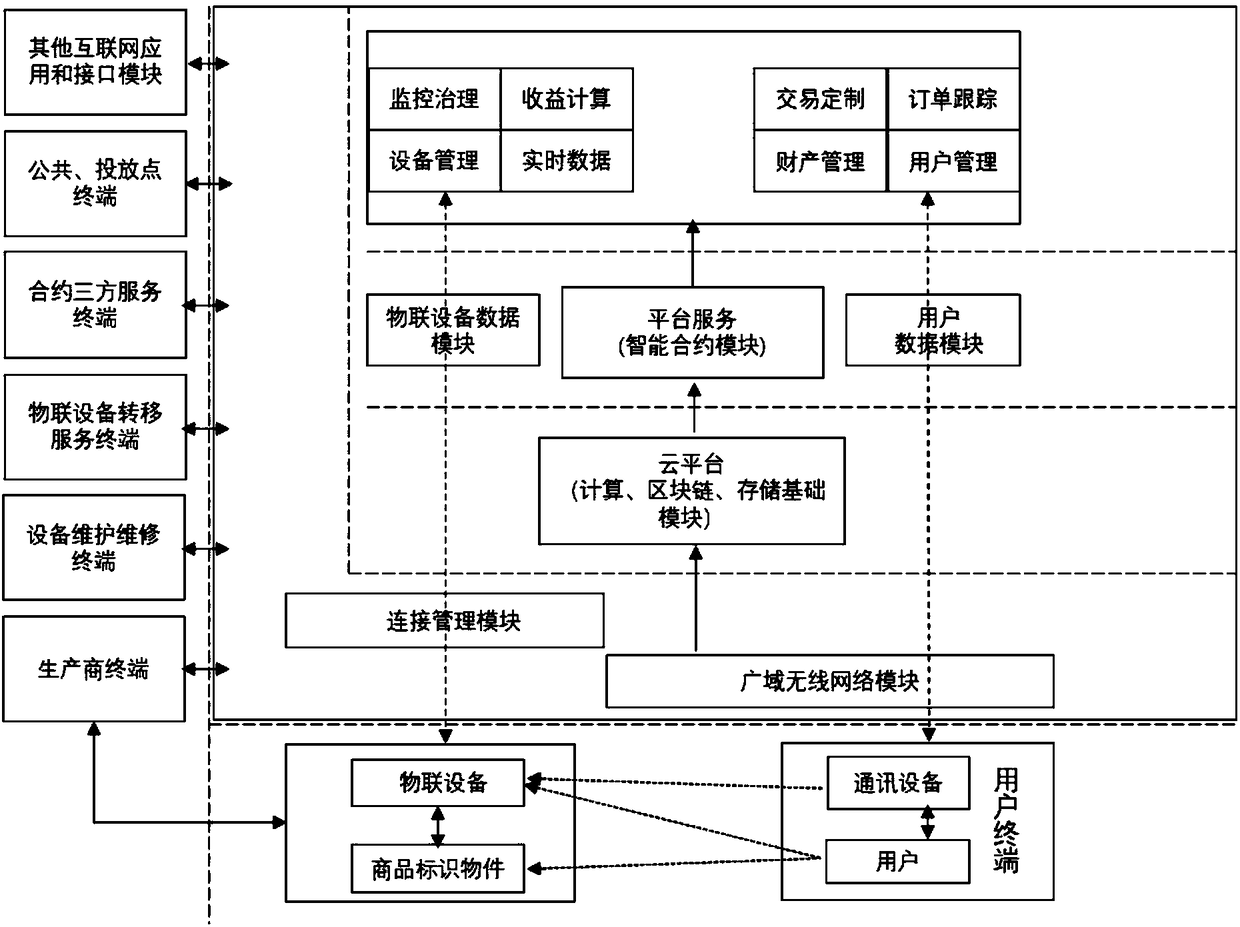

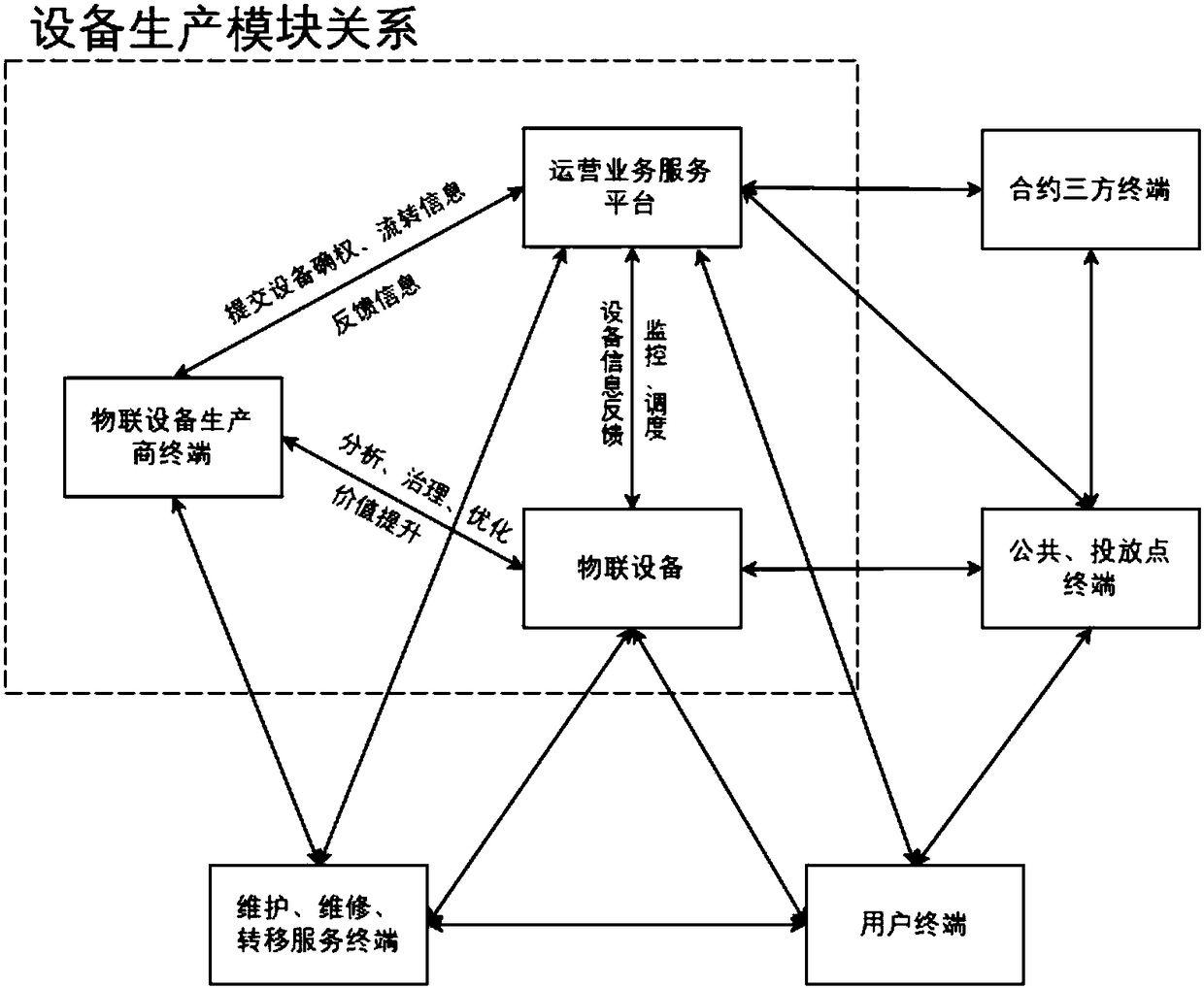

Internet of Thing equipment operating system and method based on blockchain

InactiveCN108197718AEfficiently providePrecise value matchingBuying/selling/leasing transactionsMarket data gatheringThe InternetSmart contract

The invention discloses an Internet of Thing equipment operating system and method based on blockchain. The system comprises a user terminal, an Internet of Thing equipment manufacturer terminal, Internet of Thing equipment, an operating business service platform, a maintenance service transferring terminal for the Internet of Thing equipment, a contract three party terminal and a public release point terminal. The method comprises the steps that after the Internet of Thing equipment is certificated by the operating business service platform, the Internet of Thing equipment is released in thepublic release point terminal, and the Internet of Thing equipment is managed by the operating business service platform; a user can carry out interaction, identification, recordance, positioning, checking, selection and use of the Internet of Thing equipment by a user terminal, and the user can acquire products and services provided by the operating business service platform. The operating systemand method have the advantages that by the Internet of Things, blockchain and smart contract technology, it is achieved that the products and services with accurate value matching are effectively provided for consumers, the process is also energy-saving and effective and exceeds the expectant experience.

Owner:北京晒呗科技有限公司

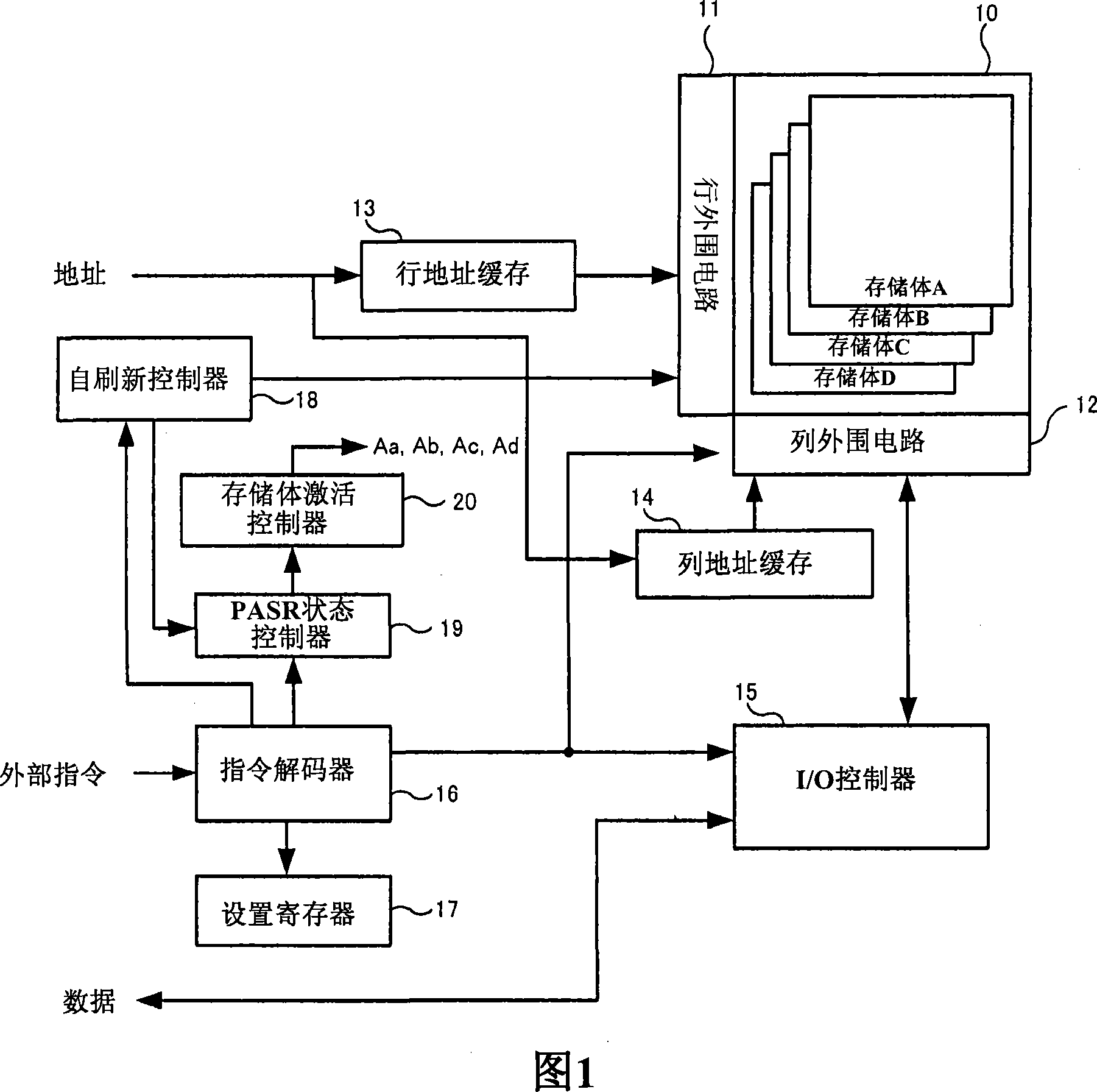

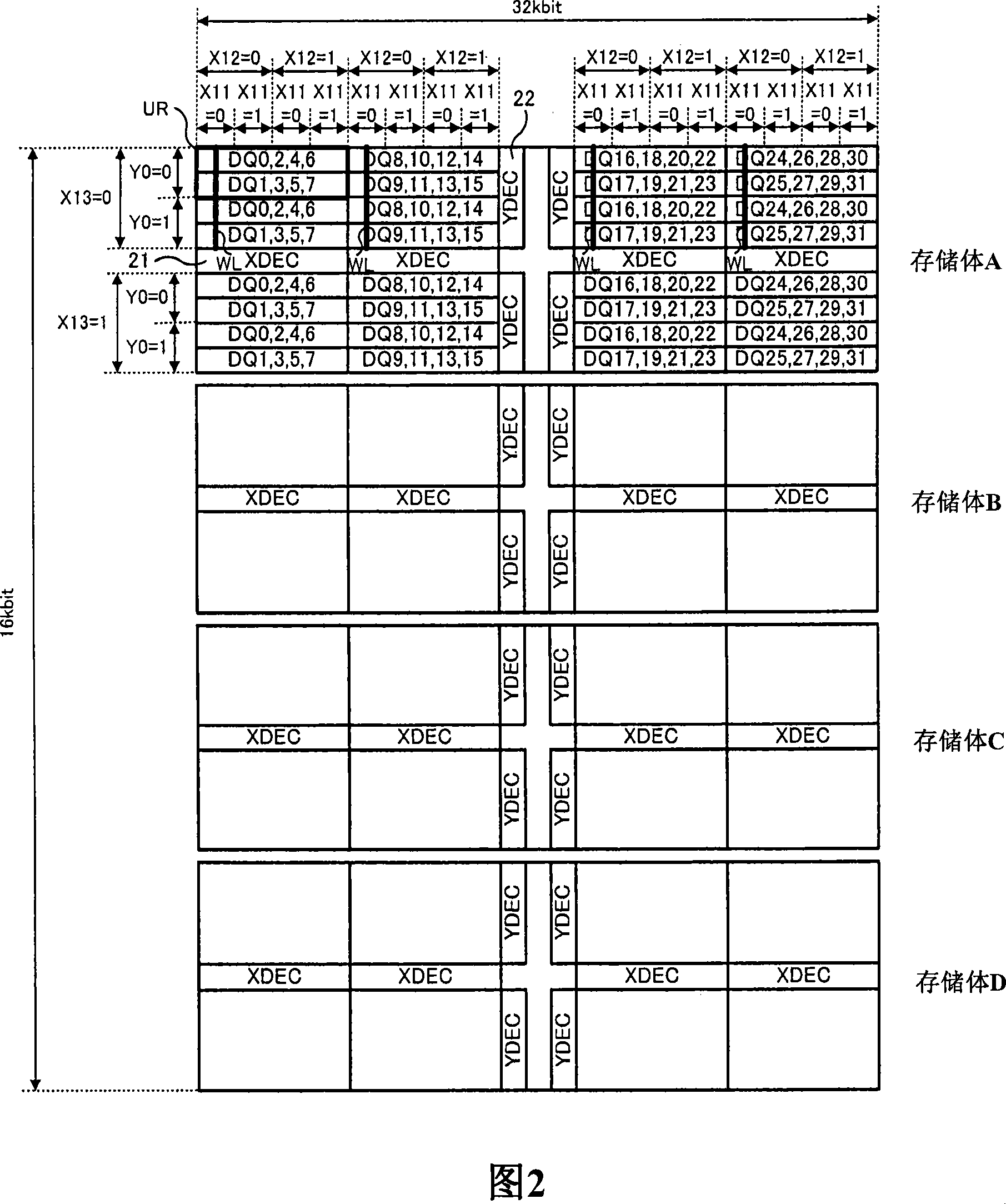

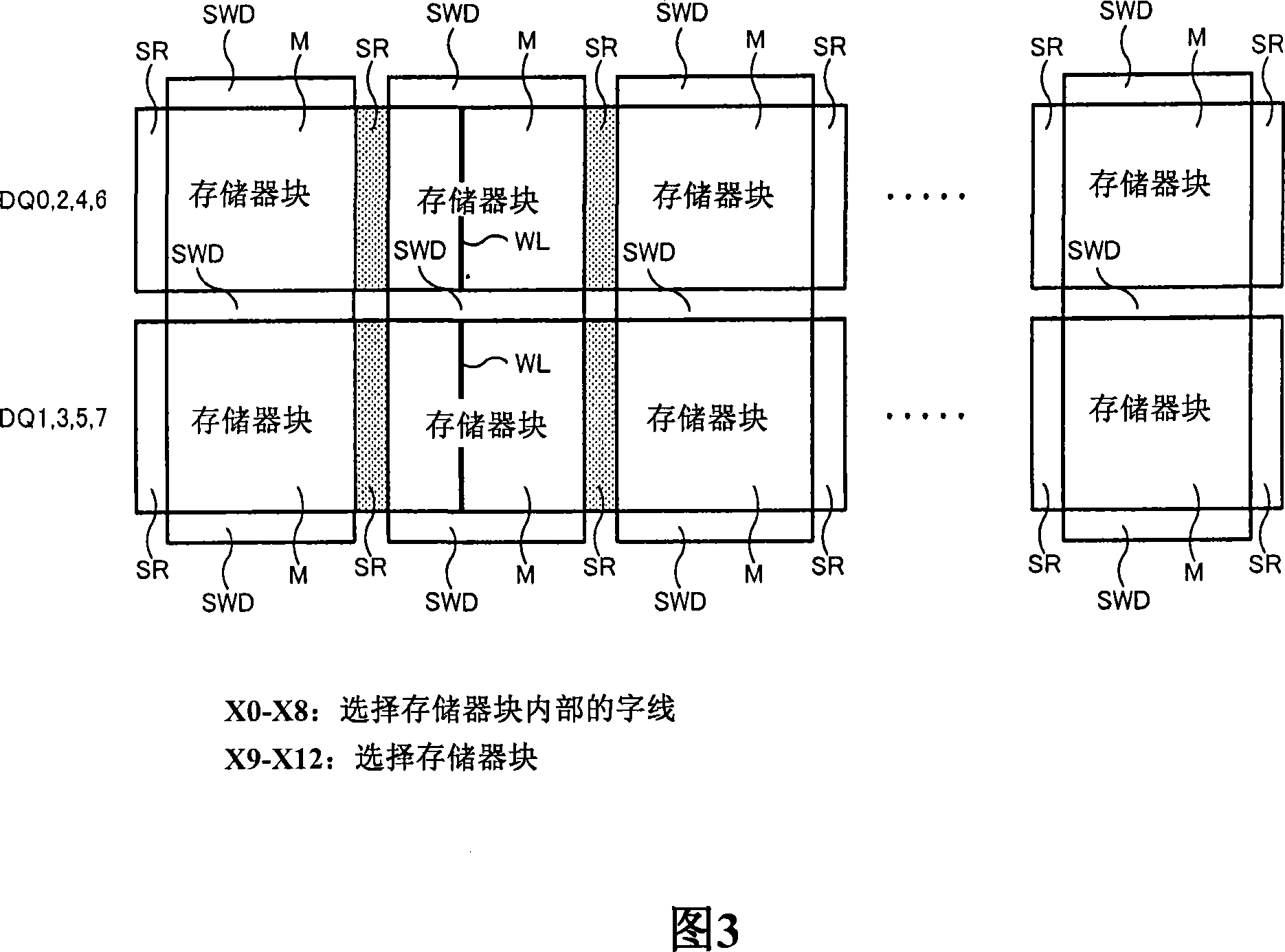

Semiconductor storing device, semiconductor device, storing system and renovating control method

A semiconductor memory device includes a memory cell array, wherein the memory cell is divided into a plurality of memory bodies; caches, each of which is used to store data of word line selected by line address; set registor, for setting data retention capacity so as to ensure a retention region for storing data during self-refresh cycle and a non retention region for non storing data during self-refresh cycle locate in a same memory bank; a refresh controller, for exporting refreshing line address with prescribed distance during self refreshing cycle and implementing refreshing operation to selective word line corresponding to the line address in enabled memory bank; and memory bank controller, for activating the memory bank when the selected work line is included in the retention region, and activating all memory banks when the selected work line is included in the non retention region.

Owner:ELPIDA MEMORY INC

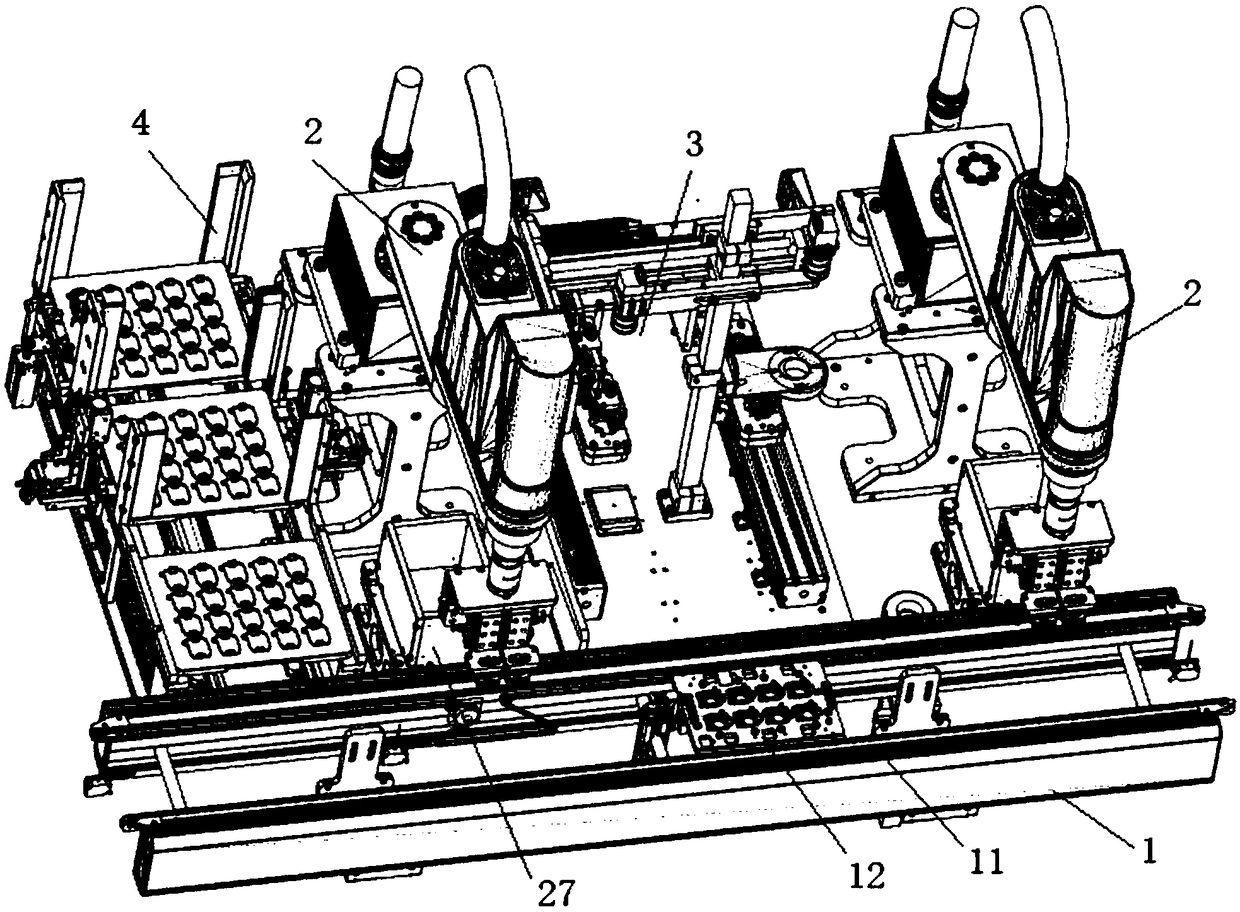

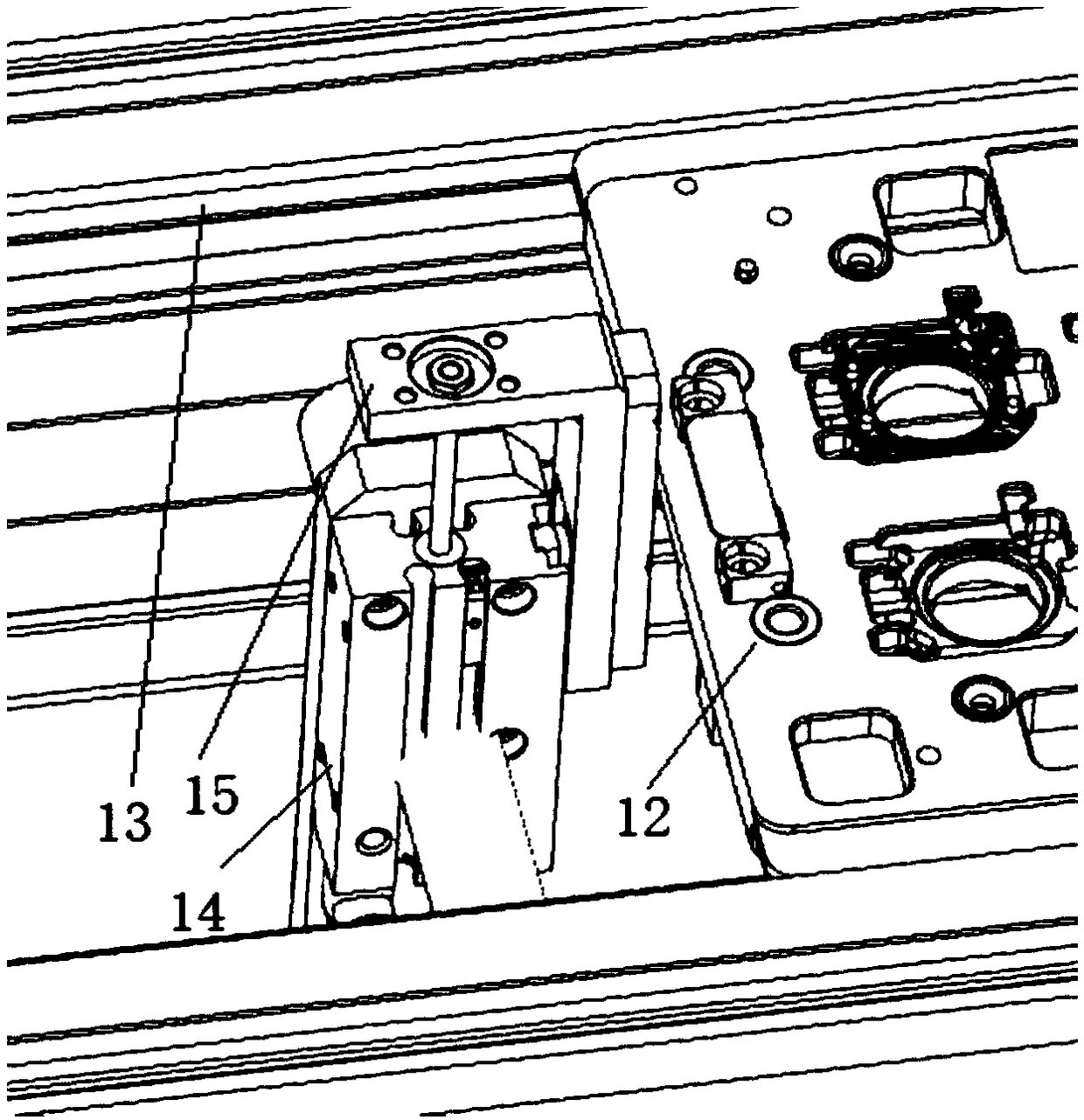

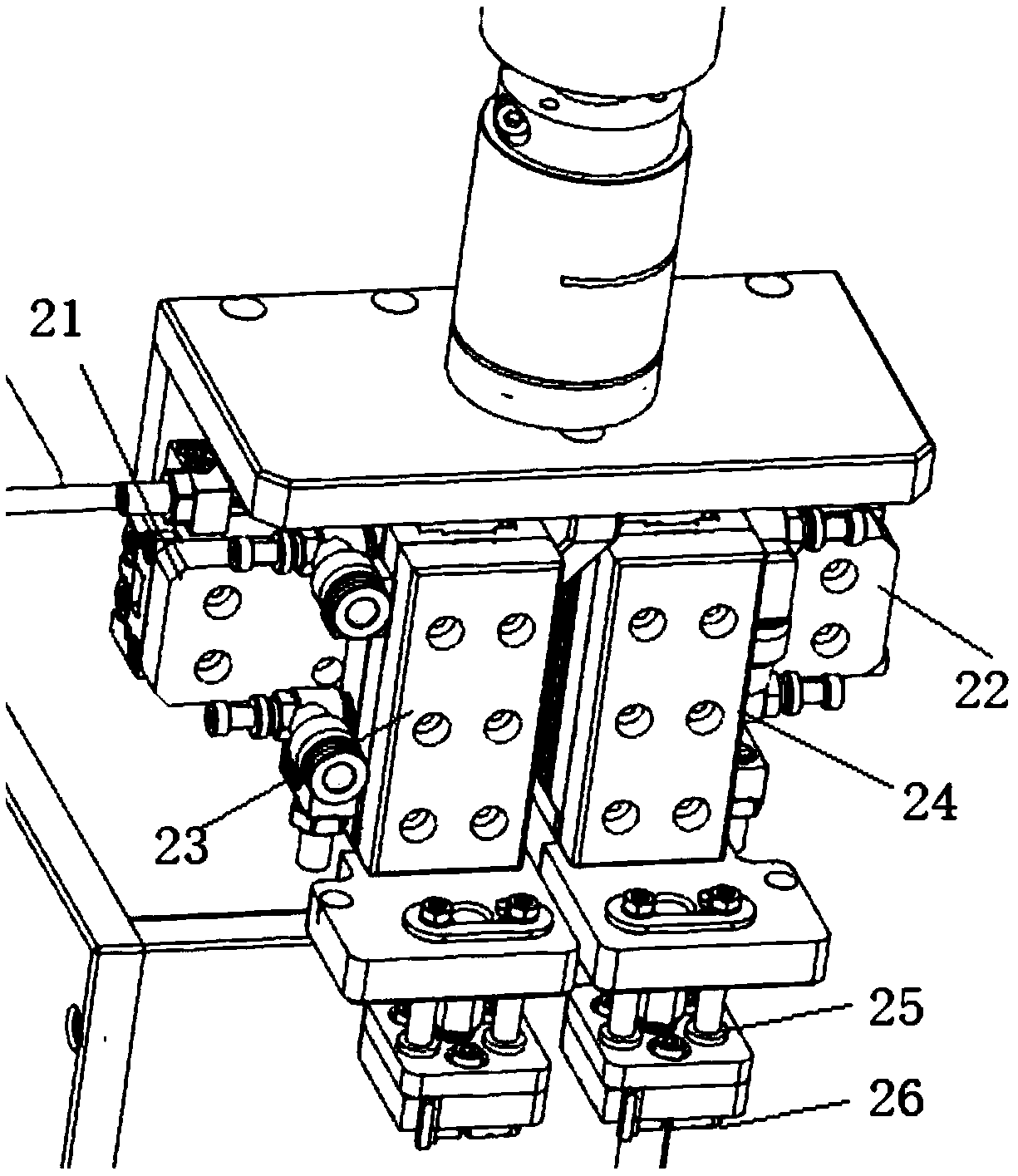

Automatic circulating feeding and material storing AOI detecting equipment

PendingCN109158335ARealize all-round data detection and analysisMaximizeSortingEngineeringMechanical engineering

The invention relates to automatic circulating feeding and material storing AOI detecting equipment. The automatic circulating feeding and material storing AOI detecting equipment comprises a feedingand transporting assembly, mechanical arm drawing assemblies, an AOI detecting assembly and a turnover carrier feeding bin assembly, wherein the AOI detecting assembly comprises lateral moving die sets which are symmetrically arranged, a longitudinal moving die set arranged on the symmetrical lateral moving die sets in a traversing manner, a sucker carrying die set located under the longitudinal moving die set, and CCD die sets which are arranged corresponding to the lateral moving die sets; the turnover carrier feeding bin assembly comprises a framework, a discharging region, an empty carriertemporary storage region, a full-material carrier temporary storage region and a turnover moving die set, wherein the discharging region, the empty carrier temporary storage region, the full-materialcarrier temporary storage region and the turnover moving die set are sequentially located on the framework; the turnover moving die set is used for orderly transferring product carriers from the empty carrier temporary storage region to a discharging region, and then to the full-material carrier temporary storage region. Through the adoption of the automatic circulating feeding and material storing AOI detecting equipment disclosed by the invention, products can be automatically circulated to be subjected to AOI detection and the operations of material storing and discharging.

Owner:KUNSHAN SYSTRONICS AUTOMATION TECH CO LTD

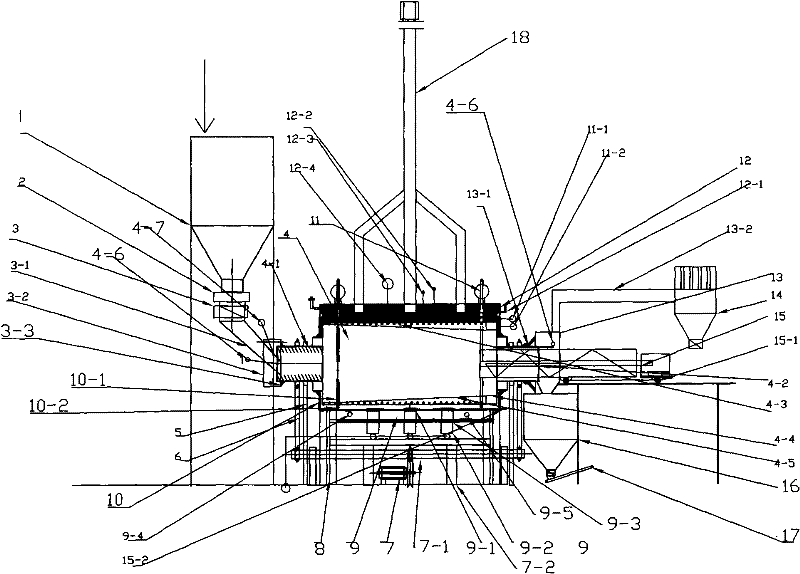

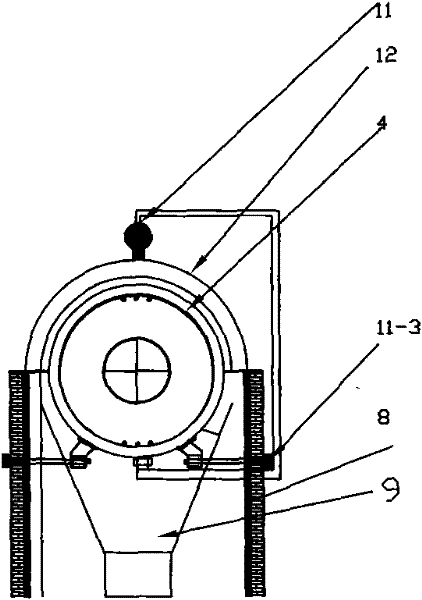

Carbonization-activation integrated activated carbon production apparatus

InactiveCN102649550AImprove controllabilityMaximizeCarbon compoundsChemical industryProcess equipmentCombustion chamber

The purpose of the invention is to provide a carbonization-activation integrated activated carbon production apparatus. The structure of a conventional activated carbon furnace is improved, so that the two-step method in which first carbonization and then activation are carried out on the activated carbon is changed into a manner that carbonization and activation are completed in one system, two-in-one furnace for short. The carbonization-activation integrated activated carbon production apparatus is characterized in that a movably connected steam jacket is added outside a rotary kiln, the bottom of the jacket is a firebox, the top of the jacket is an insulating water tank, steam pockets are arranged on the water tank, an automatic feeder is designed on one end of the rotary kiln, a discharge screw conveyer is designed on the other end of the rotary kiln, dried and weighed material is carbonized and activated and is fed from one end of the rotary kiln in a clockwise rotating manner, the activated material is discharged out from the other end of the rotary kiln in a counterclockwise rotating manner, the production is intermittent, the material is dried by residual heat after heat exchange, and intermediate steps are reduced. The process is suitable for the production of activated carbon with various activity requirements, and the stability of product quality is favorably enhanced, heat energy is effectively recycled, the production process is shortened, energy consumption is reduced, the heat efficiency is increased, and novel production process equipment is provided for the production of various specifications of activated carbon.

Owner:王全祥

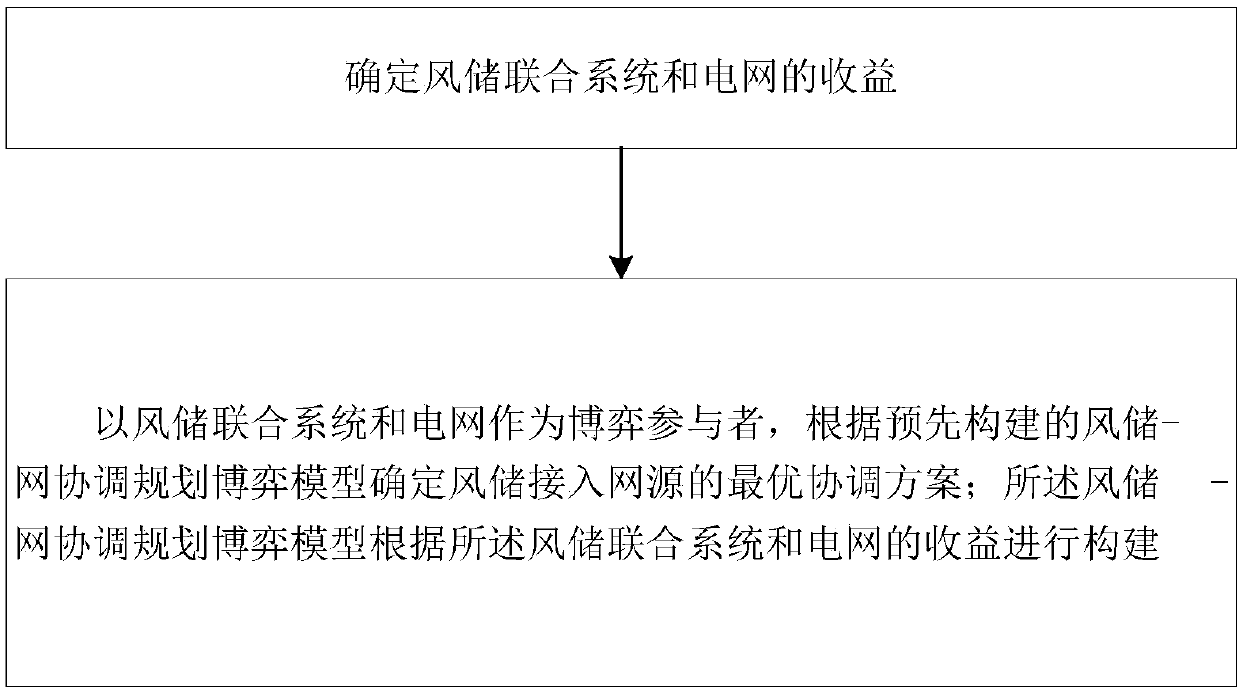

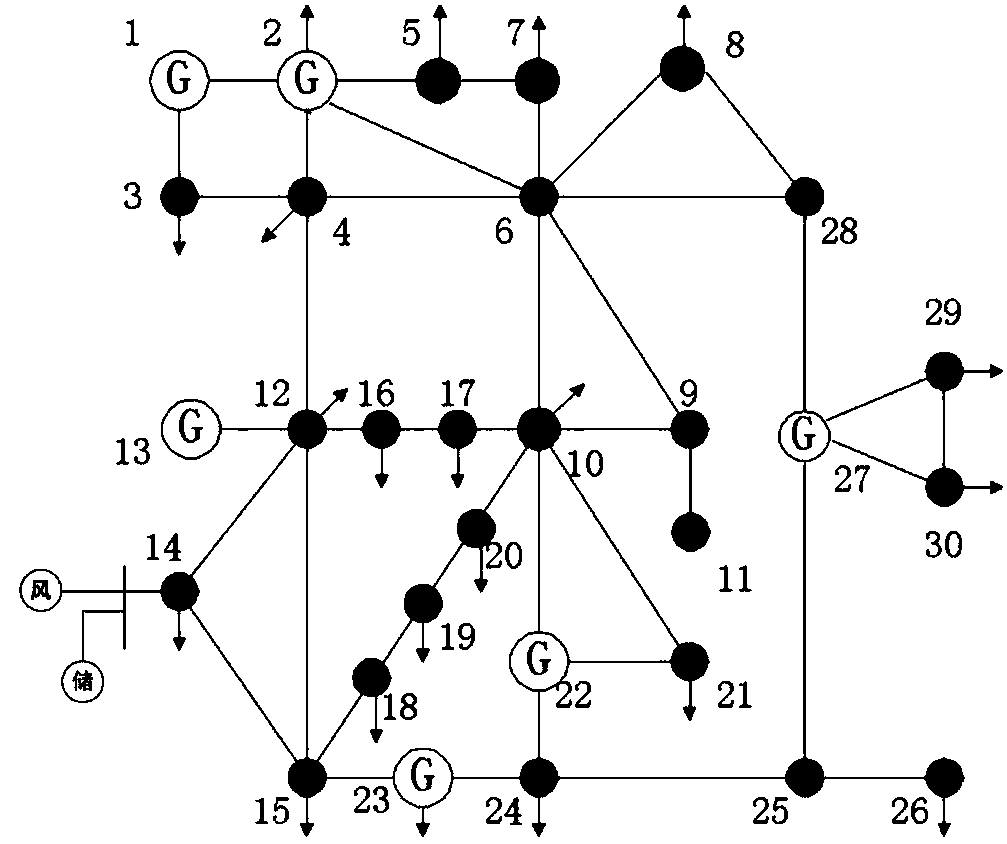

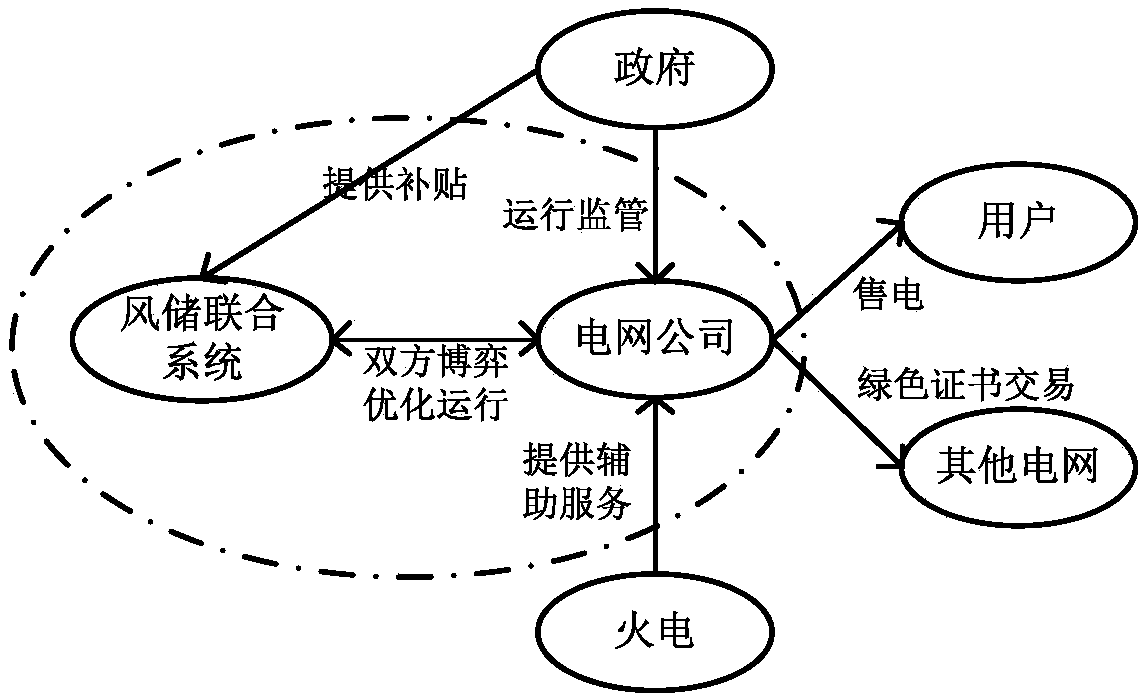

Coordination method and system for wind storage access network source

PendingCN108304961AAvoid blind configurationIncrease motivationSingle network parallel feeding arrangementsForecastingAccess networkElectricity

The invention relates to a coordination method and system for a wind storage access network source. The method comprises the steps that the benefits of a wind storage combined system and a power gridare determined; the wind storage combined system and the power grid are taken as game participants, and the optimal coordination scheme of the wind storage access network source is determined according to a pre-built wind storage-network coordination planning game model; and the wind storage-network coordination planning game model is built according to the benefits of the wind storage combined system and the power grid. According to the invention, in the market environment, the dynamic game planning of both sides of the wind storage-network is conductive to improving the enthusiasm of the power grid to absorb wind power, and is conductive to avoiding the blind configuration of energy storage; and an improved scheme is provided for source network uncoordination in the current planning of awind storage combined power plant.

Owner:BEIJING STATE GRID PURUI EXTRA HIGH VOLTAGE POWER TRANSMISSION TECH CO LTD +1

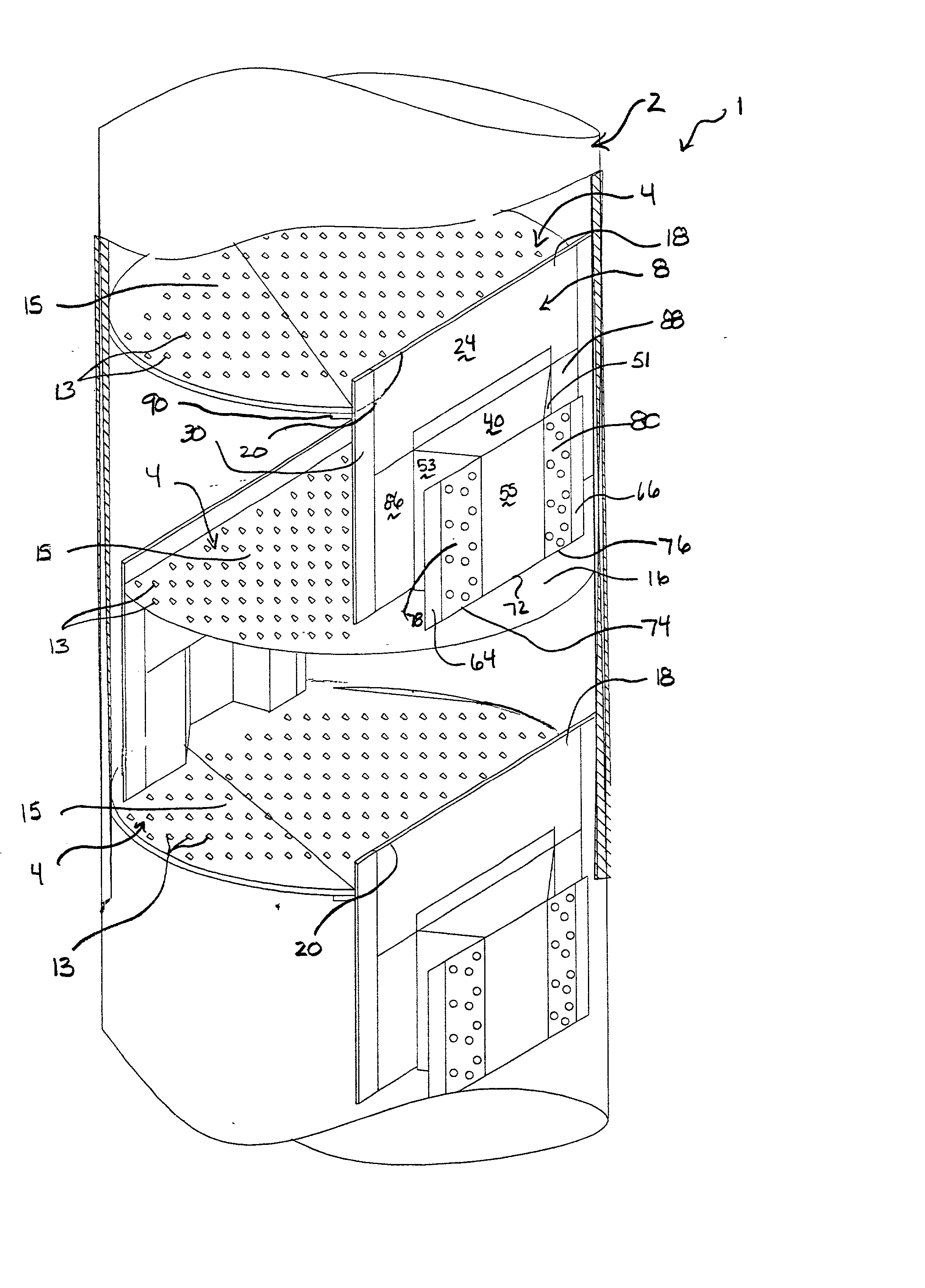

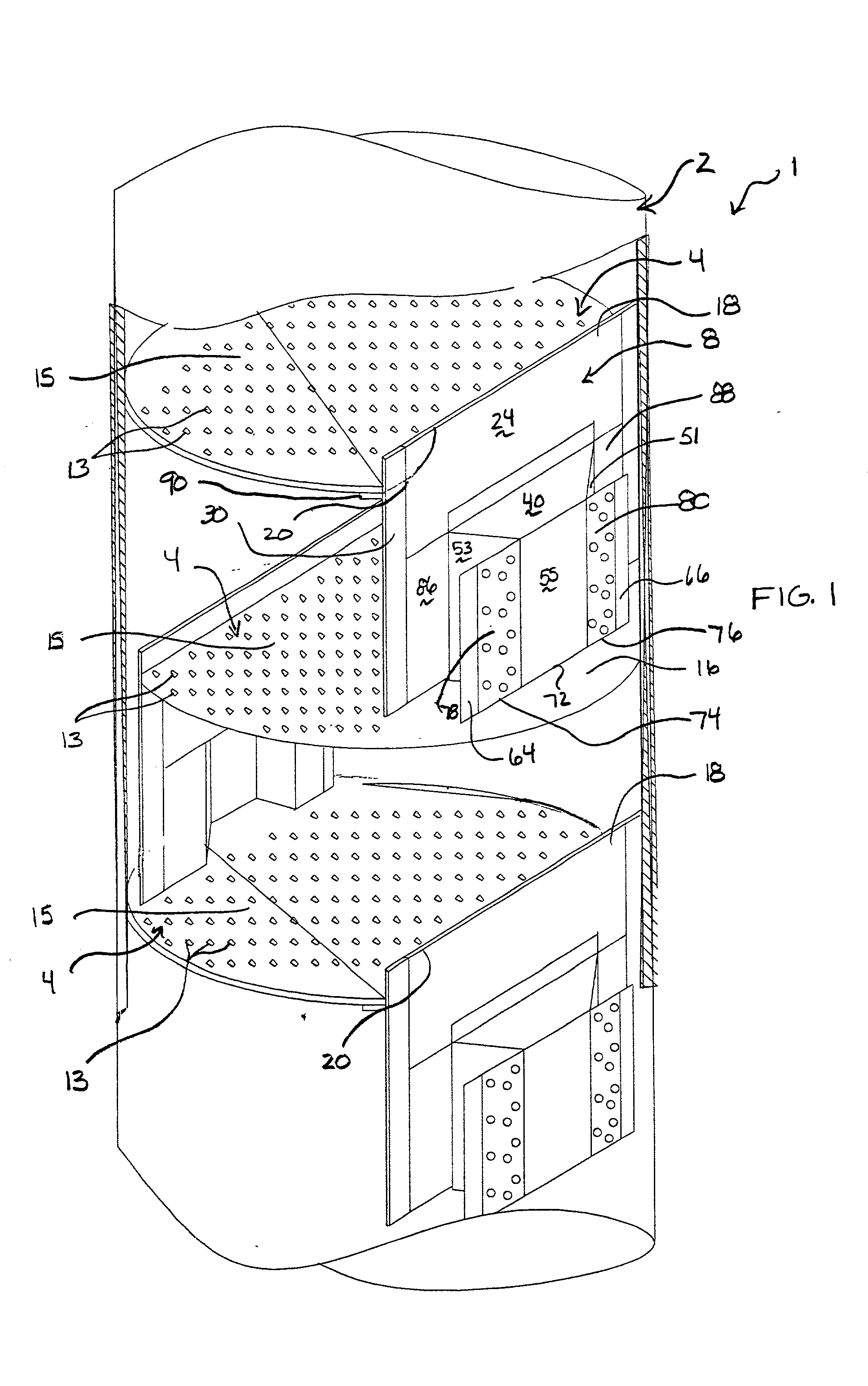

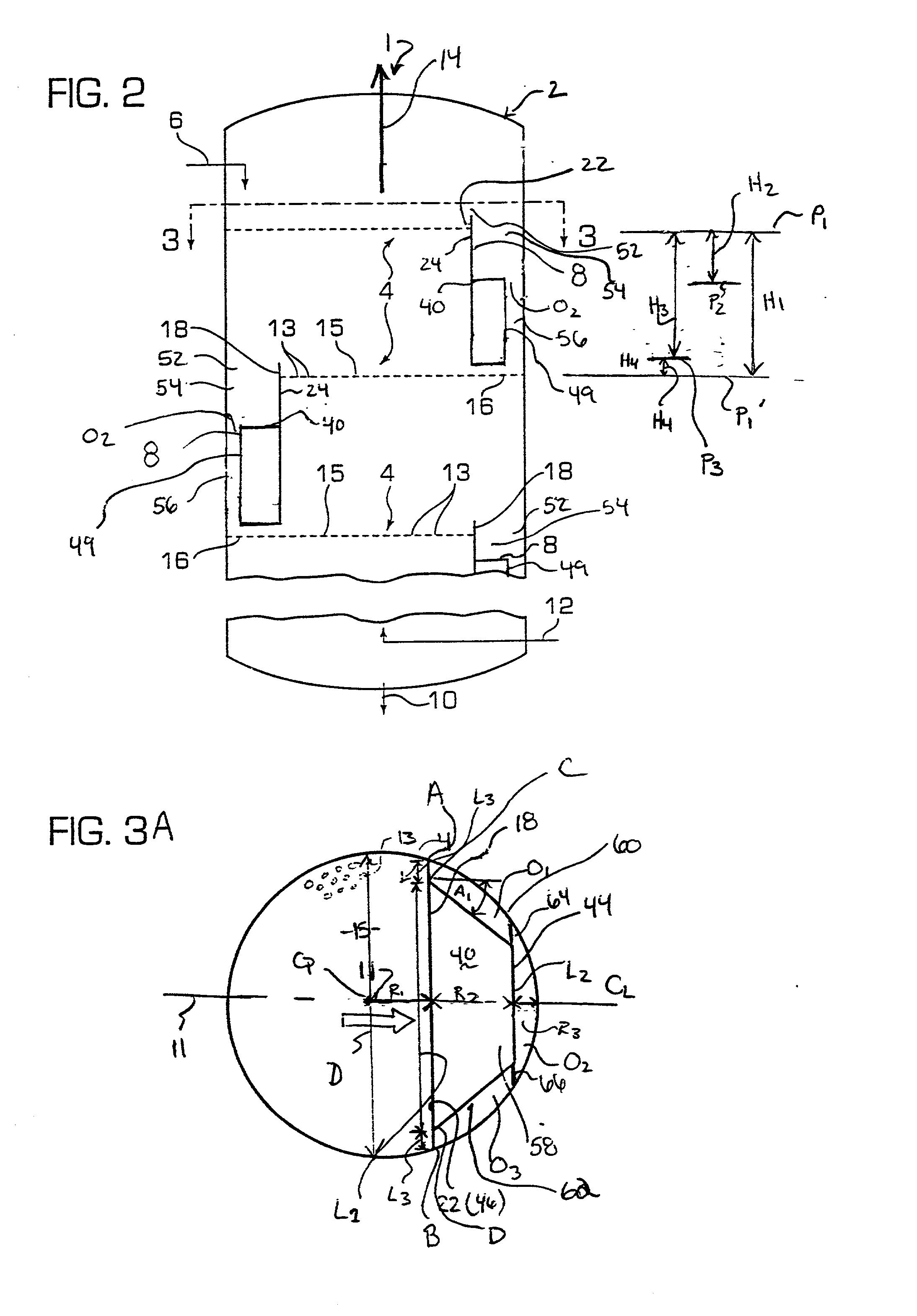

Stepped downcomer apparatus and vapor-liquid contact apparatus with same

A stepped downcomer apparatus for use in a vapor-liquid contact apparatus having an intermediate level step platform with a preferred tri-edge peripheral edge and corresponding step panels extending down from that edge to form a sealing step panel wall. As a preferred support device, extensions extend in chordal fashion out from the interior vertical edge of the opposite side step wall panels and either directly or indirectly by way of support bars into a supporting relationship with a tower of the vapor-liquid contact apparatus. A main panel extends up from the interior edge of the platform and up to the above positioned tray. A weir may extend above the above positioned tray that is an extension of the main panel. This main panel is attached to the support bars and supports the step platform and walls and extensions either alone or with added support members. A tray support ledge extends inwardly from the downcomer to provide support to the upper tray. The liquid-vapor mix contacts the step platform after passing over the weir, and off from which fluid travels both along the central axis of flow and obliquely off the opposite side panels. At opposite ends of the weir, the liquid flows directly into contact with the inlet region of the lower tray, by-passing the platform. The opposite side panel walls can slope outward to vary the downcomer lower pass through volume. An embodiment features chordal wing extensions with pressure equalization openings that extends out from opposite sides of the step wall panel also into a support relationship with the tower. The lower edge of the panels of the wall and the lower edge of the extensions control the flow of fluid as it travels under the lower edging from the inlet side of the downcomer apparatus to the active area of the tray. The relative level of the lower edges can be varied to suit the intended use. Additional or replacement downcomer structural supports include vertical support members extending from a step panel to a lower tray either in the form of support brackets or tiplet extensions.

Owner:SULZER MANAGEMENT AG

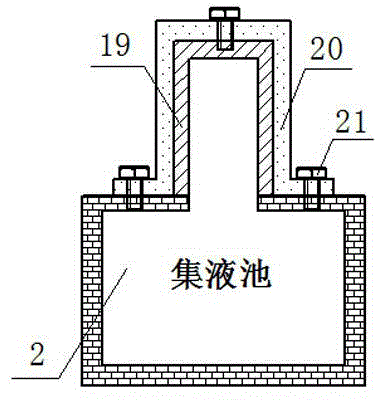

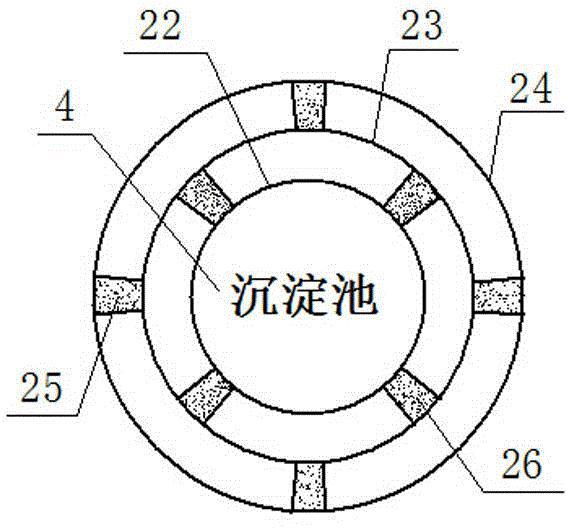

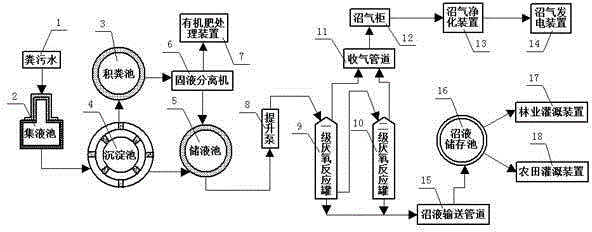

Large-scale piggery dung treatment ecological circulation system

ActiveCN104817170AAvoid emissionsIn line with the development conceptBio-organic fraction processingClimate change adaptationOxidation resistantSlurry

The invention discloses a large-scale piggery dung treatment ecological circulation system which comprises a dung collection unit, a solid-liquid separation unit, an anaerobic fermentation unit, a biogas utilization unit and a biogas slurry utilization unit. The dung collection unit comprises a slurry collection tank, a dung accumulation tank, a settling tank and a slurry storage tank, the solid-liquid separation unit comprises a solid-liquid separator and an organic fertilizer treatment device, the anaerobic fermentation unit is a multistage anaerobic reaction device and comprises a primary anaerobic reaction tank and a secondary anaerobic reaction tank, the biogas utilization unit comprises a biogas cabinet, a biogas purification device and a biogas power generation device, the biogas slurry utilization unit comprises a biogas slurry storage tank, a forestry irrigation device and a farmland irrigation device, and high-temperature oxidation resistant plastic soft protection layers are arranged above the dung accumulation tank and the slurry storage tank. Dung water is fermented to generate biogas and biogas slurry, organic fertilizers are generated after solid-liquid separation, the possibility of secondary pollution caused by waste gas is avoided, waste is effectively and sufficiently reused, and comprehensive utilization rate is increased.

Owner:MUYUAN FOODS CO LTD

Method for preparing dimethylbenzene through methylation and transalkylation

ActiveCN103121912AMaximizeHydrocarbon by metathesis reactionHydrocarbon by hydrocarbon and non-hydrocarbon condensationMethyl benzeneReaction temperature

The invention relates to a method for preparing dimethylbenzene through methylation and transalkylation, and mainly aims to solve the problems that the yield of dimethylbenzene is determined by the link relative ratio of methyl benzene in raw materials, and when a heavy aromatic raw material is insufficient, the output of the dimethylbenzene is low and a lot of byproduct benzene is generated at the same time in the existing toluene disproportionation or toluene disproportionation and transalkylation technologies. The problems are well solved by adopting the technical scheme which is s follows: the method comprises the following steps of: by using a methylation agent and aromatic hydrocarbons which has less than 12 Cs and does not contain or only contains a small amount of dimethylbenzene as raw materials, under the condition that the reaction temperature is 300-500 DEG C, the reaction pressure is between the normal pressure and 10.0MPa and the weight space velocity of the raw materials is 0.3-10h<-1>, contacting the raw materials with a solid acid catalyst to ensure that an alkylation reaction is performed on methanol and the aromatic hydrocarbons, and performing transalkylation among the aromatic hydrocarbons to obtain the dimethylbenzene. The method can be used in industrial production of dimethylbenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

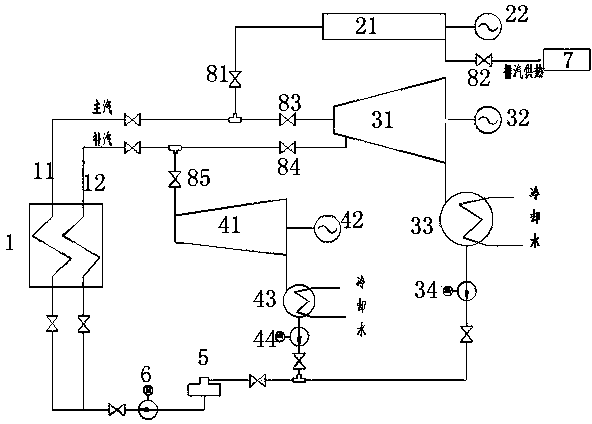

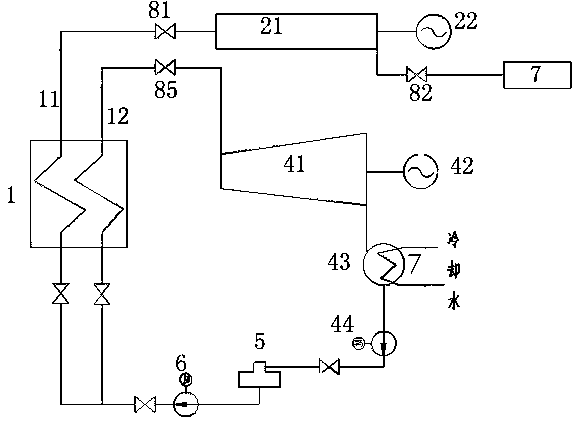

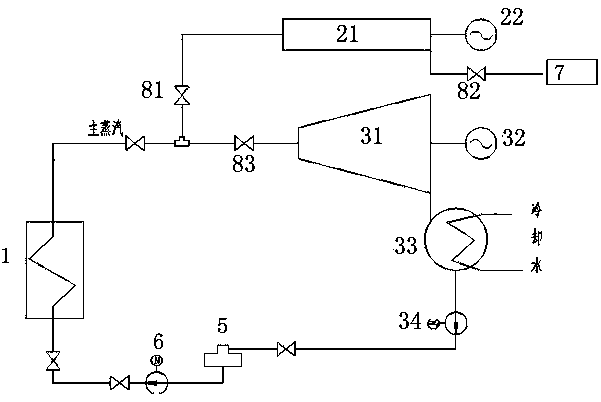

Novel waste heat recovery combined heating and power system

ActiveCN103836604AFlexible designFlexible schedulingEnergy industrySteam generation plantsEconomic benefitsProcess engineering

The invention provides a novel waste heat recovery combined heating and power system. Main system equipment includes a dual-pressure waste heat boiler, a first generating set, a second generating set, a third generating set, a condenser, a condensate pump, an oxygen extractor, a water supply pump and the like. The first generating set is connected with a high-pressure steam pipeline of the dual-pressure waste heat boiler to form a heating and power system. The second generating set is connected with the high-pressure steam pipeline and a low-pressure steam pipeline to form two generating loops. The third generating set is connected with the low-pressure steam pipeline of the dual-pressure waste heat boiler to form a generating loop. The novel waste heat recovery combined heating and power system can be flexibly designed and scheduled to achieve combined heating and power supply according to actual situations and specific needs; for users with highly varying seasonal heating needs or heat loads, steam recovered by the waste heat boiler can be fully utilized, and energy resources can be maximally utilized; the novel waste heat recovery combined heating and power system is simple, reliable and good in economic benefit.

Owner:SHANGHAI BAOSTEEL ENERGY TECH

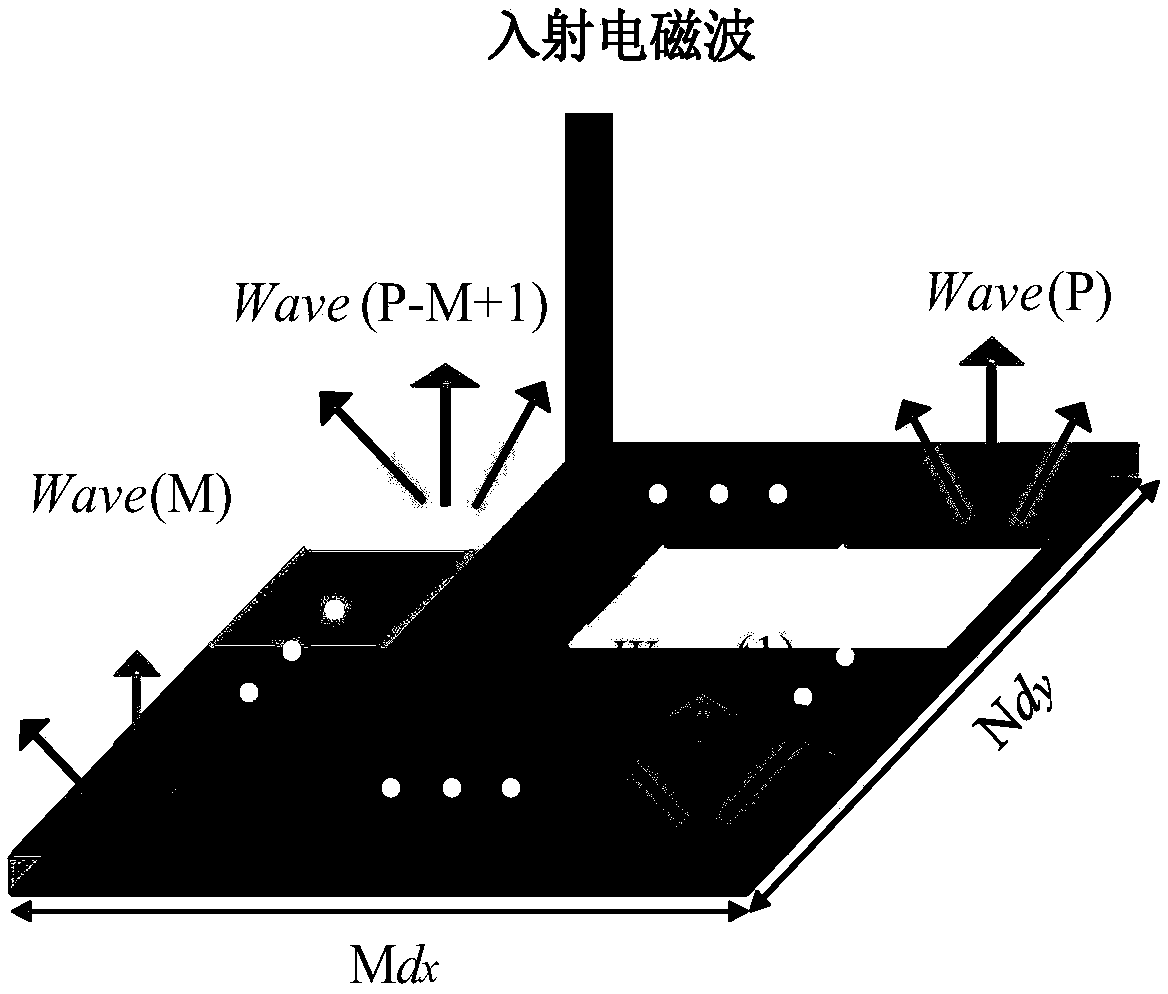

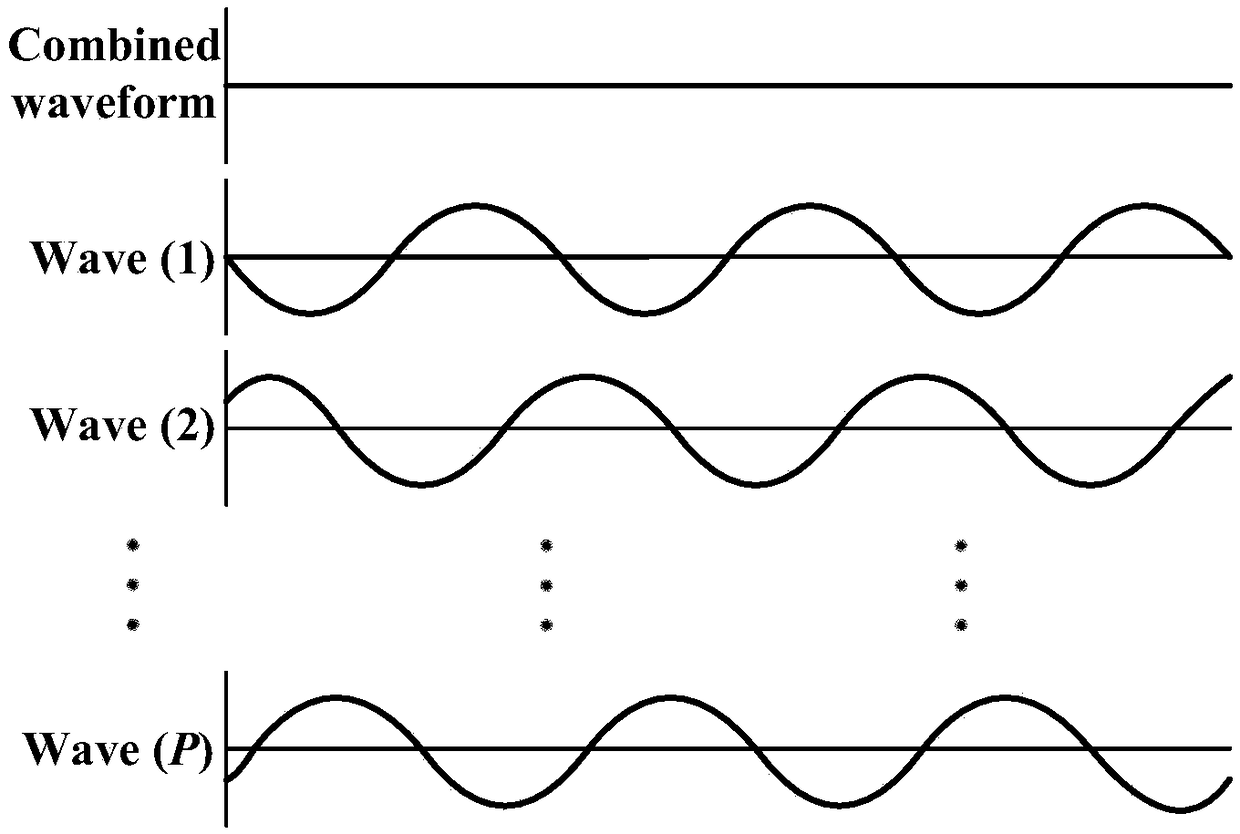

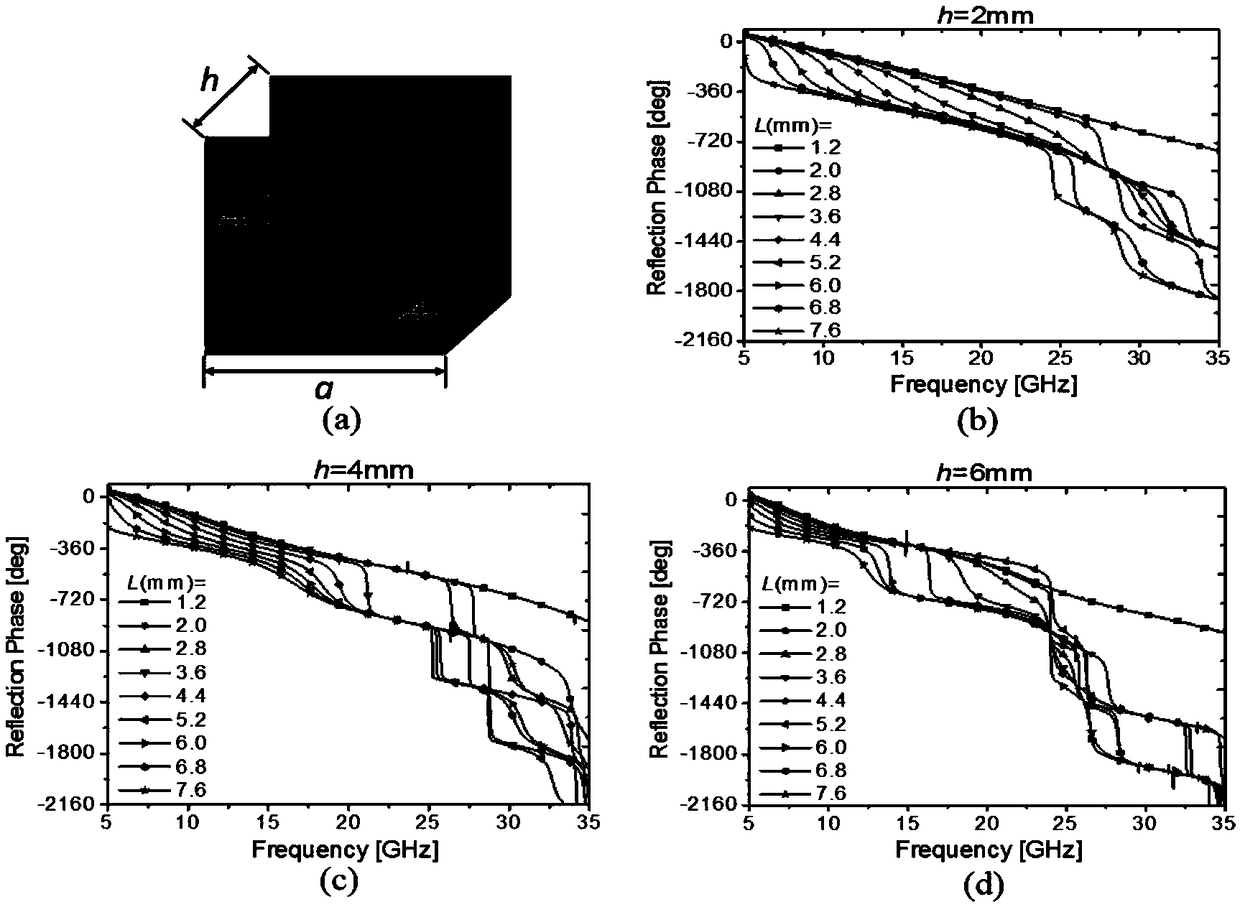

Ultra-wideband-radar-based scattering-cross-section-reducing chessboard structure and ultra-wideband radar

ActiveCN108957429ALow reverse RCS valueLow dual station RCS valueRadio wave reradiation/reflectionScattering cross-sectionDielectric plate

The invention provides an ultra-wideband-radar-based scattering-cross-section-reducing chessboard structure and an ultra-wideband radar. The chessboard structure comprises a metal floor and M*N finiteaperiodic tile units fixed on the metal floor. The finite aperiodic tile units consist of dielectric plates and metal pasters arranged on the dielectric plates; and the metal pasters include metal ring pasters distributed in an array manner.

Owner:COMMUNICATION UNIVERSITY OF CHINA

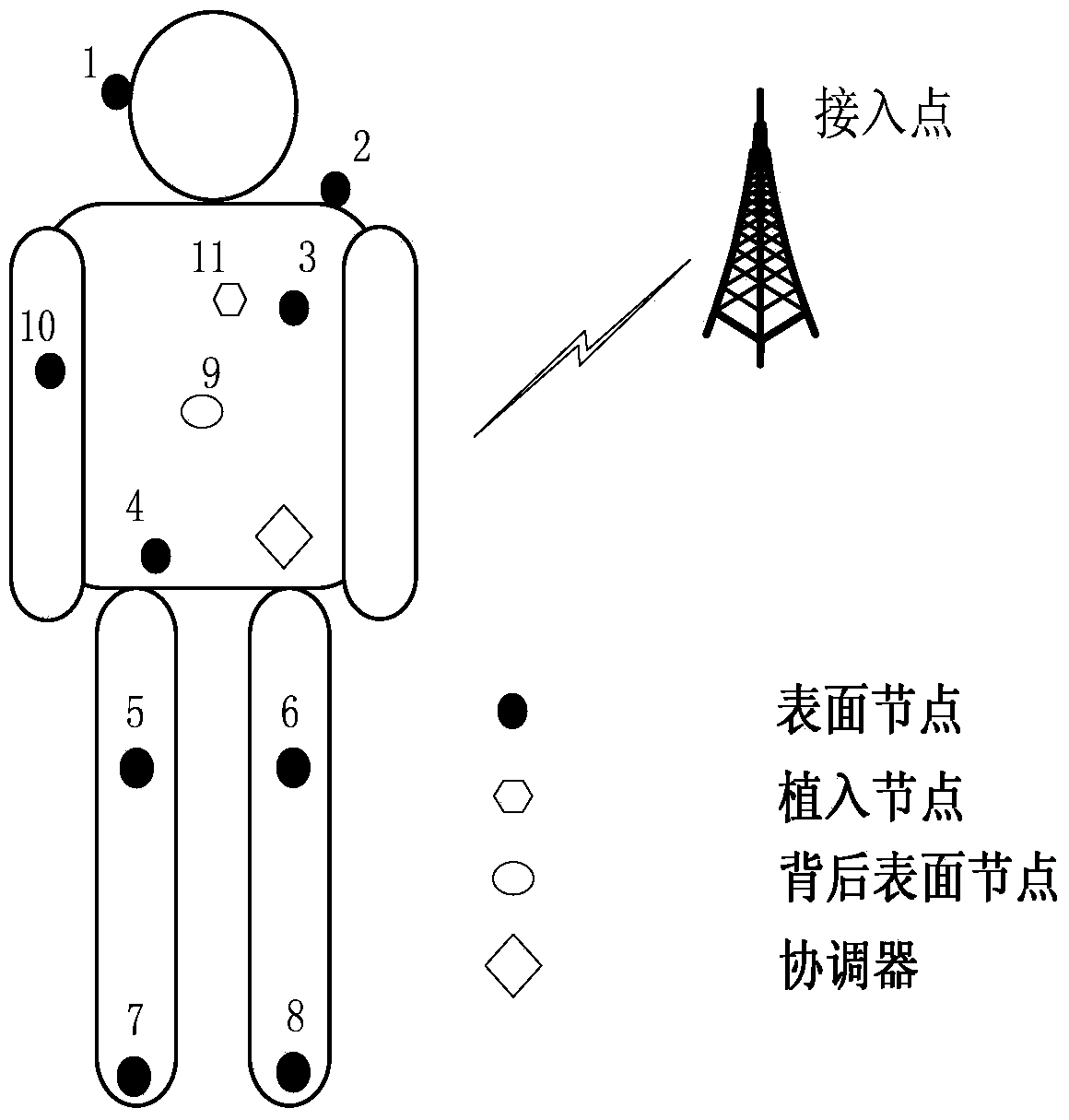

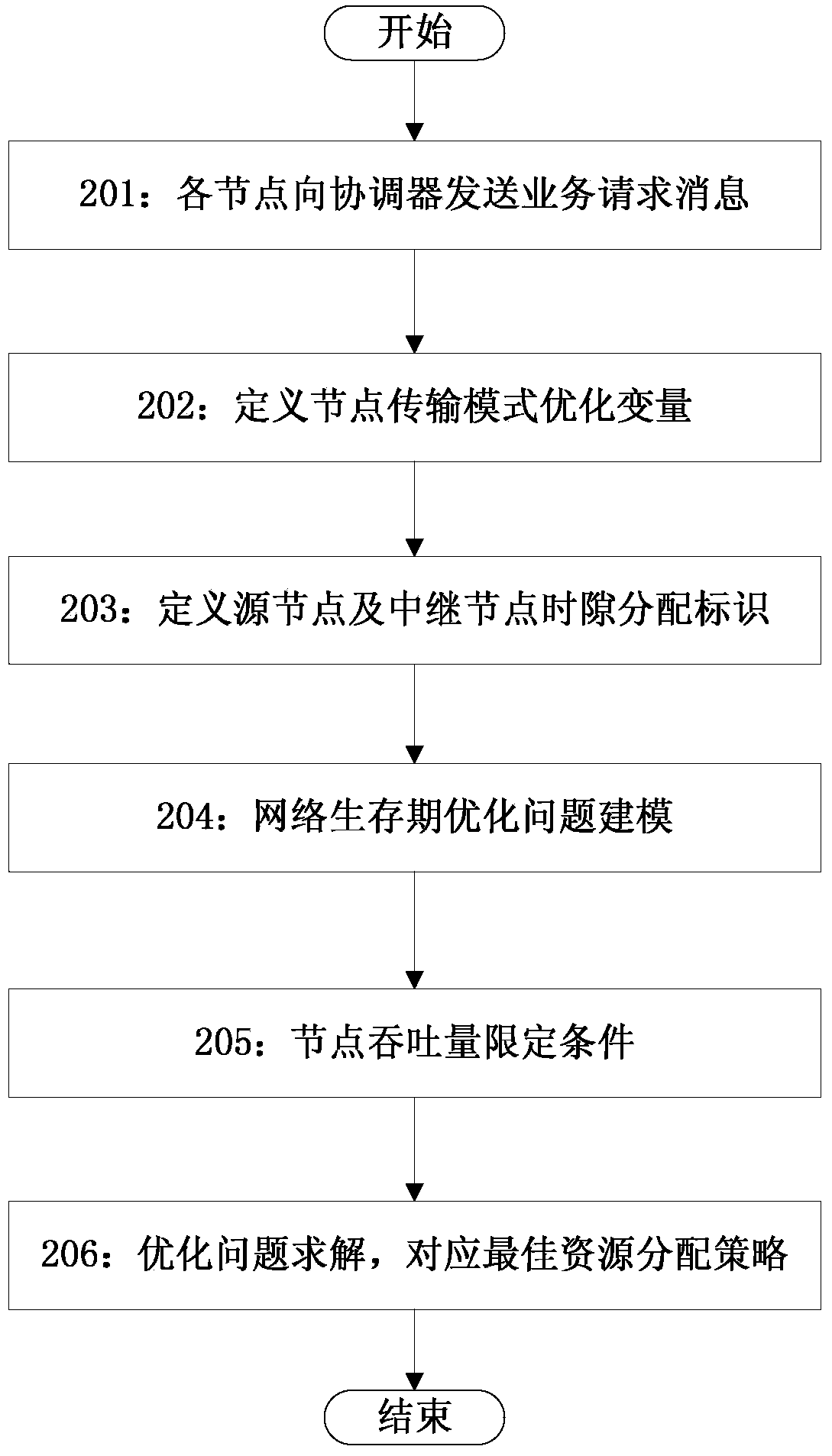

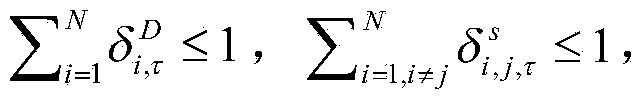

Body area network resource joint optimization scheduling method based on network lifetime maximization

ActiveCN103906248ALifetime maximizationMaximizeEnergy efficient ICTHigh level techniquesAs DirectedBody area network

The invention discloses a body area network resource joint optimization scheduling method based on network lifetime maximization, and belongs to the technical field of wireless body area network resource scheduling. The method includes the steps that nodes for carrying out information transmission in a body area network send out a service request message to a coordinator; the coordinator uniformly optimizes a scheduling network and node resources on the basis of a network lifetime maximization rule, determines information transmission modes of the nodes as direct transmission or relay cooperation, selects relay nodes for the nodes in the cooperative transmission mode in an optimized mode, and distributes and sends time slots and transmission power for source nodes and cooperative nodes in an optimized mode. According to the method, service characteristics of the nodes and the utilization rate of network time slot resources are fully taken into consideration, the time slots and the power are distributed and sent for the nodes on the basis of the network lifetime maximization rule in the optimized mode, the cooperative relay nodes are selected for the nodes needing relay cooperation in an optimized mode, and maximization of network lifetime is achieved.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

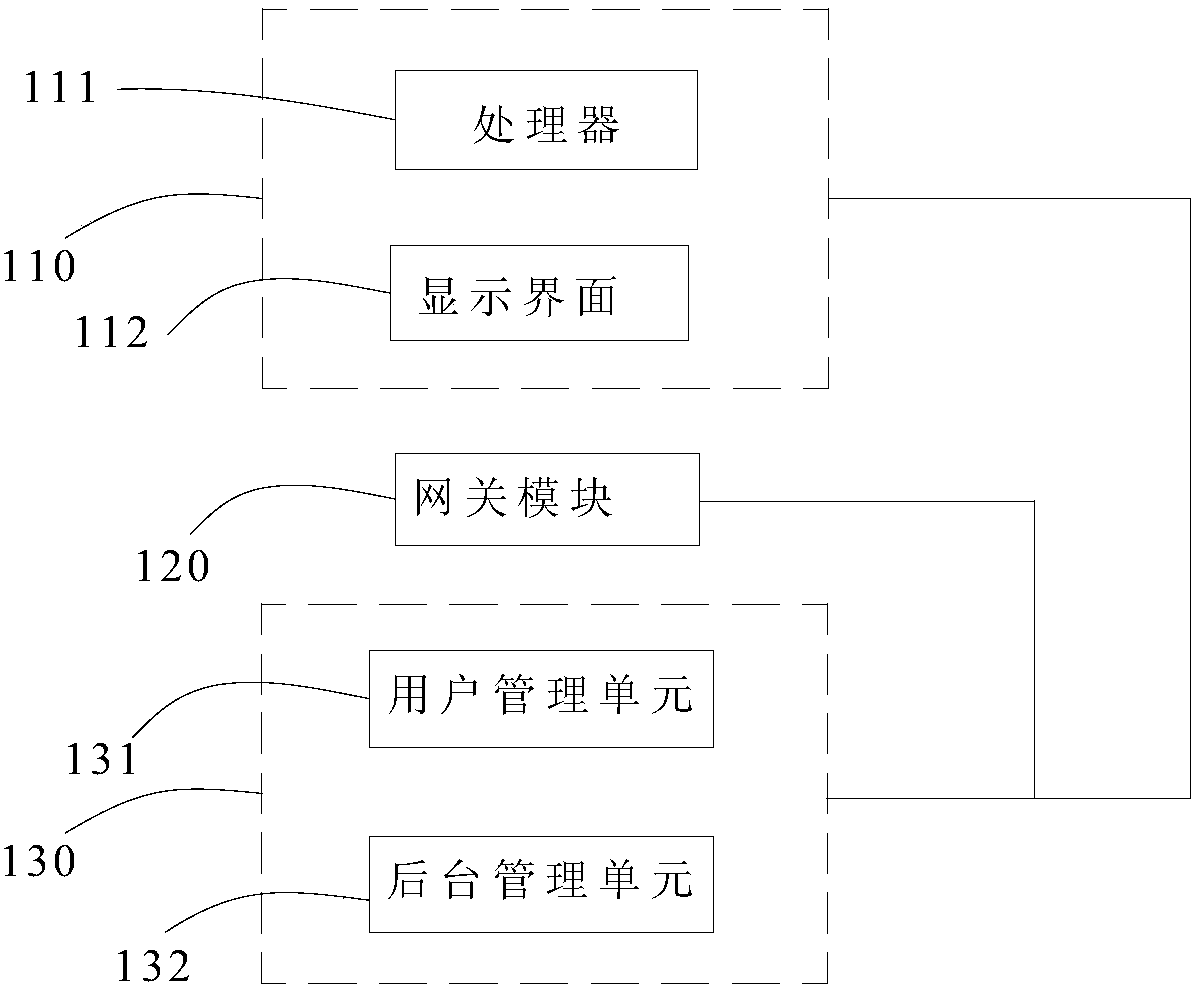

Application programming interface service device and application programming interface service system

PendingCN108111629AMaximizeReasonable useDigital data authenticationTransmissionService systemCentralized management

The invention provides an application programming interface service device comprising a gateway module and a background management module, the gateway module verifies a received application programming interface resource call request and calls a corresponding application programming interface resource in a corresponding server according to the verified application programming interface resource call request; the background management module is configured to receive issue information of the application programming interface resource and audit the received issue information of the application programming interface resource. The invention further provides an application programming interface service system. The application programming interface service system can perform centralized management on the application programming interface resources provided by application programming interface resource issuer, and provide an application programming interface resource issuing, searching and subscription platform for the requesters of the application programming interface resources.

Owner:BOE TECH GRP CO LTD

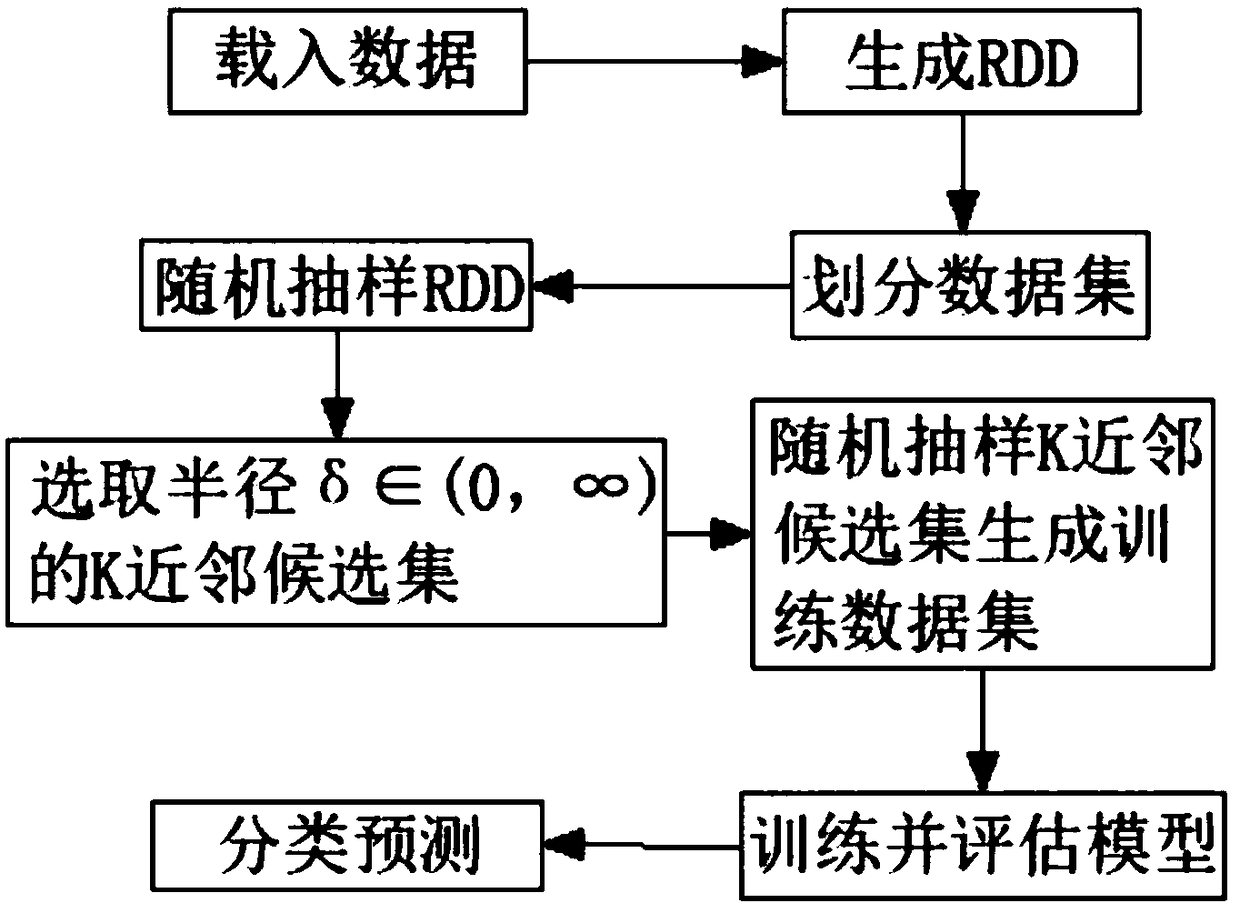

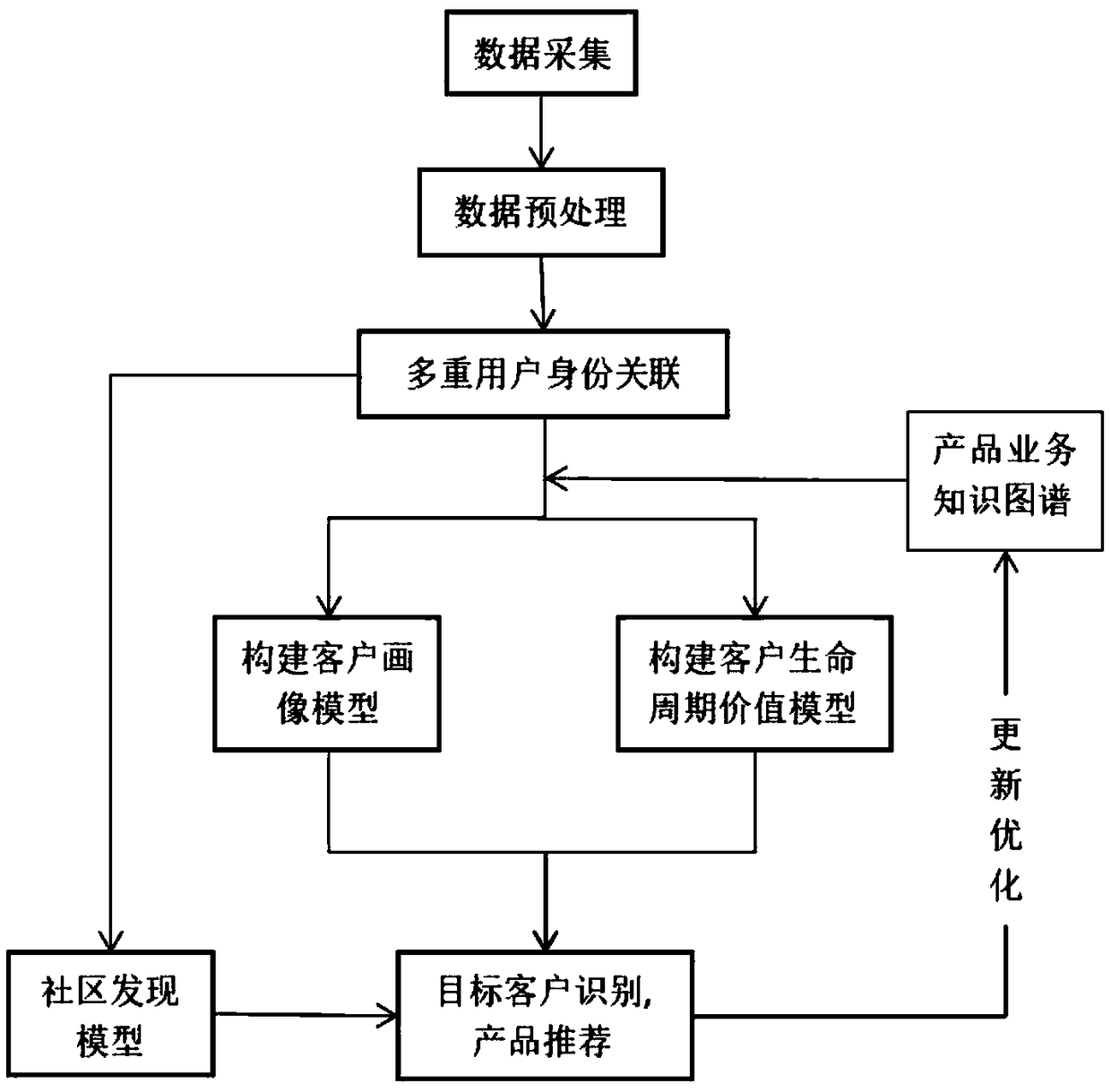

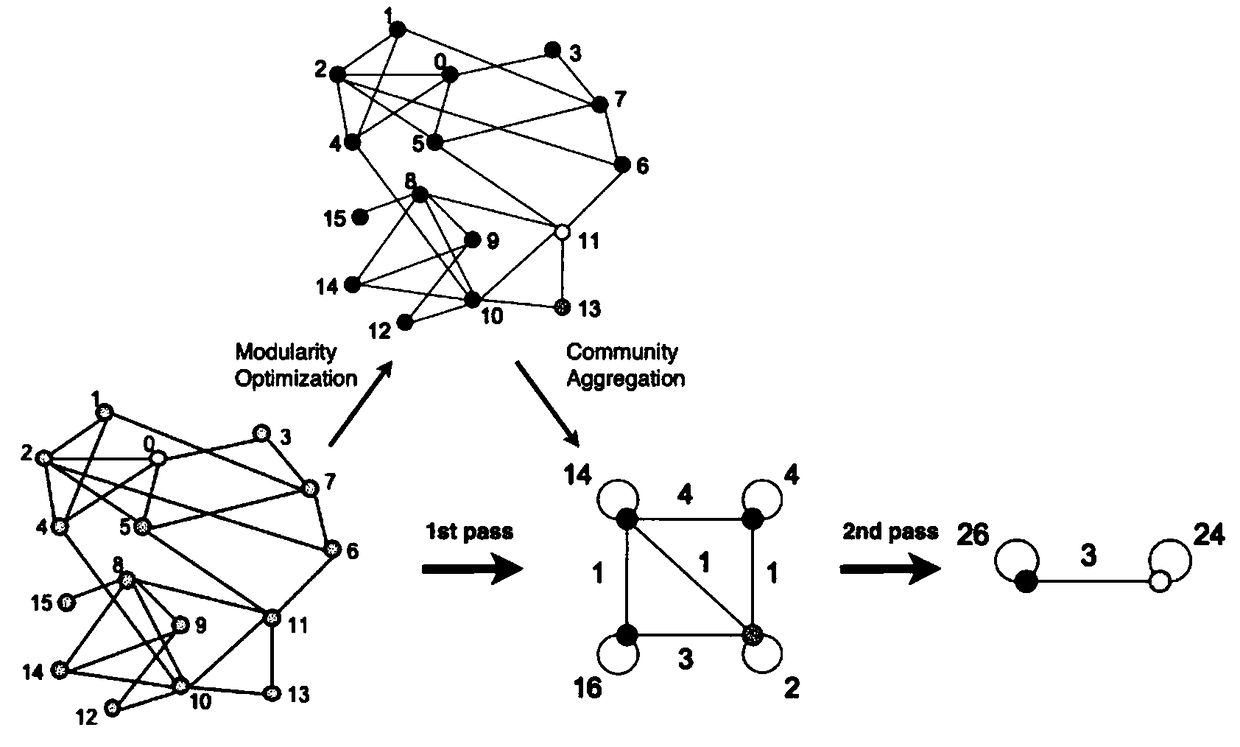

A closed-loop target customer identification method based on spark big data

InactiveCN109087140AEasy to knowEasy to analyzeCharacter and pattern recognitionBuying/selling/leasing transactionsClosed loopData acquisition

The invention relates to the technical field of Spark big data processing, in particular to a closed-loop target customer identification method based on spark big data, comprising the following steps:S1, data acquisition; S2: data preprocessing; S3: multiple user identity association; S4: constructing a customer portrait model; S5: constructing a customer life cycle value (CLV) model: according to the existing research, the customer life cycle value (CLV) model of the system includes customer current value (CCV) and customer expected value (CFV); S6: constructing a Community Discovery Model:the model adopts a Fast Unfolding algorithm based on Spark GraphX parallel graph computation, and optimizes Modularity value continuously to mine the community where the customer is located; S7: Product recommendations based on random forests. The invention can subdivide the customers, which is beneficial for the enterprise to locate and identify the target customers, and utilizes the limited resources to develop the users and potential users with high value.

Owner:GUANGZHOU MARITIME INST

Blast furnace hot slag microcrystalline glass and preparation method thereof

The invention discloses a blast furnace hot slag microcrystalline glass and a preparation method thereof. The blast furnace hot slag microcrystalline glass comprises the following raw materials by mass percentage: 50-70% of liquid blast furnace slag, 10-30% of fly ash, 2-7% of lithium carbonate, 3-8% of sodium carbonate, 3-5% of sodium fluosilicate, 1-5% of zirconium oxide, 3-6% of titanium dioxide, 0.01-1% of arsenic trioxide, 0.01-1% of antimony oxide, 0.01-3% of phosphorus pentoxide, 0.01-1% of cesium oxide, and 0-2% of a colorant. The preparation method mainly includes: putting the raw materials except liquid blast furnace slag into an auxiliary material melting tank to conduct heating and melting, letting the treated raw materials and the liquid blast furnace slag enter a mixing tank of the slagging furnace together, then making a high-temperature melt enter a melting tank, and then letting the high-temperature melt enter a material channel, subjecting the melt flowing out of the material channel to calendaring molding to obtain a semi-finished glass sheet; and then carrying out annealing and crystallization treatment, thus obtaining the microcrystalline glass.

Owner:宝钢矿棉科技(宁波)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com