Novel waste heat recovery combined heating and power system

A technology of waste heat recovery and combined heat and power supply, which is applied in lighting and heating equipment, steam engine devices, steam generating devices, etc., can solve problems such as energy waste, high energy and low use, water quality and heat energy waste, and achieve good economic benefits. Realize the effect of energy utilization and system simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

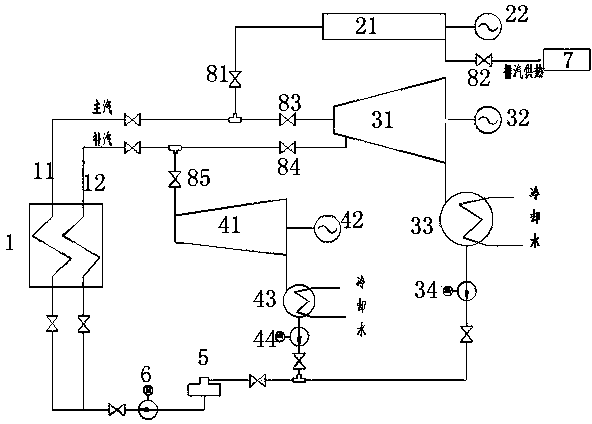

[0050] refer to figure 1 , the new waste heat recovery combined heat and power system includes a waste heat boiler 1, a first generating set, a second generating set, a first condenser 33, a first condensate pump 34, a third generating set, a second condenser 43, a second Condensate water pump 44, deaerator 5 and feed water pump 6, as well as the steam and water pipelines and auxiliary equipment connecting the various components; in addition, in this embodiment, the waste heat boiler 1 adopts a dual-pressure waste heat boiler, and the water in the waste heat boiler 1 is used in industrial Under the action of waste heat, high-pressure steam and low-pressure steam are generated, which are output from high-pressure steam pipeline 11 and low-pressure steam pipeline 12 respectively.

[0051] Specifically, the first generating set includes a first steam turbine 21 and a first generator 22 connected thereto, wherein the first steam turbine 21 can be a screw machine or a back pressure...

Embodiment 2

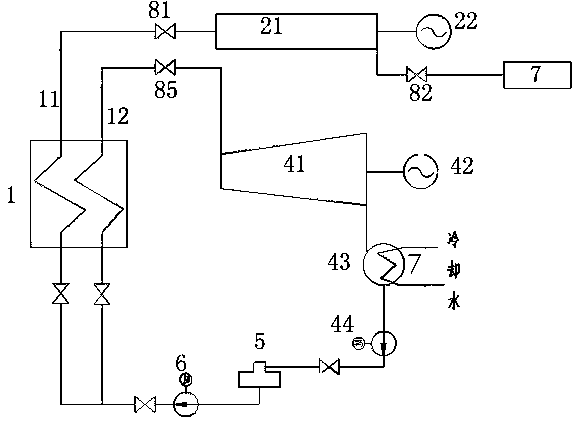

[0062] refer to figure 2 , the new waste heat recovery combined heat and power system includes a waste heat boiler 1, a first generator set, a third generator set, a second condenser 43, a second condensate pump 44, a deaerator 5 and a feed water pump 6, as well as connecting the components Some steam and water pipelines, auxiliary equipment, etc.; in this embodiment, the waste heat boiler 1 adopts a dual-pressure waste heat boiler, and the dual-pressure waste heat boiler includes a high-pressure steam pipeline 11 and a low-pressure steam pipeline 12 .

[0063] Specifically, the first generator set is connected to the output end of the high-pressure steam pipeline 11, and the first generator set further includes a first steam turbine 21 and a first generator 22 connected thereto; wherein the first steam turbine 21 can be a screw machine or a back Compression steam turbine is not limited here. The first steam turbine 21 is connected to the output end of the high-pressure stea...

Embodiment 3

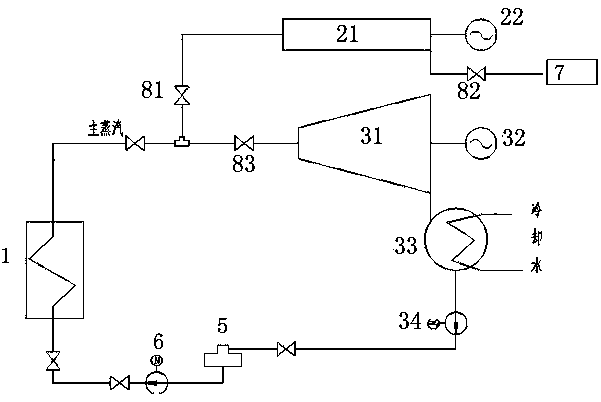

[0068] refer to image 3 , the new waste heat recovery combined heat and power system includes a waste heat boiler 1, a first generator set, a second generator set, a first condenser 33, a first condensate pump 34, a deaerator 5, a feed water pump 6, and connecting components Part of the steam and water pipelines, auxiliary equipment, etc.; wherein, the second generator set includes a second steam turbine 31 and a second generator 32 connected thereto; the waste heat boiler 1 is a single-pressure waste heat boiler that generates single-pressure steam; the second steam turbine 31 A third valve 83 is provided on the input end of the exhaust heat boiler 1 to control the on-off of the pipeline between the waste heat boiler 1 and the second steam turbine 31 .

[0069] In this embodiment, the first generator set further includes a first steam turbine 21 and a first generator 22 connected thereto. The first steam turbine 21 is connected to the steam output end of the waste heat boil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com