Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about How to "Inhibit ripening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

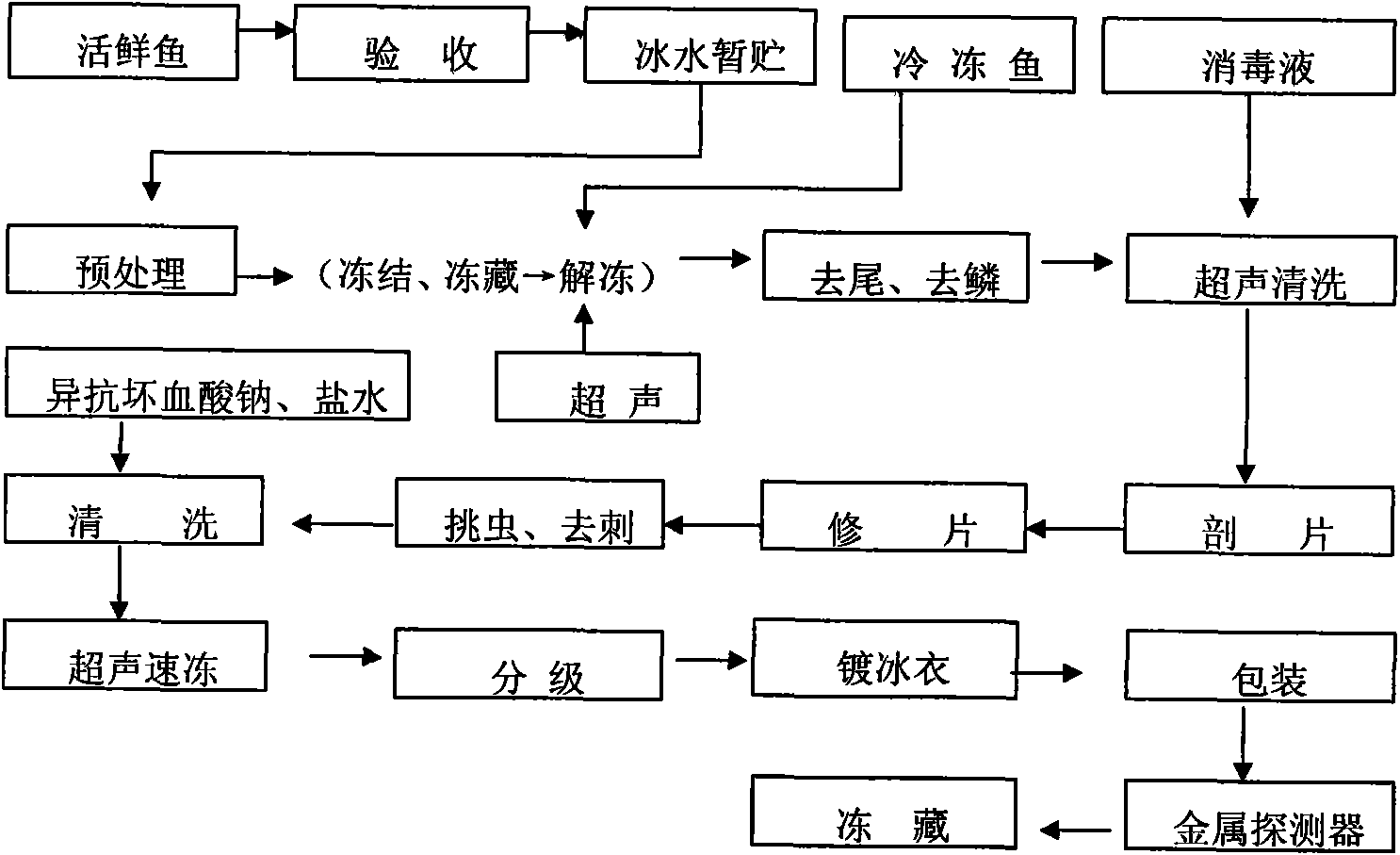

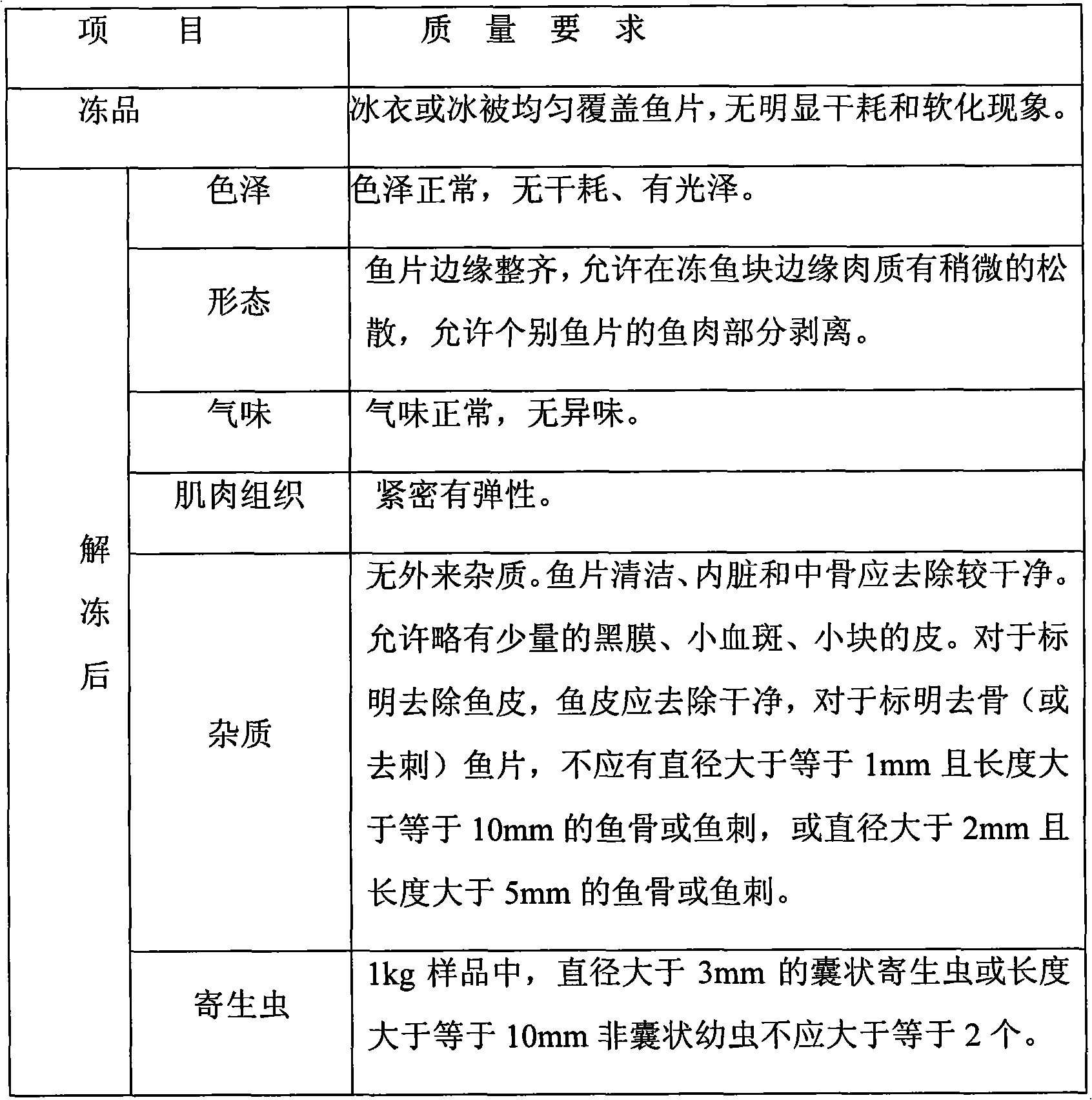

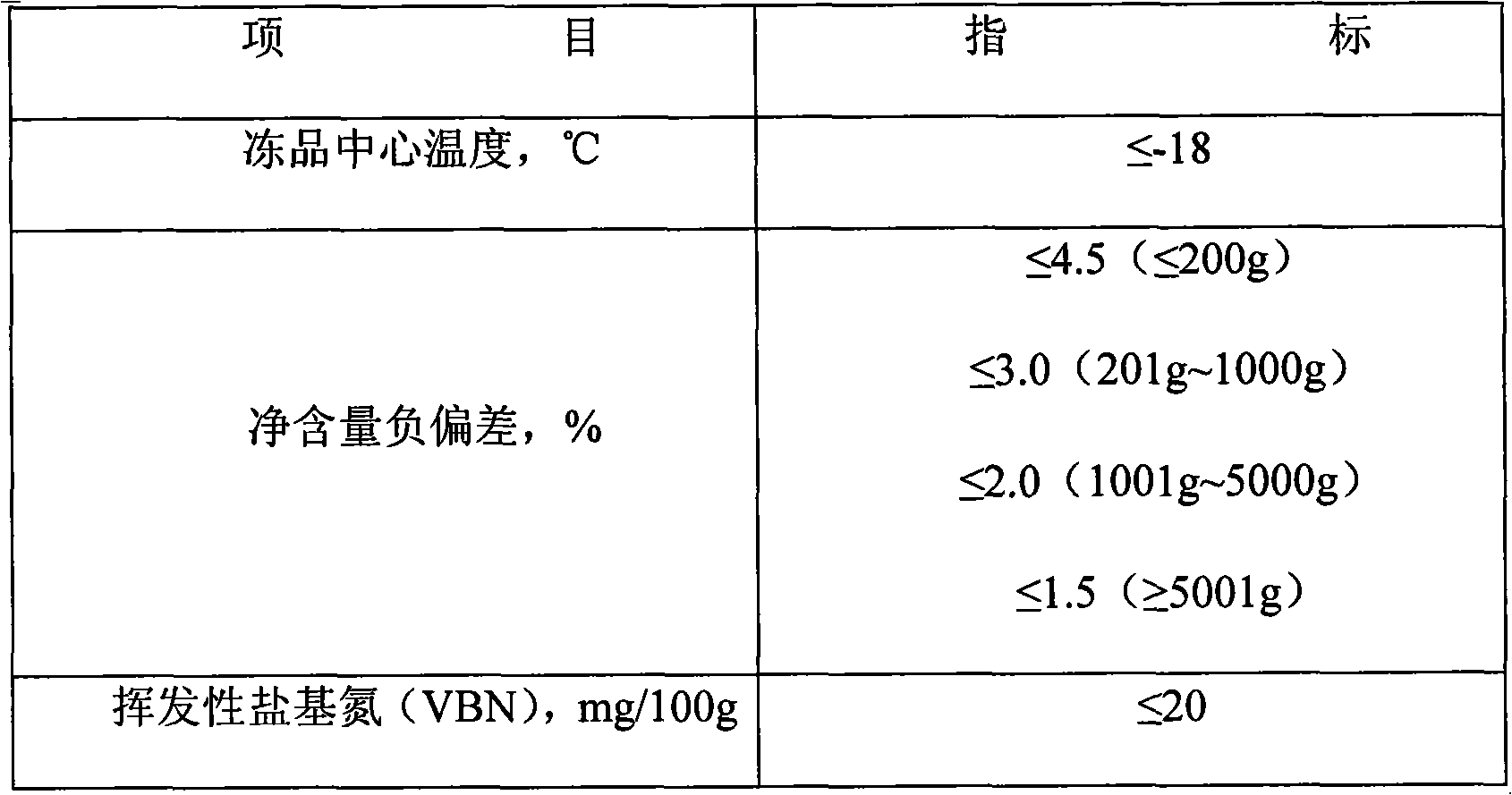

Processing method of sushi sashimi

InactiveCN101919539AExtended shelf lifeAvoid "cooking"Fish washing/descalingMeat/fish preservation by freezing/coolingIce waterAquatic product

The invention provides a processing method of sushi sashimi, which belongs to the field of processing of aquatic products. The processing method comprises the steps of taking a live fresh scaly fish as a raw material, carrying out acceptance, temporary storage in ice water and pretreatment, or taking a frozen scaly fish as the raw material, firstly carrying out ultrasonic thawing, further removing a tail, removing scales, carrying out ultrasonic cleaning, cutting into slices, trimming, picking out insects, removing bones, cleaning, carrying out ultrasonic quick freezing, classifying, glazing, packaging, carrying out metal detection, freezing, and carrying out other process steps for processing the sushi sashimi. The sushi sashimi processed by adopting the method has good quality, and the sensory, the physical and the chemical properties, as well as the safety sanitation quality are in line with requirements; furthermore, the processing method has short thawing time, short freezing time and high processing efficiency, and can be popularized in the processing of the aquatic products.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

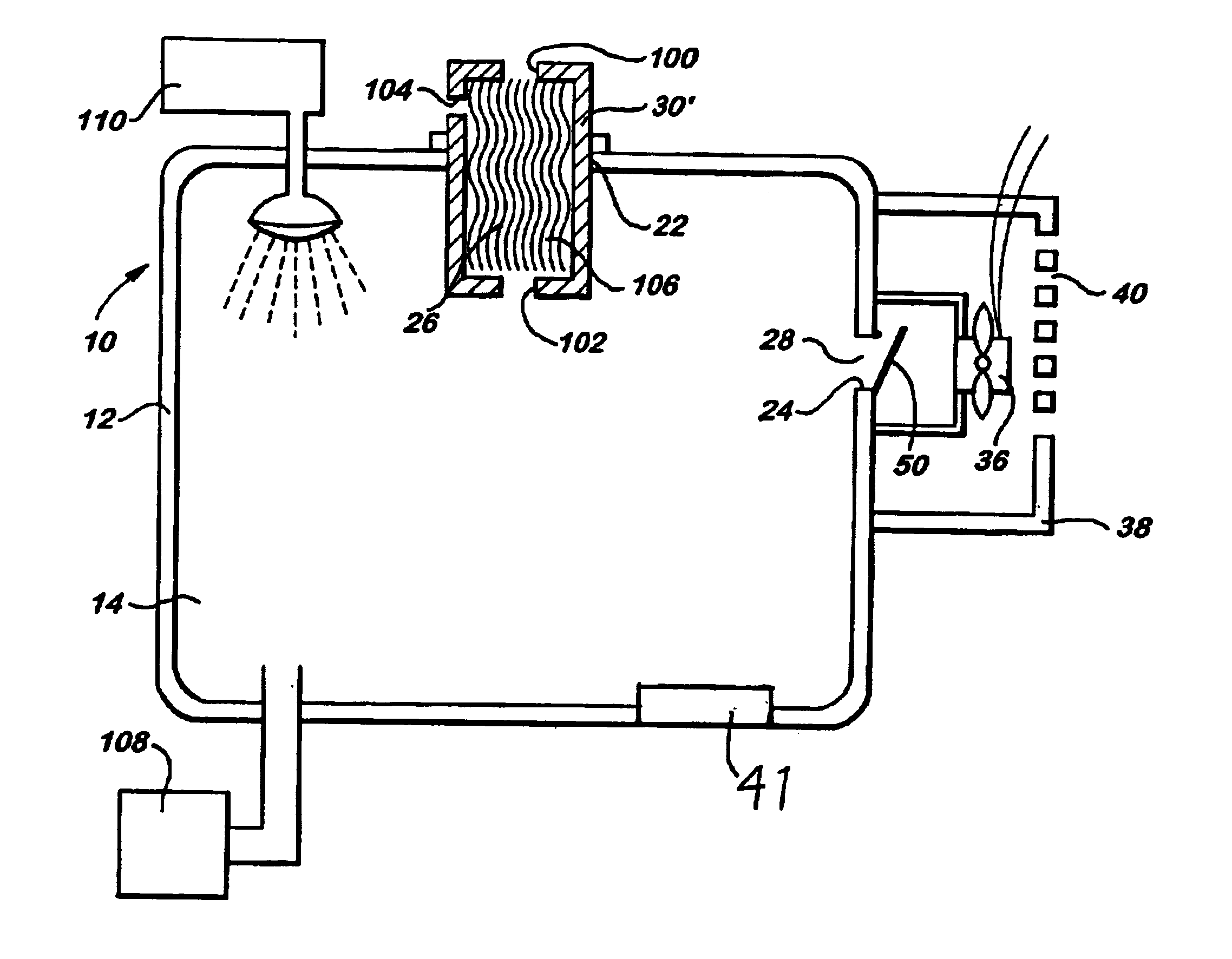

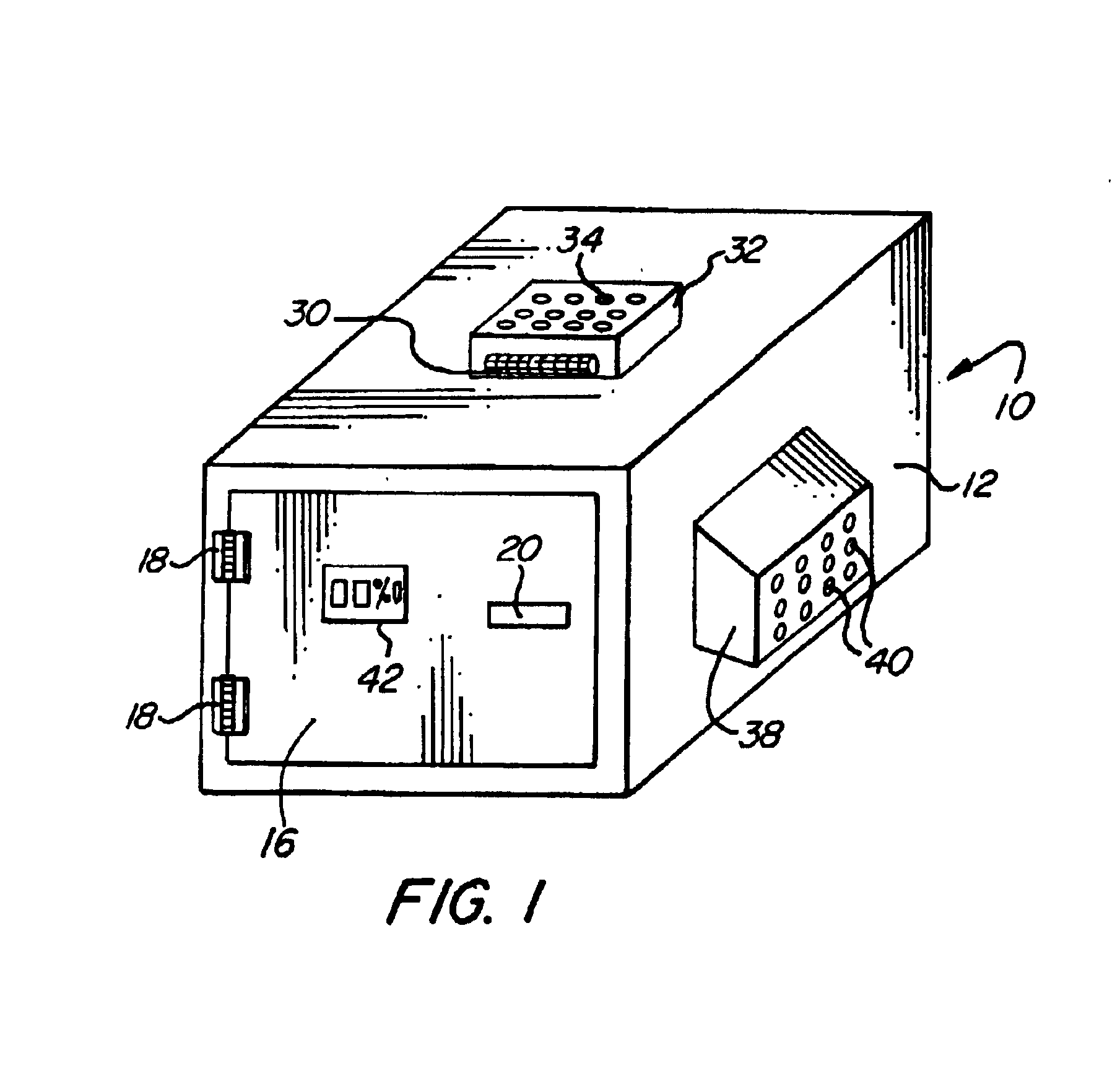

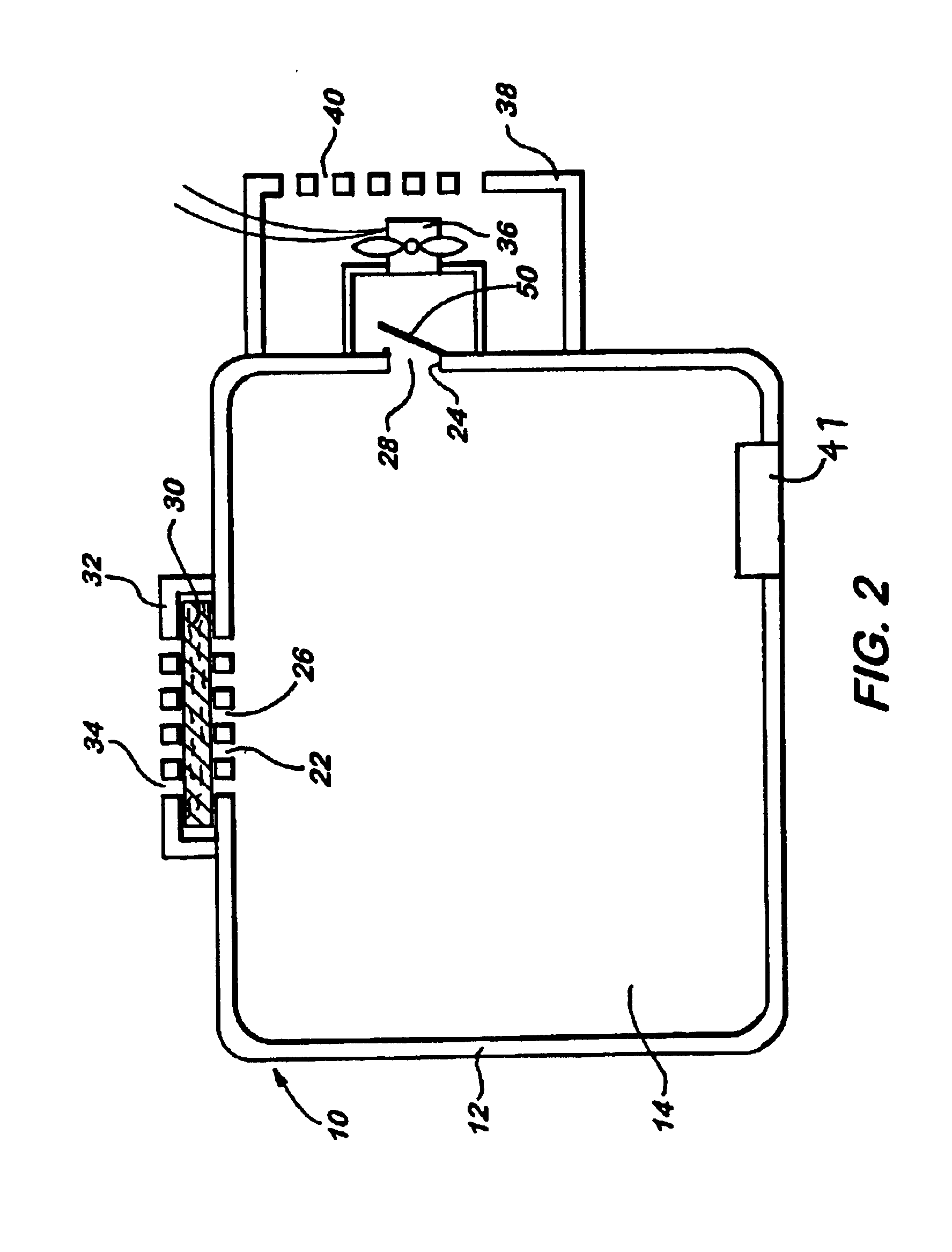

Storage device utilizing a differentially permeable membrane to control gaseous content

InactiveUS6840982B2Extended shelf lifeInhibit ripeningCombination devicesAuxillary pretreatmentProduct gasOxygen

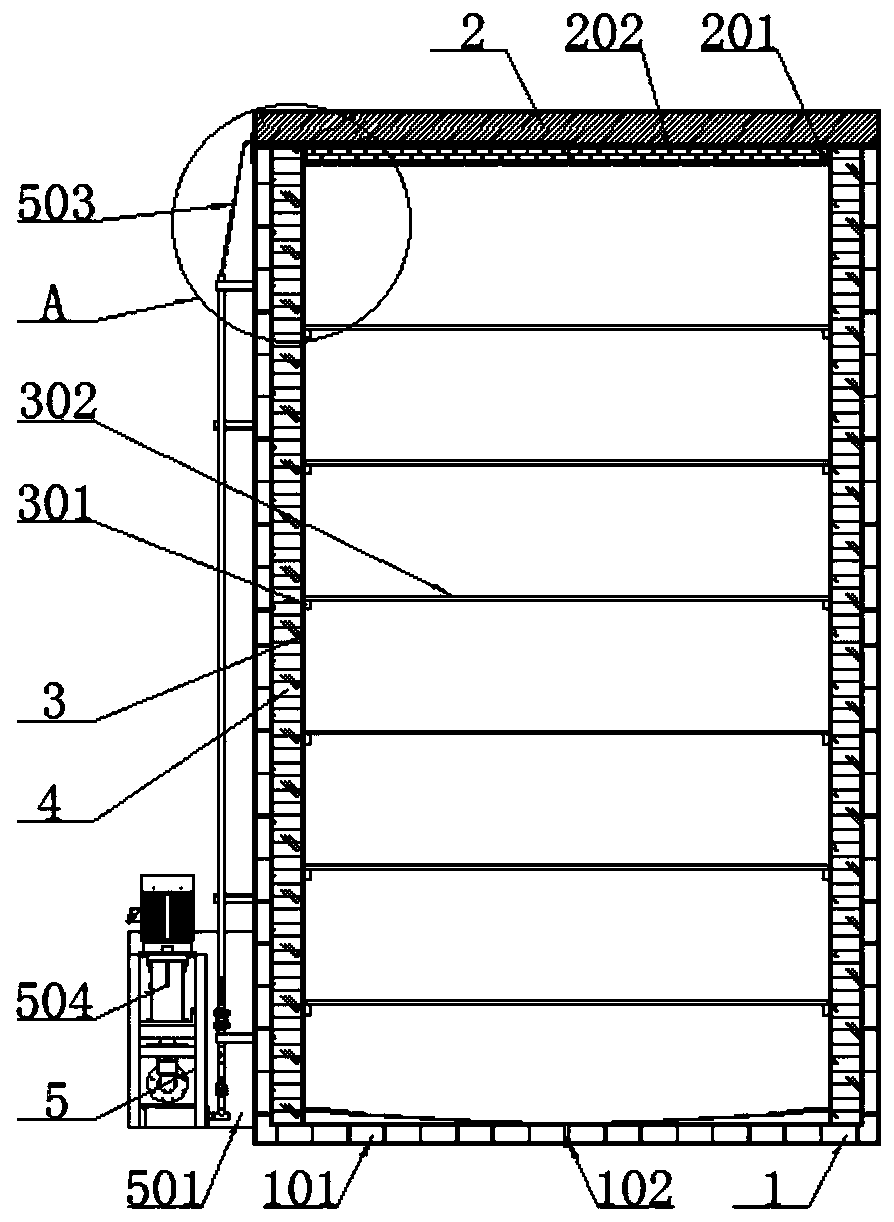

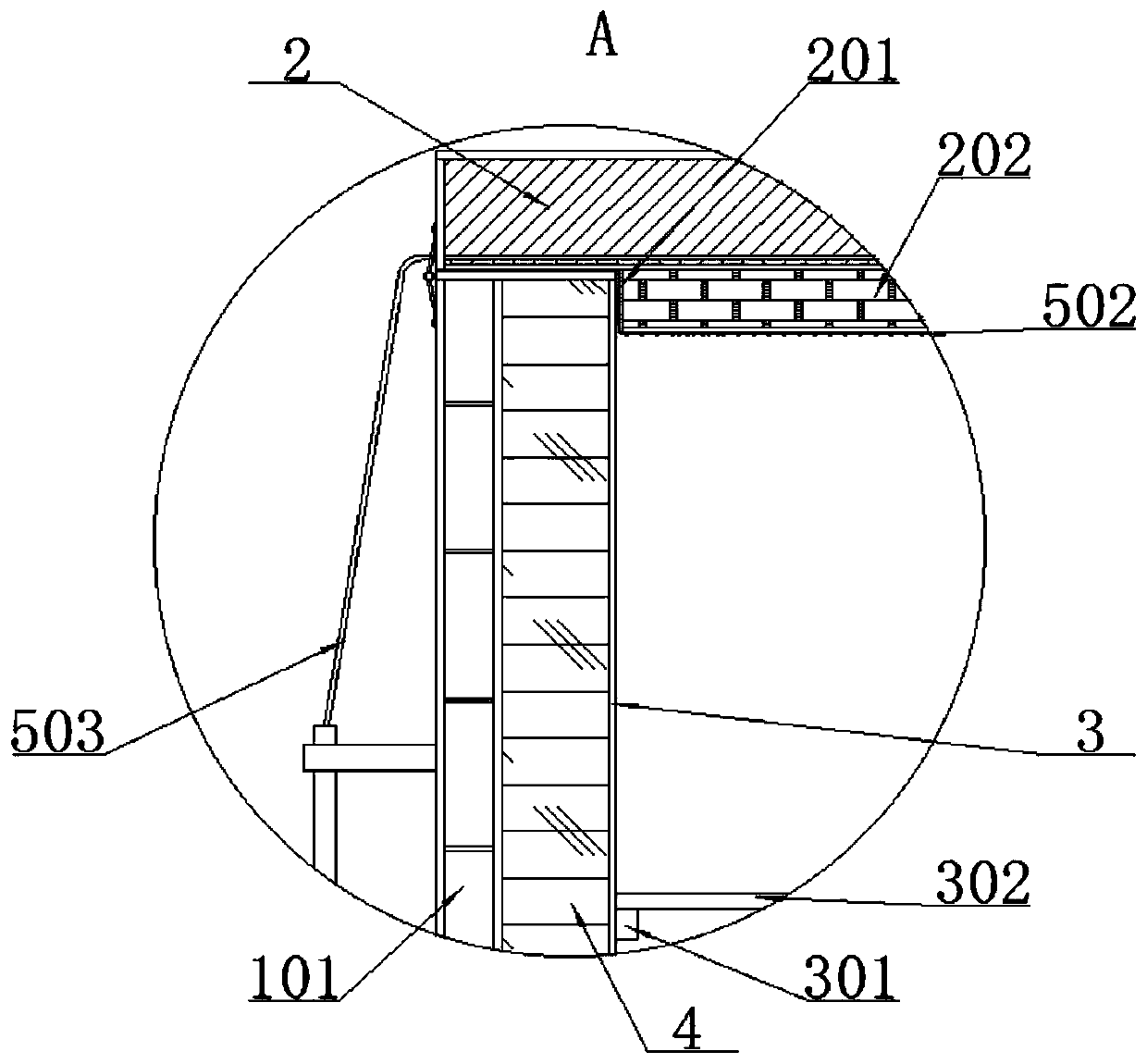

A storage device for the preservation of oxidizable materials is provided. The storage device includes a storage chamber enclosing a storage space where oxidizable materials may be placed and a differentially permeable membrane. The differentially permeable membrane allows at least one selected gas to pass therethrough while inhibiting at least oxygen from passing therethrough. The differentially permeable membrane is in fluid communication with the storage chamber such that the at least one selected gas is allowed to pass through the differentially permeable membrane flows into the storage chamber. An air mover, preferably a compressor, feeds gases to the differentially permeable membrane. A cooling element is provided for cooling the temperature within the storage chamber below that of the ambient temperature. The level of oxygen within the storage chamber is thus reduced relative to the level of oxygen in the atmosphere.

Owner:AMERICAN MOXIE

Fagopyrum tataricum hulling method

InactiveCN101745441AAvoid ripeningRetain nutrientsGrain huskingGrain polishingNutrientMicrowave oven

The invention relates to the grain processing technology, in particular to a fagopyrum tataricum hulling method, which solves the problems in the existing fagopyrum tataricum hulling method that the original nutrient components and characteristics of the shelled fagopyrum tataricum can be changed due to the large curing procedure, and the perfect kernel rate is not high. In the method, the following procedures: 1, removing the dust and impurities in the raw material fagopyrum tataricum; 2, soaking the fagopyrum tataricum by clear water; 3, placing the fagopyrum tataricum in a specially-used container, sending the container in an industrial microwave oven for heating, and controlling the heating temperature to be less than 65 DEG C; 4, sending the heated fagopyrum tataricum into hulling equipment for hulling; 5, separating hulled fagopyrum tataricum shells by screening and winnowing; 6, sorting the shelled fagopyrum tataricum by screening or by adopting a gravity paddy separator. The invention gives the brand-new fagopyrum tataricum hulling method, wherein the microwave heating can be used for fagopyrum tataricum hulling creatively, and the hulling of the fagopyrum tataricum can be realized by utilizing the characteristic of the microwave heating, thereby avoiding the curing of the fagopyrum tataricum in the hulling process, keeping the original nutrient components of the fagopyrum tataricum and obtaining more than 90% of perfect shelled fagopyrum tataricum.

Owner:CEREAL OIL & FOOD RES INST OF SHANXI PROVINCE

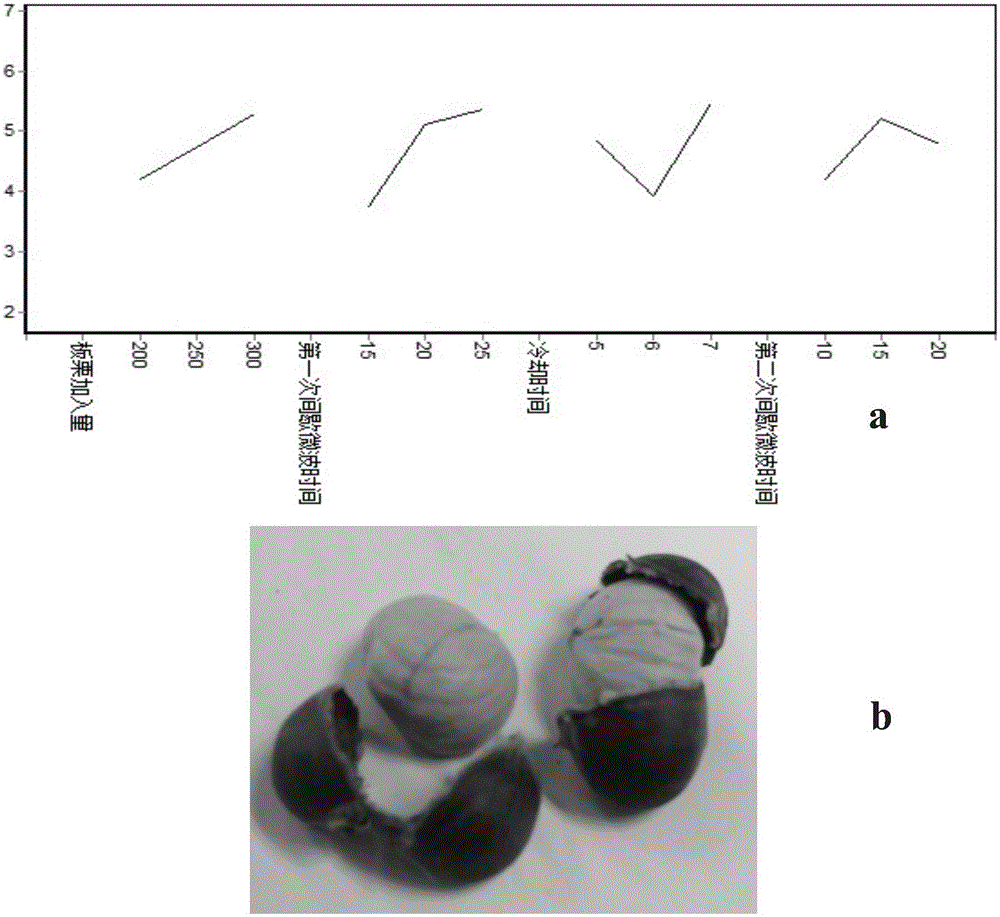

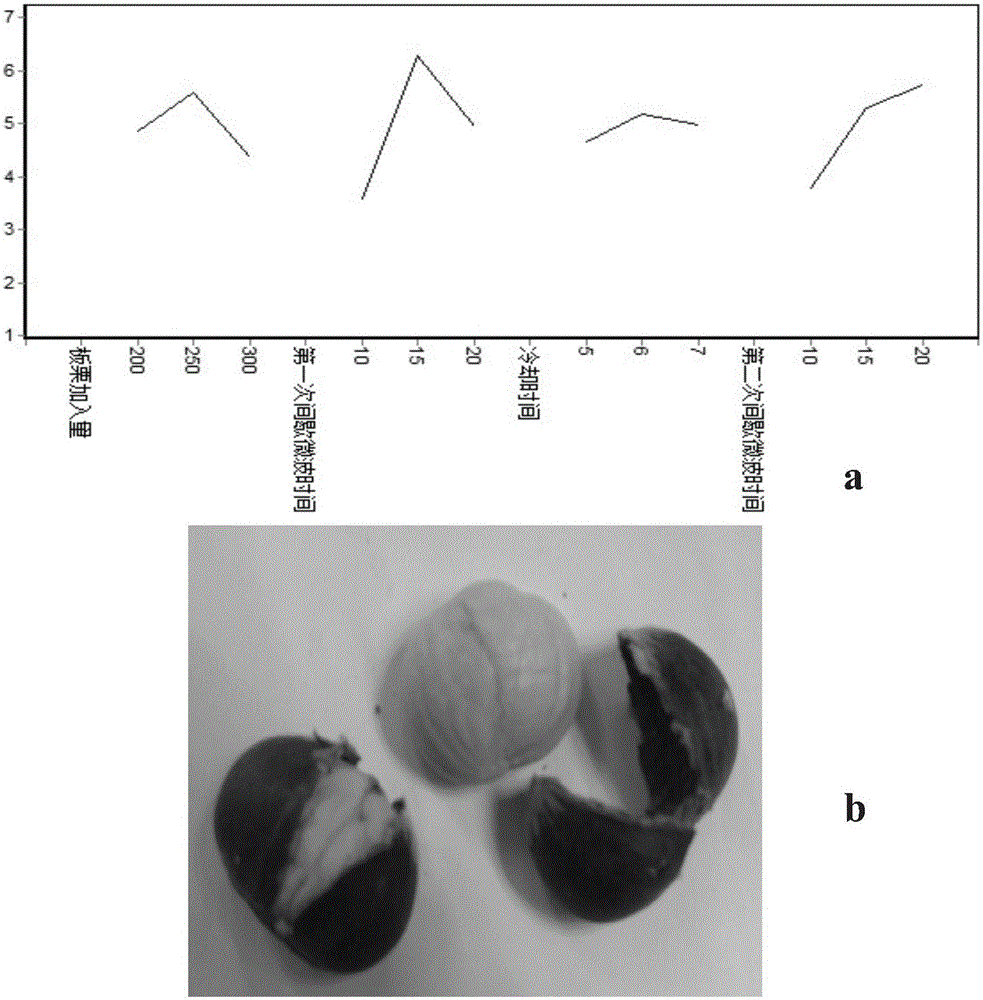

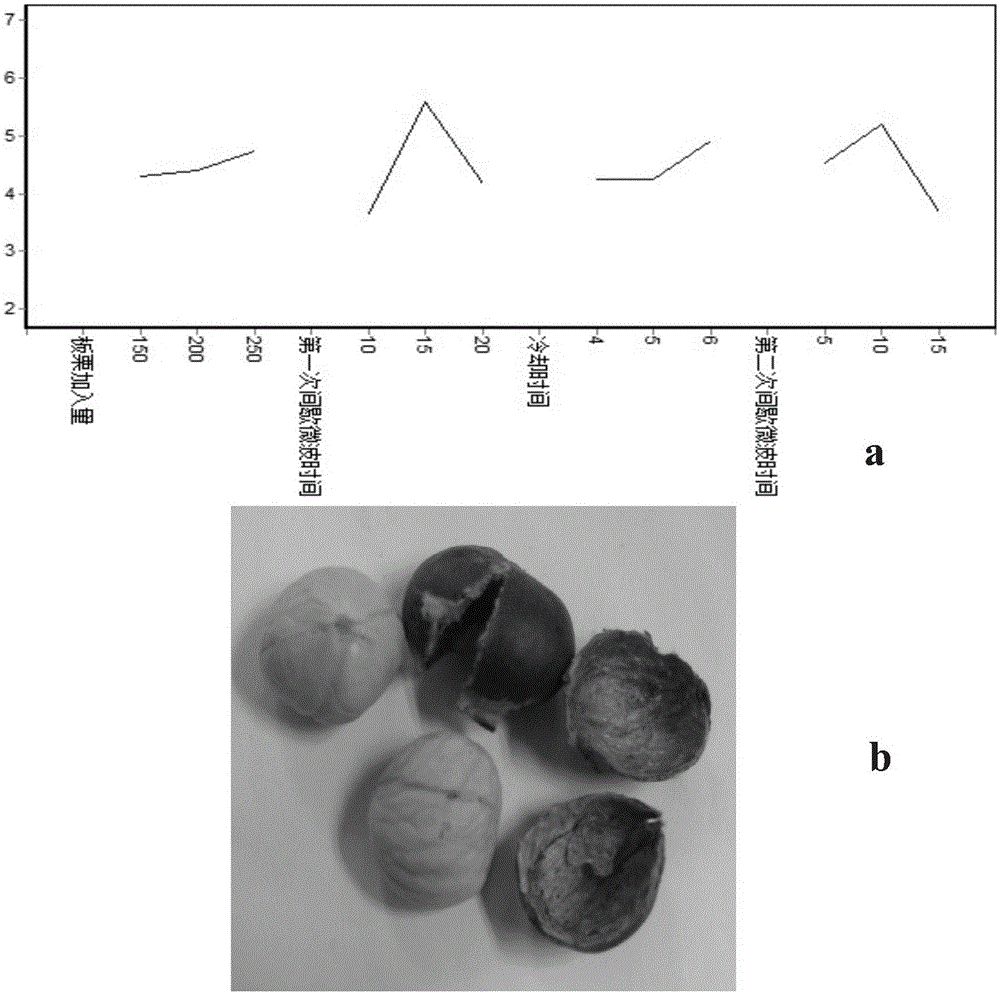

Method for synchronously removing shell and peel of Chinese chestnut through microwaves

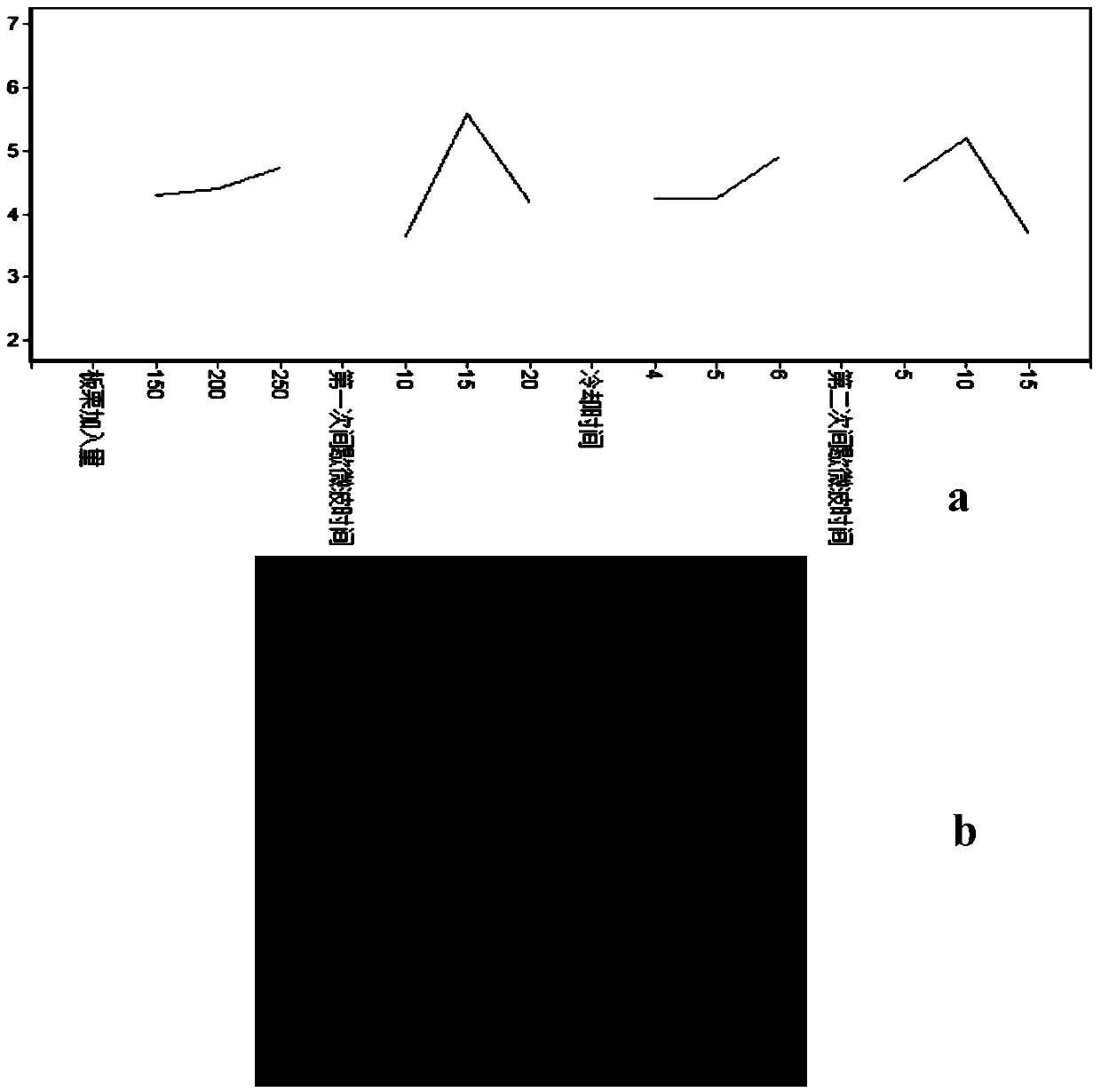

The invention discloses a method for synchronously removing the shell and peel of a Chinese chestnut through microwaves. The method comprises the following steps: the shell of the Chinese chestnut is cut, the Chinese chestnut is subjected to microwave processing for the first time, the Chinese chestnut is cooled after the microwave processing for the first time, then, the Chinese chestnut is subjected to microwave processing for the second time, the shell and the peel of the Chinese chestnut are removed after the microwave processing for the second time, and therefore the kernel of the Chinese chestnut is obtained. According to the method for synchronously removing the shell and peel of the Chinese chestnut through the microwaves, the microwaves are used for instantaneous intermittent heating with a high power, as a result, the kernel of the Chinese chestnut shrinks due to dehydration and is separated from the shell and the peel, and the phenomenon that the kernel of the Chinese chestnut is cooked and exploded due to an excessively quick temperature rise in the one-time heating process can be well avoided; meanwhile, the hot Chinese chestnut is cooled for a short time, as a result, water in the shell of the Chinese chestnut is evaporated, brittleness is further improved, and original color and luster, a special flavor and nutrition of the kernel of the Chinese chestnut are guaranteed to the maximum.

Owner:ZHEJIANG UNIV

Method for preparing corrugated cardboard box for fresh-keeping of fruits and vegetables

InactiveCN108669219AInhibit ripeningContinuous and effective adsorptionFruit and vegetables preservationBio-packagingVitamin CCarrageenan

The invention discloses a method for preparing a corrugated cardboard box for fresh-keeping of fruits and vegetables, the inner paper of a corrugated cardboard box is coated with a preservative and anethylene absorbent in turn, and dried to obtain the corrugated cardboard box for fresh-keeping of the fruits and vegetables; the preservative comprises glucose oxidase, anionic starch, sodium alginate, vitamin C, carrageenan, calcium hydroxide and water; the ethylene absorbent is made of activated carbon loaded with potassium permanganate. The corrugated cardboard box can continuously and effectively absorb gases such as ethylene and carbon dioxide generated during the storage and transportation of the fruits and vegetables, inhibits the after-ripening of the fruits and vegetables, and playsa role of preserving freshness.

Owner:JURONG MAOYUAN WEAVING FACTORY

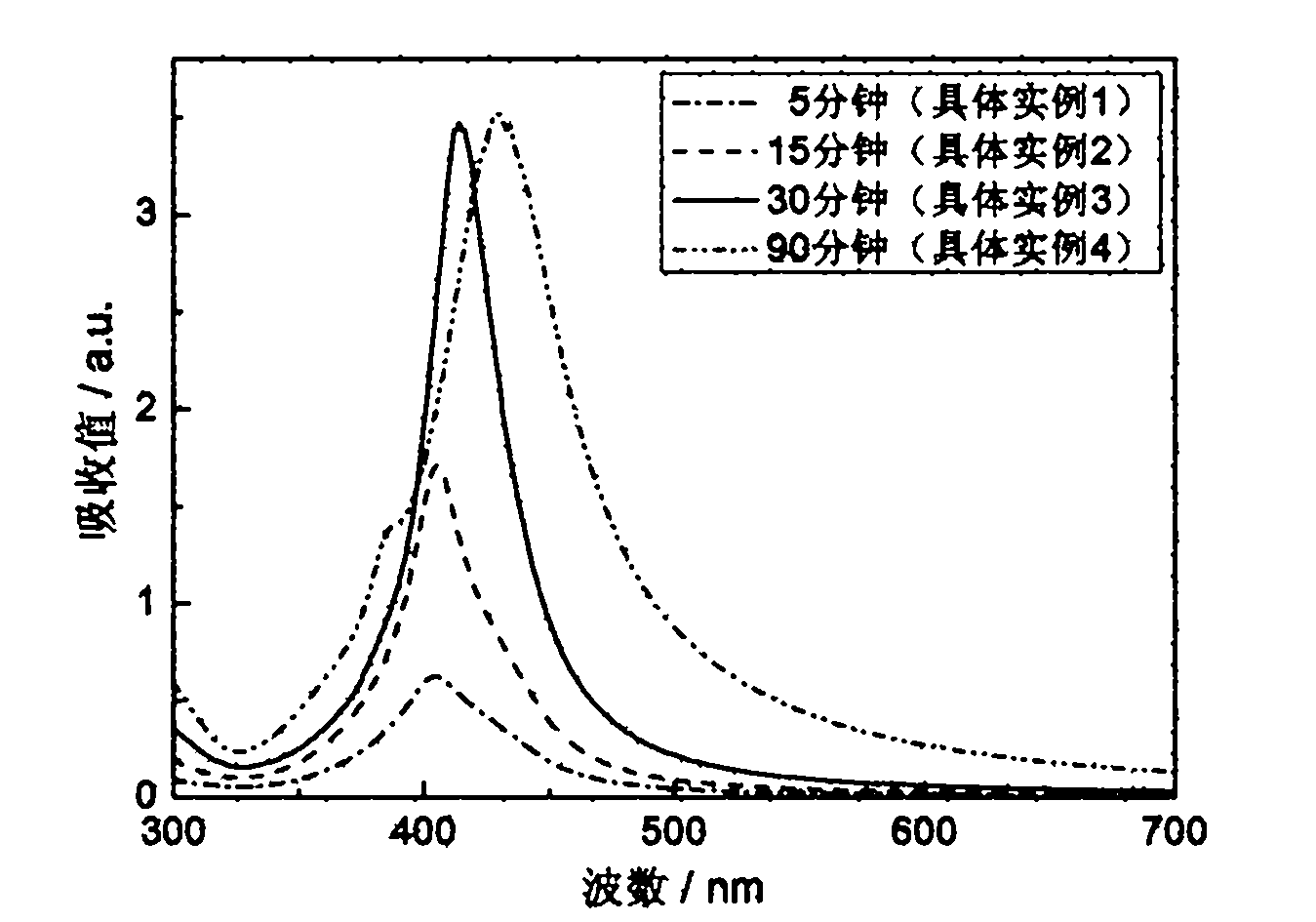

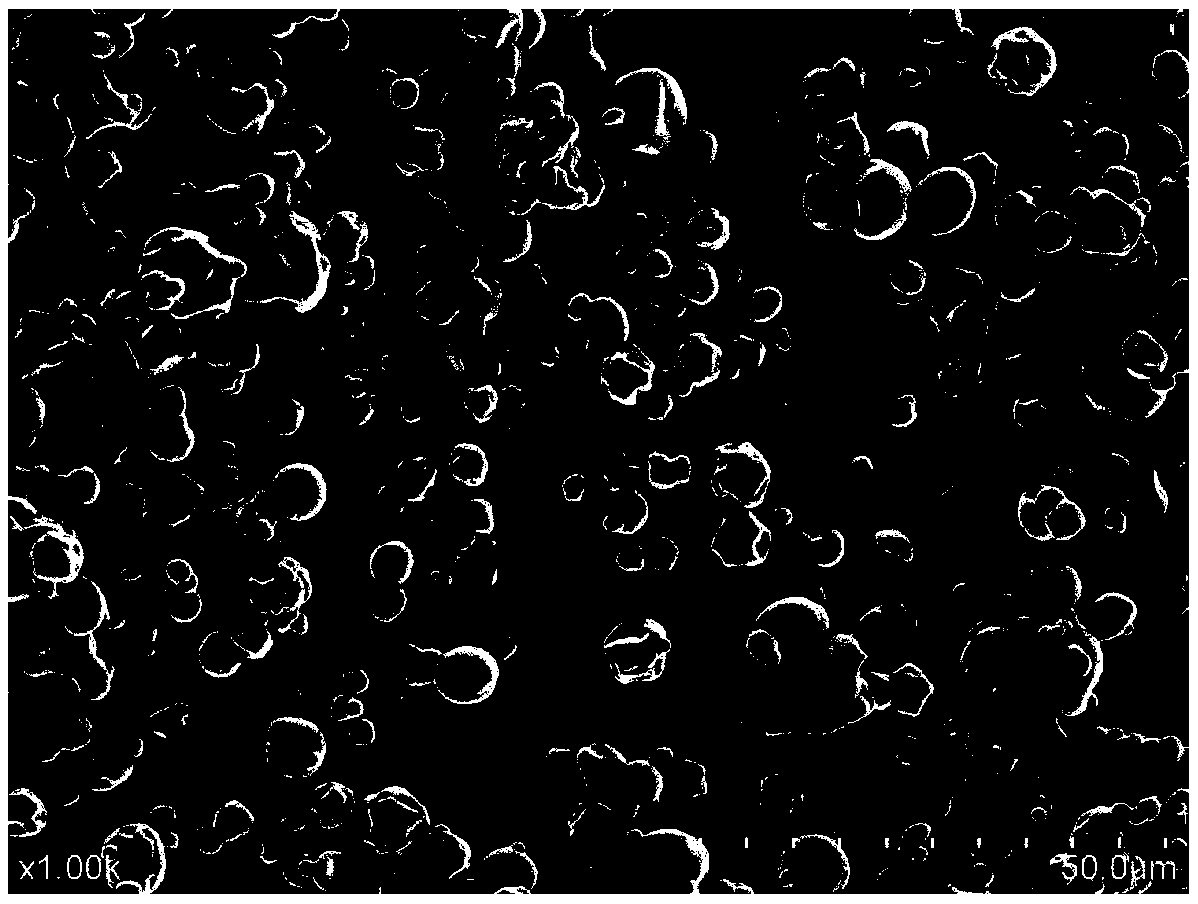

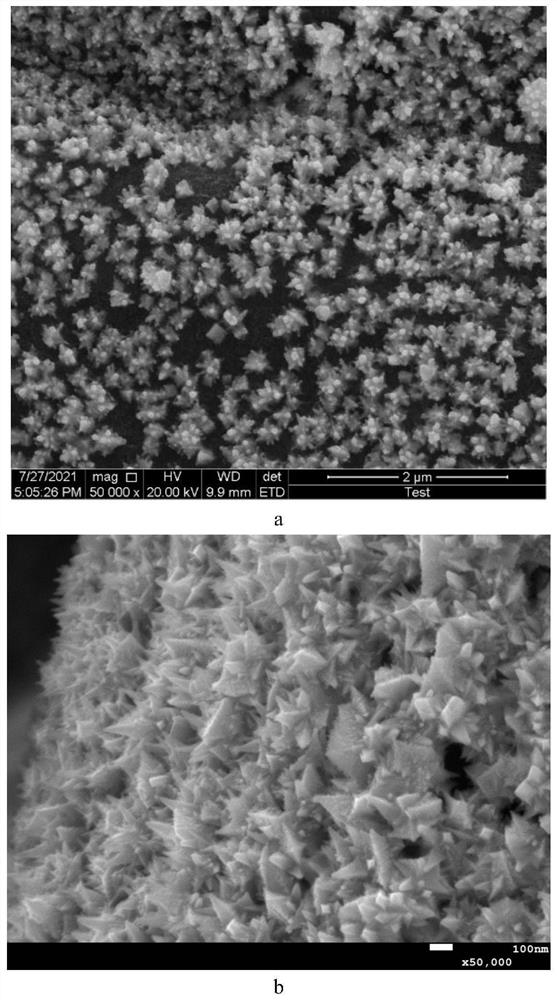

Method for preparing Ag/PMMA (polymethyl methacrylate) nano composite material

The invention provides a method for preparing an Ag / PMMA (polymethyl methacrylate) nano composite material. Particularly, in the method, PMMA is used as a polymer matrix; PMMA is the English abbreviation of polymethyl methacrylate; silver nitrate is used as an Ag source; PVP (Polyvinyl Pyrrolidone) is used as a dispersing agent; PVP is the English abbreviation of polyvinyl pyrrolidone; DMF (N,N-dimethyl formamide) is used as a solution solvent and a reducing agent; and DMF is the English abbreviation of N,N-dimethyl formamide. The method comprises the following steps of: heating the PMMA, the silver nitrate, the PVP and the DMF and performing a reaction to obtain Ag / PMMA nano sol containing Ag nano particles; then removing the reducing agent DMF in the Ag / PMMA nano sol by adopting a solvent precipitation method; drying the obtained product; and carrying out heating and forming on the dried product to obtain the Ag / PMMA nano composite material. The method adopts a simple preparation process, can effectively solve the problem of the aggregation phenomenon when the Ag / PMMA nano composite material is prepared by a conventional method and realizes accurate design, regulation and control of diameter of particles and topography of the Ag nano particles.

Owner:WUHAN UNIV OF TECH

Ice temperature combined freshness protection method for modified atmosphere storage of fruits and vegetables

InactiveCN103349061AMaintain sensory qualityExtended storage periodFruits/vegetable preservation by irradiation/electric treatmentFruits/vegetable preservation by freezing/coolingUltravioletModified atmosphere

The invention discloses an ice temperature combined freshness protection method for modified atmosphere storage of fruits and vegetables, so as to provide a method capable of improving the storage quality of fruits and vegetables and prolonging the refreshing time of fruits and vegetables. The method includes the following steps: performing ultraviolet treatment to harvested fruits and vegetables; performing two-stage cold acclimation for harvested fruits and vegetables placed in a refrigeration house within 12 hours, wherein the temperature of the first-stage cold acclimation for 24 hours is controlled to be within 4.5-5.5 DEG C, and the temperature of the second-stage cold acclimation for 24 hours is controlled to be within minus 0.5-0.5 DEG C; fruits and vegetables subjected to acclimation are placed in a freshness protection bag, tightening the bag opening, placing the bag in an ice-temperature refrigeration house and storing at the temperature of minus 1.2- minus 0.2 DEG C, wherein the thickness of the freshness protection bag is 0.03-0.05 mm. The freshness protection method provided by the invention adopts the ultraviolet treatment, two-stage cold acclimation for adaptation and then packaging through the freshness protection bag for ice-temperature freshness protection in sequence, and keeps the original sensory quality and physicochemical quality of fruits and vegetables and has long storage refreshing time through the combination of the technologies and all technological parameters.

Owner:TIANJIN UNIV OF COMMERCE

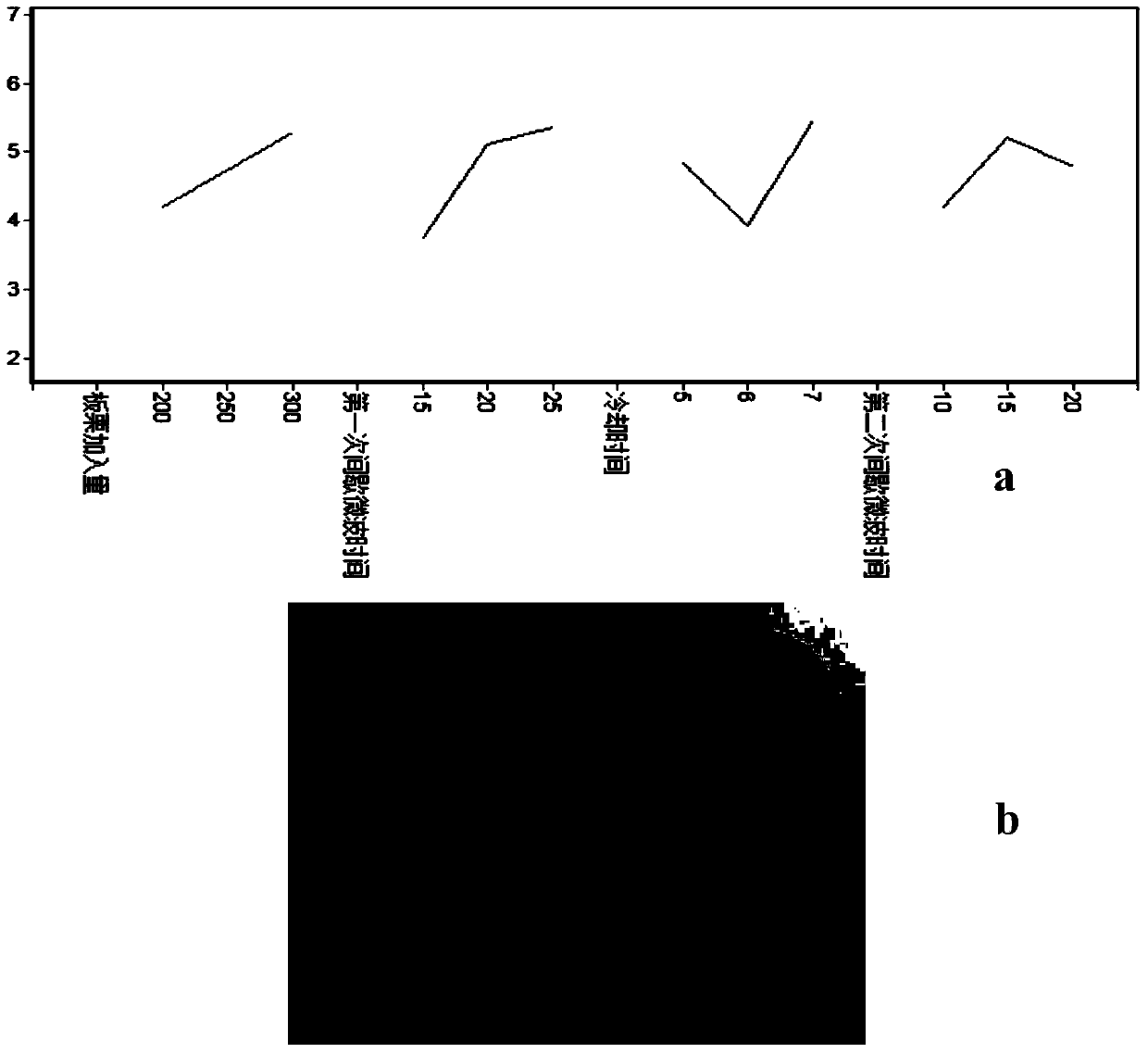

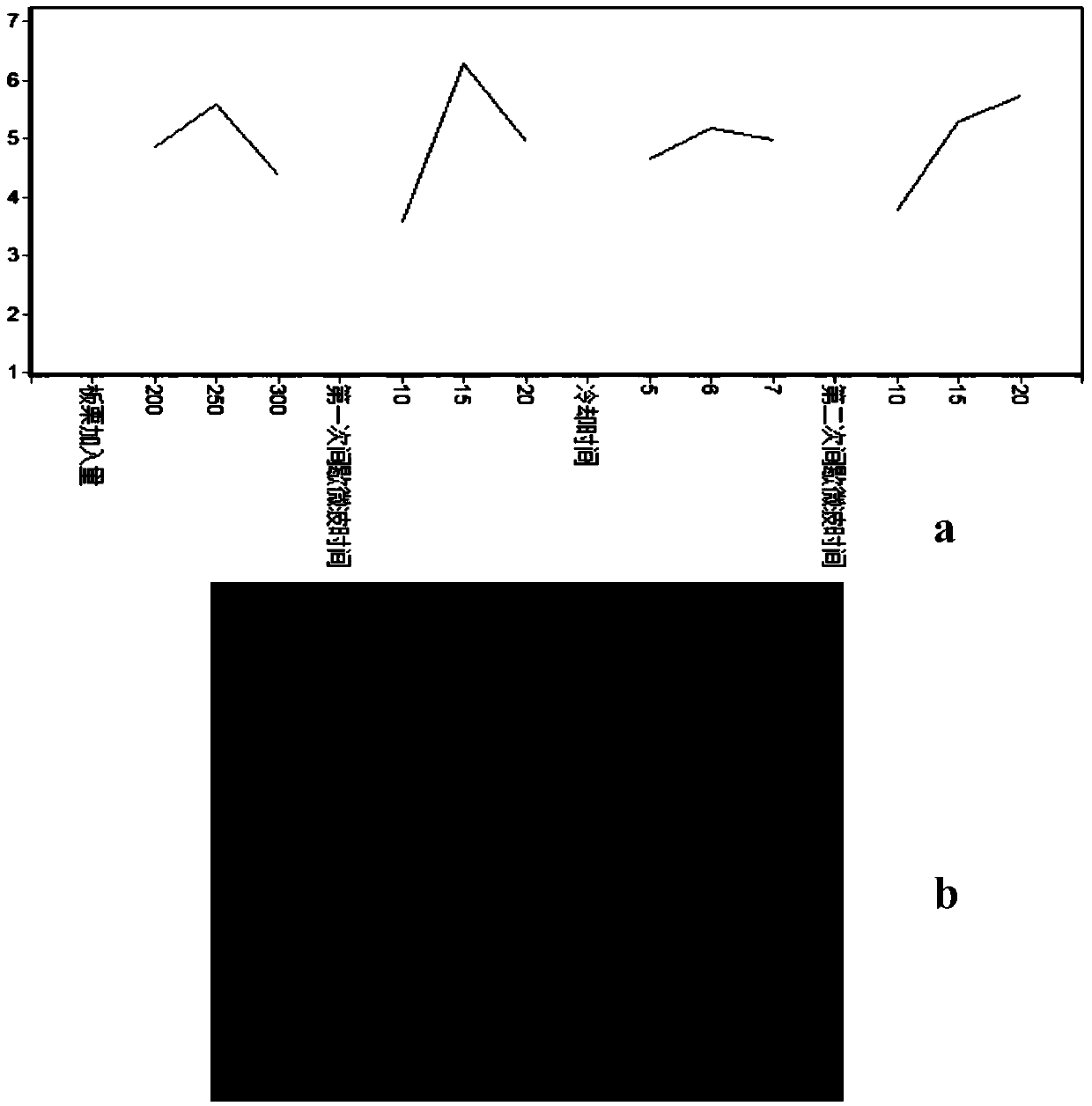

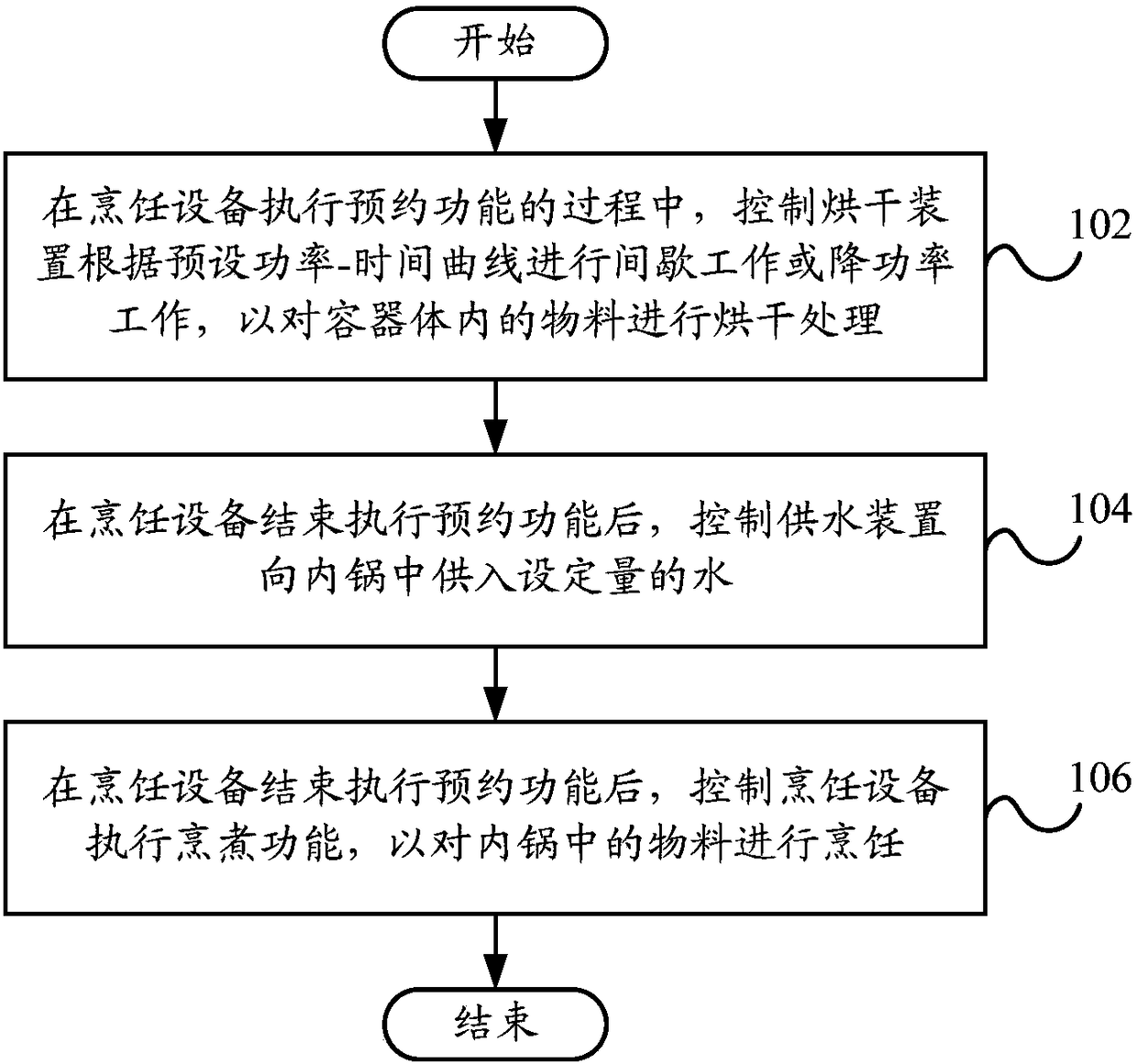

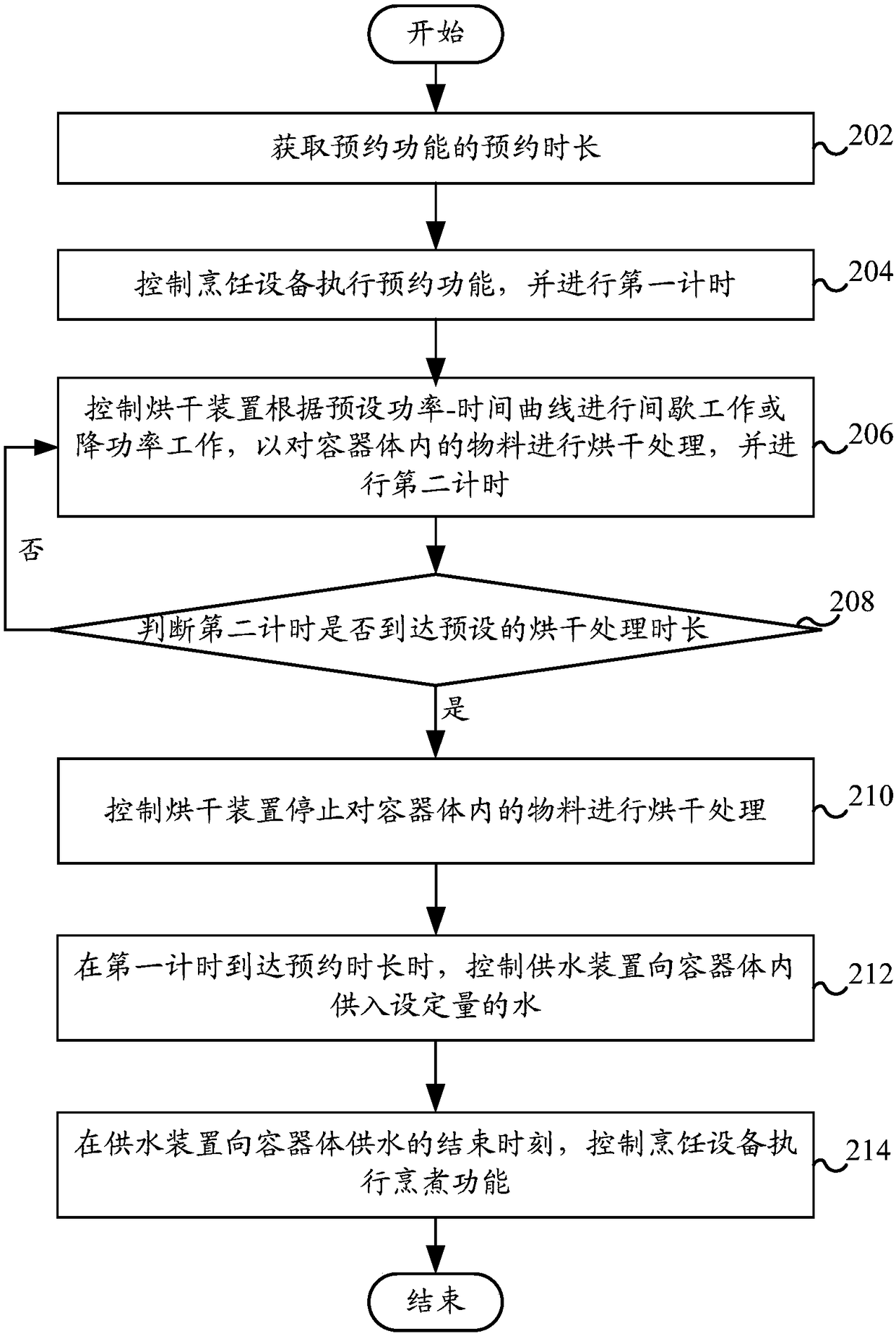

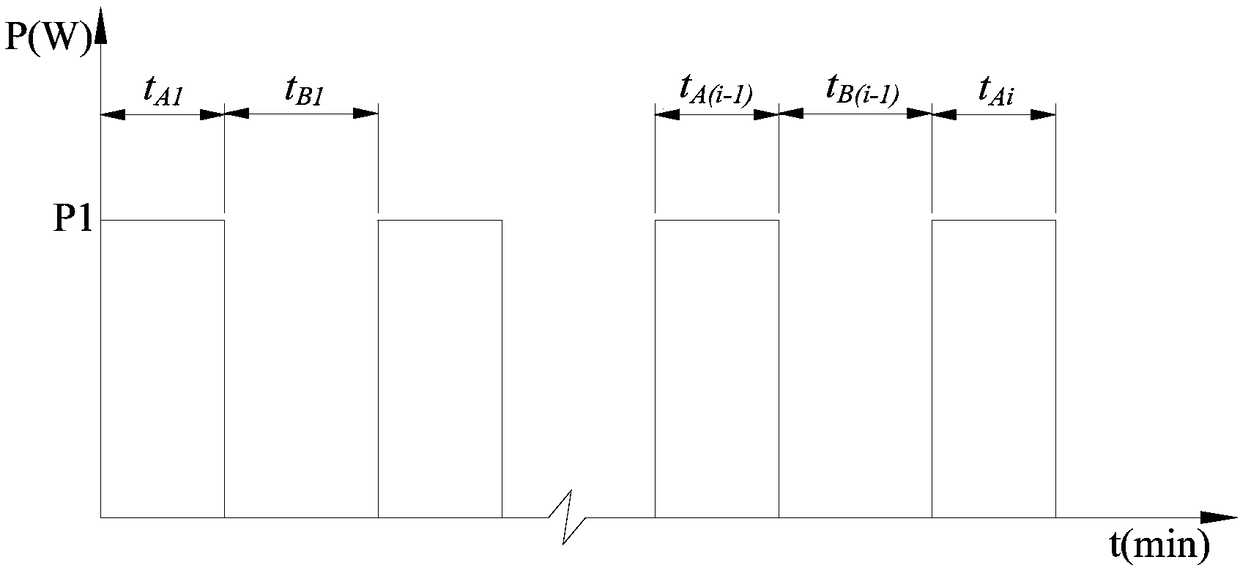

Cooking equipment and control method thereof

PendingCN108125570AAvoid continuous heatingInhibit ripeningBeverage vesselsPressure-cookersProcess engineeringTime curve

The invention provides cooking equipment and a control method thereof. The cooking equipment comprises a container body and a drying device. The control method of the cooking equipment comprises a drying step, wherein the drying device is controlled to perform intermittent operation or power-lowering operation according to a preset power-time curve to dry materials in the container body. Accordingto the method, by controlling the drying device to operate according to the preset power-time curve in the process that the cooking equipment perform a reservation function, the materials can be dried while the problem that the temperature of the drying device continues to rise is avoided, so that the problems that the materials are cured or gelatinized or the freshness is lowered in the drying process due to too high temperature of the drying device are avoided, and the cooking taste of the materials is ensured.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

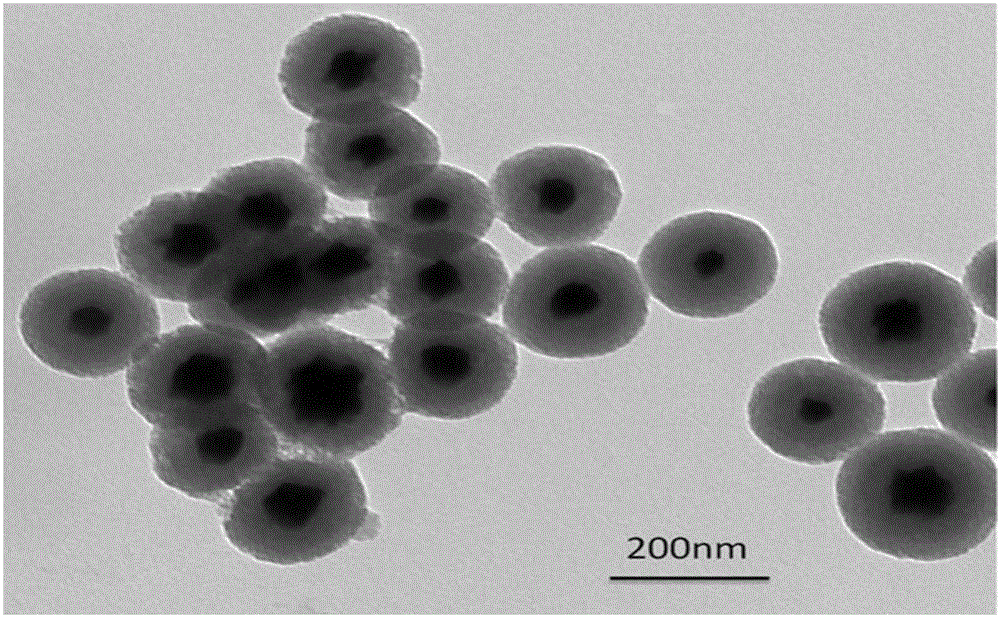

Multifunctional gold nanoflower drug compound carrier material and preparation method thereof

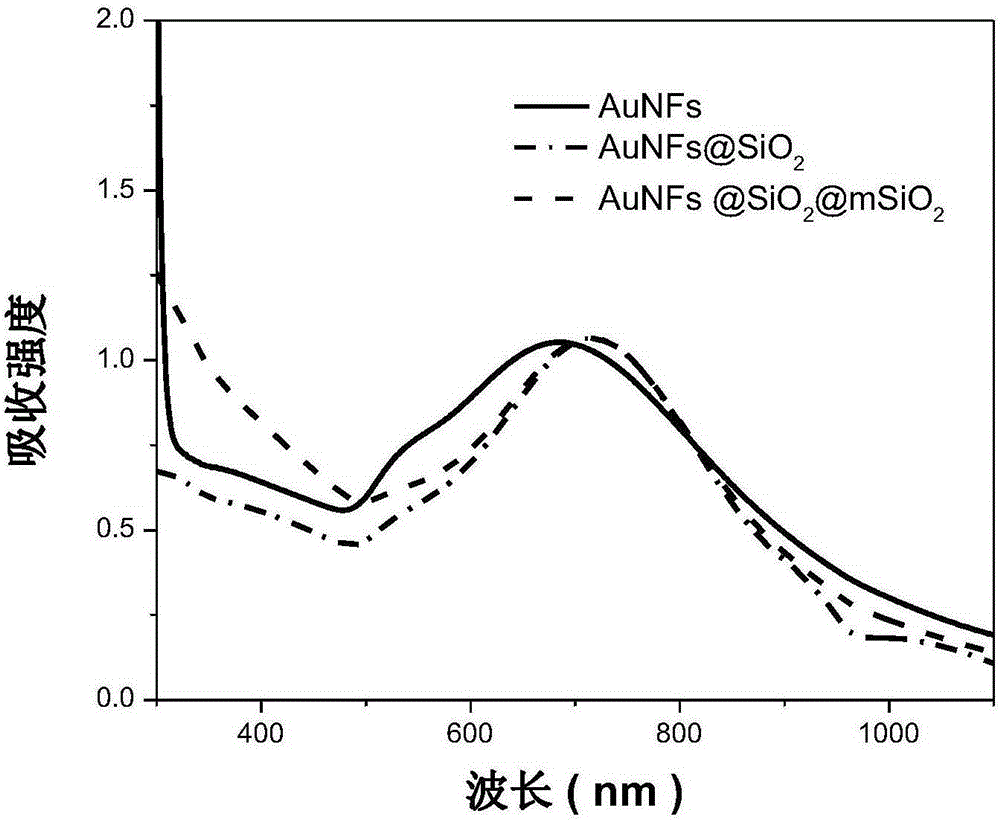

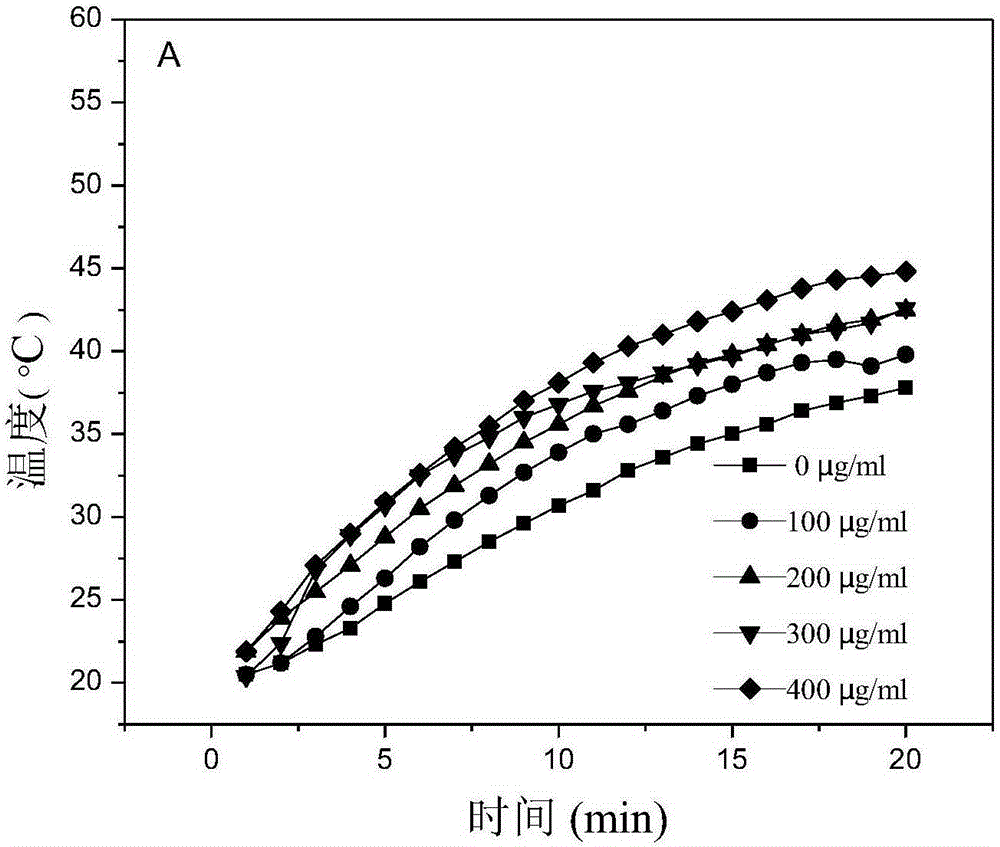

InactiveCN105214091AAchieve controlled releaseWith near-infrared hyperthermia functionEnergy modified materialsInorganic non-active ingredientsMesoporous silicaSilicon dioxide

The invention relates to a multifunctional gold nanoflower drug compound carrier material and a preparation method thereof. A drug compound carrier is nano particles formed by taking gold nanoflower with a near infrared absorption function as a core, coating a layer of silicon dioxide on the surface of the gold nanoflower, and then coating a mesoporous silica layer on the silicon dioxide layer. The carrier material is characterized in that double-silicon shell coating is adopted, the outer mesoporous silica layer can be used for carrying multiple chemotherapeutics, photodynamics therapy drugs and the like and has universality, the inner silicon dioxide layer directly coats the gold nanoflower, avoids the curing of the gold nanoflower, enables material performance to be stable, the gold nanoflower with a near infrared photothermal conversion function can realize drug controllable release under near infrared light irradiation, and meanwhile a synergistic effect of chemotherapy, photodynamics therapy and near infrared photothermal treatment can be realized by carrying different drugs.

Owner:JILIN UNIV

Processing method for coproducing sweet potato juice, starch and total-sweet potato starch by using sweet potato

The invention relates to the technical field of food processing, and concretely relates to a processing method for coproducing a sweet potato juice, starch and total-sweet potato starch by using sweet potato. The method adopting sweet potato as a raw material comprises the following steps: dicing the peeled raw material, crushing the diced raw material, juicing the crushed raw material, dehydrating the juiced raw material, carrying out low temperature drying on the obtained solid phase material to obtain powder, crushing the powder, and screening the crushed powder to obtain screen underflow which is the total-sweet potato starch; and allowing the above obtained liquid part to enter a fresh fruit and vegetable normal juice processing device, processing the liquid part, and separating the processed liquid part to obtain free starch and an NFC sweet potato juice. The method avoids cooking the raw material through blanching, microwave and pre-boiling, guarantees that the product is the sweet potato starch, and reduces loss of nutrients.

Owner:朱渭兵

Platnum antibacterial and deodorant freshness-retaining block

InactiveCN102166510AAvoid odorPrevent odors and prevent ethylene from ripening fruits and vegetablesPhysical/chemical process catalystsOther chemical processesFiberActivated carbon

The invention discloses a platnum antibacterial and deodorant freshness-retaining block and relates to the technical field of antibacterial and freshness-retaining technology. The block is characterized in that: activated carbon fibers serve as an adsorption layer; a catalyst is carried on the activated carbon fiber; the catalyst is solution prepared from chloroplatinic acid, silver nitrate, copper nitrate, manganese nitrate and water; the activated carbon fibers are dipped in the prepared solution; and then the activated carbon fibers are dried and activated at the temperature of between 200 and 500 DEG C. In the block, a novel adsorption material, namely the activated carbon fibers serve as the adsorption layer and the carrier, and the catalysts of platinum, copper, manganese, silver and the like, is carried on the activated carbon fibers at the same time, so the functions of resisting bacteria, deodorizing, retaining the freshness of foods are achieved through the high adsorptivity and moisture absorbing and adjusting properties of the activated carbon fibers, and the catalyst characteristic of the catalysts of platinum, copper, manganese, silver and the like.

Owner:胡冰

Zinc oxide nanocrystal, preparation method thereof, nanocrystal composition containing zinc oxide nanocrystal and quantum dot light emitting device

ActiveCN109509841AReduce sensitivityDecreased drop sensitivity with higher water resistanceMaterial nanotechnologyNanoinformaticsEtherQuantum dot

The invention provides a zinc oxide nanocrystal, a preparation method thereof, a nanocrystal composition containing the zinc oxide nanocrystal and a quantum dot light emitting device. The zinc oxide nanocrystal includes a zinc oxide nanocrystal body and a siloxane ligand coated on the surface of the zinc oxide nanocrystal body, wherein the zinc oxide nanocrystal body is Y, the zinc oxide nanocrystal is selected from any of the compounds shown in a formula defined in the description, B1, B2 and B3 are one respectively and separately selected from the following: a formula defined in the description, C1-8 alkyl, C1-8 hydroxyalkyl, C1-8 carboxylic acid alkyl and C1-8 ether alkyl; n range from 1 to 20000, and R1 and R2 are one respectively and separately selected from the C1-8 hydroxyalkyl. Thezinc oxide nanocrystal solves a problem of poor stability of the zinc oxide nanocrystal in the prior art.

Owner:NANJING TECH CORP LTD

Garlic essential oil microcapsule and preparation method thereof

InactiveCN109380700AReduce density differenceGood emulsifying effectLipidic food ingredientsFood ingredient as emulsifierFlavorEmbedding rate

The invention relates to a garlic essential oil microcapsule. The garlic essential oil microcapsule comprises the following raw material components in parts by weight: 24-47 parts of whey protein concentrate, 6-24 parts of inulin, 8-15 parts of garlic essential oil, 1.5-9.5 parts of compound vegetable oil and 180-240 parts of water. From principles of relieving poor density of an oil-water systemand reducing Austenitic maturation effect, the emulsibility of the garlic essential oil is strengthened, the stability of the lactescence of the garlic essential oil is enhanced, and therefore, the embedding rate of the garlic essential oil microcapsule prepared by a spray drying technology is increased remarkably; and the whey protein concentrate and the inulin are used as wall materials, the garlic essential oil is embedded by the spray drying technology, the embedding rate of the garlic essential oil is increased remarkably and can reach 74% or above, and the product is easily dissolved inwater, is good in flavor stability and has good slow-release effect.

Owner:TIANJIN UNIV OF SCI & TECH

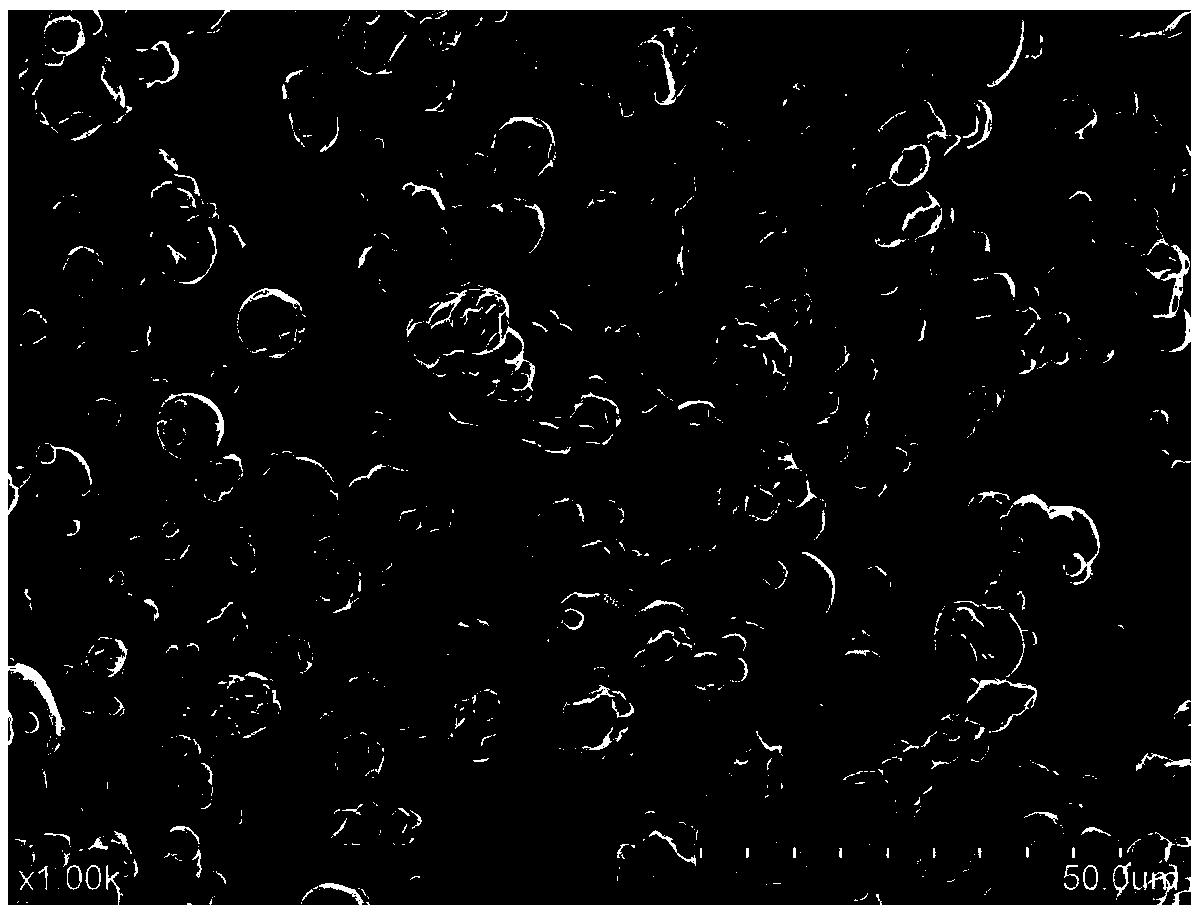

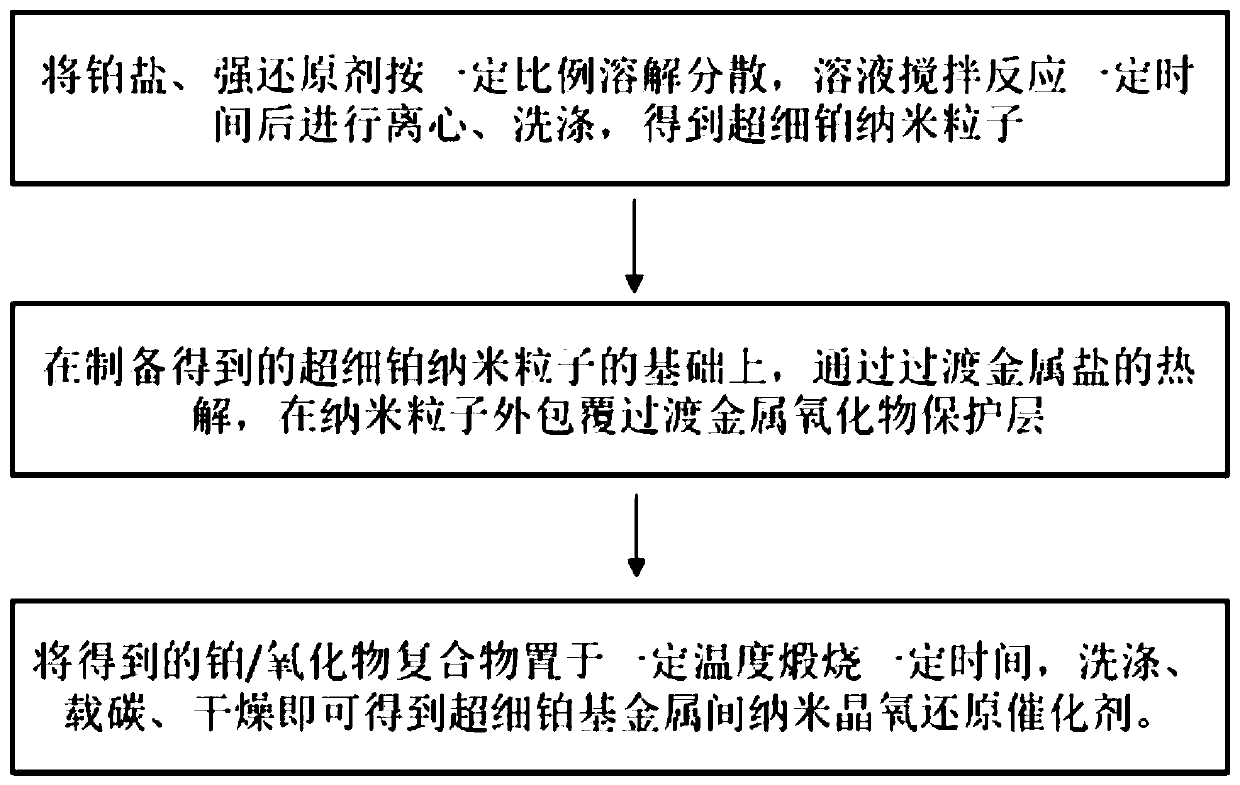

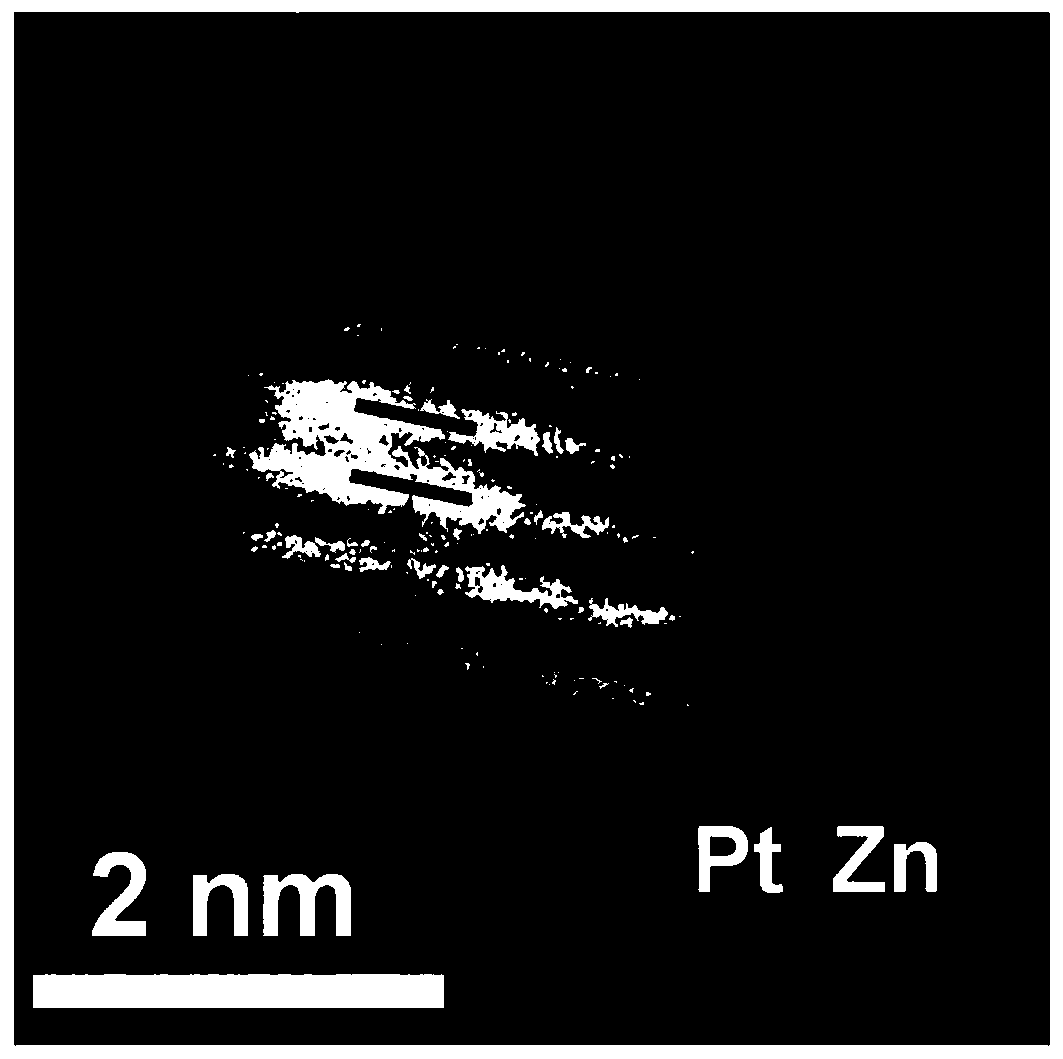

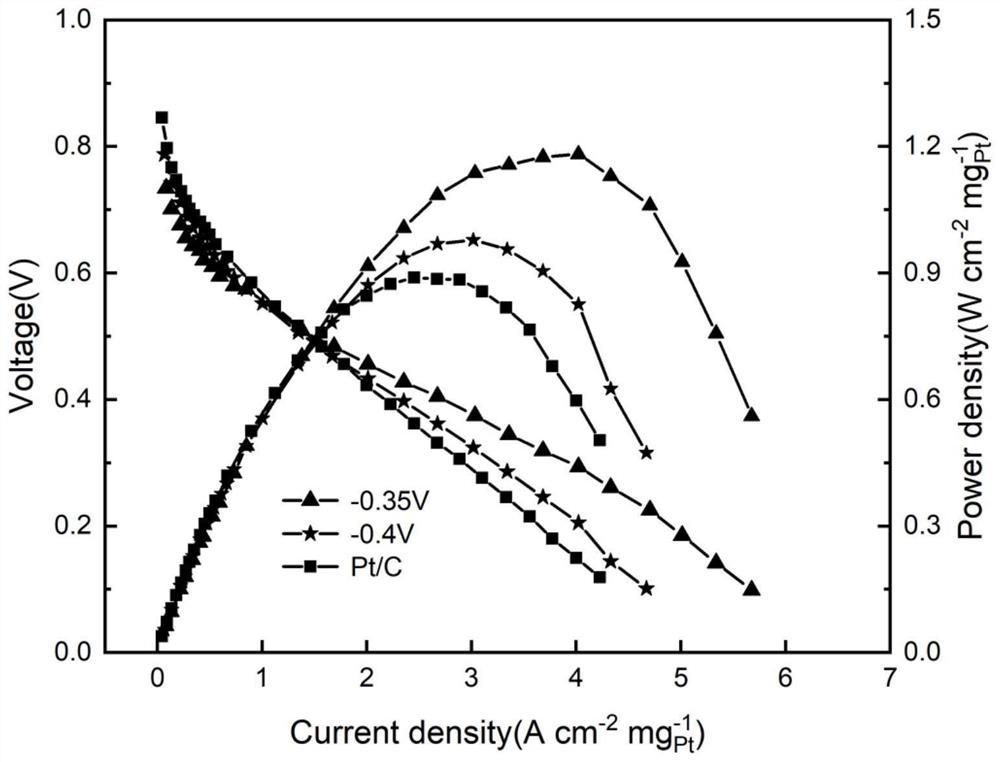

Platinum-based intermetallic nanocrystal with ordered structure and preparation and application thereof

ActiveCN113206259ARaise the chemical potentialEasy to driveCell electrodesPlatinum saltsPtru catalyst

Owner:HUAZHONG UNIV OF SCI & TECH

Apple preservation and storage method

InactiveCN105875811ANot easy to lose waterGood fresh-keeping effectFood ingredientsFruits/vegetable preservation by freezing/coolingDiseaseHigh humidity

The present invention relates to an apple preservation and storage method. The method comprises the following steps: fresh apple selecting, soaking and cleaning, disinfecting and sterilizing, and sealing and storing. The apples stored and preserved by the method are not easy to dehydrate, the fruits are fresh and sweet as ever, and even the fruit stems are also kept to be green; after the apples are ozone disinfected and sterilized, harmful gases in the storage environment are reduced, so that the freshness retaining effects are better. The apples are stored in a high humidity environment, water evaporation is greatly reduced, natural wear and tear are reduced, and the fruits are kept to be fresh and full; and after the apples are pickled, the apples are soaked with chlorine calcium, which can better prevent physiological diseases of the apples during the storage, inhibit apple after-ripening, and keep hardness.

Owner:重庆市涪陵区佳利生态农业有限责任公司

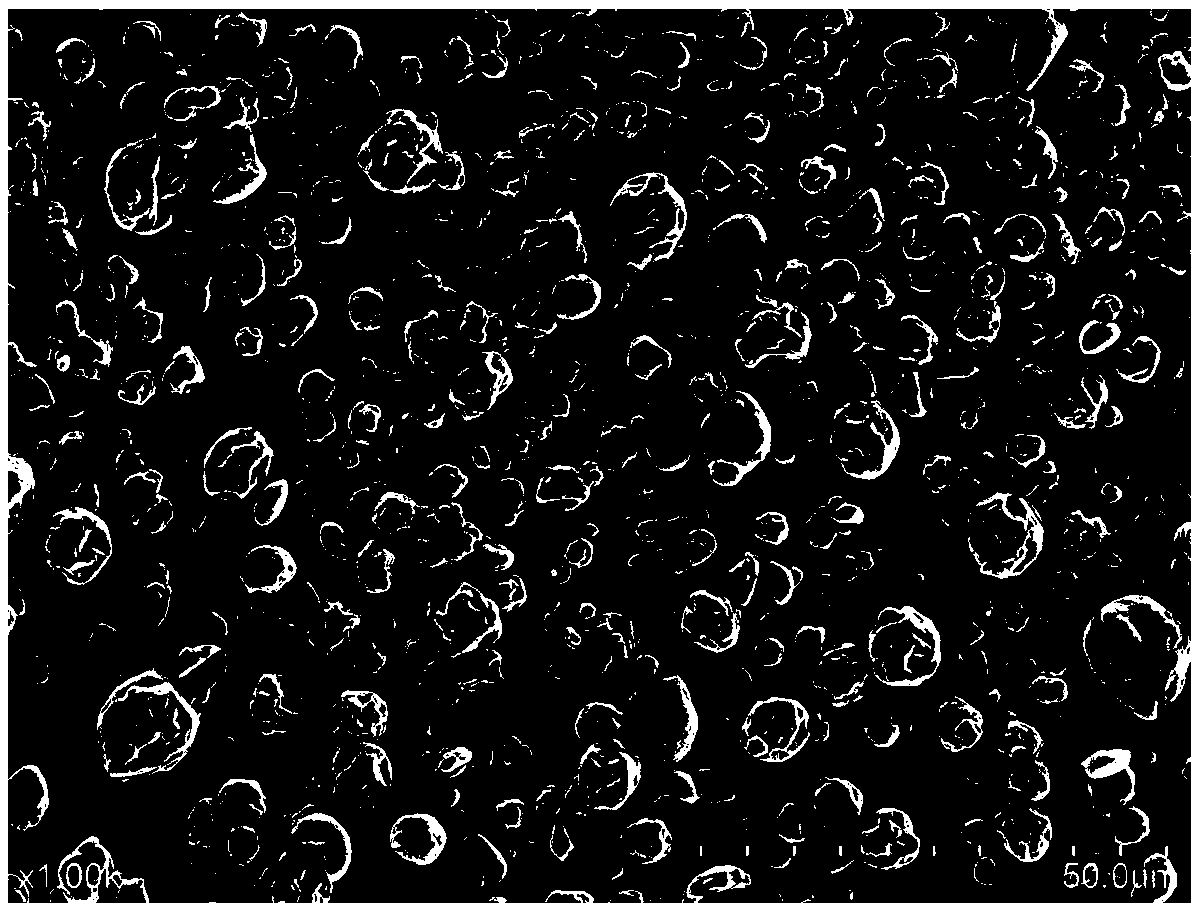

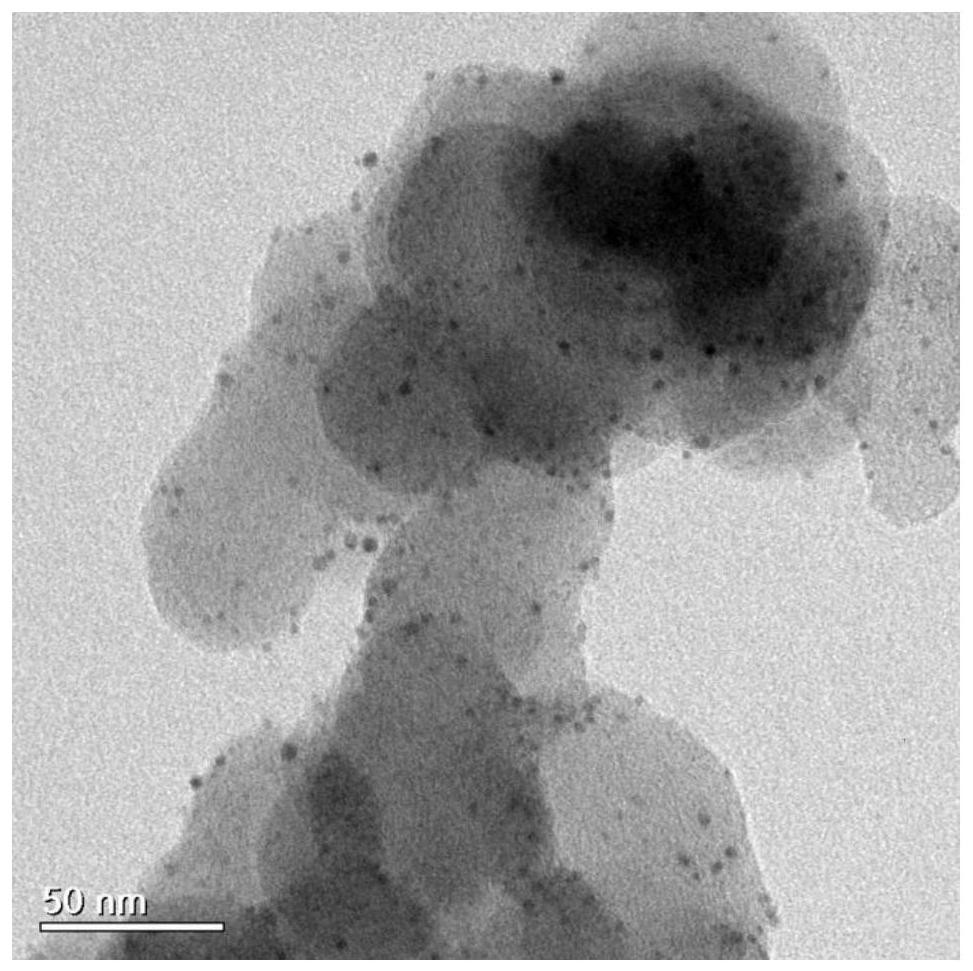

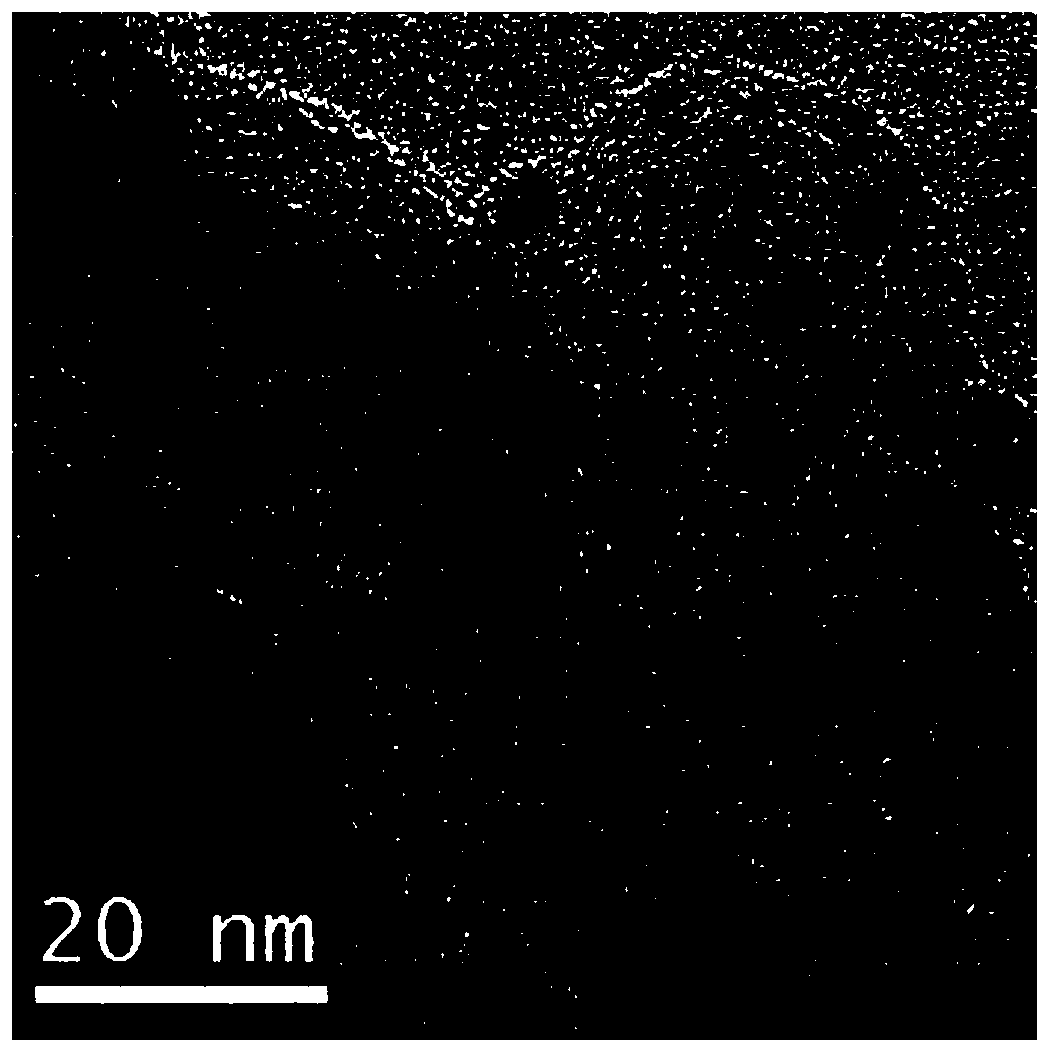

Platinum-based intermetallic nanocrystalline oxygen reduction catalyst and preparation method thereof

ActiveCN110783584AHigh activityIncreased durabilityMaterial nanotechnologyCell electrodesPlatinum saltsPtru catalyst

The invention belongs to the field of fuel cell cathode materials, and particularly discloses a platinum-based intermetallic nanocrystalline oxygen reduction catalyst and a preparation method thereof.The preparation method comprises the following steps: S1 mixing a platinum salt solution and a reducing agent solution to obtain a mixed solution, reacting the platinum salt in the mixed solution with the reducing agent to obtain platinum nanoparticles and separating the platinum nanoparticles from the mixed solution; and S2 coating a metal oxide on the surface of the platinum nanoparticles to obtain a platinum and metal oxide composite and performing annealing treatment on the platinum and metal oxide composite to obtain the platinum-based intermetallic nanocrystalline oxygen reduction catalyst. The platinum-based intermetallic nanocrystalline oxygen reduction catalyst is used for accelerating the cathode oxygen reduction reaction rate of the fuel cell and has good activity and durability and has simple synthesis process and can effectively regulate and control the size of nanoparticles and is easy to produce in mass.

Owner:HUAZHONG UNIV OF SCI & TECH

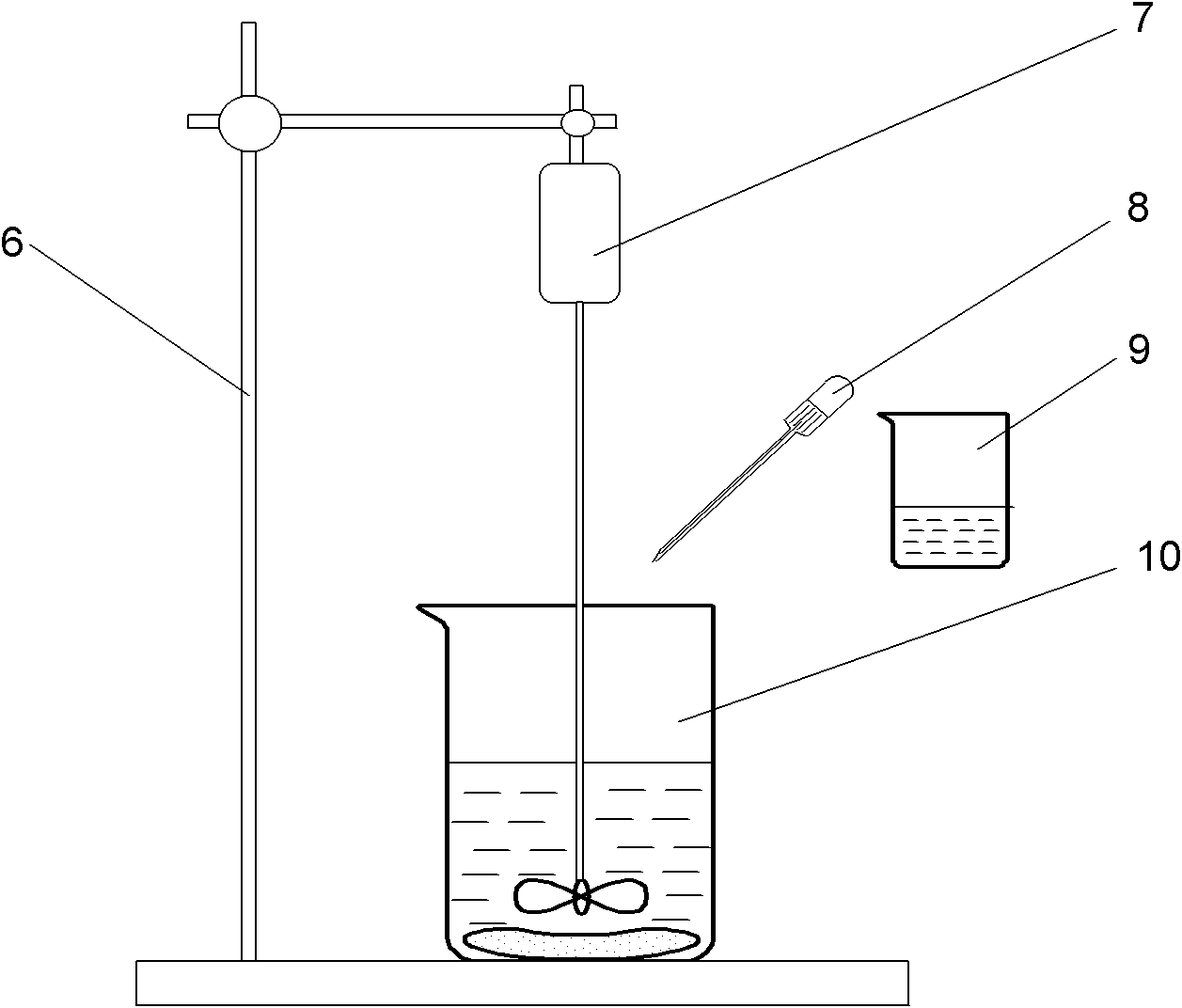

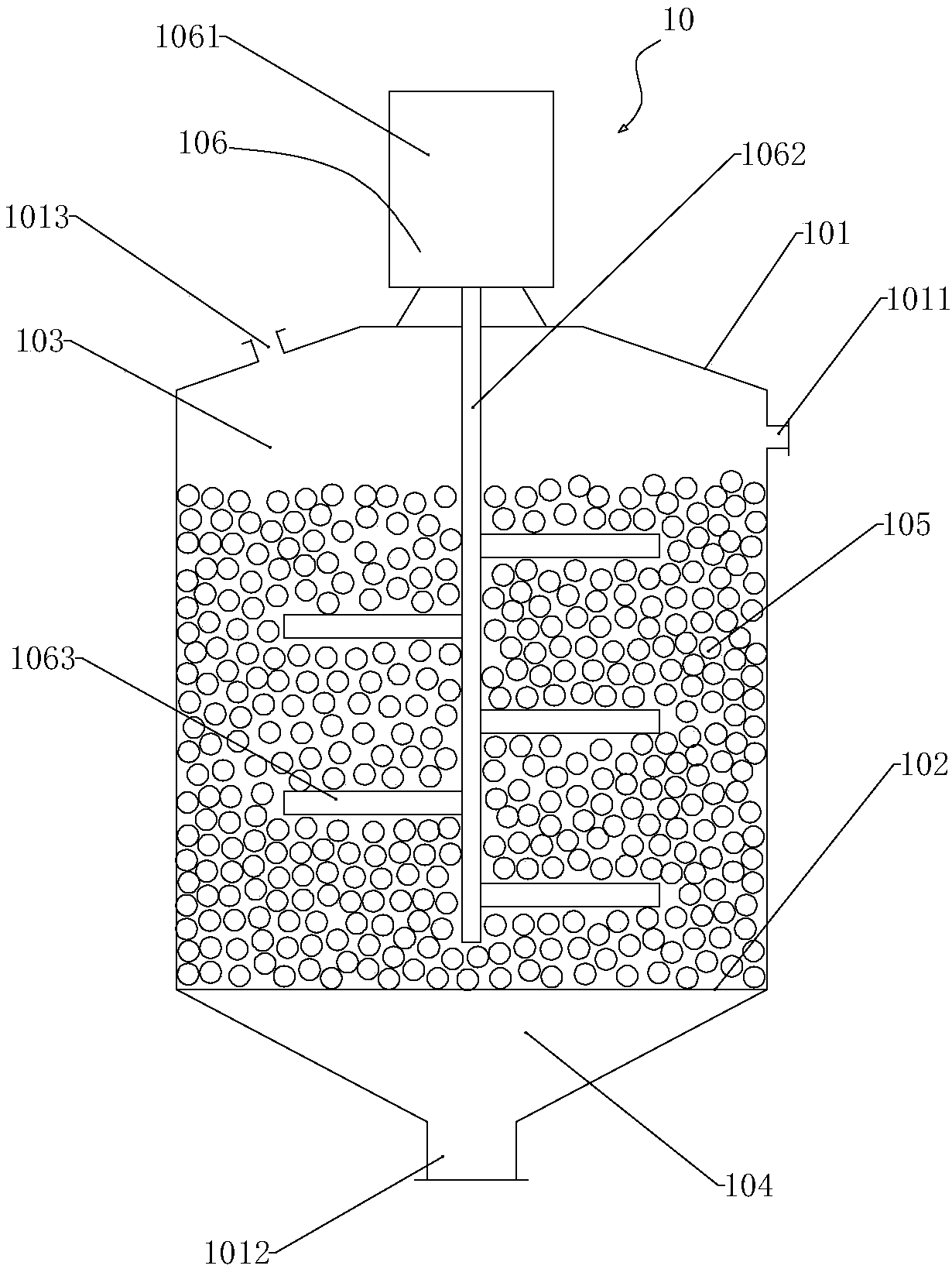

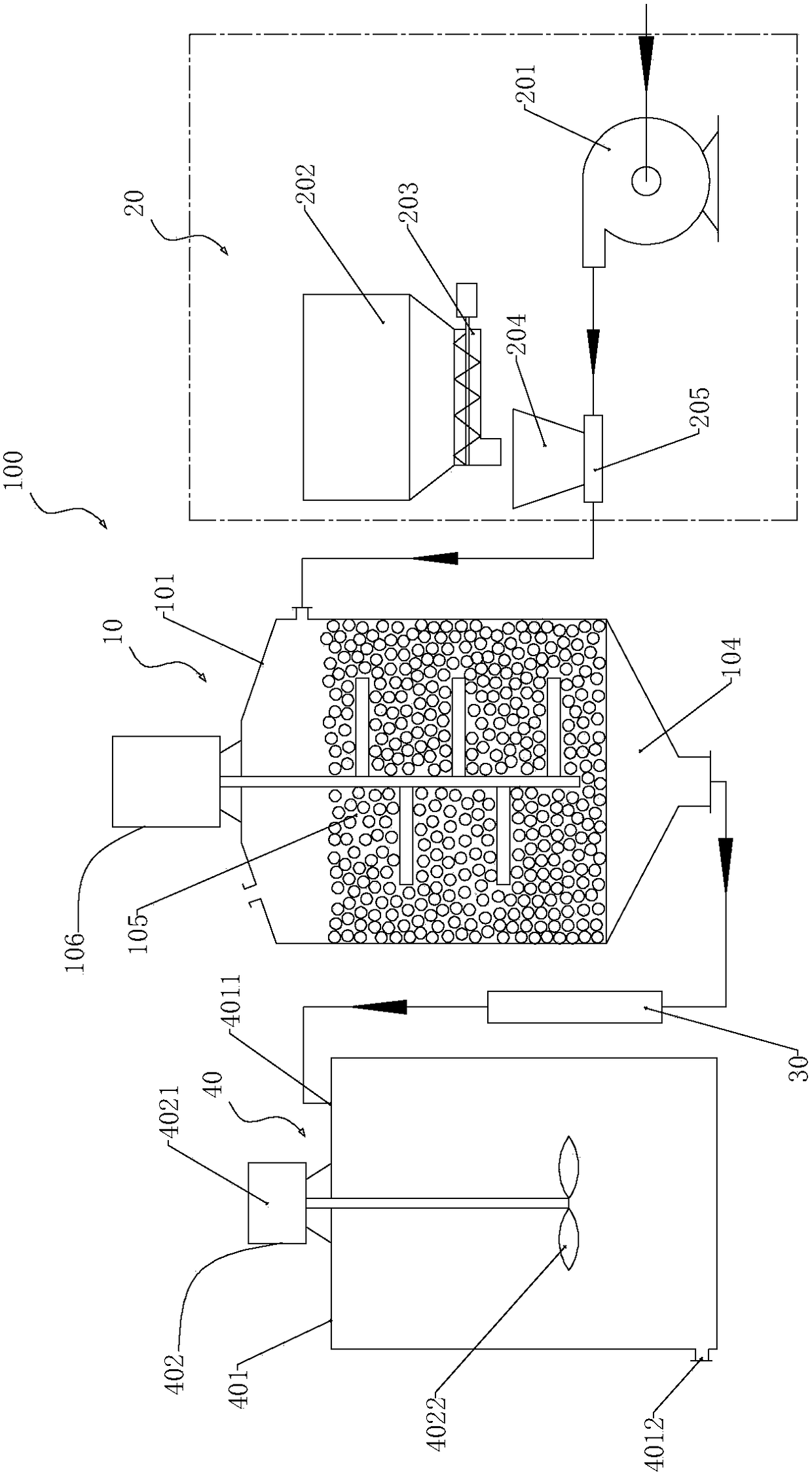

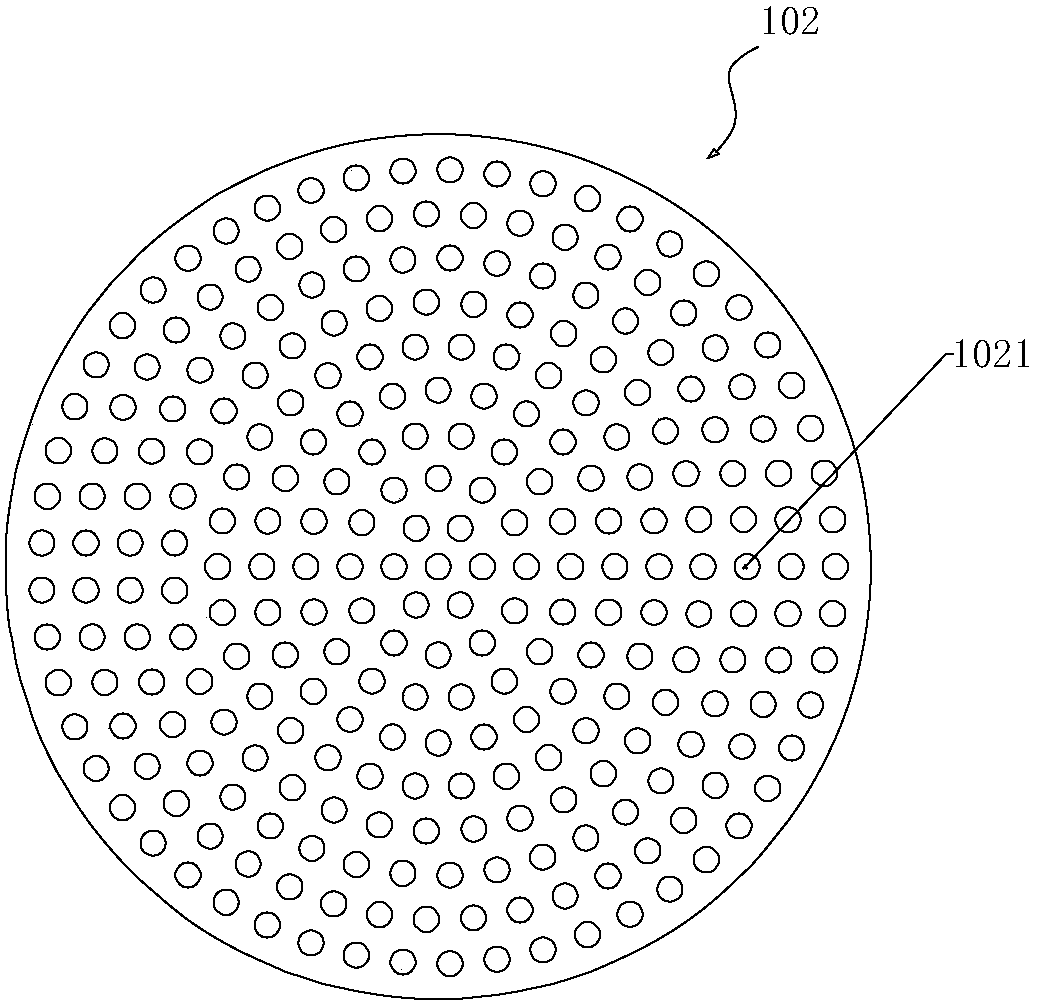

Maturation device and polymer preparation system for chemical flooding oil recovery

ActiveCN105921038BFast dissolutionShorten the ripening timeTransportation and packagingMixersParticulatesEngineering

The invention relates to a curing device for chemical flooding oil recovery, which has a tank body, and a support plate is arranged in the tank body, and the support plate divides the inside of the tank body into an upper cavity and a lower cavity; particle filler is arranged in the upper cavity and a first agitator, the first agitator is used to stir the mixture and the granular filler entering the upper cavity; a plurality of through holes are arranged on the support plate, and the diameter of the through holes is smaller than the particle diameter of the granular filler. The curing device can reduce "fish eyes" and air bubbles, shorten the curing time of the polymer, and prevent the polymer molecular chain from shearing and degrading. The present invention also relates to a polymer preparation system using the above-mentioned curing device. The polymer preparation system has a compact process flow and reduces ground equipment investment and floor space.

Owner:PETROCHINA CO LTD

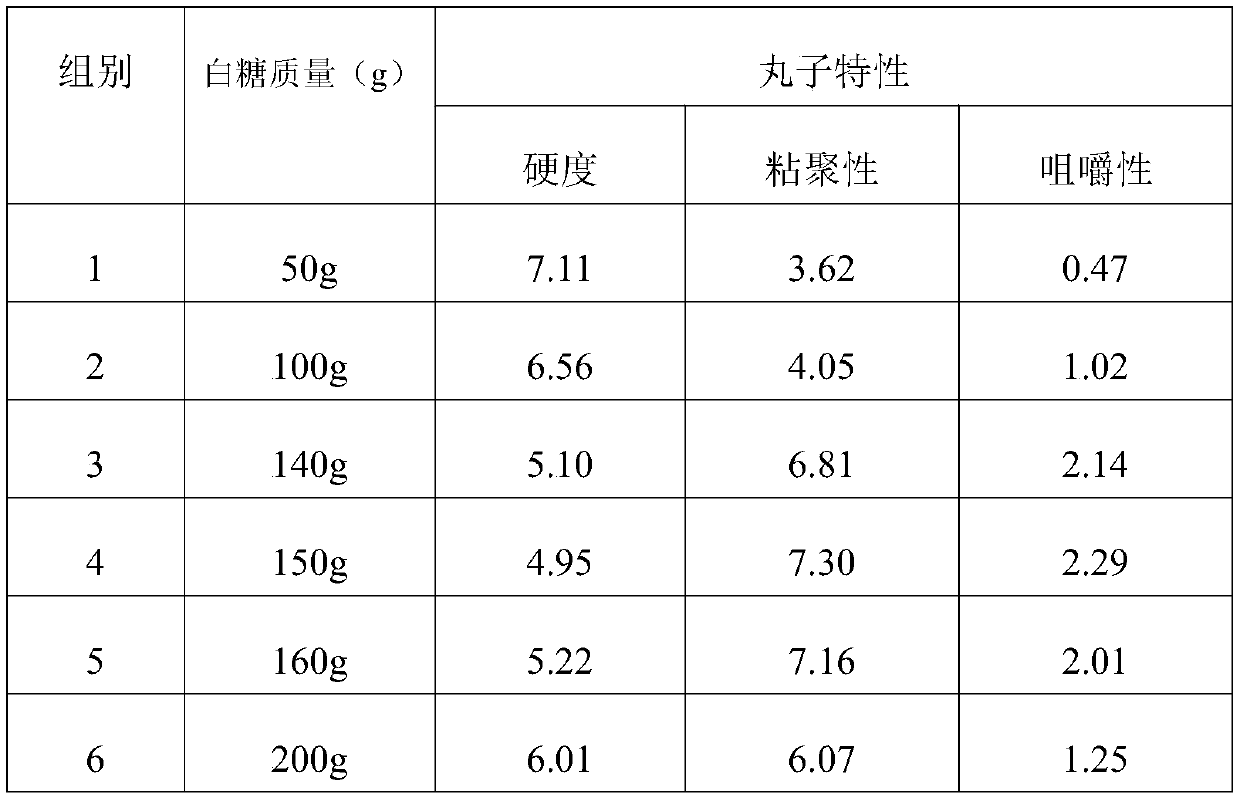

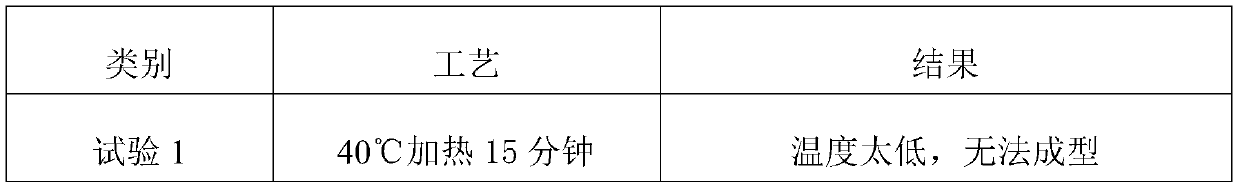

Making method of bamboo shoot crisp balls

The invention discloses a making method of bamboo shoot crisp balls. The making method comprises the following steps of blanching bamboo shoot dices, performing quick freezing on the bamboo shoot dices, performing flaking into slices, making balls, and performing shaping. The quick-freezing process of the bamboo shoot dices comprises the steps of taking the bamboo shoot dices made in the step (1) with saccharide in the mass ratio of 500 to (140-160 ), performing stirring and mixing, performing preserving until the saccharide completely dissolves, adding the bamboo shoot dices with the saccharide into the environment of minus 25 to minus 35 DEG C or below, and performing quick freezing until the center temperature of the bamboo shoot dices is minus 18 DEG C or below; and during shaping, heating the bamboo shoot balls to the temperature of 58-62 DEG C, performing heating for 18-22 minutes until the bamboo shoot balls are in the shape of gelation, after the surfaces of the bamboo shoot balls are cured and shaped, performing boiling at the temperature of 90 DEG C or above until the bamboo shoot balls are completely cooked, and performing fishing out to complete making. The method solves the problems of maintaining the brittleness of fresh bamboo shoots and preventing the mixing temperature of meat paste from raising, so that the bamboo shoot balls which are fresh and rich in bamboo shoots, and high in elasticity and brittleness, are obtained.

Owner:龙岩市小南牛食品有限公司

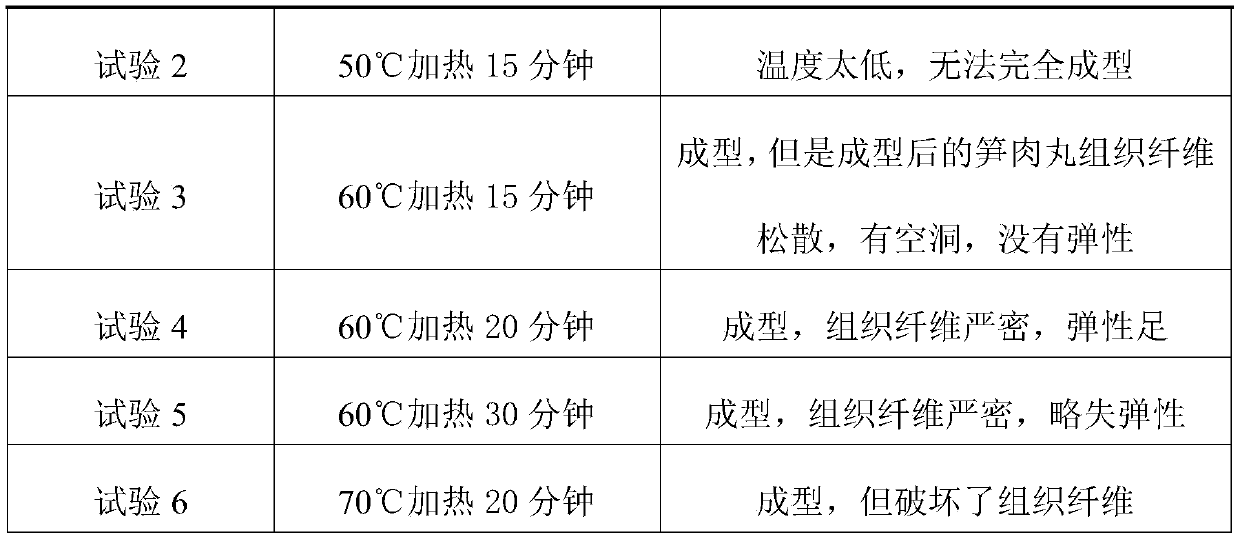

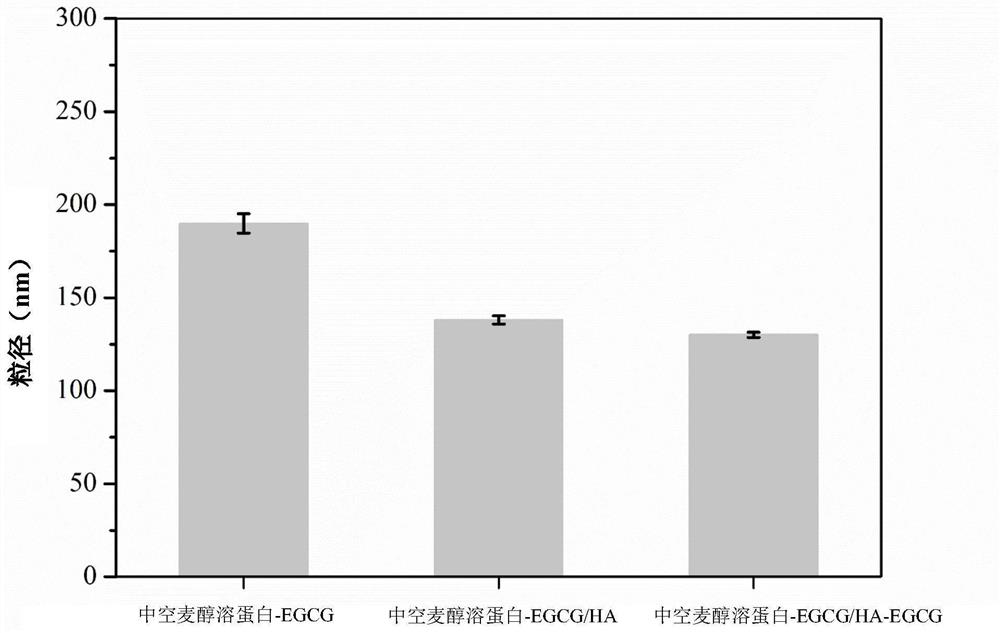

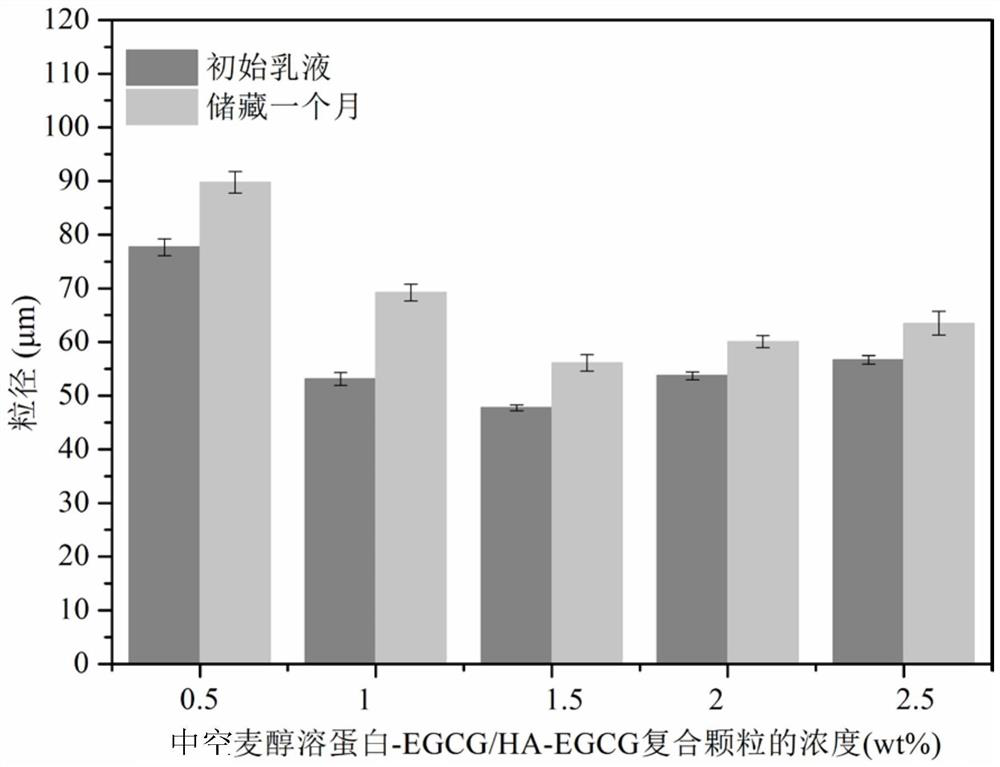

Hyaluronic acid-based modified gliadin nanoparticles as well as preparation method and application thereof

ActiveCN112120212AEnhanced solubility and emulsificationGood emulsificationPowder deliveryCosmetic preparationsGlycerolOil phase

The invention discloses hyaluronic acid-based modified gliadin nanoparticles as well as a preparation method and application thereof. The method for preparing the W2 / O2 / (O1 / W1) type multiple emulsionfrom the nanoparticles comprises the following steps: mixing polyglycerol ricinoleate with corn oil at 65 DEG C to form a first oil phase, mixing a mixed solution of sodium chloride and gelatin with the obtained first oil phase, and performing homogenizing by adopting high-pressure microjet to obtain a W2 / O2 type primary emulsion; mixing a second oil phase with the nanoparticle suspension, and performing high-shear treatment to obtain an O1 / W1 type Pickering emulsion; and mixing the W2 / O2 type primary emulsion with the O1 / W1 type Pickering emulsion by adopting a high-pressure homogenization technology, so as to prepare the W2 / O2 / (O1 / W1) type multiple emulsion. The preparation method of the multiple emulsion is simple, mild in reaction condition and suitable for industrial production, and can be applied to the fields of foods, medicines, cosmetics and the like.

Owner:HEFEI UNIV OF TECH

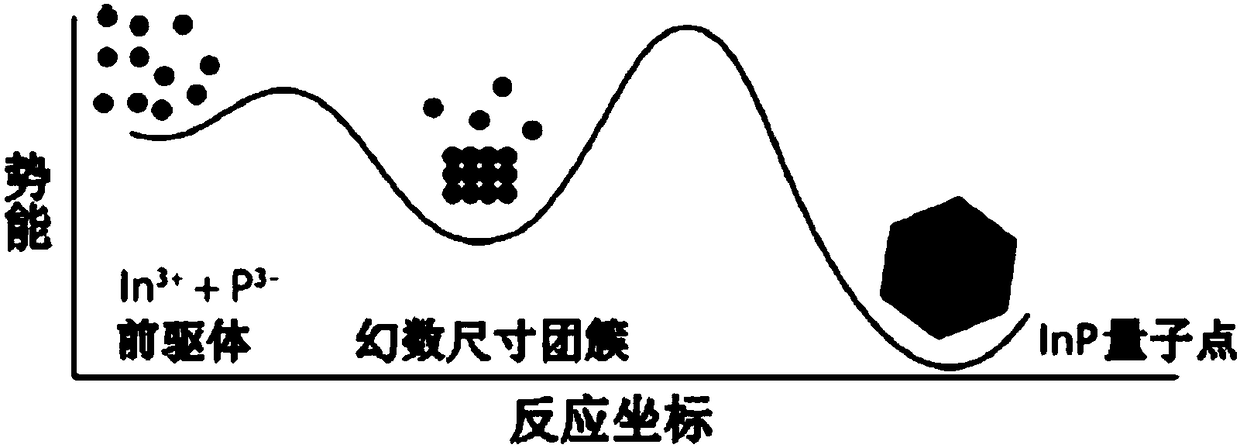

Composite structure quantum dot, preparation method and use thereof

InactiveCN108485650AUnique structureReduce half peak widthNanotechnologyLuminescent compositionsQuantum yieldPhotovoltaic detectors

The invention provides a composite structure quantum dot, a preparation method and use thereof. The composite structure quantum dot comprises a core, a fluorescent layer coating on the surface of thecore and a passivation layer coating on the surface of the fluorescent layer, the core does not generate fluorescence with wavelengths in the visible range, and the fluorescent layer is a quantum dotmaterial layer. The preparation method comprises the following steps of 1) growing the fluorescent layer on the outer edge of the core surface to obtain an intermediate product; 2) coating the surfaceof the fluorescent layer of the intermediate product in step 1) with the passivation layer to obtain the composite structure quantum dot. The composite structure quantum dot is used in light emittingdevices, bioprobes or photodetectors. The composite structure quantum dot has unique structure, the half width is less than 50 nm, the fluorescence wavelength is controllable, the quantum yield is above 30%, and the dot is suitable for various fields; the preparation method has short process and simple operation, and the thickness of the fluorescence layer is precisely adjusted.

Owner:SHENZHEN PLANCK INNOVATION TECH CO LTD +1

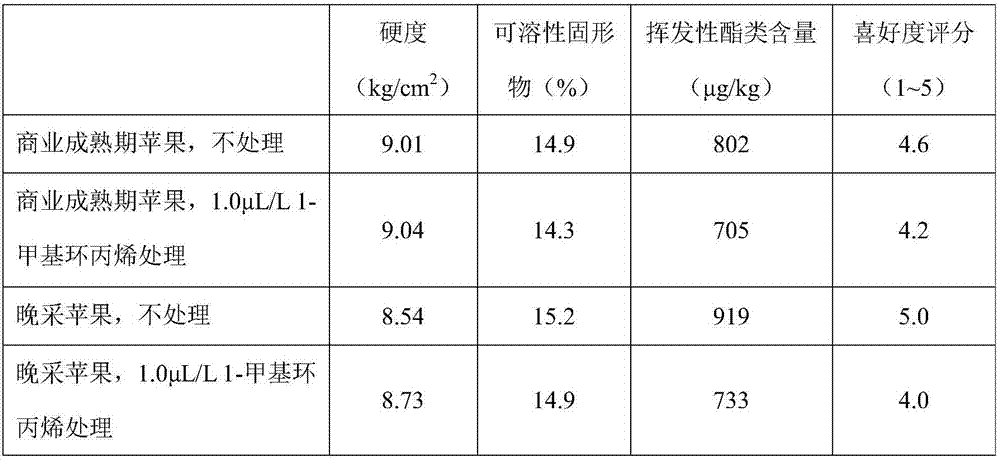

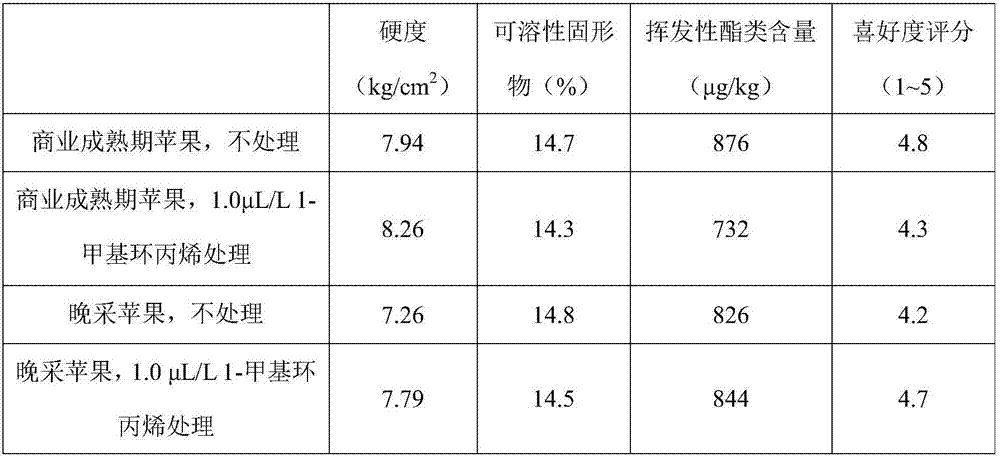

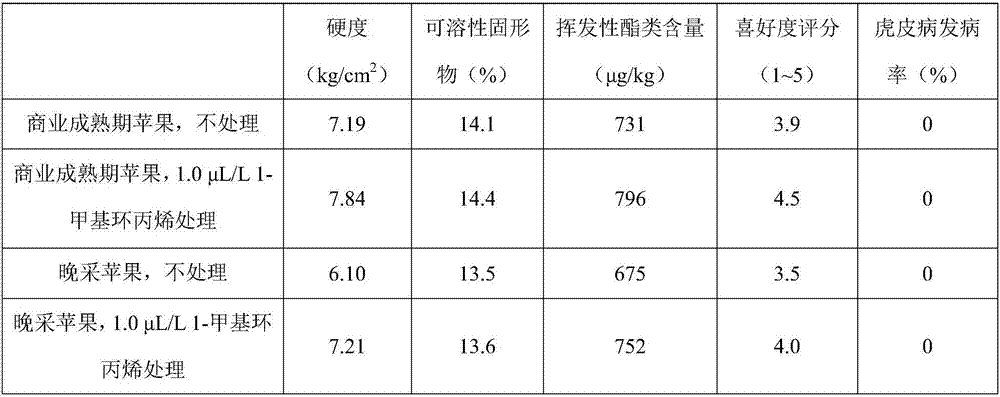

Apple low-temperature storage method

PendingCN107960458AImprove food qualityInhibit ripeningFruits/vegetable preservation by freezing/cooling1-MethylcyclopropeneRefrigeration

The invention relates to an apple low-temperature segmented storage method, which comprises the following steps: 1) stacking apples in a pre-cooling chamber at the temperature of 0-1 DEG C after beingharvested, pre-cooling the apples for 2-3 days, and adopting 1-methylcyclopropene for processing a part of apples during a pre-cooling process; wherein the remaining apples are only pre-cooled; the apple includes apple harvested at a commercial mature stage of the apple and late harvested apple, and the late harvested apple is the apple harvested 7 to 12 days after the commercial mature period; 2) performing pre-cooling and storage refrigeration of apples; wherein the cold storage temperature is -1 to 1 DEG C, and humidity is not lower than 90%; 3) according to the selling time of the storedapples, dividing an entire storage period into different time periods, and selecting the apples with different harvest maturity and different processed storage at each time period for sales. The method aims at short-term, middle-term and long-term storage of apples, and uses the apples with different maturity and post-harvest treatment methods with different intensities, and at the same time, low-temperature storage is combined to improve food quality during shelf storage of the apples.

Owner:NORTHWEST UNIV(CN)

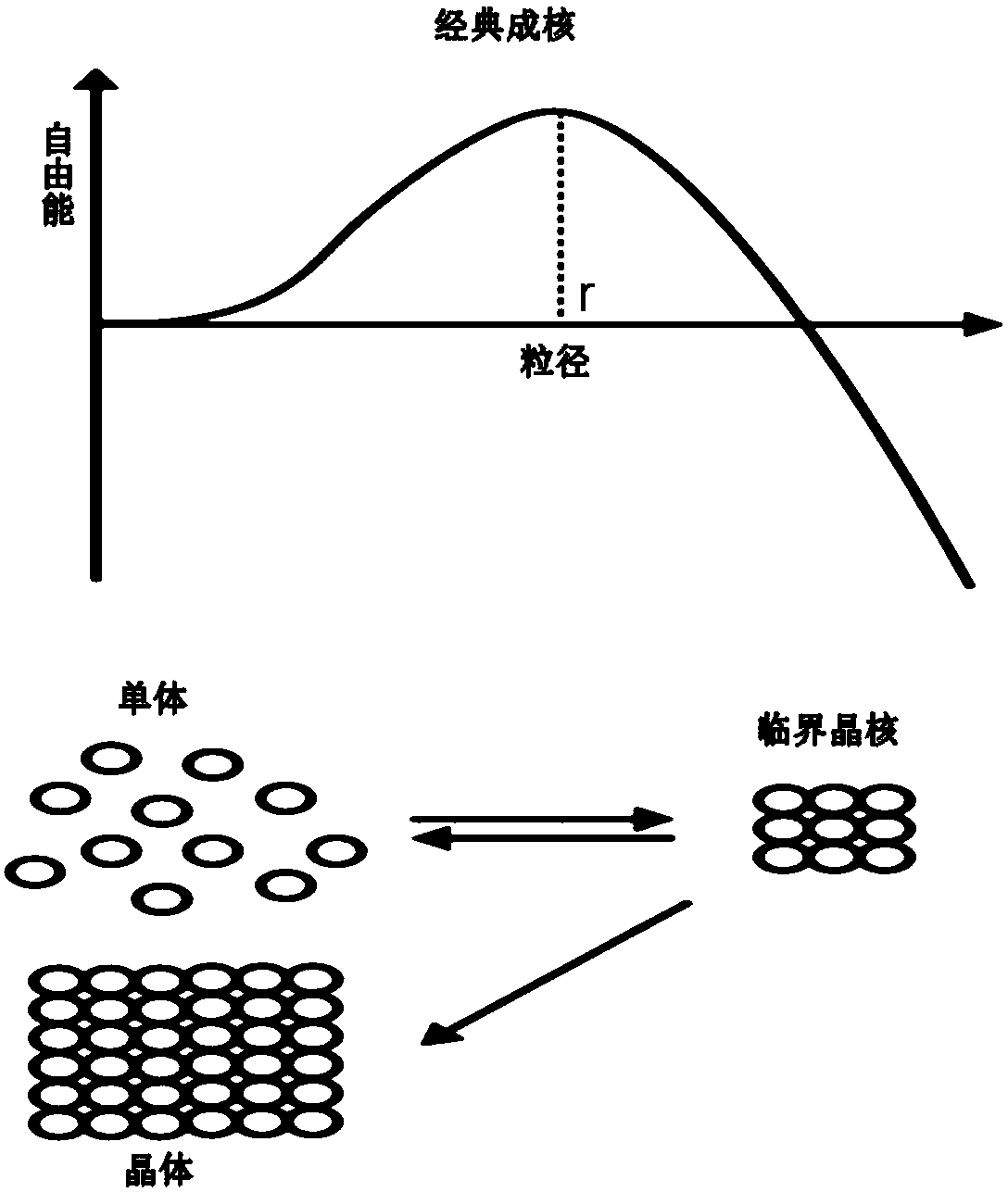

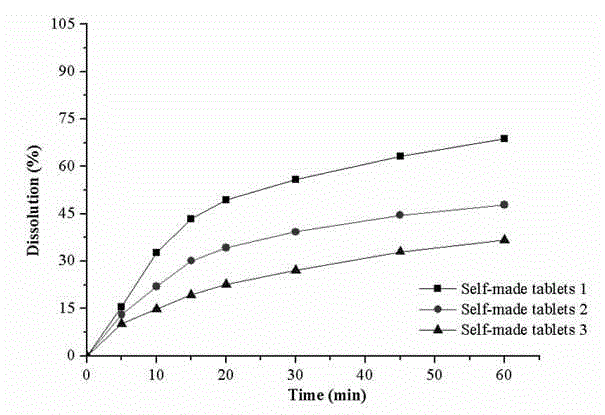

Preparation and application of drug powder

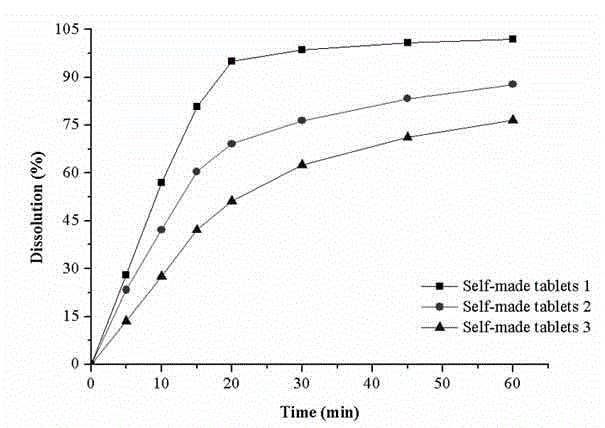

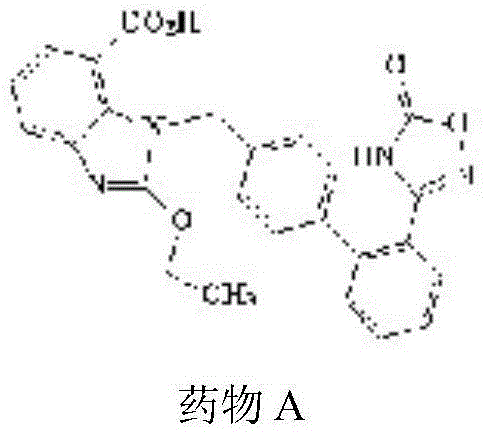

ActiveCN104606139AGood dispersionInhibit aggregationPowder deliveryOrganic active ingredientsMicrometerDissolution

Belonging to the field of pharmaceutical preparations, the invention provides a preparation method for a drug A (formula 1) powder and its application in oral solid preparations. The method includes: dispersing the crude drugs of drug A in a hydrophilic suspending aid solution, employing wet grinding to reduce the particle size to less than 5 micrometers, adding a spray-drying support agent, and combining spray drying, thus obtaining the drug A powder with an average particle size of less than 20 micrometers. The drug A powder prepared by the invention has high surface hydrophilicity, small particle size and good redispersibility in water. Compared with the crude drugs, the oral solid preparations prepared from the drug A powder and suitable auxiliary materials can significantly improve the dissolution rate. The preparation method for the drug A powder provided by the invention is suitable for industrial production and has high application value. (formula I).

Owner:SHENYANG PHARMA UNIVERSITY +2

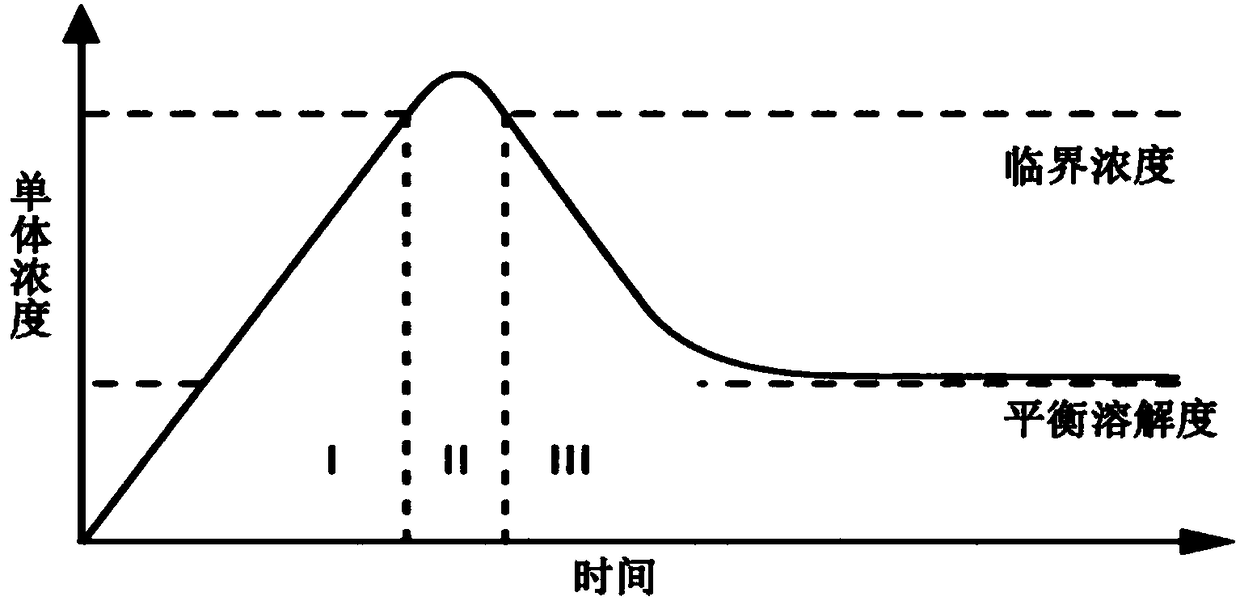

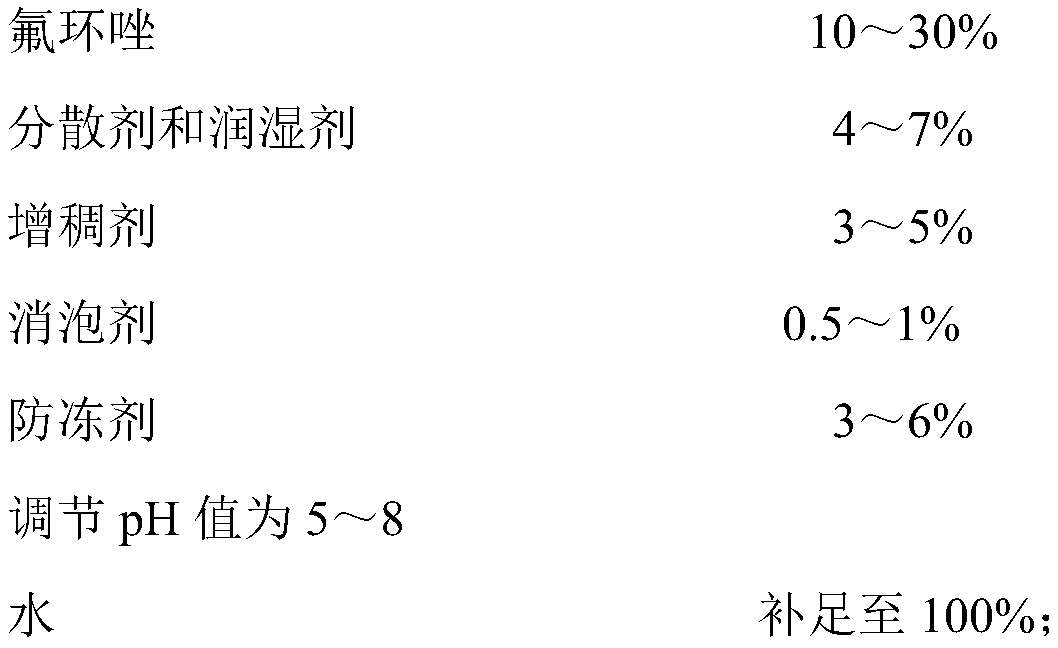

Epoxiconazole water suspension agent and preparation method thereof

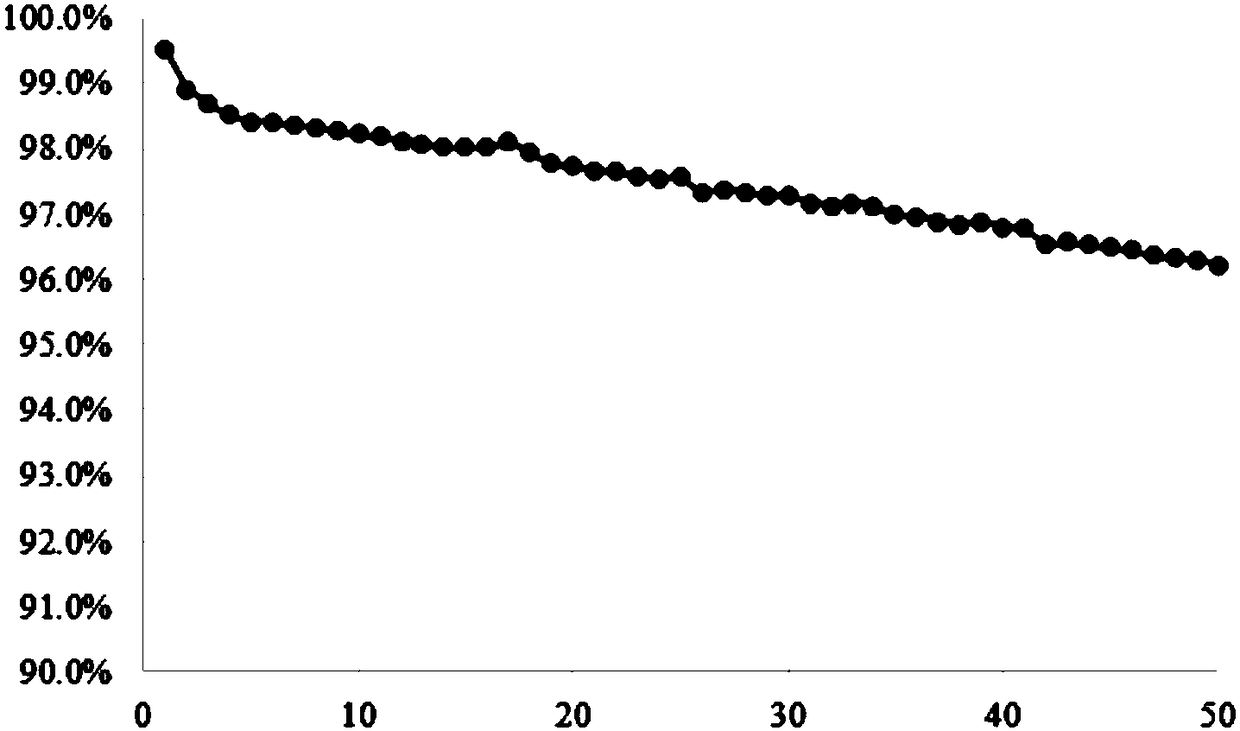

ActiveCN109699653ALow viscosityHigh suspension rateBiocideFungicidesDefoaming AgentsOstwald ripening

The invention discloses an epoxiconazole water suspension agent and a preparation method thereof. The epoxiconazole water suspension agent is composed of the following components in percentage by weight: 10-30% of epoxiconazole, 4-7% of dispersant and wetting agent, 3-5% of thickening agent, 0.5-1% of defoaming agent, 3-6% of antifreezing agent and water replenished to reach 100%, wherein the pH value is regulated to 5-8; the dispersant is a tristyrylphenol polyoxyethylene ether sulfate dispersant; the wetting agent is selected from one or a combination of more than two of NP-series nonylphenol polyoxyethylene ether, AEO-series fatty alcohol polyoxyethylene ether, a polymer EO-PO block copolymer, alkylphenol polyoxyethylene and styrylphenol polyoxypropylene ether. The problems such as poorheat (cold) storage stability, more foam, poor automatic dispersibility and ostwald ripening in suspension agent processing are remarkably reduced.

Owner:SHANGHAI NORMAL UNIVERSITY

Preparation method of lithium-sulfur battery positive electrode material

ActiveCN108493410AEvenly distributedImprove conductivityMaterial nanotechnologyCell electrodesCarbon compositesHigh rate

The invention relates to a preparation method of a lithium-sulfur battery positive electrode material, and belongs to the technical field of preparation of a battery positive electrode material. In order to solve the problem that a traditional sulfur-carbon composite material is easy to agglomerate during the preparation process and the grain size is difficult to control, the preparation method ofthe lithium-sulfur battery positive electrode material is provided. The method comprises the steps of adding an alkali metal element and a sulfur element into an organic solvent for reaction under acondition of inert gas protection to obtain a polysulfide organic solution; and taking a mixed liquid of a conductive polymer monomer and the polysulfide organic solution, adding an acid oxidizing agent solution, adjusting a pH value of the mixed liquid to be neutral or weak acid, and obtaining the sulfur / conductive polymer composite material after full reaction. By the preparation method, nanoscale or submicron-scale sulfur particle can be obtained, an effect of relatively narrow size distribution is achieved, the sulfur utilization ratio and the high-rate performance are improved, and the volume expansion phenomenon of the positive electrode material during the lithiation process is favorably reduced.

Owner:ZHEJIANG FOREVER NEW ENERGY TECH CO LTD +1

A method for simultaneous shelling and peeling of chestnuts by microwave

The invention discloses a method for synchronously removing the shell and peel of a Chinese chestnut through microwaves. The method comprises the following steps: the shell of the Chinese chestnut is cut, the Chinese chestnut is subjected to microwave processing for the first time, the Chinese chestnut is cooled after the microwave processing for the first time, then, the Chinese chestnut is subjected to microwave processing for the second time, the shell and the peel of the Chinese chestnut are removed after the microwave processing for the second time, and therefore the kernel of the Chinese chestnut is obtained. According to the method for synchronously removing the shell and peel of the Chinese chestnut through the microwaves, the microwaves are used for instantaneous intermittent heating with a high power, as a result, the kernel of the Chinese chestnut shrinks due to dehydration and is separated from the shell and the peel, and the phenomenon that the kernel of the Chinese chestnut is cooked and exploded due to an excessively quick temperature rise in the one-time heating process can be well avoided; meanwhile, the hot Chinese chestnut is cooled for a short time, as a result, water in the shell of the Chinese chestnut is evaporated, brittleness is further improved, and original color and luster, a special flavor and nutrition of the kernel of the Chinese chestnut are guaranteed to the maximum.

Owner:ZHEJIANG UNIV

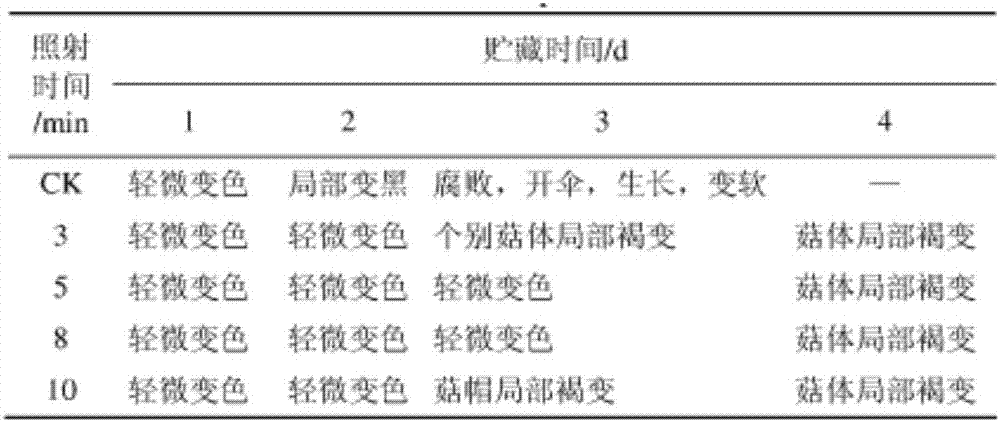

Operation process for preservation of drumstick mushrooms

InactiveCN107467170AExtend freshnessLow costFood freezingFruits/vegetable preservation by irradiation/electric treatmentCuticleUltraviolet

The invention discloses an operation process for preservation of drumstick mushrooms. The operation process is characterized by comprising the following steps: 1) picking drumstick mushrooms, then selecting fresh mushrooms which are white in color and luster, free of plant diseases and insect pests, free of mechanical damage and moderate in size, immediately removing roots and mud, scraping pileus skin, and then carrying out ultraviolet treatment; 2) according to preliminary tests in the early stage, selecting an ultraviolet lamp of which the power is 30w and the effective wavelength is less than 280nm, carrying out irradiation for 4min and 8min respectively, and overturning the front and rear parts of the drumstick mushrooms when the irradiation is carried out halfway, so as to enable the drumstick mushrooms to be uniformly irradiated; and 3) after ultraviolet treatment, putting the irradiated drumstick mushrooms in a container, packaging the container with a nitrogen-filled preservative film, preserving the container in refrigeration equipment of which the temperature is 0-10 DEG C and the relative humidity is 80-90%, and carrying out periodic detection. The operation process disclosed by the invention has the characteristics of being simple in operation, small in investment, low in cost and easy to manage.

Owner:雷燕梅

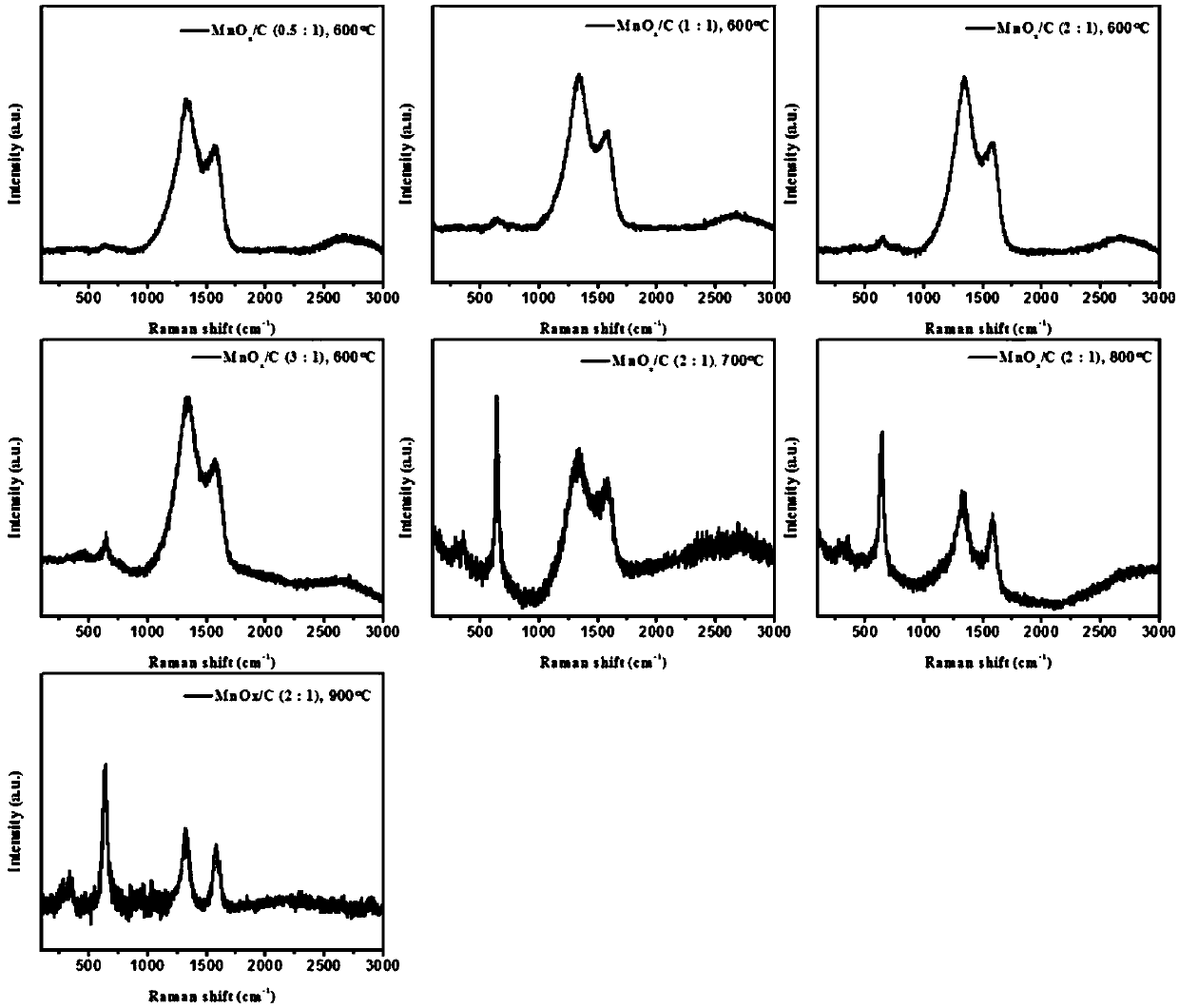

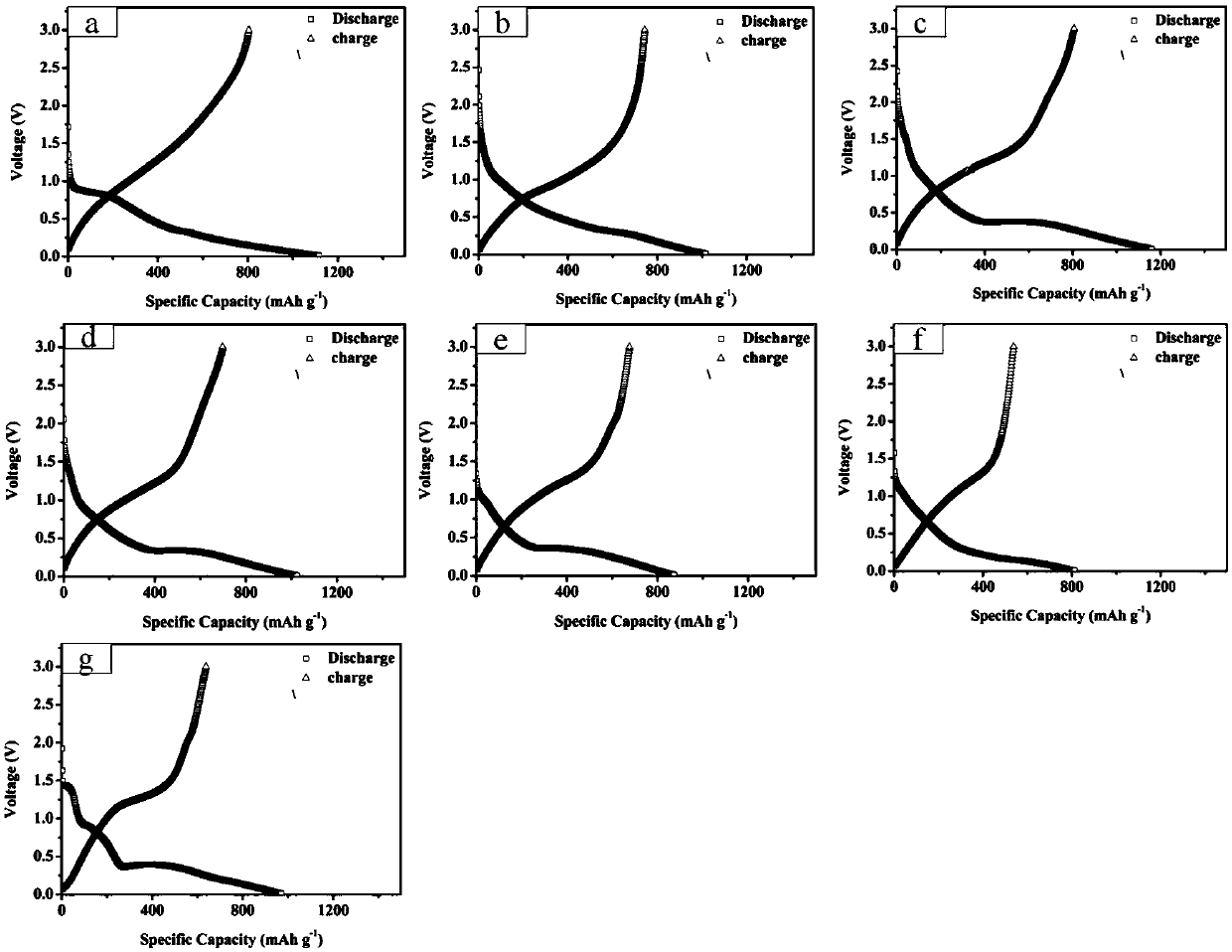

Carbon fiber-coated manganese oxide-carbon composite material with egg yolk shell structure as well as preparation method and application thereof

InactiveCN109616636AInhibit ripeningSmall volume expansionCell electrodesSecondary cellsCarbon compositesCarbon layer

The invention discloses a carbon fiber-coated manganese oxide-carbon composite material with an egg yolk shell structure as well as a preparation method and an application thereof. The preparation method comprises the following steps of preparing a powdery manganese-containing metal organic framework material, and carrying out mixing and electrostatic spinning with polyacrylonitrile to obtain a composite nanofiber membrane; and sequentially carrying out pre-oxidation and carbonization on the composite nanofiber membrane to obtain the manganese oxide-carbon composite material. The invention further provides the manganese oxide-carbon composite material prepared by the preparation method, and an application of the composite material used as a thin film electrode. According to the manganese oxide-carbon composite material, the dispersibility of the particles in the fiber is high, the operation is convenient, the carbon layer of the fiber can effectively protect the internal active substance, and the unique egg yolk shell structure is beneficial to improving the stability of the material in the aspect of a lithium ion battery.

Owner:SUZHOU UNIV

Peach preservative and preservation method

InactiveCN105010510AMaintain hardnessKeep the flavorFruits/vegetable preservation by freezing/coolingFruits/vegetable preservation by dehydrationCold storageAscorbic acid

The invention discloses a peach preservative which is a mixed solution prepared by blending citric acid, calcium chloride and ascorbic acid, wherein mass concentration of citric acid is 1-2 g / ml, mass concentration of calcium chloride is 2-4 g / ml and mass concentration of ascorbic acid is 0.02-0.1 g / ml. The invention also discloses a peach preservation method which comprises the following steps: harvesting normally-developed peach fruits with no mechanical damage or insect diseases in the maturity period of peaches; putting the harvested peach fruits into a refrigeration house to be precooled to 2-4 DEG C; putting the precooled peach fruits into the peach preservative as mentioned in the claim 1 to be immersed for 5-10 min, and naturally airing the peach fruits; and packaging the peaches processed with the peach preservative with foam mesh bags, and putting the packaged peaches into carton boxes to be ready for transport. The mixed solution prepared by blending of citric acid, calcium chloride and ascorbic acid is used as the peach preservative, and citric acid, calcium chloride and ascorbic acid can together maintain hardness and flavor of peach flesh, inhibit after-ripening and prevent deterioration of the fruits.

Owner:周凌云

Vehicle-mounted fruit and vegetable fresh-keeping box

InactiveCN110145909AReduce oxidationInhibit ripeningDomestic cooling apparatusLighting and heating apparatusChlorine dioxideDisinfectant

The present invention relates to a vehicle-mounted fruit and vegetable fresh-keeping box. The box comprises a box body and a box cover; the box body comprises a hollow vacuum layer, the inner wall ofthe box body is provided with a tube-mesh shell, and a gap for containing dry ice is reserved between the tube-mesh shell and the inner wall of the box body; the inner surface of the box cover is provided with a storage mesh basket, the storage mesh basket is filled therein with ethylene absorbent; and the box further comprises a sterilization mechanism, the sterilization mechanism comprises a liquid storage tank containing chlorine dioxide disinfectant and a plurality of atomizing nozzles arranged on the lower surface of the storage mesh basket at intervals, the spraying direction of each atomizing nozzle is vertically downward, the liquid storage tank communicates with the atomizing nozzles through a liquid discharging pipe, and the liquid discharging pipe is connected with a circulationboosting pump. Due to the presence of the atomizing nozzles, the mist-like chlorine dioxide disinfectant can kill microorganisms on the surface of fruits and vegetables, and due to the presence of dry ice, the storage temperature of fruits and vegetables is reduced, the oxygen concentration for the storage of fruits and vegetables is reduced, and the self-oxidation and respiration of fruits and vegetables are delayed; and due to the presence of the ethylene absorber, ethylene can be prevented from ripening fruits and vegetables.

Owner:扬州熊猫汽车科技服务有限公司

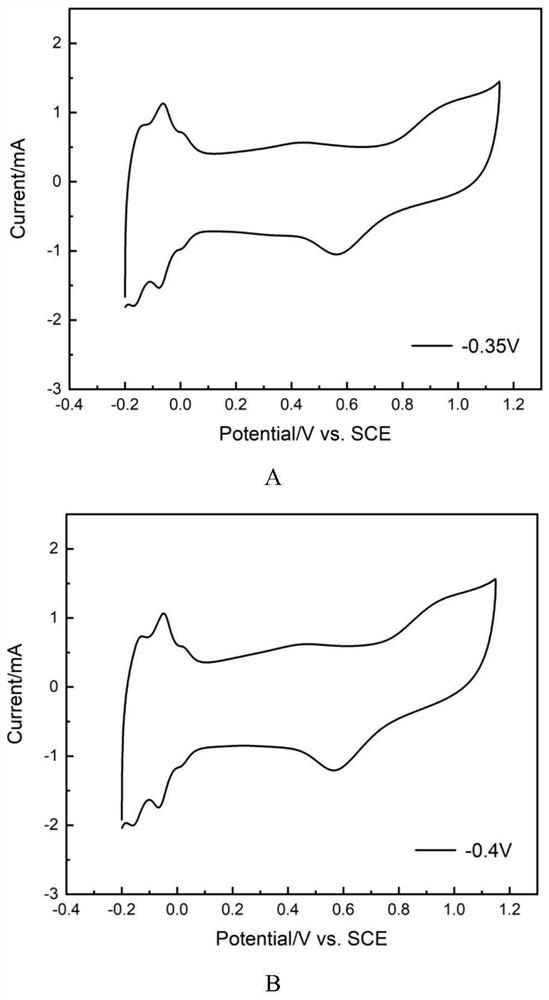

Preparation method and application of self-supporting membrane electrode

ActiveCN114079071AAvoid lostEnhanced redox reaction performanceSolid electrolyte fuel cellsPtru catalystPhysical chemistry

The invention belongs to the field of fuel cells, and particularly relates to a preparation method and application of a self-supporting membrane electrode. The method comprises the following steps: pretreating an electrode substrate layer; preparing a hydrophilic electrode substrate layer; adopting H2PtCl6 powder, water and sulfuric acid for preparing an electro-deposition solution; and preparing a self-supporting electrode and a self-supporting membrane electrode. According to the invention, the self-supporting membrane electrode is prepared in an electro-deposition mode, operation is simple and easy, deposition is uniform, and loss of a noble metal catalyst in the traditional commercial catalyst spraying process is avoided; meanwhile, platinum particles with different morphologies are obtained by changing the lower limit potential in an electro-deposition manner, so that the dissolution and Ostwald ripening of the platinum-based catalyst are effectively avoided, and the durability of the fuel cell is improved; and the oxidation-reduction reaction performance of the catalyst can be further enhanced. The self-supporting membrane electrode prepared by the invention is applied to a high-temperature proton exchange membrane fuel cell, and has a wide application prospect.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com